吉林大学学报(工学版) ›› 2022, Vol. 52 ›› Issue (11): 2735-2745.doi: 10.13229/j.cnki.jdxbgxb20210348

• 农业工程·仿生工程 • 上一篇

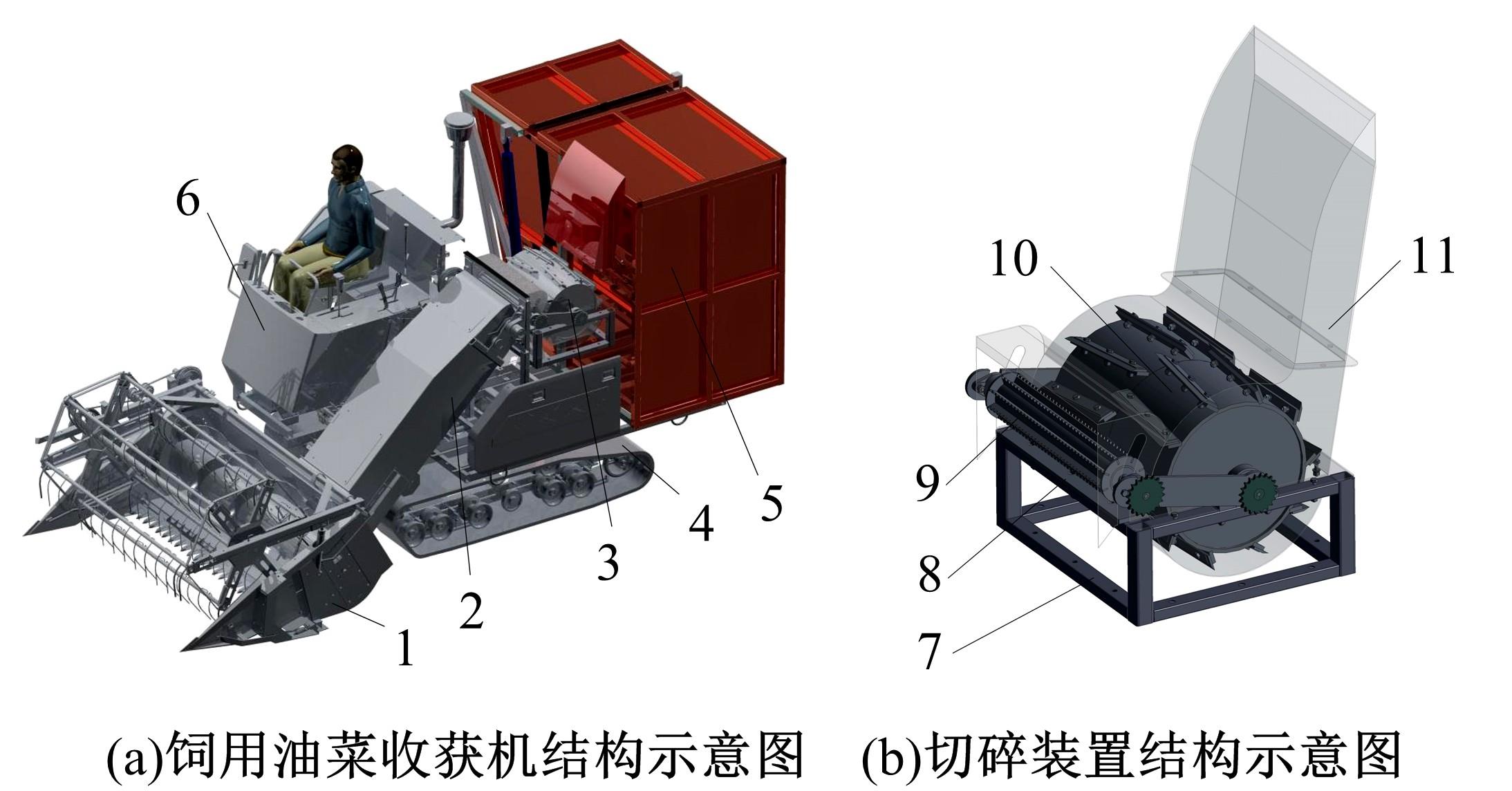

饲用油菜机械化收获切碎过程离散元仿真与试验

万星宇1( ),廖庆喜1,2,蒋亚军1,单伊尹1,周宇1,廖宜涛1,2(

),廖庆喜1,2,蒋亚军1,单伊尹1,周宇1,廖宜涛1,2( )

)

- 1.华中农业大学 工学院,武汉 430070

2.农业农村部长江中下游农业装备重点实验室,武汉 430070

Discrete element simulation and experiment of mechanized harve- sting and chopping process for fodder rape crop harvest

Xing-yu WAN1( ),Qing-xi LIAO1,2,Ya-jun JIANG1,Yi-yin SHAN1,Yu ZHOU1,Yi-tao LIAO1,2(

),Qing-xi LIAO1,2,Ya-jun JIANG1,Yi-yin SHAN1,Yu ZHOU1,Yi-tao LIAO1,2( )

