Journal of Jilin University(Engineering and Technology Edition) ›› 2023, Vol. 53 ›› Issue (8): 2165-2184.doi: 10.13229/j.cnki.jdxbgxb.20211099

Research progress of vibration control of vibration damping boring bar

Qiang LIU1,2( ),Da-yong GAO1,Xian-li LIU1(

),Da-yong GAO1,Xian-li LIU1( ),Ru-hong JIA1,Qiang ZHOU1,Zheng-yan BAI1

),Ru-hong JIA1,Qiang ZHOU1,Zheng-yan BAI1

- 1.Key Laboratory of Advanced Manufacturing and Intelligent Technology,Ministry of Education,Harbin University of Science and Technology,Harbin 150080,China

2.Postdoctoral Research Station of Electrical Engineering,Harbin University of Science and Technology,Harbin 150080,China

CLC Number:

- TG713.3

| 1 | 王立平,杨叔子,杨兆军,等. 振动钻削的国内外研究状况和发展趋势[J]. 机械设计与制造工程,1999(2):6-9, 3. |

| Wang Li-ping, Yang Shu-zi, Yang Zhao-jun,et al. Research status and development trend of vibration drilling at home and abroad[J]. Mechanical Design and Manufacturing Engineering,1999(2):6-9, 3. | |

| 2 | 张月星,李强. 浅谈火炮身管加工工艺[J]. 装备制造技术,2014(2):241-242. |

| Zhang Yue-xing, Li Qiang. Talking about the processing technology of artillery barrel[J]. Equipment Manufacturing Technology,2014(2):241-242. | |

| 3 | 姚素娴,杨洪平. 某细长涡轮轴加工工艺研究[J]. 航空精密制造技术,2015(2):35-38. |

| Yao Su-xian, Yang Hong-ping. Research on machining processing for a slender turbine shaft[J]. Aviation Precision Manufacturing Technology,2015(2):35-38. | |

| 4 | 谈尚炯. 核电汽轮机低压转子的应力腐蚀寿命预测建模及计算分析[D]. 上海:上海交通大学机械与动力工程学院,2013. |

| Tan Shang-jiong. Modeling and calculation analysis of stress corrosion life prediction for low-pressure rotors of nuclear power steam turbines[D]. Shanghai:School of Mechanical Engineering,Shanghai Jiaotong University,2013. | |

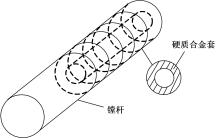

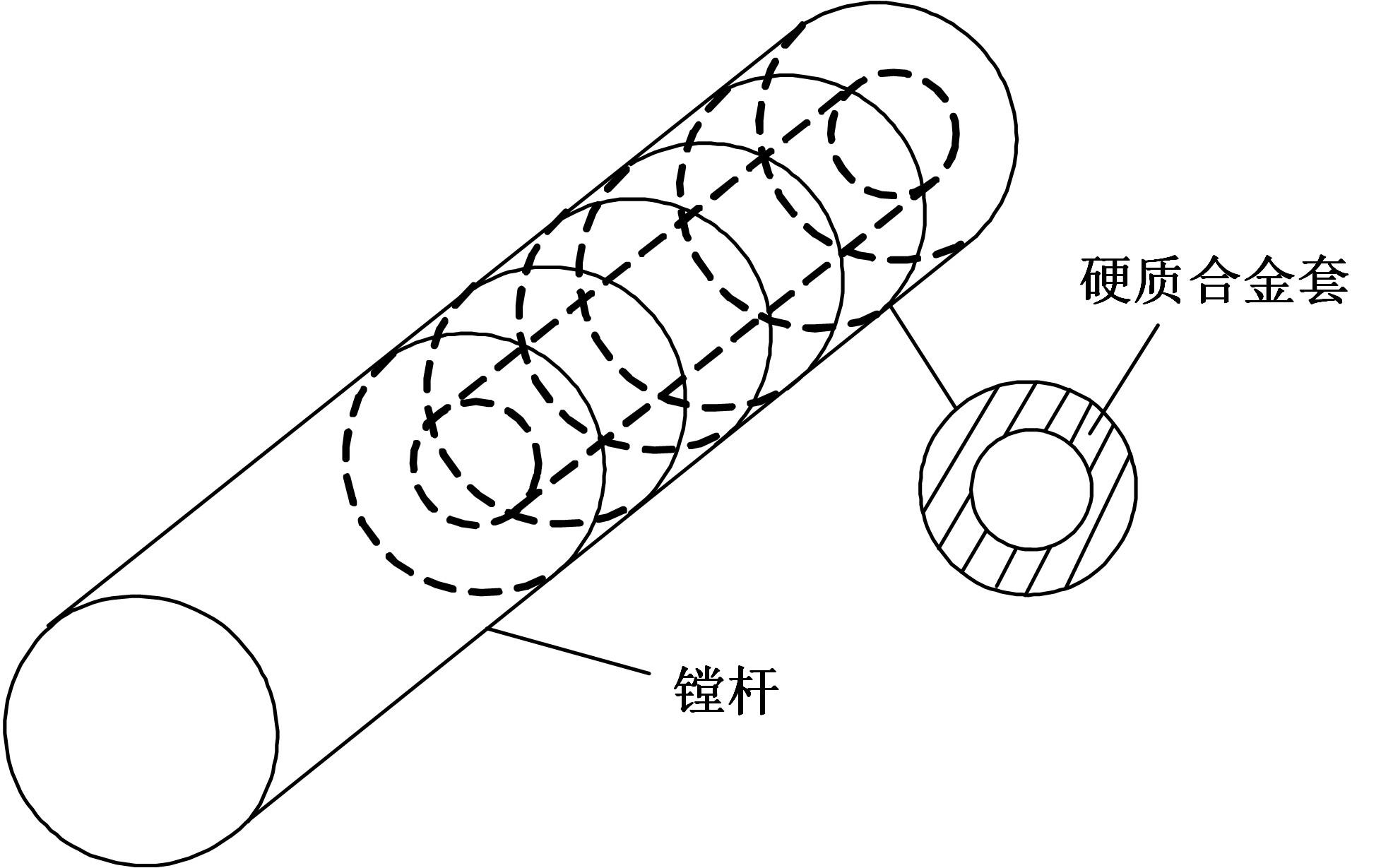

| 5 | 章宗诚. 日本三菱公司新型高阻尼抗振FSCL型镗杆[J]. 工具技术,2000(5): 40. |

| Zhang Zong-cheng. New high damping and vibration resistant FSCL type boring bar from Mitsubishi Japan[J]. Tool Engineering,2000(5): 40. | |

