吉林大学学报(工学版) ›› 2023, Vol. 53 ›› Issue (4): 998-1006.doi: 10.13229/j.cnki.jdxbgxb.20210797

空冷中冷器百叶窗翅片结构参数优化

李胜1( ),朱佳2,黄德惠1,陈存福1,费洪庆1,丰伟1,胡兴军2(

),朱佳2,黄德惠1,陈存福1,费洪庆1,丰伟1,胡兴军2( )

)

- 1.一汽解放青岛汽车有限公司,山东 青岛 266043

2.吉林大学 汽车仿真与控制国家重点实验室,长春 130022

Structural parameters optimization of louver fins of air⁃cooled charge air cooler

Sheng LI1( ),Jia ZHU2,De-hui HUANG1,Cun-fu CHEN1,Hong-qing FEI1,Wei FENG1,Xing-jun HU2(

),Jia ZHU2,De-hui HUANG1,Cun-fu CHEN1,Hong-qing FEI1,Wei FENG1,Xing-jun HU2( )

)

- 1.China FAW Jiefang Automotive Co. ,Ltd. (Qingdao),Qingdao 266043,China

2.State Key Laboratory of Automotive Simulation and Control,Jilin University,Changchun 130022,China

摘要:

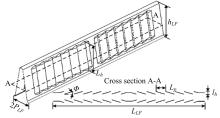

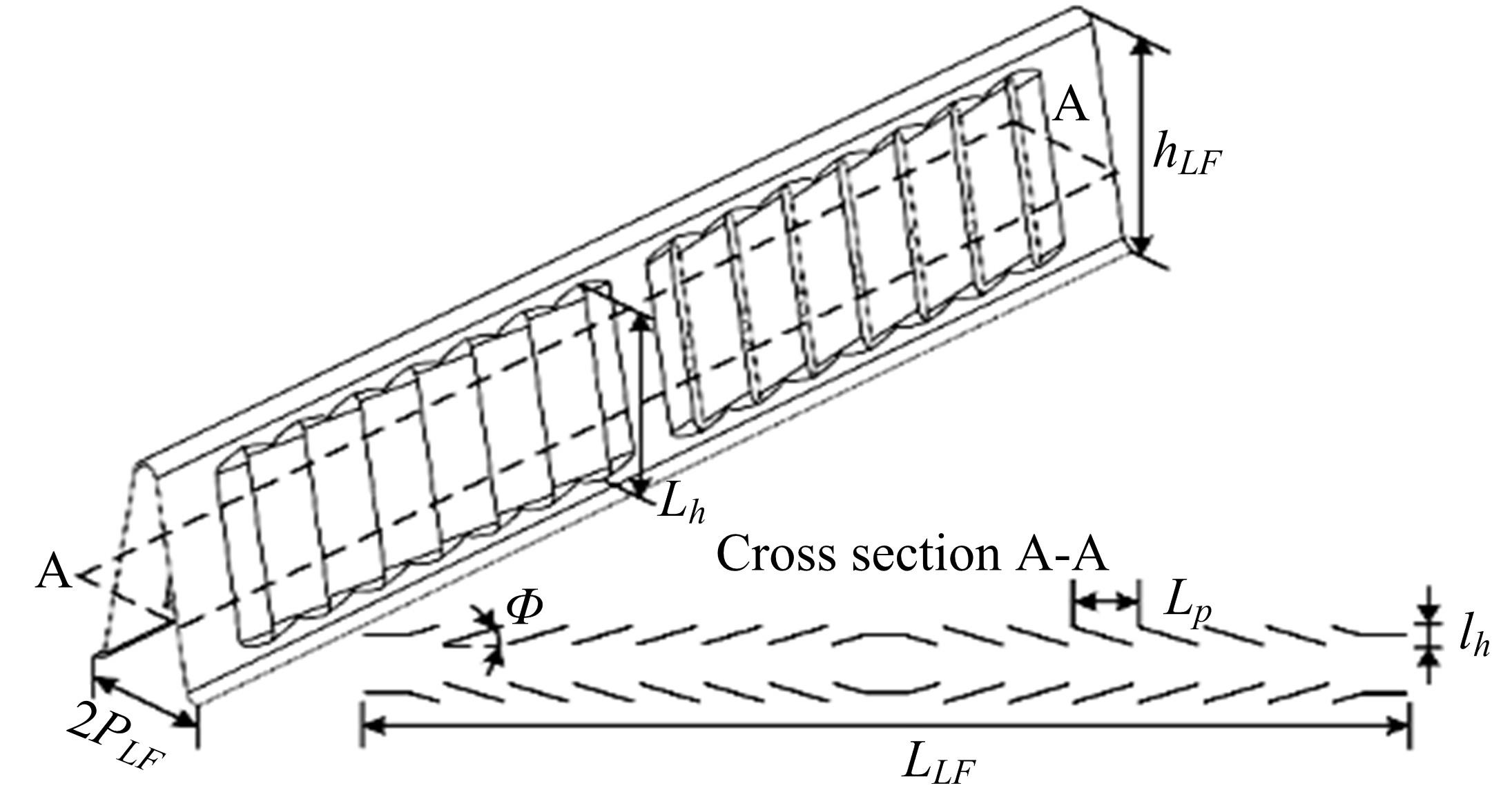

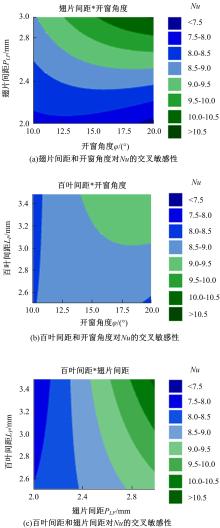

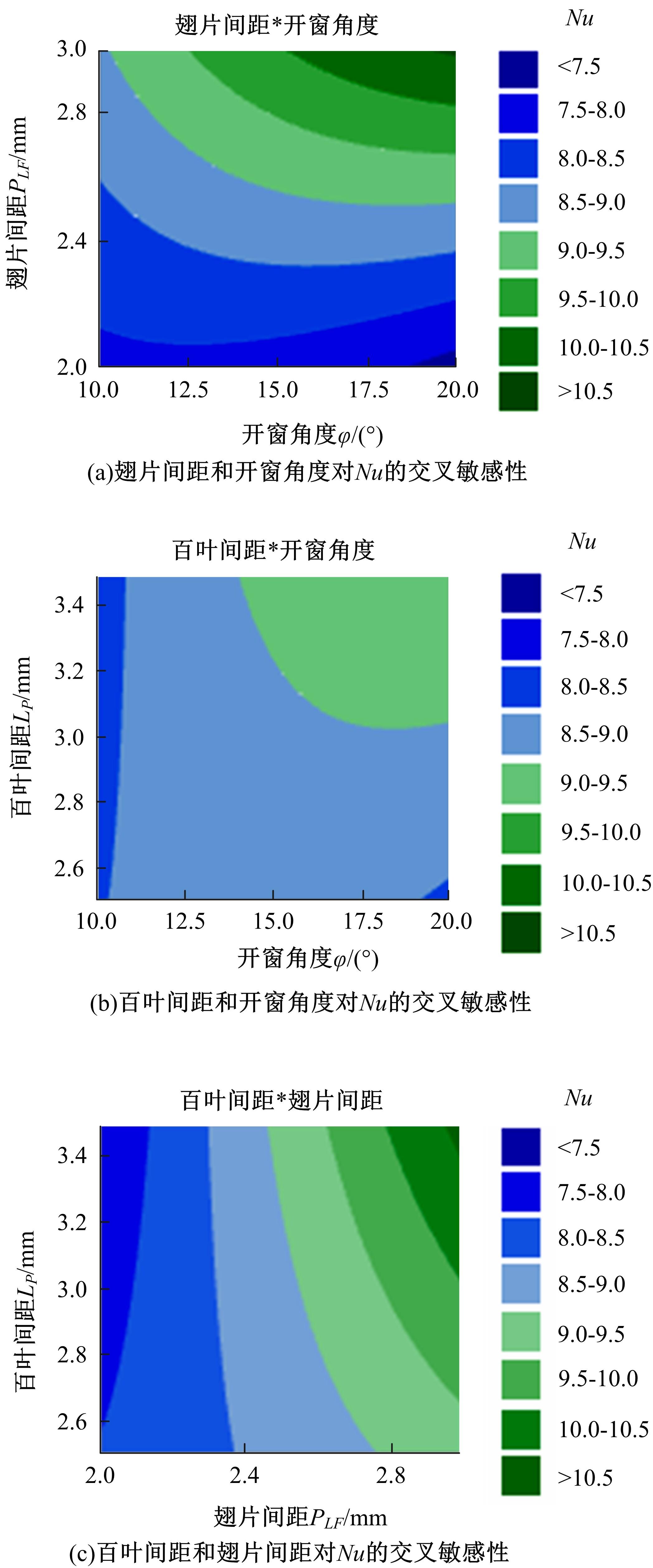

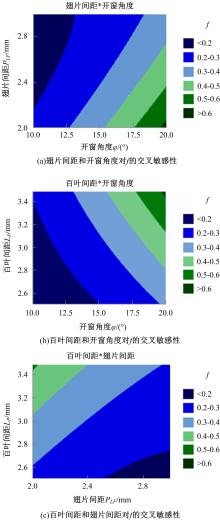

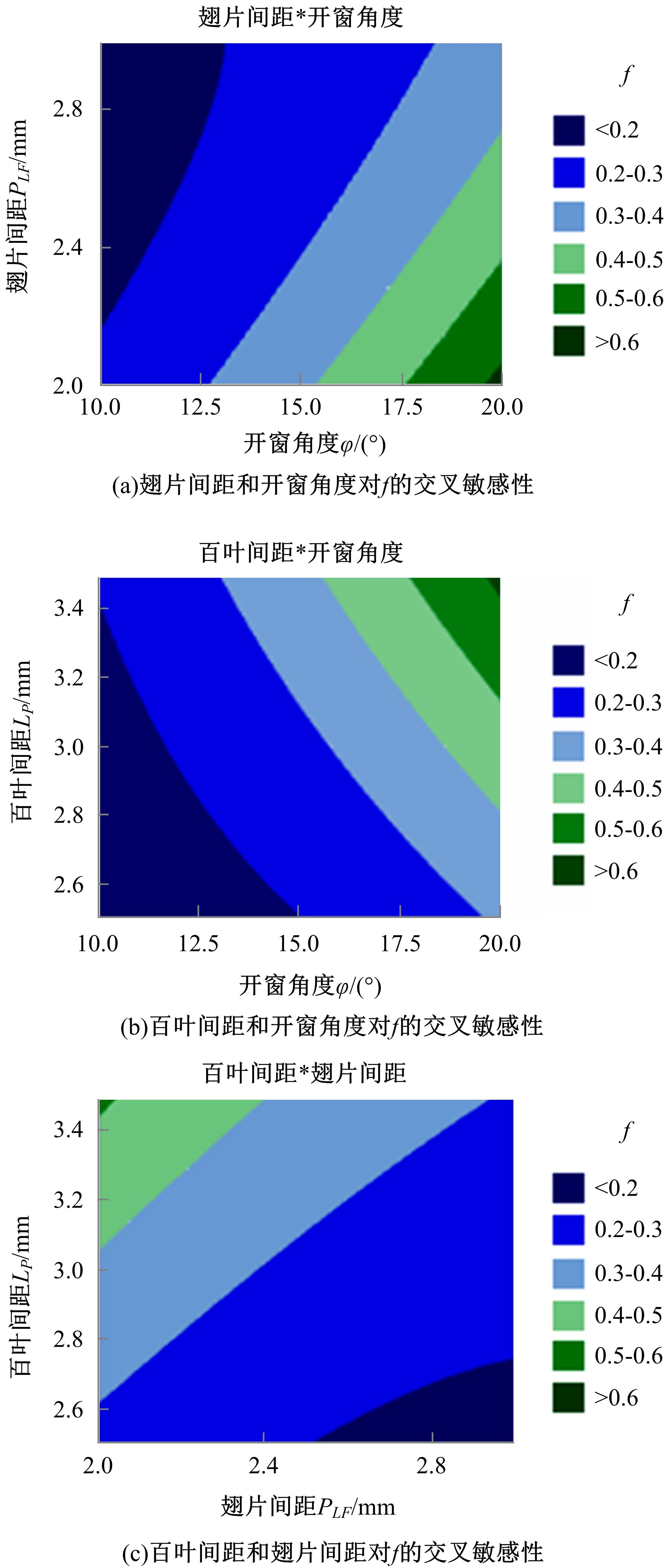

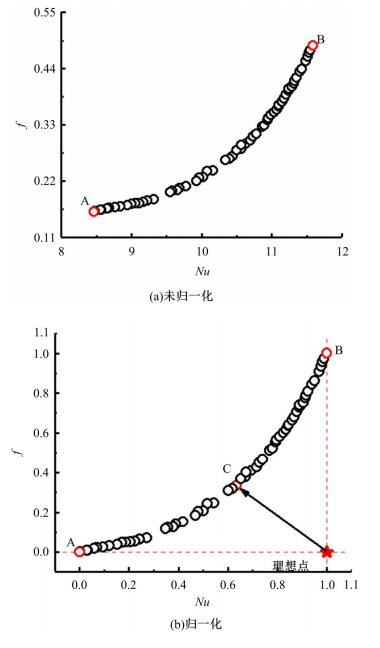

基于中心复合设计对空冷中冷器百叶窗翅片的3个几何参数开窗角度、翅片间距和百叶间距,进行三因素五水平的试验设计,然后建立以传热特性Nu和流动阻力特性f为目标函数的完全二阶回归模型,并采用响应曲面法分析各结构参数的影响重要性,最后根据多目标遗传算法进行寻优计算。结果表明:传热特性主要受翅片间距影响,而阻力特性受开窗角度影响最大,多目标优化得到一组Pareto解集,决策者可以根据实际需求在Pareto解集中进行选取。