)

- 1.College of Engineering,Huazhong Agricultural University,Wuhan 430070,China

2.Key Laboratory of Agricultural Equipment in Mid-Lower Yangtze River,Ministry of Agriculture and Rural Affairs,Wuhan 430070,China

摘要:

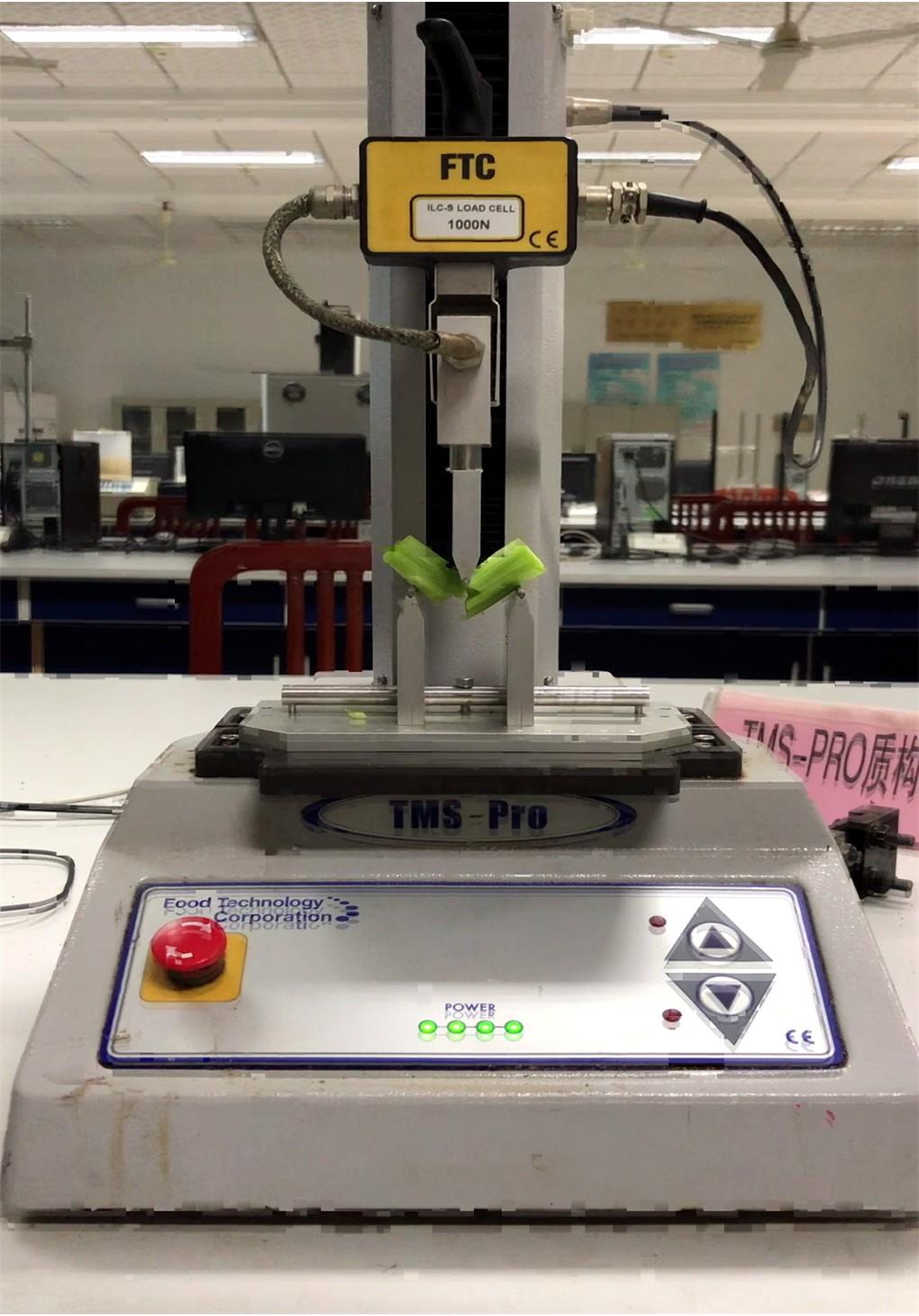

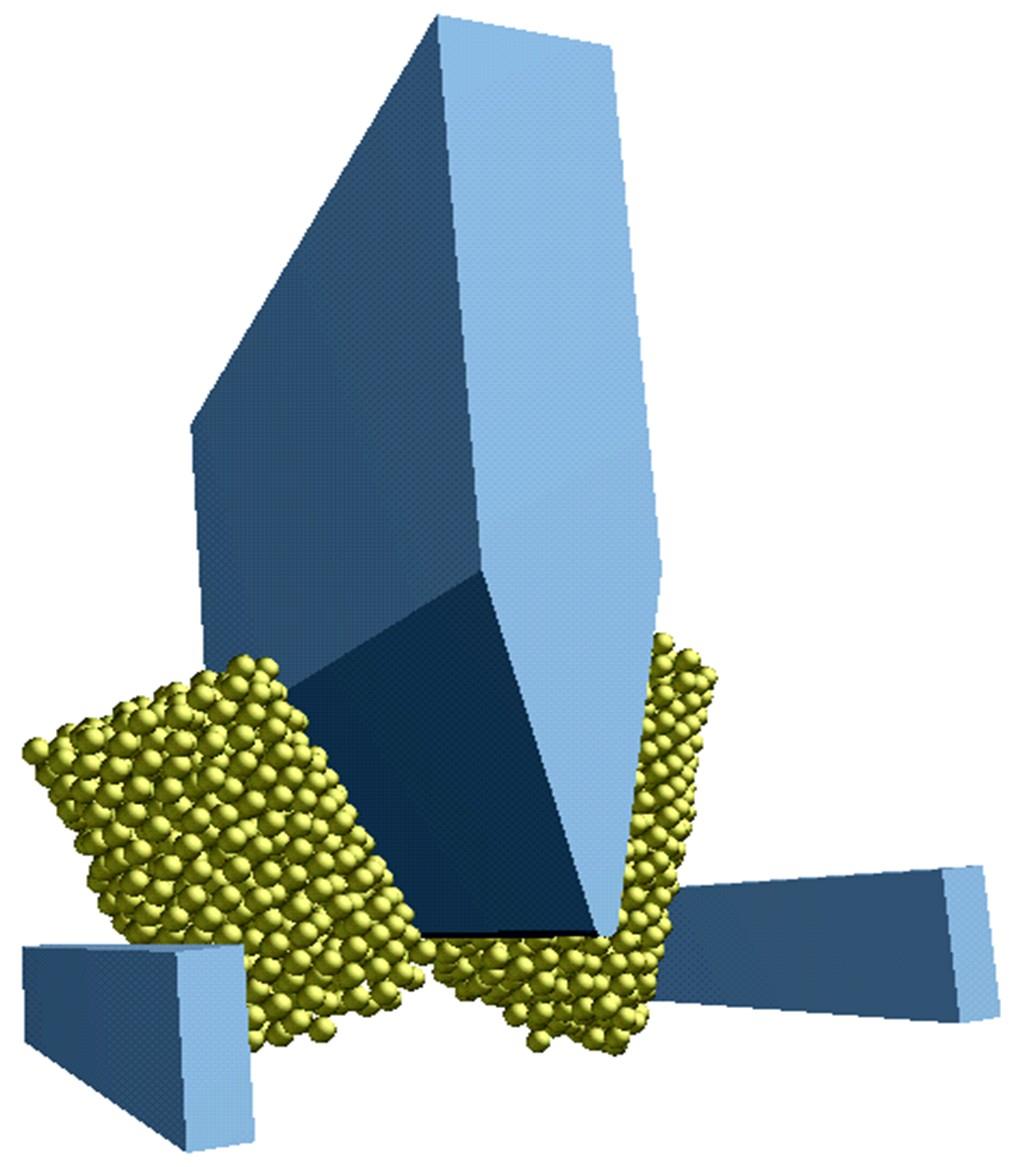

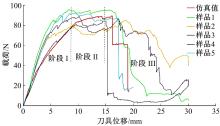

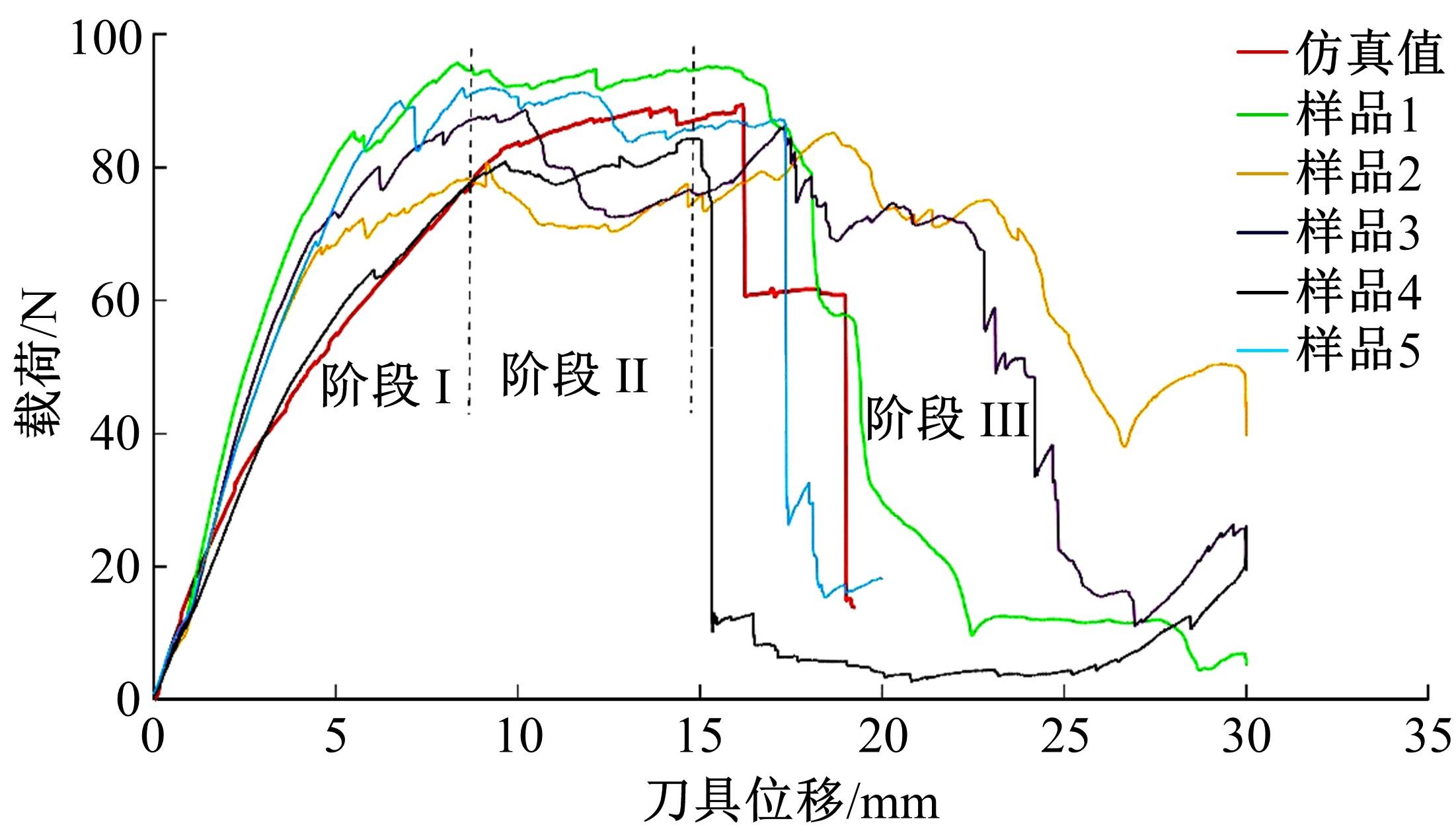

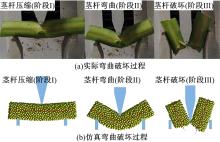

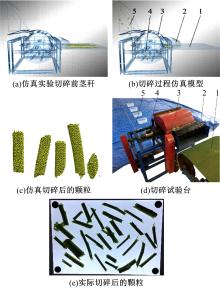

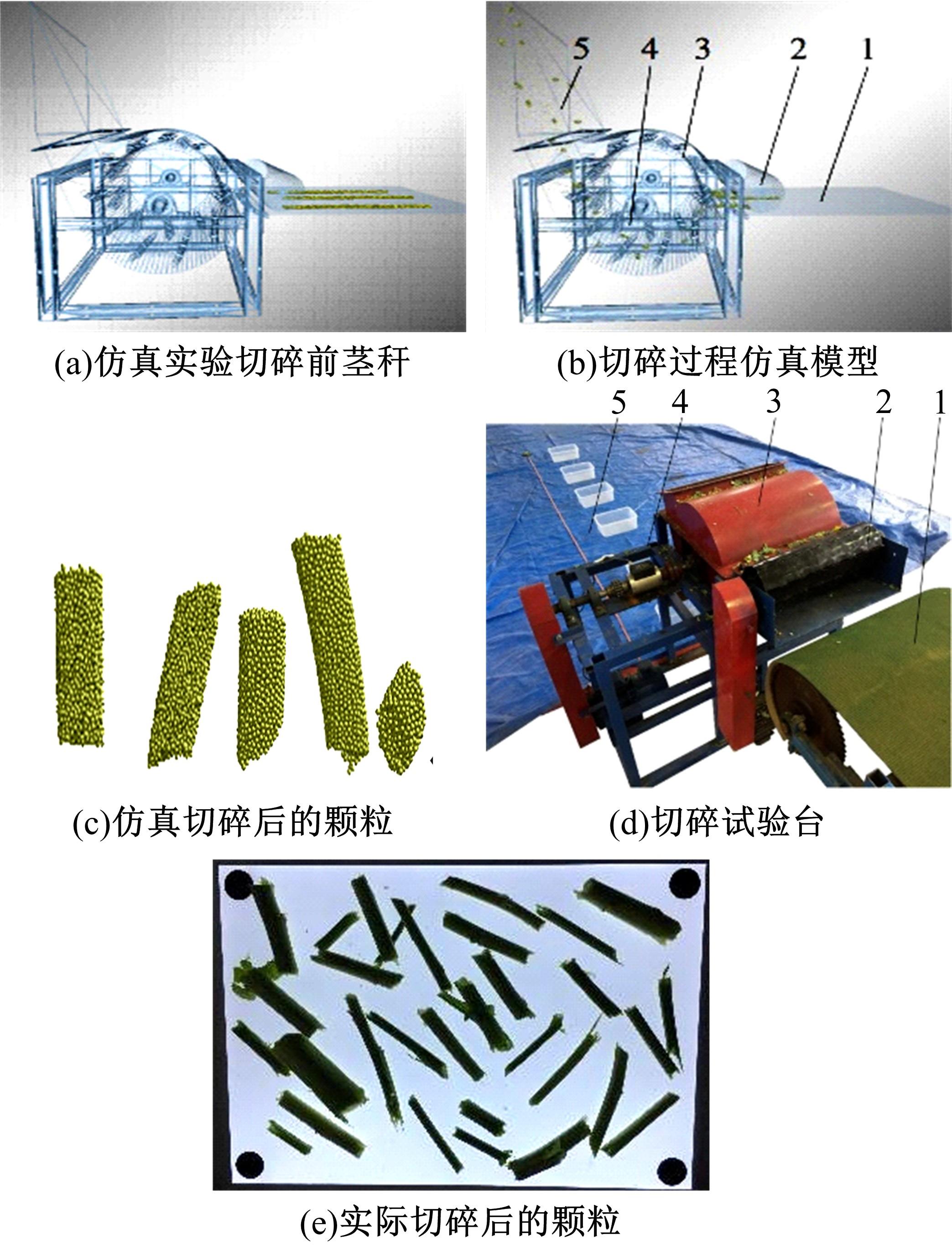

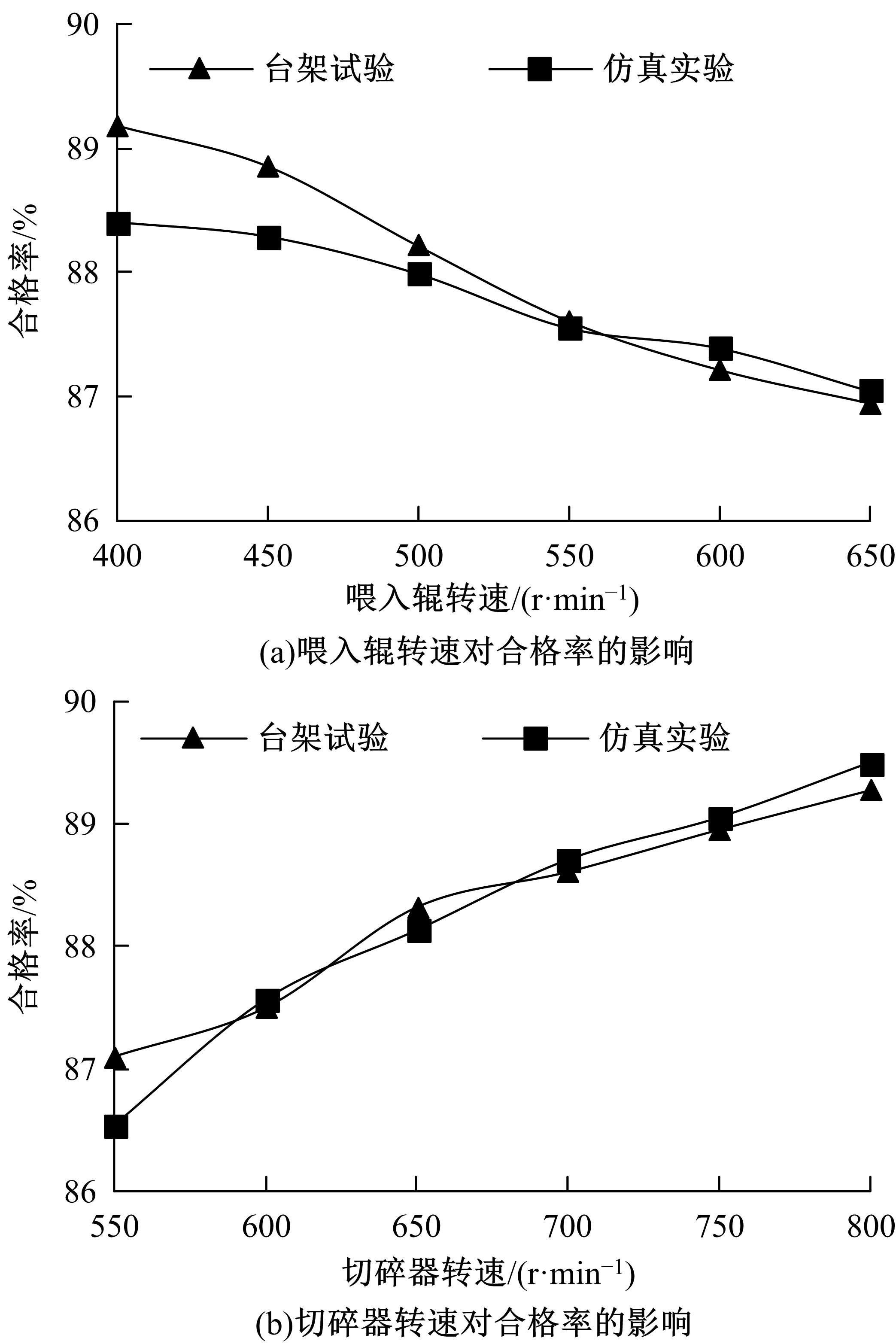

针对饲用油菜收获缺乏有效数值模拟方法,影响收获装备研发成本与效率的问题,开展了饲用油菜机械化收获茎秆切碎过程离散元仿真与试验。以盛花期饲用油菜茎秆为对象,应用三点弯曲法开展了响应面分析试验,标定了茎秆离散元仿真参数,以标定参数开展弯曲破坏仿真实验获得的最大破坏力与实际试验测试值相对误差为0.12%,表明标定参数相对准确。