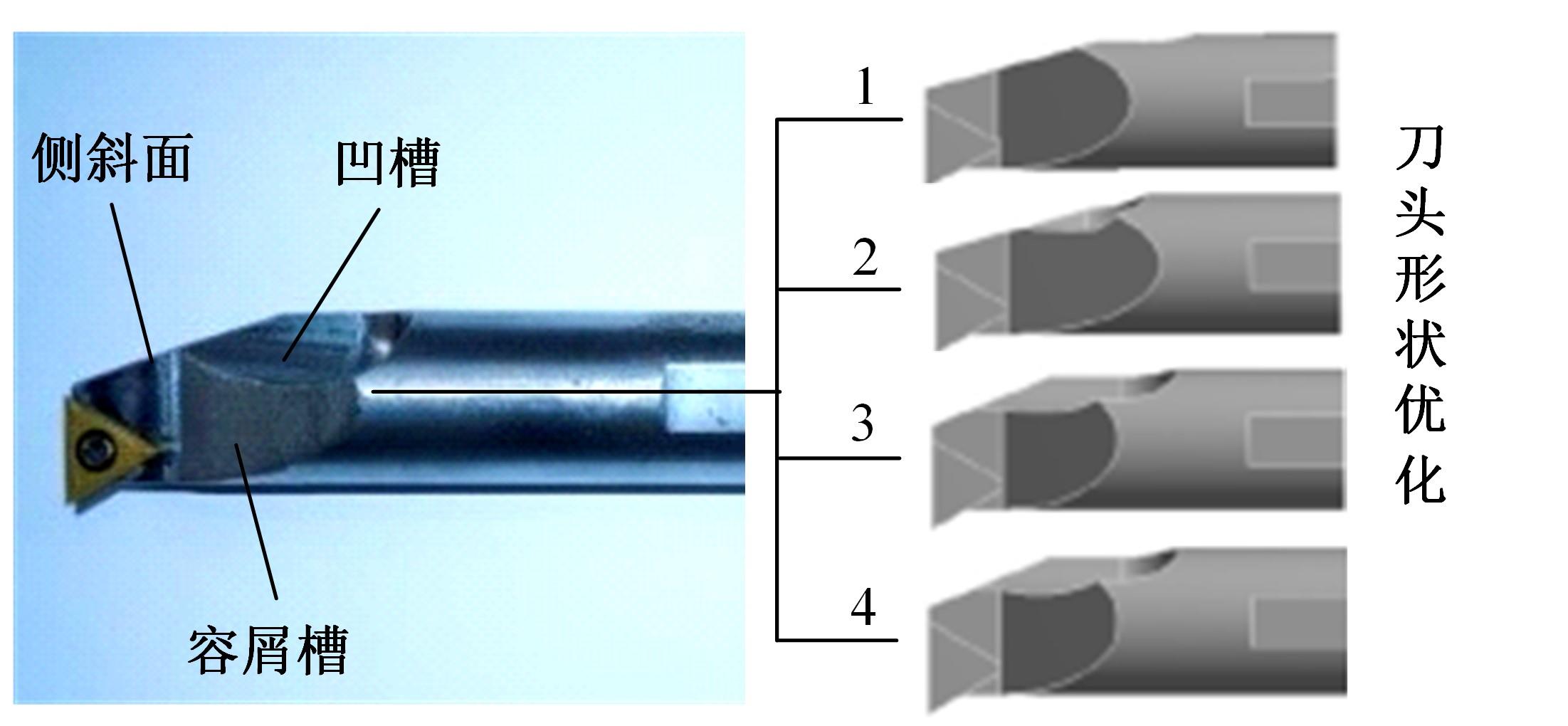

| 6 | 袁黎. 大长径比减振镗杆的形状优化设计[D]. 湘潭:湖南科技大学机电工程学院,2014. |

| Yuan Li. Shape optimization design of large aspect ratio vibration-damping boring bar[D]. Xiangtan:School of Electromechanical Engineering,Hunan Uni-versity of Science and Technology,2014. | |