中图分类号:

- U461.8

| 1 | 沙拉·塞库利克.换热器设计技术[M].程林,译.北京:机械工业出版社, 2010. |

| 2 | 钱颂文.换热器设计手册[M].北京:化学工业出版社, 2003. |

| 3 | Ferrero M, Scattina A, Chiavazzo E, et al. Louver finned heat exchangers for automotive sector: numerical simulations of heat transfer and flow resistance coping with industrial constraints[J]. Journal of Heat Transfer, 2013, 135(12):1-12. |

| 4 | Kwon Young Chul, Chang Keun Sun. Heat transfer and friction characteristics of louver fin and tube heat exchangers under wet conditions[J]. Applied Chemistry for Engineering, 2008, 19(1): 73-79. |

| 5 | Javaherdeh K, Vaisi A, Moosavi R. The effects of fin height, fin-tube contact thickness and louver length on the performance of a compact fin-and-tube heat exchanger[J]. International Journal of Heat and Technology, 2018, 36(3): 825-834. |

| 6 | 王任远, 李建雄, 吴金星. 散热器空气侧百叶窗翅片结构参数优化[J]. 流体机械, 2013, 41(6): 74-78. |

| Wang Ren-yuan, Li Jian-xiong, Wu Jin-xing. Structure parameters optimized for louvered fin in air side of radiator[J]. Fluid Machinery, 2013, 41(6): 74-78. | |