基于标定参数开展了饲用油菜机械化收获切碎过程离散元仿真实验,确定了切碎装置最佳工作参数组合如下:喂入辊转速为467 r/min、切碎器转速为770 r/min,在此条件下仿真实验与台架试验茎秆切碎长度合格率分别为89.52%和89.86%。

中图分类号:

- S817.11

| 1 | 张哲, 殷艳, 刘芳, 等. 我国油菜多功能开发利用现状及发展对策[J]. 中国油料作物学报, 2018, 40(5): 618-623. |

| Zhang Zhe, Yin Yan, Liu Fang, et al. Current situation and development countermeasures of Chinese rapeseed multifunctional development and utilization[J]. Chinese Journal of Oil Crop Sciences, 2018, 40(5): 618-623. | |

| 2 | 毛鑫,刘桂琼,姜勋平,等. 饲料油菜鲜饲对哺乳母羊和羔羊体质量和血清生化指标的影响[J]. 河南农业科学, 2020, 49(5): 161-167. |

| Mao Xin, Liu Gui-giong, Jiang Xun-ping, et al. Effects of feeding fresh forage rape on body weight and serum parameters of lactating ewes and their lambs[J]. Journal of Henan Agricultural Sciences, 2020, 49(5): 161-167. | |

| 3 | 易四凤, 杨华, 余陵峰, 等. 新鲜饲料油菜对肉牛育肥效果的研究[J]. 中国饲料, 2017(20): 39-43. |

| Yi Si-feng, Yang Hua, Yu Ling-feng, et al. Study on fresh Brassica napus L. on fattening effects in beef cattle[J]. China Feed, 2017(20): 39-43. | |

| 4 | 汪波, 宋丽君, 王宗凯, 等. 我国饲料油菜种植及应用技术研究进展[J]. 中国油料作物学报, 2018, 40(5): 695-701. |

| Wang Bo, Song Li-jun, Wang Zong-kai, et al. Production and feeding technology of fodder rapeseed in china[J]. Chinese Journal of Oil Crop Sciences, 2018, 40(5): 695-701. | |

| 5 | 杨雪海, 张巍, 赵娜, 等. 油菜华油杂62不同生长期氨基酸组成及营养价值评价[J]. 中国油料作物学报, 2017, 39(2): 197-203. |

| Yang Xue-hai, Zhang Wei, Zhao Na, et al. Forage amino acid composition and nutrition of Brassica napus L.cv Huayouza 62 in different growth stages[J]. Chinese Journal of Oil Crop Sciences, 2017, 39(2): 197-203. | |