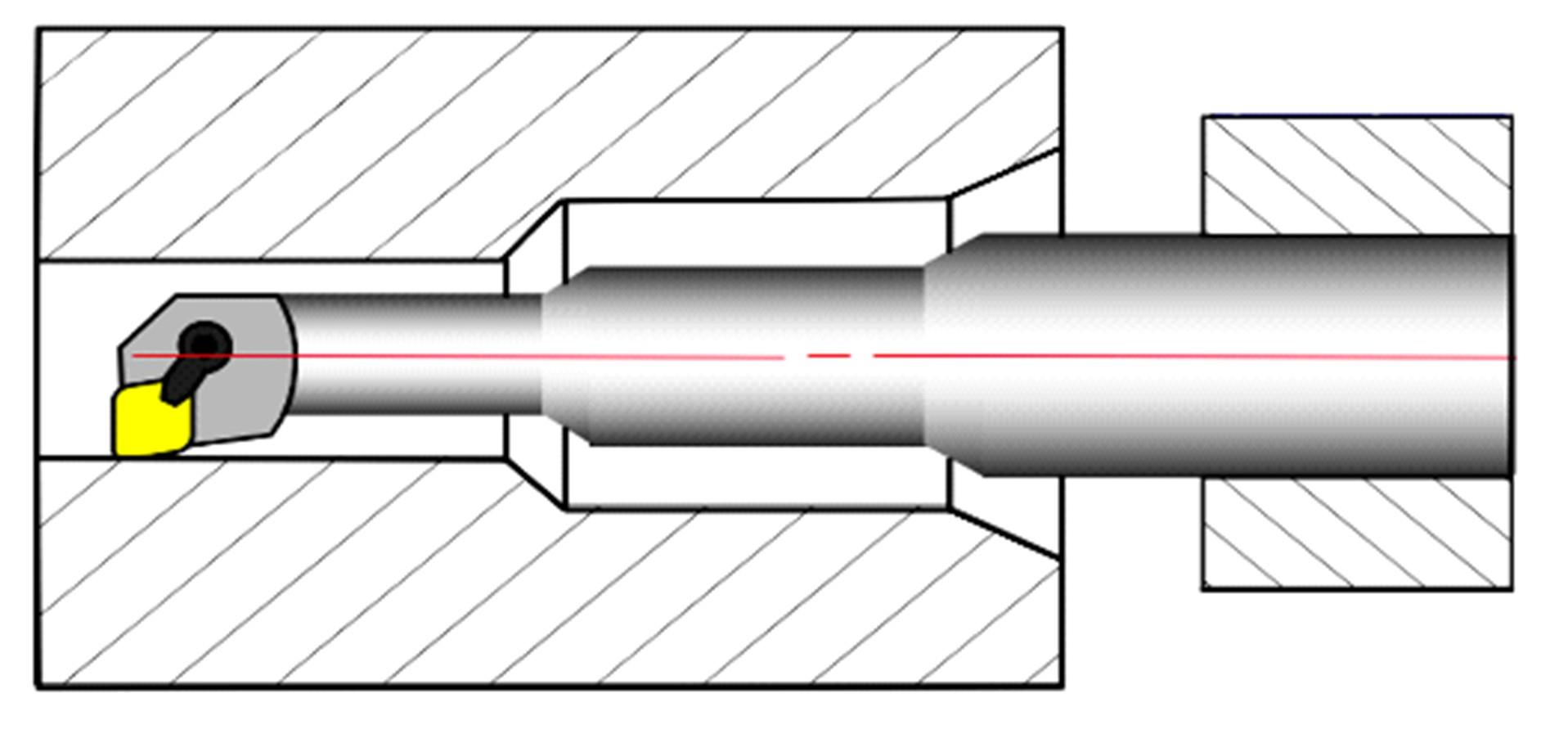

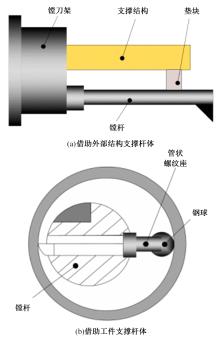

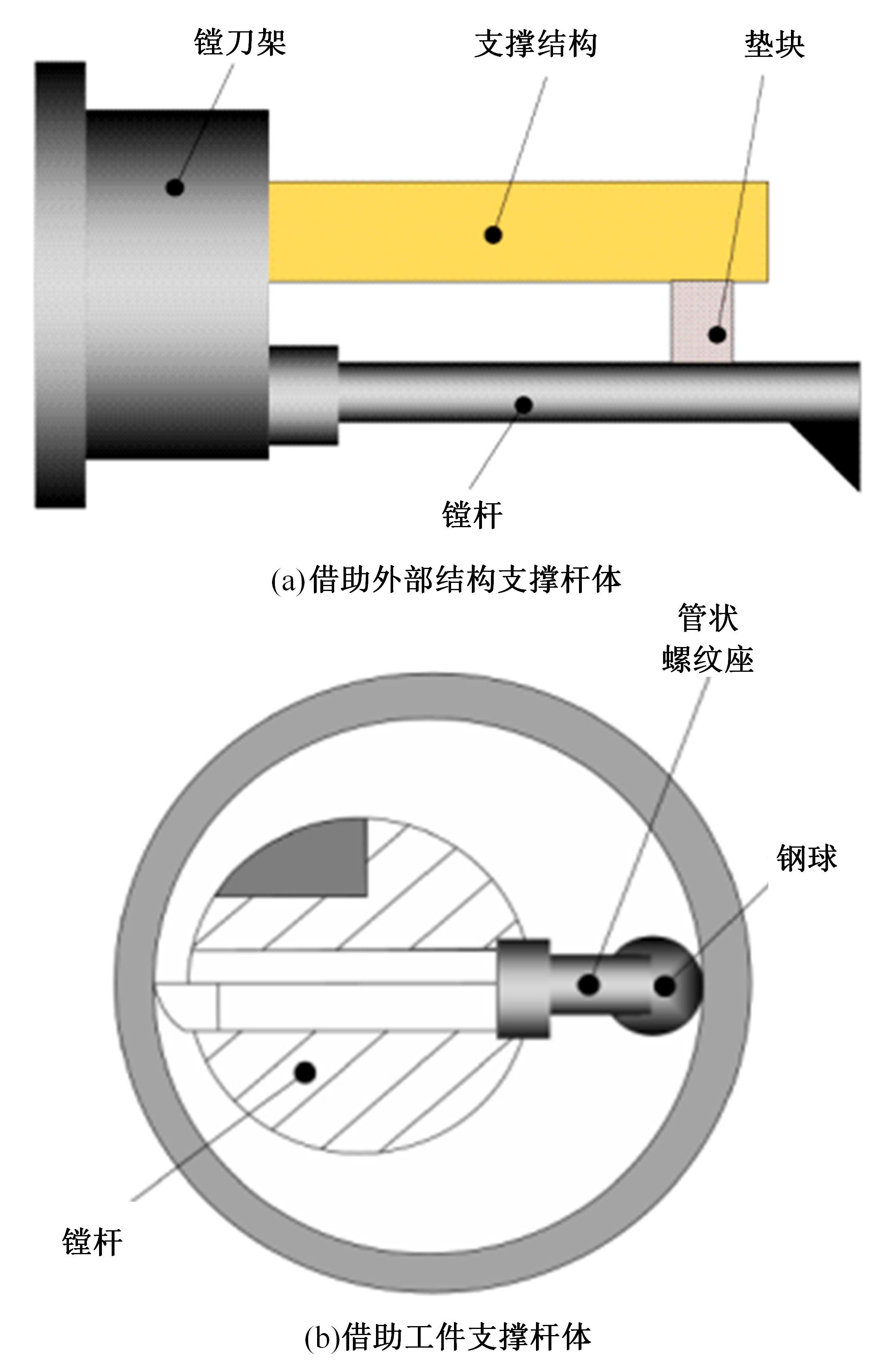

| 7 | 徐凤霞. 镗杆的辅助支撑[J]. 铁道机车车辆工人,1999(5):32. |

| Xu Feng-xia. Auxiliary support for boring bars[J]. Railway Locomotive and Rolling Stock Workers,1999(5):32. | |

| 8 | 夏元清. 工件支撑长镗杆[J]. 机械工人冷加工技术资料,1978(9):11. |

| Xia Yuan-qing. Workpiece support long boring bar[J]. Cold Working Technical Data for Mechanics,1978(9):11. | |

| 9 | 熊阳,张彬,鲍龙祥,等. 气浮镗杆在镗孔中的应用试验[J]. 航空精密制造技术,2017,53(6):42-45. |

| Xiong Yang, Zhang Bin, Bao Long-xiang,et al. Application of pneumatic boring bar in boring[J]. Aviation Precision Manufacturing Technology,2017,53(6):42-45. | |

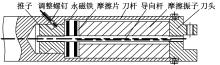

| 10 | Hayati S, Hajaliakbari M, Rajabi Y,et al. Chatter reduction in slender boring bar via a tunable holder with variable mass and stiffness[J]. Proceedings of the Institution of Mechanical Engineers Part B, Journal of Engineering Manufacture,2017,232(12):2098-2108. |

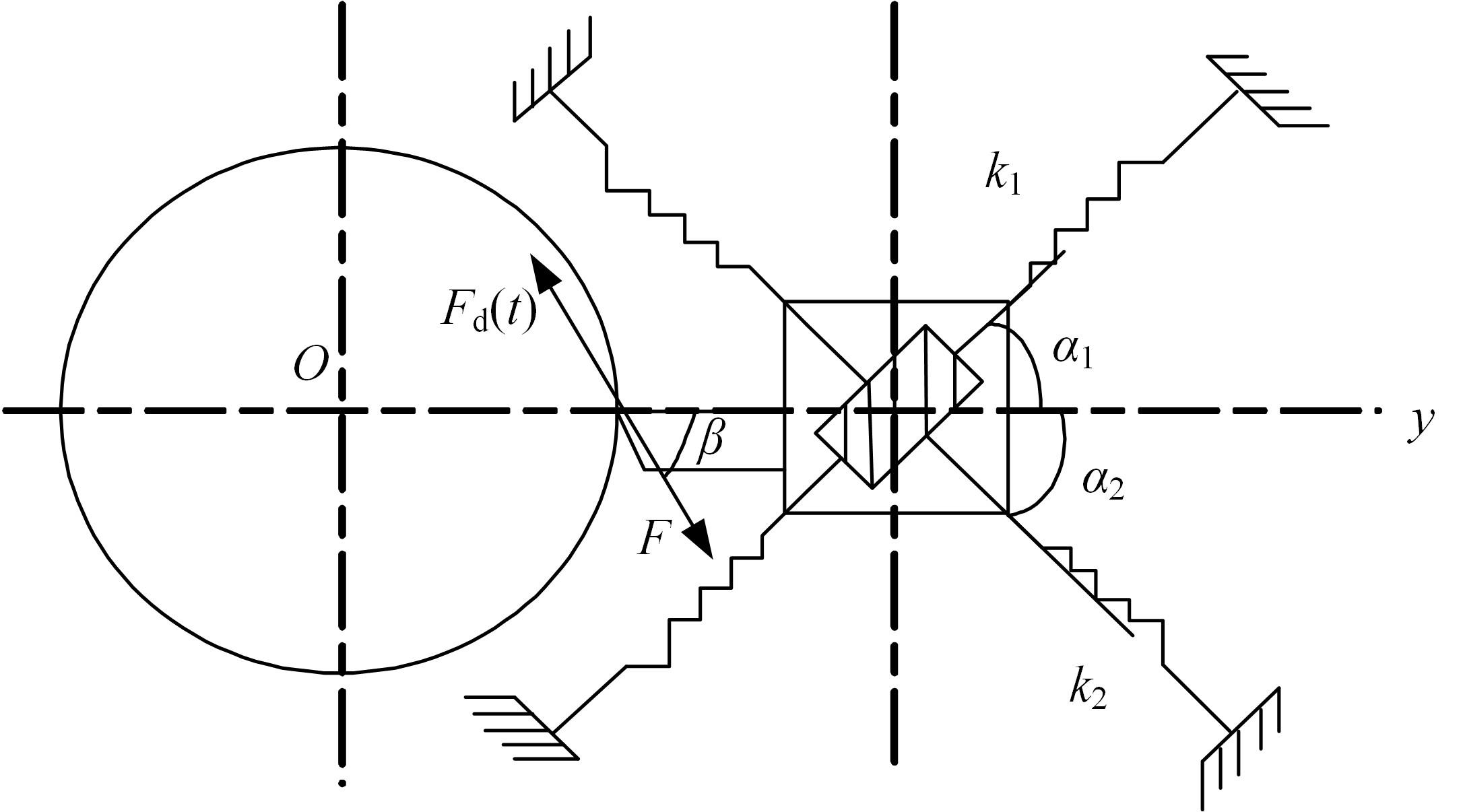

| 11 | 谢峰,王文轩,雷小宝. 两种材料组合结构的削扁镗杆设计与仿真[J]. 系统仿真学报,2017,29(6):1290-1296. |

| Xie Feng, Wang Wen-xuan, Lei Xiao-bao. Design and simulation of cut flat boring bar by both materials' composite structure[J]. Journal of System Simulation,2017,29(6):1290-1296. | |

| 12 | 吴能章,周利平. 一种新型复合材料镗刀杆的建模与有限元分析[J]. 西华大学学报:自然科学版,2005(5):22-25. |

| Wu Neng-zhang, Zhou Li-ping. Mathematical model and finite element analysis for a new type of boring bar made of composite materials[J]. Journal of Xihua University (Natural Science Edition),2005(5):22-25. | |

| 13 | Sortino M, Totis G, Prosperi F. Modeling the dynamic properties of conventional and high-damping boring bars[J]. Mechanical Systems & Signal Processing,2013,34(1/2):340-352. |

| 14 | Singaravelu C, Varatharajan P, Ramu G,et al. Investigation of damping characteristics on copper-based shape memory alloy frictional damper in boring process[J]. Arabian Journal for Science and Engineering,2021,21(6):501-512. |

| 15 | Hayati S, Shahrokhi M, Hedayati A. Development of a frictionally damped boring bar for chatter suppression in boring process[J]. The International Journal of Advanced Manufacturing Technology,2021,113(9):2761-2778. |

