Journal of Jilin University(Engineering and Technology Edition) ›› 2022, Vol. 52 ›› Issue (2): 450-457.doi: 10.13229/j.cnki.jdxbgxb20211139

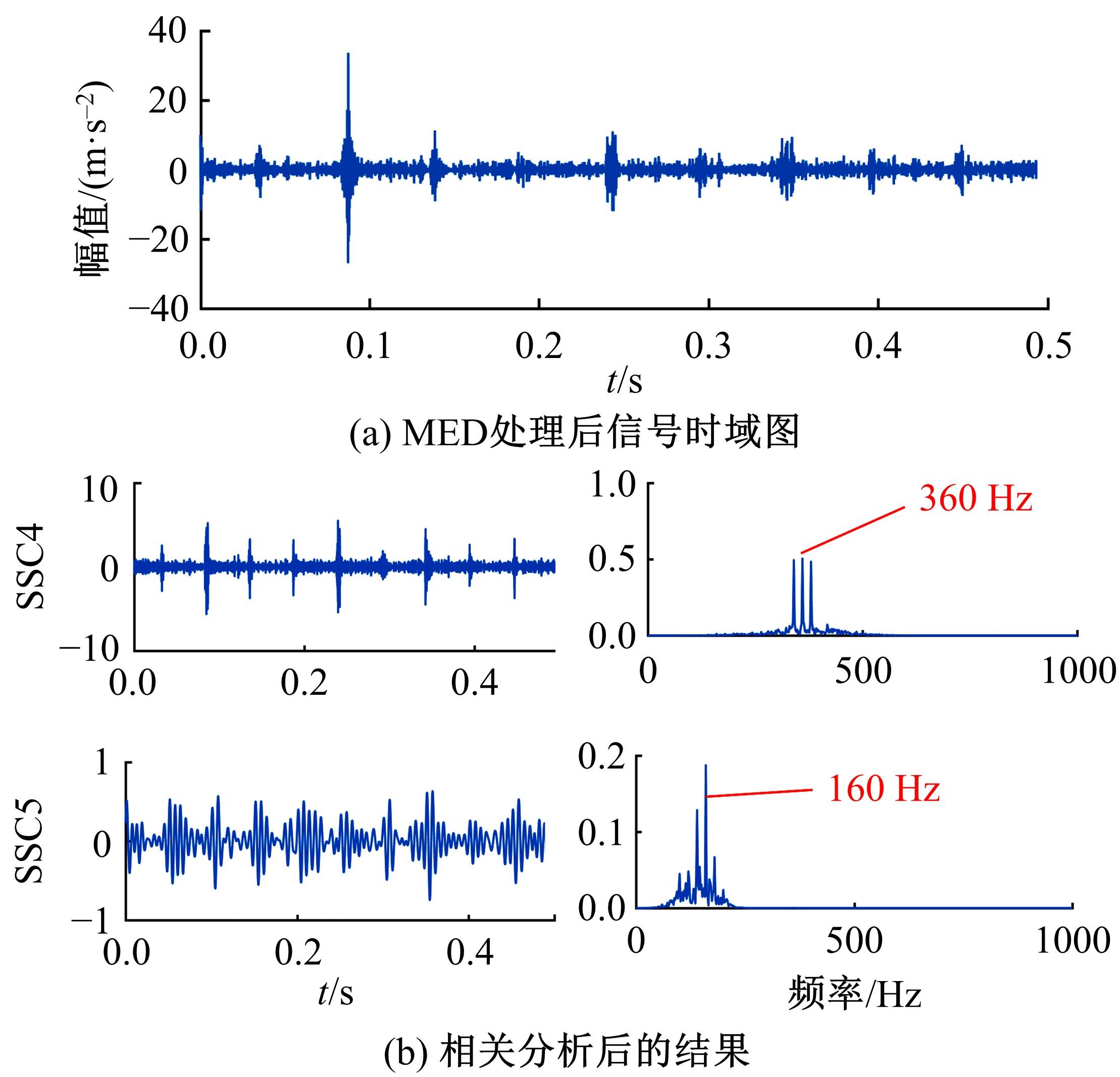

Gearbox complex fault diagnosis method based on improved minimum entropy deconvolution and singular spectrum decomposition