| 6 | 赵娜,杨雪海,魏金涛,等. 饲用油菜的营养成分分析及其在山羊瘤胃降解特性研究[J]. 草业学报, 2020, 29(5): 50-57. |

| Zhao Na, Yang Xue-hai, Wei Jin-tao, et al. Nutritional composition of forage rape and its rumen degradation characteristics in goats[J]. Acta Prataculturac Sinica, 2020, 29(5): 50-57. | |

| 7 | 蒋亚军,廖宜涛,廖庆喜. 冬春鲜喂饲用油菜收获机滚刀式切碎装置设计与试验[J]. 农业机械学报, 2019, 50(2): 102-111. |

| Jiang Ya-jun, Liao Yi-tao, Liao Qing-xi. Design and experiment on cylinder-type chopping device of harvester for fodder rapeseed in winter and spring[J]. Transactions of the Chinese Society for Agricultural Machinery, 2019, 50(2): 102-111. | |

| 8 | 谢方平,吴正阳,王修善,等. 基于无侧限抗压强度试验的土壤离散元参数标定[J]. 农业工程学报, 2020, 36(13): 39-47. |

| Xie Fang-ping, Wu Zheng-yang, Wang Xiu-shan, et al. Calibration of discrete element parameters of soils based on unconfined compressive strength test[J]. Transactions of the Chinese Society of Agricultural Engineering, 2020, 36(13): 39-47. | |

| 9 | 赵淑红,王加一,陈君执,等. 保护性耕作拟合曲线型深松铲设计与试验[J]. 农业机械学报, 2018, 49(2): 82-92. |

| Zhao Shu-hong, Wang Jia-yi, Chen Jun-zhi, et al. Design and experiment of fitting curve subsoiler of conservation tillage[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(2): 82-92. | |

| 10 | Barr J B, Desbiolles J M A, Fielke J M, et al. Development and field evaluation of a high-speed no-till seeding system[J]. Soil and Tillage Research, 2019, 194: 104337. |