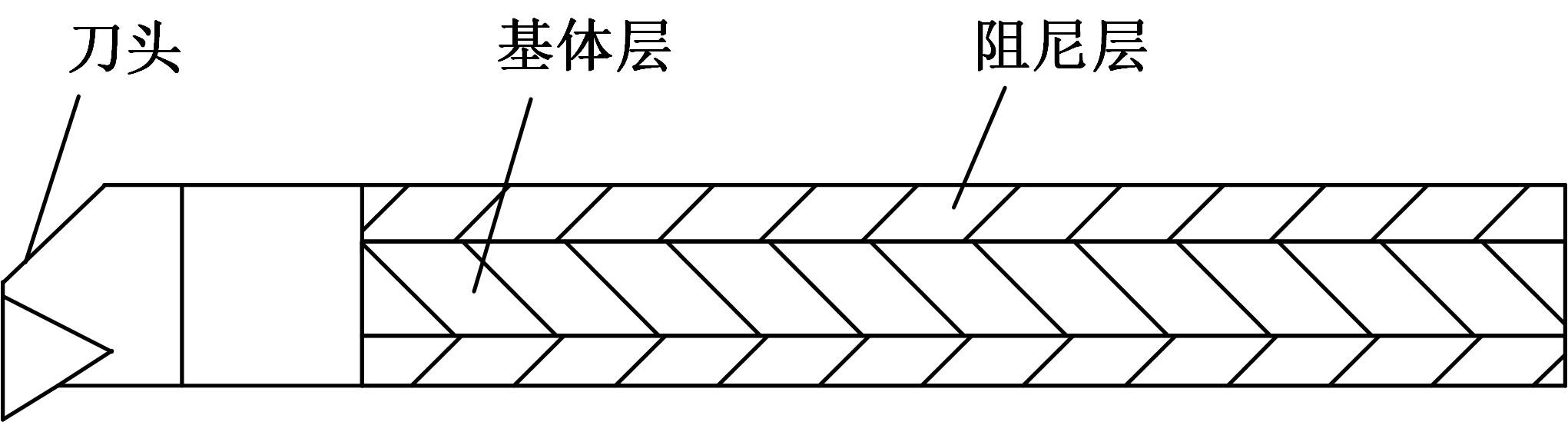

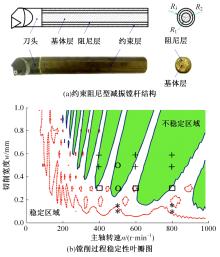

| 16 | Song Q H, Shi J H, Liu Z Q,et al. Boring bar with constrained layer damper for improving process stability[J]. International Journal of Advanced Manufacturing Technology,2016,83(9):1951-1966. |

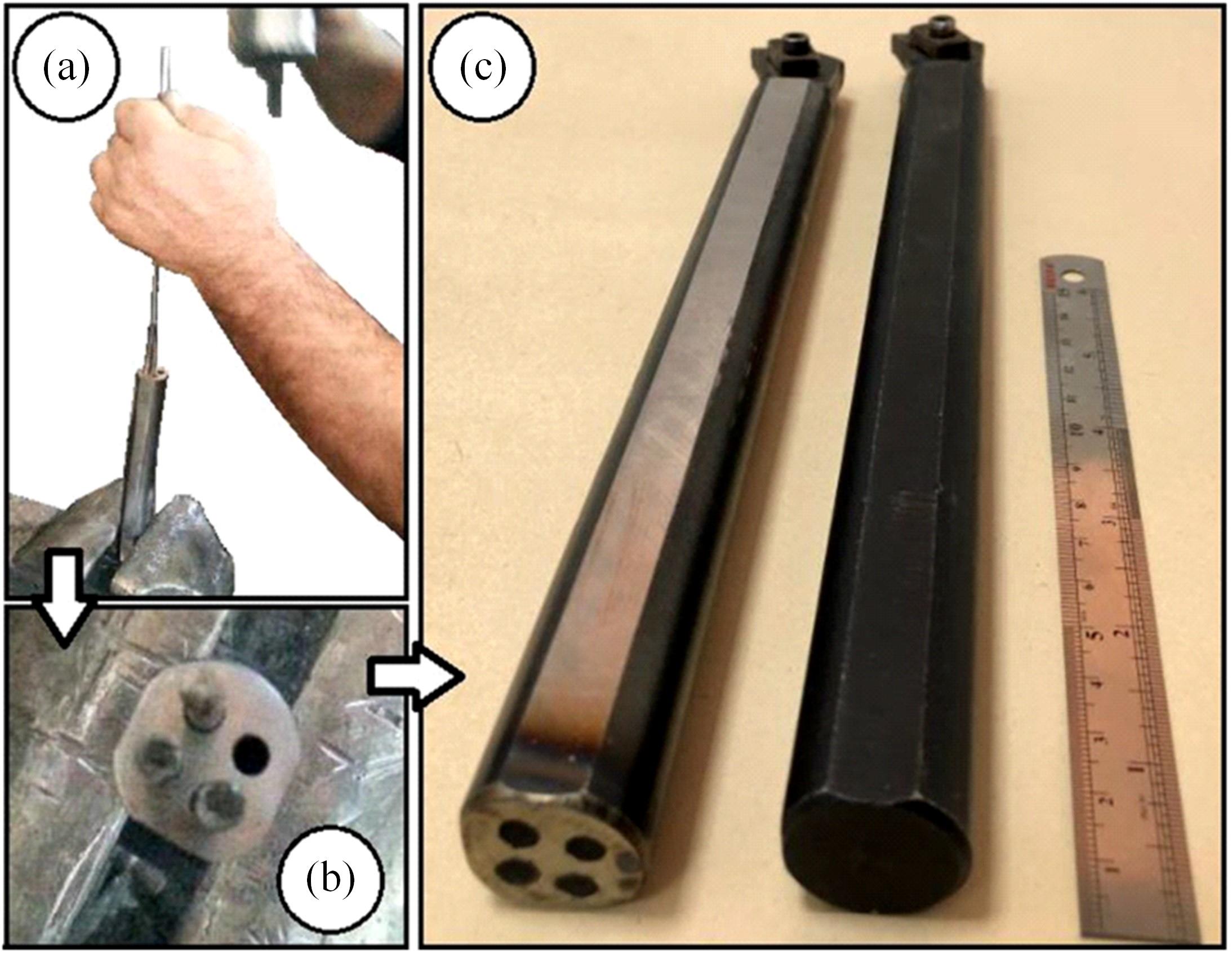

| 17 | Dai G L, Hwang H Y, Kim J K. Design and manufacture of a carbon fiber epoxy rotating boring bar[J]. Composite Structures,2003,60:115-124. |

| 18 | Bonda A, Srinivas J, Nanda B K. Investigation of stability in internal turning using a boring bar with a passive constrained layer damping[J]. FME Transactions,2021, 49(2):384-394. |