Jie ZHOU1,2( ),Yun-yi WANG2,Chuan-hai CHEN1,2(

),Yun-yi WANG2,Chuan-hai CHEN1,2( ),Li-ding WANG2,3,Kuo LIU3

),Li-ding WANG2,3,Kuo LIU3

- 1.Key Laboratory of CNC Equipment Reliability,Ministry of Education,Jilin University,Changchun 130022,China

2.College of Mechanical and Aerospace Engineering,Jilin University,Changchun 130022,China

3.School of Mechanical Engineering,Dalian University of Technology,Dalian 116024,China

CLC Number:

- TH132.41

| 1 | 鄢小安, 贾民平. 基于改进奇异谱分解的形态学解调方法及其在滚动轴承故障诊断中的应用[J]. 机械工程学报, 2017, 53(7): 104-112. |

| Yan Xiao-an, Jia Min-ping. Morphological demodulation method based on improved singular spectrum decomposition and its application in rolling bearing fault diagnosis[J]. Journal of Mechanical Engineering, 2017, 53(7): 104-112. | |

| 2 | Wang Z, Zhou J, Lei Y, et al. Bearing fault diagnosis method based on adaptive maximum cyclostationarity blind deconvolution[J]. Mechanical Systems and Signal Processing, 2021, 162: 108018. |

| 3 |

张龙, 徐天鹏, 王朝兵, 等. 基于卷积门控循环网络的齿轮箱故障诊断[J]. 吉林大学学报: 工学版. DOI: 10.13229/j.cnki.jdxbgxb20200930.

doi: 10.13229/j.cnki.jdxbgxb20200930 |

|

Zhang Long, Xu Tian-peng, Wang Chao-bing, et al. Gearbox fault diagnosis baed on convolutional gated recurrent network[J]. Journal of Jilin University(Engineering and Technology Edition). DOI:10.13229/j.cnki.jdxbgxb20200930.

doi: 10.13229/j.cnki.jdxbgxb20200930 |

|

| 4 | Wang Z, Zhao W, Du W, et al. Data-driven fault diagnosis method based on the conversion of erosion operation signals into images and convolutional neural network[J]. Process Safety and Environmental Protection, 2021, 149, 591-601. |

| 5 |

陈菲, 杨峥, 张志成, 等. 面向无标签数据的旋转机械故障诊断方法[J]. 吉林大学学报: 工学版. DOI: 10.13229/j.cnki.jdxbgxb20210355.

doi: 10.13229/j.cnki.jdxbgxb20210355 |

|

Chen Fei, Yang Zheng, Zhang Zhi-cheng, et al. Fault diagnosis method of rotating machinery for unlabeled data [J]. Journal of Jilin University (Engineering and Technology Edition). DOI:10.13229/j.cnki.jdxbgxb20210355.

doi: 10.13229/j.cnki.jdxbgxb20210355 |

|

| 6 | Wang Z J, He X X, Yang B, et al. Subdomain adaptation transfer learning network for fault diagnosis of roller bearings[J]. IEEE Transactions on Industrial Electronics, 2021(99): 3108726. |

| 7 | 乔志城, 刘永强, 廖英英. 改进经验小波变换与最小熵解卷积在铁路轴承故障诊断中的应用[J]. 振动与冲击, 2021, 40(2): 81-90, 118. |

| Qiao Zhi-cheng, Liu Yong-qiang, Liao Ying-ying. Application of improved wavelet transform and minimum entropy deconvolution in railway bearing fault diagnosis[J]. Journal of Vibration and Shock, 2021, 40(2): 81-90, 118. | |

| 8 | 陈是扦, 彭志科, 周鹏. 信号分解及其在机械故障诊断中的应用研究综述[J]. 机械工程学报, 2020, 56(17): 91-107. |

| Chen Shi-qian, Peng Zhi-ke, Zhou Peng. Review of signal decomposition theory and its applications in machine fault diagnosis[J]. Journal of Mechanical Engineering, 2020, 56(17): 91-107. | |