| 7 | Taylor J R. 误差分析导论-物理测量中的不确定度[M]. 王中宇,译. 北京: 高等教育出版社, 2015: 43-105. |

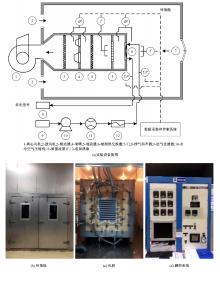

| 8 | 胡兴军,张靖龙,辛俐,等. 冷却管结构及风速对空冷中冷器性能的影响[J]. 吉林大学学报: 工学版, 2021, 51(5): 1557-1564. |

| Hu Xing-jun, Zhang Jing-long, Xin Li, et al. Investigation on influence of cooling tube structure and airflow speed on cold side performance of air-cooled charge air cooler[J]. Journal of Jilin University (Engineering and Technology Edition), 2021, 51(5): 1557-1564. | |

| 9 | 胡兴军, 张靖龙, 罗雨霏, 等. 冷却管结构及进气方向对空冷中冷器性能的影响[J]. 吉林大学学报: 工学版, 2021, 51(6): 1933-1942. |

| Hu Xing-jun, Zhang Jing-long, Luo Yu-fei, et al. Influence investigation of cooling tube structure and airflow direction on the thermal-hydraulic performance of air-cooled charge air cooler[J]. Journal of Jilin University (Engineering and Technology Edition), 2021, 51(6): 1933-1942. | |

| 10 | Han H Z, Li B X, Shao W. Multi-objective optimization of outward convex corrugated tubes using response surface methodology[J]. Applied Thermal Engineering, 2014, 70 (1): 250-262. |

| 11 | 张志红, 何桢, 郭伟. 在响应曲面方法中三类中心复合设计的比较研究[J]. 沈阳航空工业学院学报, 2007, 23(1): 87-91. |

| Zhang Zhi-hong, He Zhen, Guo Wei. A comparative study of three central composite designs in response surface methodology[J]. Journal of Shenyang Institute of Aeronautical Engineering, 2007, 23(1): 87-91. | |

| 12 | Qian Zuo-qin, Wang Qiang, Cheng Jun-lin, et al. Simulation investigation on inlet velocity profile and configuration parameters of louver fin[J]. Applied Thermal Engineering, 2018, 138: 173-182. |

| 13 | 王维. 外胀式螺旋波纹管强化传热机理及换热器优化研究[D]. 哈尔滨:哈尔滨工业大学能源科学与工程学院, 2019. |

| Wang Wei. Study on the heat transfer mechanism and heat exchanger optimization of outward helically corrugated tube[D]. Harbin: School of Energy Science and Engineering, Harbin Institute of Technology, 2019. | |

| 14 | Kamel M S, Mojtaba M, Soroush M, et al. Numerical investigation of heat exchanger effectiveness in a double pipe heat exchanger filled with nanofluid: a sensitivity analysis by response surface methodology[J]. Powder Technology, 2017, 313: 99-111. |

| 15 | Liu Y W, Liu L, Liang L L, et al. Thermodynamic optimization of the recuperative heat exchanger for Joule-Thomson cryocoolers using response surface methodology[J]. International Journal of Refrigeration, 2015, 60: 155-165. |

| 16 | Han H Z, Yu R T, Li B X, et al. Multi-objective optimization of corrugated tube with loose-fit twisted tape using RSM and NSGA-II[J]. International Journal of Heat and Mass Transfer, 2019, 131: 781-794. |

| 17 | Whitley D. A genetic algorithm tutorial[J]. Statistics and Computing, 1994, 4(2): 65-85. |

| 18 | 陈凯,汪双凤. 基于遗传算法的风冷式动力电池热管理系统优化[J]. 工程热物理学报, 2018, 39(2): 384-388. |

| Chen Kai, Wang Shuang-feng. Optimization of air-cooled battery thermal management system based on genetic algorithm[J]. Journal of Engineering Thermophysics, 2018, 39(2): 384-388. | |

| 19 | Hemmat E M, Hajmohammad H, Moradi R, et al. Multi-objective optimization of cost and thermal performance of double walled carbon nanotubes/water nanofluids by NSGA-II using response surface method[J]. Applied Thermal Engineering, 2017, 112: 1648-1657. |