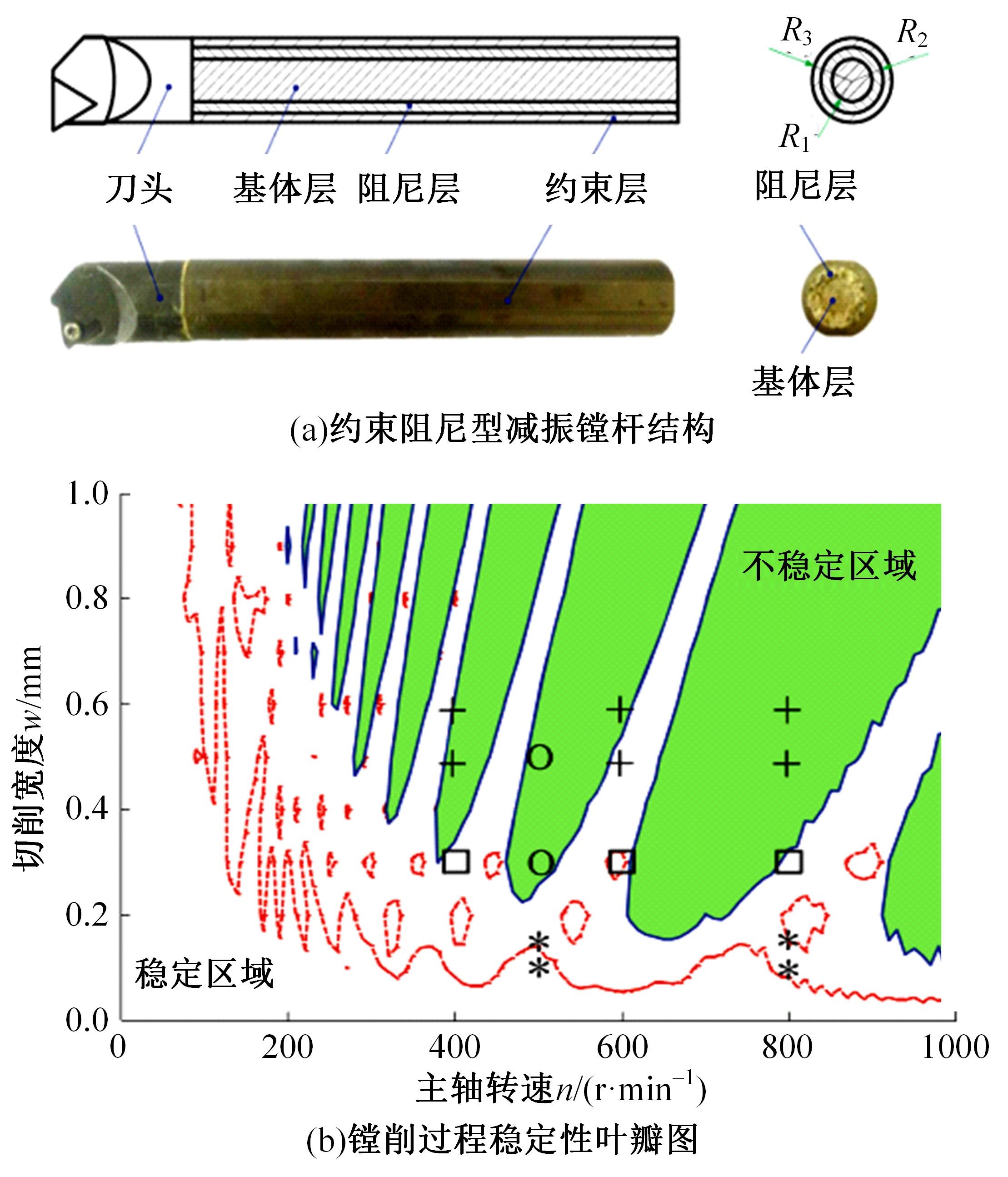

| 19 | Zhang Y H, Ren Y S, Tian J C, et al. Chatter stability of the constrained layer damping composite boring bar in cutting process[J]. Journal of Vibration and Control,2019,25(1):2204-2214. |

| 20 | 马伯乐,任勇生,张玉环,等. 旋转镗杆切削颤振稳定性预测[J]. 振动与冲击,2019,38(16):115-122. |

| Ma Bo-le, Ren Yong-sheng, Zhang Yu-huan,et al. Stability prediction of rotating boring bar[J]. Journal of Vibration and Shock,2019,38(16):115-122. | |

| 21 | 王栋. 冲击减振器对振动能量耗散性能分析[J]. 机械工程学报,2014,50(17):87-92. |

| Wang Dong. Analysis of vibration energy dissipation with vibro-impact absorber[J]. Journal of Mechanical Engineering,2014,50(17):87-92. | |

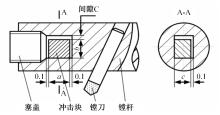

| 22 | 侯廷惠. 关于镗杆冲击减振器基本参数间隙C的确定[J]. 太原机械学院学报,1988,9(2):107-112. |

| Hou Ting-hui. Determination of the basic parameter clearance C of the boring bar shock absorber[J]. Journal of Taiyuan Institute of Machinery,1988,9(2):107-112. | |

| 23 | Kanase S, Patil J, Jadhav S.Improvement of Ra value of boring operation using passive damper[J]. The International Journal of Engineering and Science,2013,2(7):103-108. |

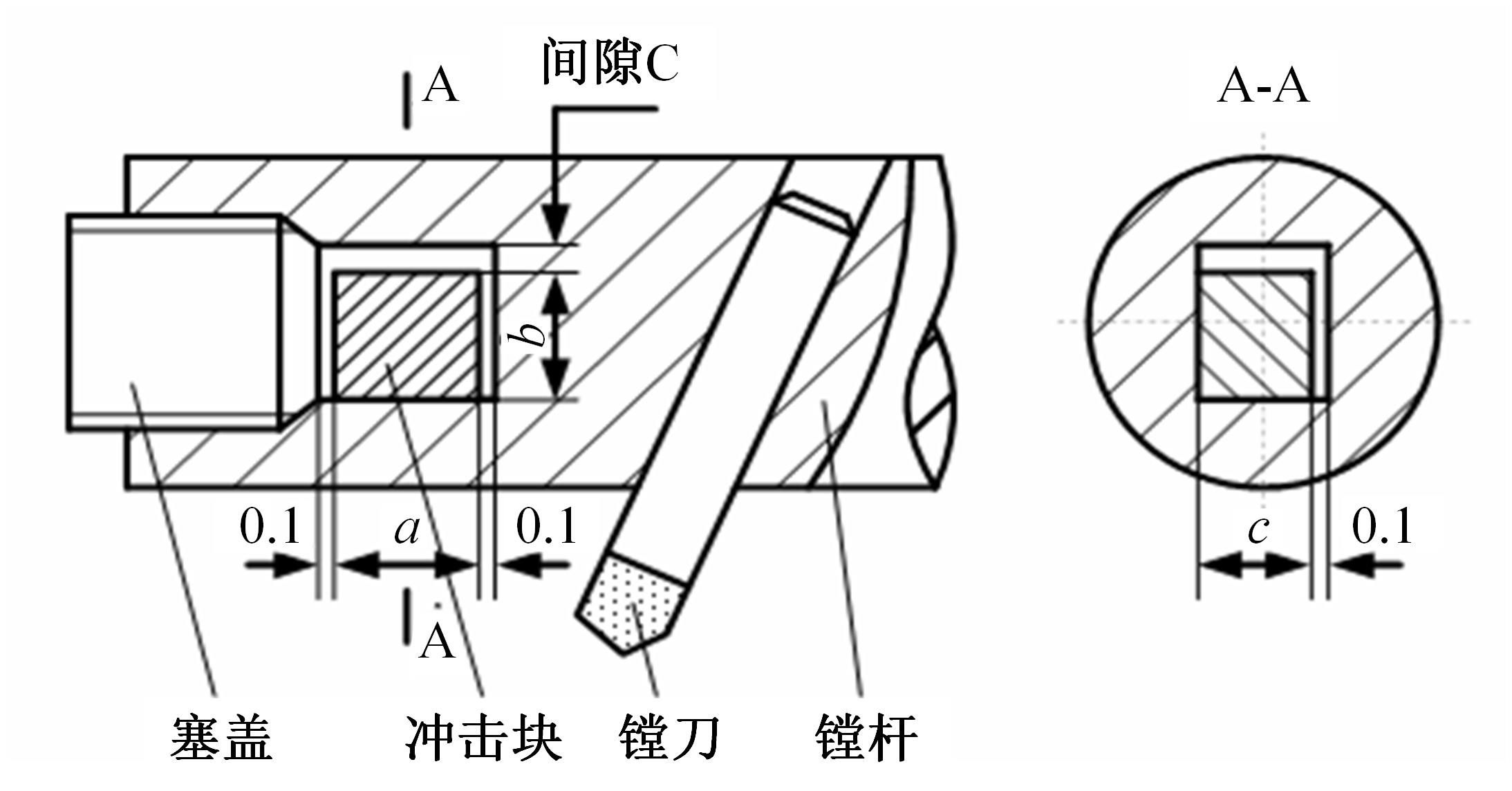

| 24 | Biju C V, Shunmugam M S. Investigation into effect of particle impact damping (PID) on surface topography in boring operation[J]. International Journal of Advanced Manufacturing Technology,2014,75(5-8):1219-1231. |

| 25 | Senthil K M, Mohanasundaram K, Sathishkumar B. A case study on vibration control in a boring bar using particle damping[J]. International Journal of Engineering Science & Technology,2012,3(8):177-184. |

| 26 | Chockalingam S, Natarajan U, George C A. Damping investigation in boring bar using hybrid copper-zinc particles[J]. Journal of Vibration and Control,2015,23(13):2128-2134. |

| 27 | Edhi E, Hoshi T. Stabilization of high frequency chatter vibration in fine boring by friction damper[J]. Precision Engineering,2001,25(3):224-234. |

| 28 | 区炳显. 摩擦减振镗杆的理论与实验研究[D]. 北京:北京工业大学机械工程与应用电子技术学院,2009. |

| Qu Bing-xian. Research on the theory and experiment of boring bar based on friction damper[D]. Beijing:College of Mechanical Engineering and Applied Electronics Technology, Beijing University of Technology, 2009. | |