| 11 | 廖庆喜,张朋玲,廖宜涛,等. 基于EDEM的离心式排种器排种性能数值模拟[J]. 农业机械学报, 2014, 45(2): 109-114. |

| Liao Qing-xi, Zhang Peng-ling, Liao Yi-tao, et al. Numerical simulation on seeding performance of centrifugal rape-seed metering device based on EDEM[J]. Transactions of the Chinese Society for Agricultural Machinery, 2014, 45(2): 109-114. | |

| 12 | 刘彩玲,王亚丽,都鑫,等. 摩擦复充种型孔带式水稻精量排种器充种性能分析与验证[J]. 农业工程学报, 2019, 35(4): 29-36. |

| Liu Cai-ling, Wang Ya-li, Du Xin, et al. Performance analysis and verification of cell-belt rice precision seed-metering based on friction and repeated filling principle[J]. Transactions of the Chinese Society of Agricultural Engineering, 2019, 35(4): 29-36. | |

| 13 | 钱震杰,金诚谦,袁文胜,等. 柔性脱粒齿杆与谷物含摩擦打击动力学模型[J]. 吉林大学学报: 工学版, 2021, 51(3): 1121-1130. |

| Qian Zhen-jie, Jin Cheng-qian, Yuan Wen-sheng, et al. Frictional impact dynamics of threshing process between flexible teeth and grains[J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(3): 1121-1130. | |

| 14 | 马彦华,宋春东,宣传忠,等. 苜蓿秸秆压缩仿真离散元模型参数标定[J]. 农业工程学报, 2020, 36(11): 22-30. |

| Ma Yan-hua, Song Chun-dong, Xuan Chuan-zhong, et al. Parameters calibration of discrete element model for alfalfa straw compression simulation[J]. Transactions of the Chinese Society of Agricultural Engineering, 2020, 36(11): 22-30. | |

| 15 | 耿端阳,孙延成,牟孝栋,等. 基于差速辊的青贮玉米籽粒破碎仿真试验及优化[J]. 吉林大学学报: 工学版, 2022, 52(3): 693-702. |

| Geng Duan-yang, Sun Yan-cheng, Mou Xiao-dong, et al. Simulation test and optimization of grain breakage of silage maize based on differential roller[J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(3): 693-702. | |

| 16 | 王扬,吕凤妍,徐天月,等. 大豆籽粒形状和尺寸分析及其建模[J]. 吉林大学学报: 工学版, 2018, 48(2): 507-517. |

| Wang Yang, Feng-yan Lyu, Xu Tian-yue, et al. Shape and size analysis of soybean kernel and modeling[J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(2): 507-517. | |

| 17 | Su Z, Li Y, Dong Y, et al. Simulation of rice threshing performance with concentric and non-concentric threshing gaps[J]. Biosystems Engineering, 2020, 197: 270-284. |

| 18 | 付宏,吕游,李艳双,等. 基于离散元法的玉米脱粒过程分析[J]. 吉林大学学报: 工学版, 2012, 42(4): 997-1002. |

| Fu Hong, You Lyu, Li Yan-shuang, et al. Analysis for corn threshing process based DEM[J]. Journal of Jilin University(Engineering and Technology Edition), 2012, 42(4): 997-1002. | |

| 19 | Mao H, Wang Q, Li Q. Modelling and simulation of the straw-grain separation process based on a discrete element model with flexible hollow cylindrical bonds[J]. Computers and Electronics in Agriculture, 2020, 170: 105229. |

| 20 | 王宪良,胡红,王庆杰,等. 基于离散元的土壤模型参数标定方法[J]. 农业机械学报, 2017, 48(12): 78-85. |

| Wang Xian-liang, Hu Hong, Wang Qing-jie, et al. Calibration method of soil contact characteristic parameters based on DEM theory[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(12): 78-85. | |

| 21 | 丁启朔,任骏,Belal Eisa Adam,等. 湿粘水稻土深松过程离散元分析[J]. 农业机械学报, 2017, 48(3): 38-48. |

| Ding Qi-shuo, Ren Jun, Belal Eisa Adam, et al. DEM analysis of subsoiling process in wet clayey paddy soil[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(3): 38-48. | |

| 22 | 李建桥,黄晗,王颖,等. 松软地面机器系统研究进展[J]. 农业机械学报, 2015, 46(5): 306-320. |

| Li Jian-qiao, Huang Han, Wang Ying, et al. Development on research of soft-terrain machine systems[J]. Transactions of the Chinese Society for Agricultural Machinery, 2015, 46(5): 306-320. | |

| 23 | 王笑丹,王洪美,韩云秀,等. 基于离散元法的牛肉咀嚼破碎模型构建[J]. 农业工程学报, 2016, 32(4): 228-234. |

| Wang Xiao-dan, Wang Hong-mei, Han Yun-xiu, et al. Structure of beef chewing model based on discrete element method[J]. Transactions of the Chinese Society of Agricultural Engineering, 2016, 32(4): 228-234. | |