| 20 | 易凯. “三条红线”约束下的钦州市水资源优化配置研究[D]. 南宁:广西大学土木建筑工程学院, 2017. |

| Yi Kai. The research on water resources optimal allocation of qinzhou city under constraint of three red lines[D]. Nanning: College of Civil and Architectural Engineering, Guangxi University, 2017. | |

| 21 | 孙靖明,梁迎春. 机械优化设计[M]. 北京:机械工业出版社, 2012. |

| [1] | 王建,于威,王斌. 高原状态下甲醇替代率对柴油机燃烧与排放的影响[J]. 吉林大学学报(工学版), 2023, 53(4): 954-963. |

| [2] | 于立娟,安阳,何佳龙,李国发,王升旭. 机电装备载荷谱外推技术研究进展及发展趋势[J]. 吉林大学学报(工学版), 2023, 53(4): 941-953. |

| [3] | 朱凌,王秋成. 空间几何约束下新能源汽车驱动系统协调控制方法[J]. 吉林大学学报(工学版), 2022, 52(7): 1509-1514. |

| [4] | 金兆辉,谷乐祺,洪伟,解方喜,尤田. 液压可变气门系统压力波动的影响分析[J]. 吉林大学学报(工学版), 2022, 52(4): 773-780. |

| [5] | 张岩,刘玮,张树勇,裴毅强,董蒙蒙,秦静. 二/四冲程可变柴油机燃烧室热负荷的改善[J]. 吉林大学学报(工学版), 2022, 52(3): 504-514. |

| [6] | 姚玉权,仰建岗,高杰,宋亮. 基于性能-费用模型的厂拌再生沥青混合料优化设计[J]. 吉林大学学报(工学版), 2022, 52(3): 585-595. |

| [7] | 李国发,王彦博,何佳龙,王继利. 机电装备健康状态评估研究进展及发展趋势[J]. 吉林大学学报(工学版), 2022, 52(2): 267-279. |

| [8] | 章子玲,胡雄,亓寅,王微,陶志强,刘志峰. 基于向量投影响应面的数控机床几何误差分配方法[J]. 吉林大学学报(工学版), 2022, 52(2): 384-391. |

| [9] | 王磊,黄秉汉,丛家慧,回丽,周松,徐永臻. 超声冲击对搅拌摩擦焊缝疲劳性能的影响[J]. 吉林大学学报(工学版), 2022, 52(11): 2542-2548. |

| [10] | 赵文伯,李玉洁,邓俊,李理光,吴志军. 针阀运动规律及其对喷嘴内流和喷雾特性影响[J]. 吉林大学学报(工学版), 2022, 52(10): 2234-2243. |

| [11] | 胡兴军,张靖龙,罗雨霏,辛俐,李胜,胡金蕊,兰巍. 冷却管结构及进气方向对空冷中冷器性能的影响[J]. 吉林大学学报(工学版), 2021, 51(6): 1933-1942. |

| [12] | 胡兴军,张靖龙,辛俐,罗雨霏,王靖宇,余天明. 冷却管结构及风速对空冷中冷器性能的影响[J]. 吉林大学学报(工学版), 2021, 51(5): 1557-1564. |

| [13] | 杨开宇,刘伟,王天皓,于显利,高印寒,马喜来. 一种多导体传输线串扰不确定性问题的计算方法[J]. 吉林大学学报(工学版), 2021, 51(2): 747-753. |

| [14] | 李志军,刘浩,张立鹏,李振国,邵元凯,李智洋. 过滤壁结构对颗粒捕集器深床过滤影响的模拟[J]. 吉林大学学报(工学版), 2021, 51(2): 422-434. |

| [15] | 赵庆武,程勇,杨雪,王宁. 高重频纳秒脉冲放电点火系统设计[J]. 吉林大学学报(工学版), 2021, 51(2): 414-421. |

|

||