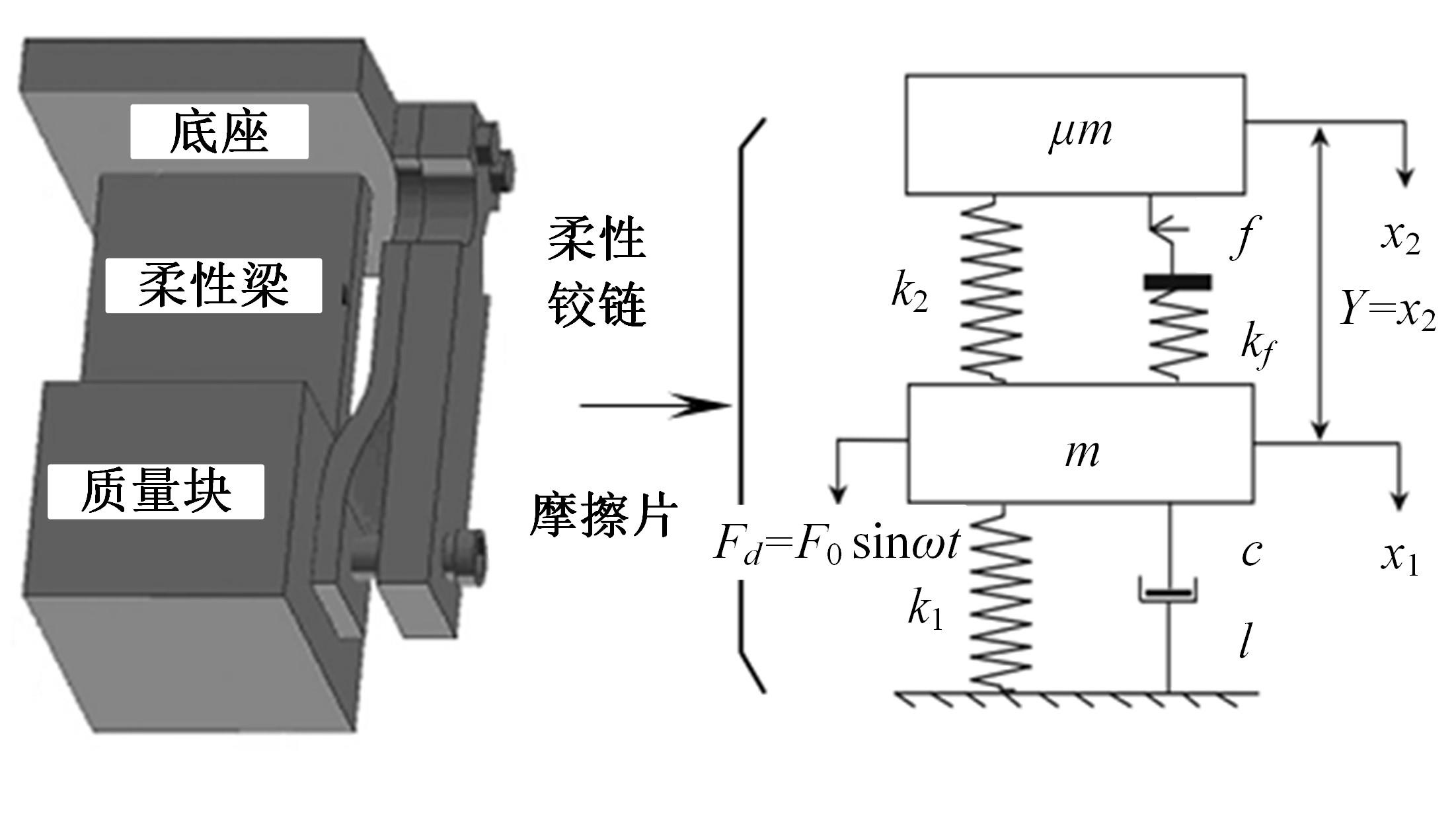

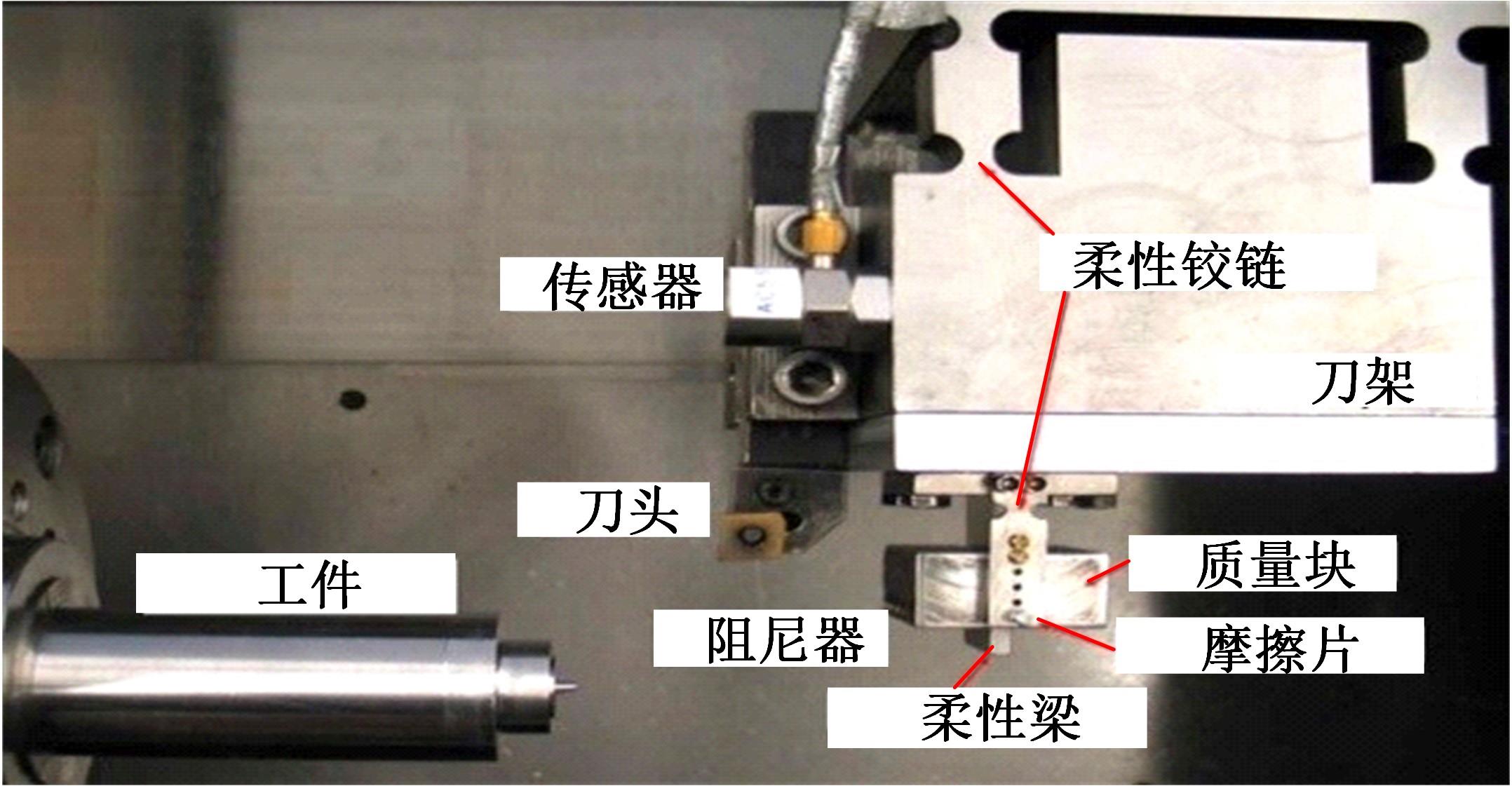

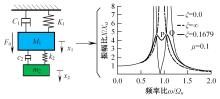

| 29 | Wang M, Zan T, Yang Y,et al. Design and implementation of nonlinear TMD for chatter suppression: an application in turning processes[J]. International Journal of Machine Tools & Manufacture,2010,50(5):474-479. |

| 30 | Yang Y, Liu Q, Wang M. Optimization of the tuned mass damper for chatter suppression in turning[J]. Chinese Journal of Mechanical Engineering,2011,23(16):717-724. |