| 24 | 张锋伟,宋学锋,张雪坤,等. 玉米秸秆揉丝破碎过程力学特性仿真与试验[J]. 农业工程学报, 2019, 35(9): 58-65. |

| Zhang Feng-wei, Song Xue-feng, Zhang Xue-kun, et al. Simulation and experiment on mechanical characteristics of kneading and crushing process of corn straw[J]. Transactions of the Chinese Society of Agricultural Engineering, 2019, 35(9): 58-65. | |

| 25 | Horabik J, Molenda M. Parameters and contact models for DEM simulations of agricultural granular materials: a review[J]. Biosystems Engineering, 2016,147: 206-225. |

| 26 | 廖宜涛,廖庆喜,周宇,等. 饲料油菜薹期收获茎秆破碎离散元仿真参数标定[J]. 农业机械学报, 2020, 51(6): 73-82. |

| Liao Yi-tao, Liao Qing-xi, Zhou Yu, et al. Parameters calibration of discrete element model of fodder rape crop harvest in bolting stage[J]. Transactions of the Chinese Society for Agricultural Machinery, 2020, 51(6): 73-82. | |

| 27 | Liao Y, Wang Z, Liao Q, et al. Calibration of discrete element parameters of fodder rape crop stem at flowering stage[C/OL]. [2020-05-18]. |

| 28 | 中国农业机械化科学研究院. 农业机械设计手册(下册)[M]. 北京: 中国农业科学技术出版社, 2007. |

| 29 | Wan X Y, Liao Q X, Jiang Y J, et al. Cattle feeding experiment and chopping device parameter determination for mechanized harvesting of forage rape crop[J]. Transactions of the ASABE, 2021, 64(2): 715-725. |

| 30 | 郭茜,张西良,徐云峰,等. 基于EDEM的番茄秸秆切割性能仿真及试验研究[J]. 排灌机械工程学报, 2018, 36(10): 1017-1022. |

| Guo Qian, Zhang Xi-liang, Xu Yun-feng, et al. EDEM-based simulation and experiment on tomato cane straw cutting performance[J]. Journal of Drainage and Irrigation Machinery Engineering, 2018, 36(10): 1017-1022. |

| [1] | 曾山,黄登攀,杨文武,刘伟健,文智强,曾力. 三角履带式再生稻收割机底盘的设计与试验[J]. 吉林大学学报(工学版), 2022, 52(8): 1943-1950. |

| [2] | 魏国粱,张青松,王彪,何坤,廖庆喜. 油菜直播机扣垡犁体参数分析与试验[J]. 吉林大学学报(工学版), 2022, 52(7): 1709-1718. |

| [3] | 朱光强,李天宇,周福君. 鲜食玉米仿生摘穗柔性夹持输送装置设计与试验[J]. 吉林大学学报(工学版), 2022, 52(10): 2486-2500. |

| [4] | 梁荣庆,钟波,蒙贺伟,孙志民,坎杂. 4QJ⁃3型青贮燕麦捡拾割台的研制[J]. 吉林大学学报(工学版), 2021, 51(5): 1887-1896. |

| [5] | 袁佳诚,王昌,何坤,万星宇,廖庆喜. 油菜联合收获机筛下物组分质量比对清选性能的影响[J]. 吉林大学学报(工学版), 2021, 51(5): 1897-1907. |

| [6] | 王刚,刘慧力,贾洪雷,郭春江,丛永健,屈明浩. 触碰定位式玉米行间除草装置的设计与试验[J]. 吉林大学学报(工学版), 2021, 51(4): 1518-1527. |

| [7] | 耿端阳,谭德蕾,于兴瑞,苏国粱,王骞,鹿秀凤,金诚谦. 玉米柔性脱粒滚筒脱粒元件设计与试验[J]. 吉林大学学报(工学版), 2020, 50(5): 1923-1933. |

| [8] | 付君,张屹晨,程超,陈志,唐心龙,任露泉. 刚柔耦合式小麦脱粒弓齿设计及试验[J]. 吉林大学学报(工学版), 2020, 50(2): 730-738. |

| [9] | 薛钊,付君,陈志,王锋德,韩少平,任露泉. 青饲玉米收获机械切碎装置参数优化试验[J]. 吉林大学学报(工学版), 2020, 50(2): 739-748. |

| [10] | 程超,付君,郝付平,陈志,周德义,任露泉. 清选筛运动参数对玉米芯轴堵筛规律的影响[J]. 吉林大学学报(工学版), 2020, 50(1): 351-360. |

| [11] | 程超,付君,唐心龙,陈志,任露泉. 振动形式对水稻脱出物界面粘附规律的影响[J]. 吉林大学学报(工学版), 2019, 49(4): 1228-1235. |

| [12] | 付君,钱志辉,尹维,王甲甲,任露泉. 小麦摩擦与拉伸性能[J]. 吉林大学学报(工学版), 2015, 45(2): 501-507. |

| [13] | 王殿海, 陶鹏飞, 金盛, 马东方. 跟驰模型参数标定及验证方法[J]. 吉林大学学报(工学版), 2011, 41(增刊1): 59-65. |

|

||