| 9 | Pietro B, Joël M, Karel H, et al. Singular spectrum decomposition: a new method for time series decomposition[J]. Advances in Adaptive Data Analysis, 2014, 6(4): 107-109. |

| 10 | Movahedifar M, Yarmohammadi M, Hassani H. Bicoid signal extraction: another powerful approach[J]. Mathematical Biosciences, 2018, 303: 52-61. |

| 11 | Yi C, Lv Y, Ge M, et al. Tensor singular spectrum decomposition algorithm based on permutation entropy for rolling bearing fault diagnosis[J]. Entropy, 2017, 19(4): 19040139. |

| 12 | Endo H, Randall R B. Application of a minimum entropy deconvolution filter to enhance autoregressive model based gear tooth fault detection technique[J]. Mechanical Systems and Signal Processing, 2007, 1(2): 906-919. |

| 13 | 贺志远, 陈果, 何超, 等. 一种MED最优滤波长度选择新方法及其应用[J]. 航空学报, 2020, 41(10): 394-408. |

| He Zhi-yuan, Chen Guo, He Chao, et al. MED optimal filter length selection new method and applications[J]. Acta Aeronautica et Astronautica Sinica, 2020, 41(10): 394-408. | |

| 14 | Zhao W, Wang L, Zhang Z. A novel atom search optimization for dispersion coefficient estimation in groundwater[J]. Future Generation Computer Systems, 2019, 91: 601-610. |

| 15 | Mcdonald G L, Zhao Q. Multipoint optimal minimum entropy deconvolution and convolution fix: application to vibration fault detection[J]. Mechanical Systems & Signal Processing, 2017, 82: 461-477. |

| 16 | Li J, Li M, Zhang J. Rolling bearing fault diagnosis based on time-delayed feedback monostable stochastic resonance and adaptive minimum entropy deconvolution[J]. Journal of Sound Vibration, 2017, 401: 139-151. |

| 17 | Liu Z, He Z, Guo W, A hybrid fault diagnosis method based on second generation wavelet de-noising and local mean decomposition for rotating machinery[J]. ISA Transactions, 2016, 61: 211-220. |

| 18 | Zhang Z, Zhang X, Zhang P, et al. Gearbox composite fault diagnosis method based on minimum entropy deconvolution and improved dual-tree complex wavelet transform[J]. Entropy, 2018, 21(1): 21010018. |

| 19 | He D, Wang X, Li S, et al. Identification of multiple faults in rotating machinery based on minimum entropy deconvolution combined with spectral kurtosis[J]. Mechanical Systems and Signal Processing, 2016, 81: 235-249. |

| [1] | OUYANG Tian-cheng, CHEN Nan, NIU Ya-feng. Mixed elastohydrodynamic lubrication for involute gear with different rough surfaces [J]. 吉林大学学报(工学版), 2016, 46(6): 1933-1939. |

| [2] | SONG Bao-yu,XIE Zhi-jie,ZHANG Feng,WANG Rui-ze,HAO Ming-hui,SU Dai-zhong. Fault diagnosis algorithm for helical gear rotating at low speed on angular domain synchronous average and order tracking analysis [J]. 吉林大学学报(工学版), 2015, 45(2): 454-459. |

| [3] | LI Wen-liang, WANG Li-qin, CHANG Shan, DAI Guang-hao. Impact of tooth surface friction on harmonic resonance of gear system [J]. 吉林大学学报(工学版), 2013, 43(05): 1290-1294. |

| [4] | HONG Zhao-bin, YANG Zhao-jun, ZHANG Xue-cheng, WANG Bai-chao. Milling simulation analysis of spiral bevel gear based on tooth generating line [J]. 吉林大学学报(工学版), 2013, 43(02): 334-339. |

| [5] | LI Li-nan, YANG Zhao-jun, WANG Yan-kun, ZHANG Xue-cheng. Modeling and substituting of generating lines of cutting hypoid gears by generating-line method [J]. 吉林大学学报(工学版), 2011, 41(增刊1): 127-133. |

|

||