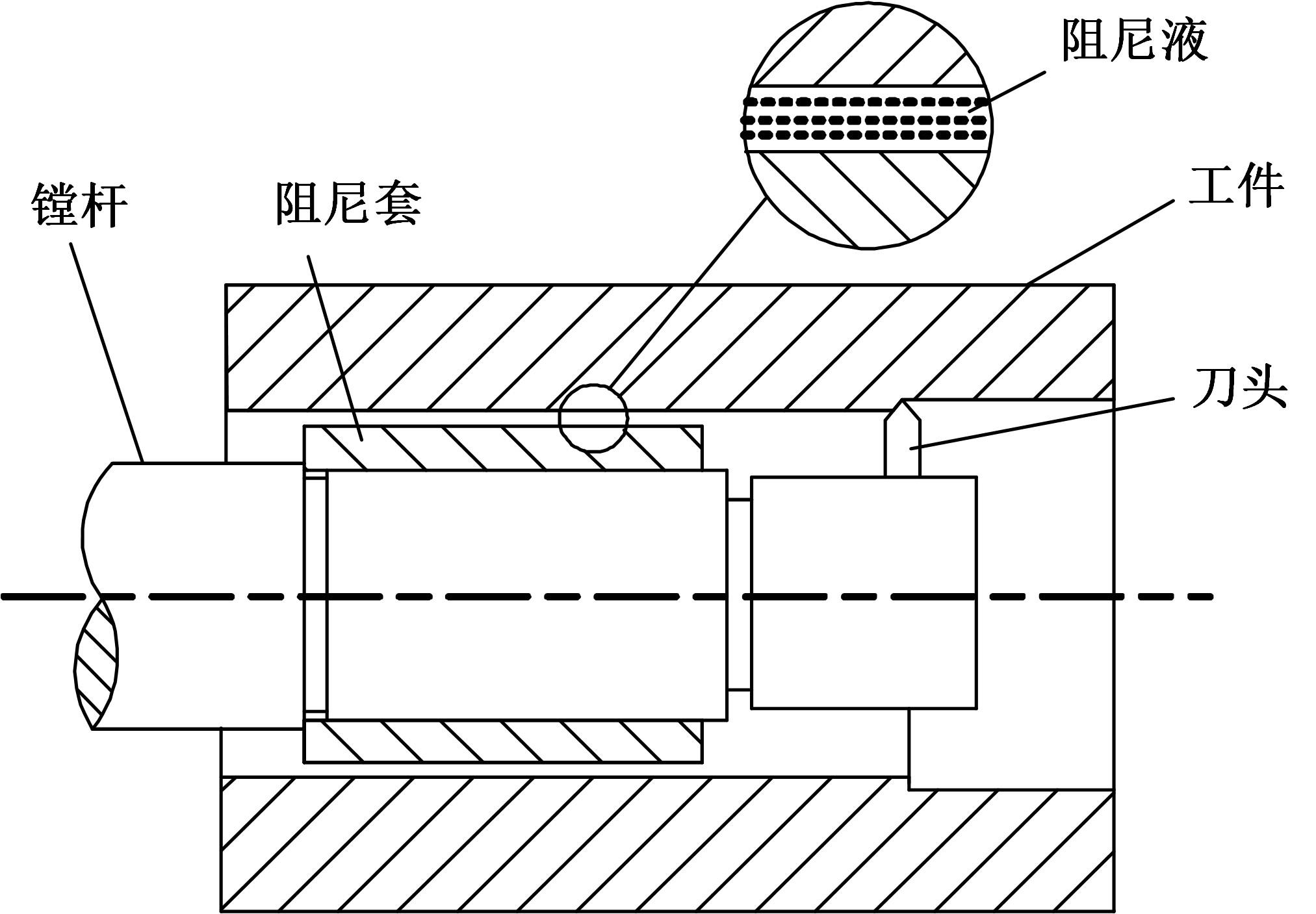

| 31 | 赵永成,黄宏彪,闫长罡,等. 精镗孔挤压液膜阻尼系统的仿真研究[J]. 机械工程学报,2003(8):151-154. |

| Zhao Yong-cheng, Huang Hong-biao, Yan Chang-gang,et al. Simulation research on precision boring squeeze film damping system[J]. Journal of Mechanical Engineering,2003(8):151-154. | |

| 32 | 赵永成,马飞,闫长罡,等. 精镗孔时液膜阻尼减振效果的研究[J]. 中国机械工程,2002(21):33-35, 61,4. |

| Zhao Yong-cheng, Ma Fei, Yan Chang-gang,et al. Research on the vibration reduction effect of liquid film damping in fine boring[J]. China Mechanical Engineering,2002(21):33-35, 61,4. | |

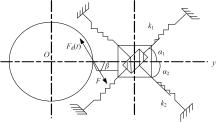

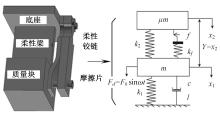

| 33 | 石建飞,苟向锋,张艳龙. 两自由度减振镗杆系统的安全盆侵蚀与分岔[J]. 振动与冲击,2018,37(22):238-244. |

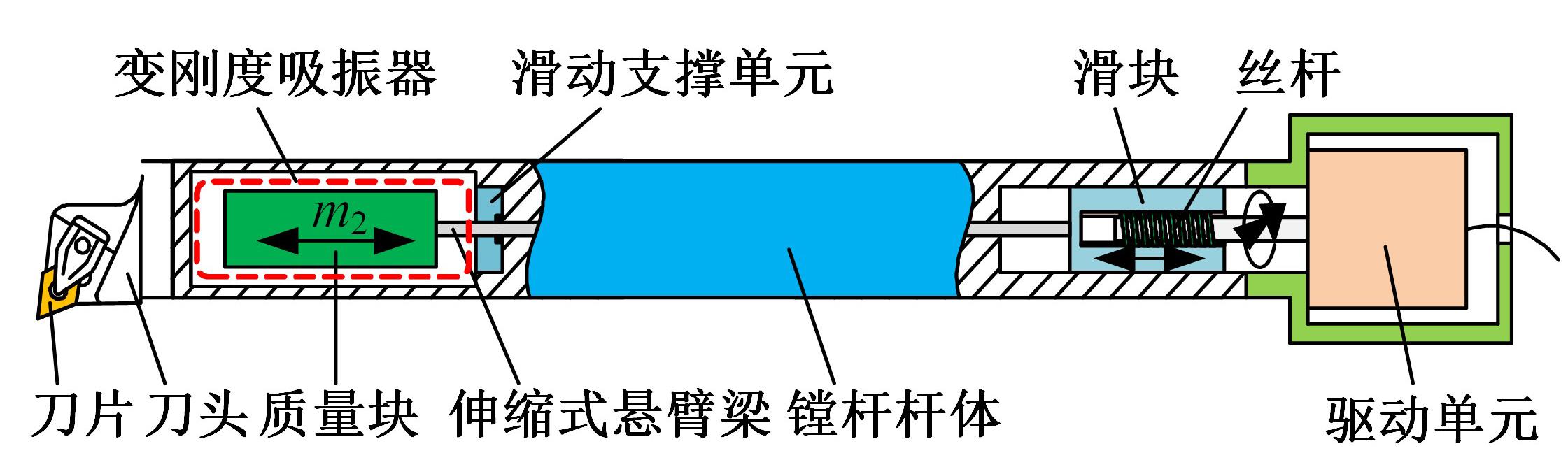

| Shi Jian-fei, Gou Xiang-feng, Zhang Yan-long. Erosion and bifurcation of the safe basin of a two-degree-of-freedom damping boring bar system[J]. Journal of Vibration and Shock,2018,37(22):238-244. | |

| 34 | 贾富淳,孟宪皆,雷雨龙. 基于多目标遗传算法的二自由度动力吸振器优化设计[J]. 吉林大学学报:工学版,2019,49(6):1969-1976. |

| Jia Fu-chun, Meng Xian-jie, Lei Yu-long. Optimal design of two degrees of freedom dynamic vibration absorber based on multi-objective genetic algorithm[J]. Journal of Jilin University (Engineering and Technology Edition),2019,49(6):1969-1976. | |

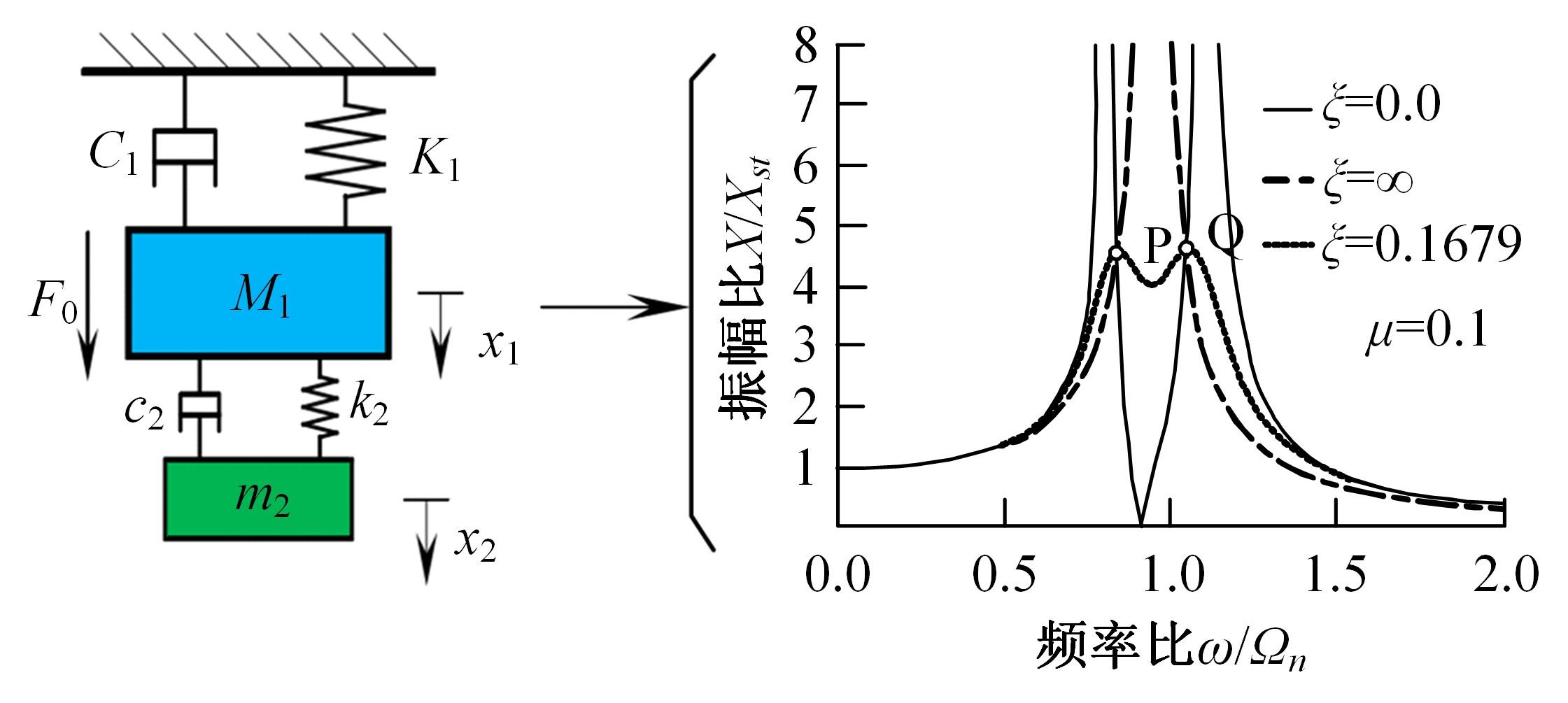

| 35 | Rubio L, Loya J A, Miguelez M H,et al. Optimization of passive vibration absorbers to reduce chatter in boring[J]. Mechanical Systems & Signal Processing,2013,41(1/2):691-704. |

| 36 | G.AWRANCE, PAUL P.SAM, et al. Attenuation of vibration in boring tool using spring controlled impact damper[J]. International Journal on Interactive Design & Manufacturing,2015,11(4):903-915. |

| 37 | Hong J H, Guo Y Y, Song D S. A study on the design model of passive tunable damped boring bar[J]. Journal of the Korean Society for Precision Engineering,2017,34(12):917-926. |

| 38 | Li L, Sun B, Hua H. Analysis of the vibration characteristics of a boring bar with a variable stiffness dynamic vibration absorber[J]. Shock and Vibration,2019(9):2501-2513. |

| 39 | 何苗,孙蓓蓓. 识别动力减振镗杆主系统等效参数的数学计算方法[J]. 振动与冲击,2019,38(6):194-198, 244. |

| He Miao, Sun Bei-bei. Mathematical method for the equivalent parameters identification of the main system of a dynamic damping boring bar[J]. Journal of Vibration and Shock,2019,38(6):194-198, 244. | |

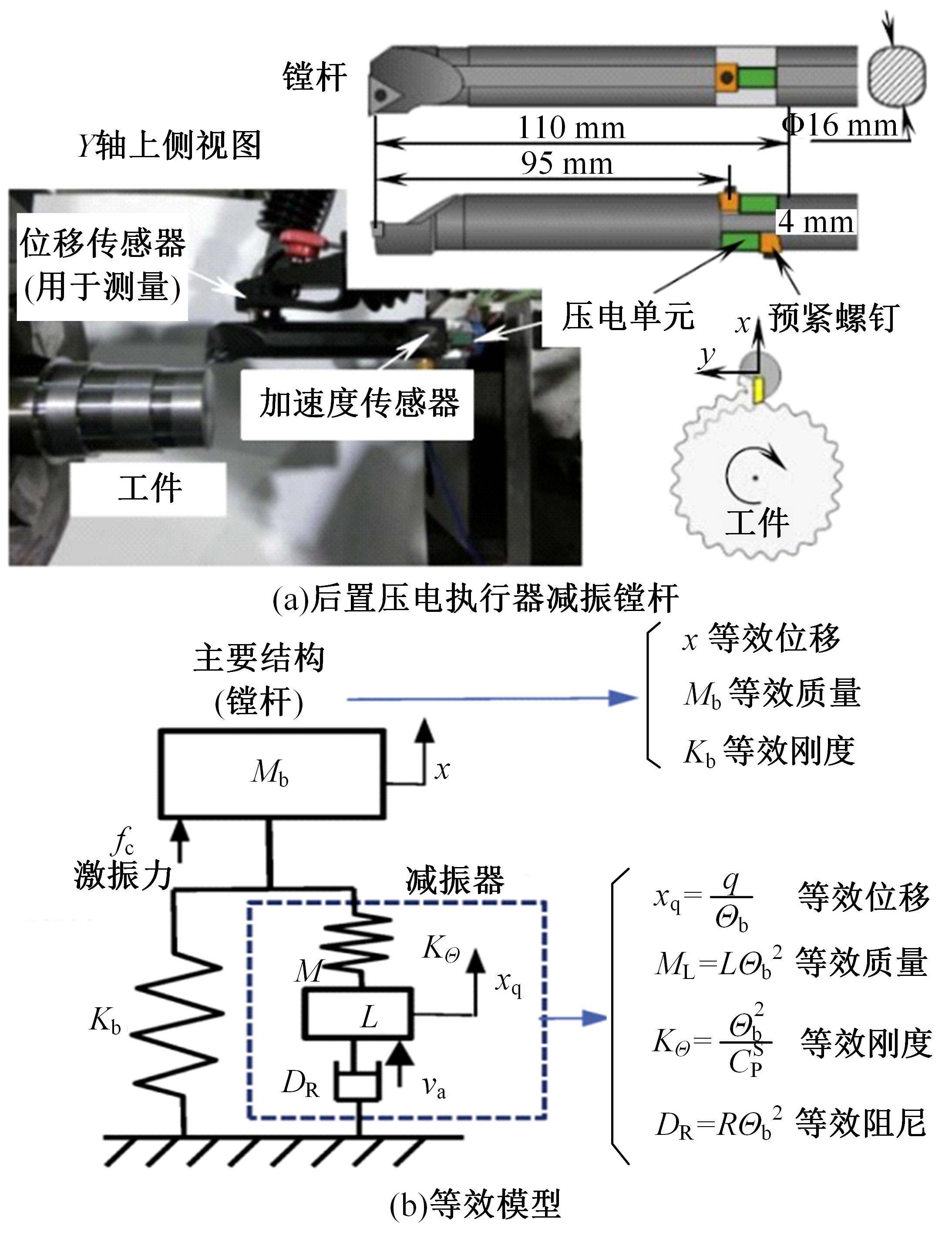

| 40 | Yoshimura M. Vibration-proof design of boring bar with multidegree-of-freedom dampers[J]. Journal of Mechanical Design,1986,108(4):442-447. |

| 41 | 罗红波, 李伟. 内置式双减振镗杆动力学模型参数优化[J]. 四川大学学报: 工程科学版, 2012, 44(5):207-212. |

| Luo Hong-bo, Li Wei. Parameter optimization of dynamic model of built-in double-damping boring bar[J]. Journal of Sichuan University (Engineering Science Edition),2012,44(5):207-212. | |

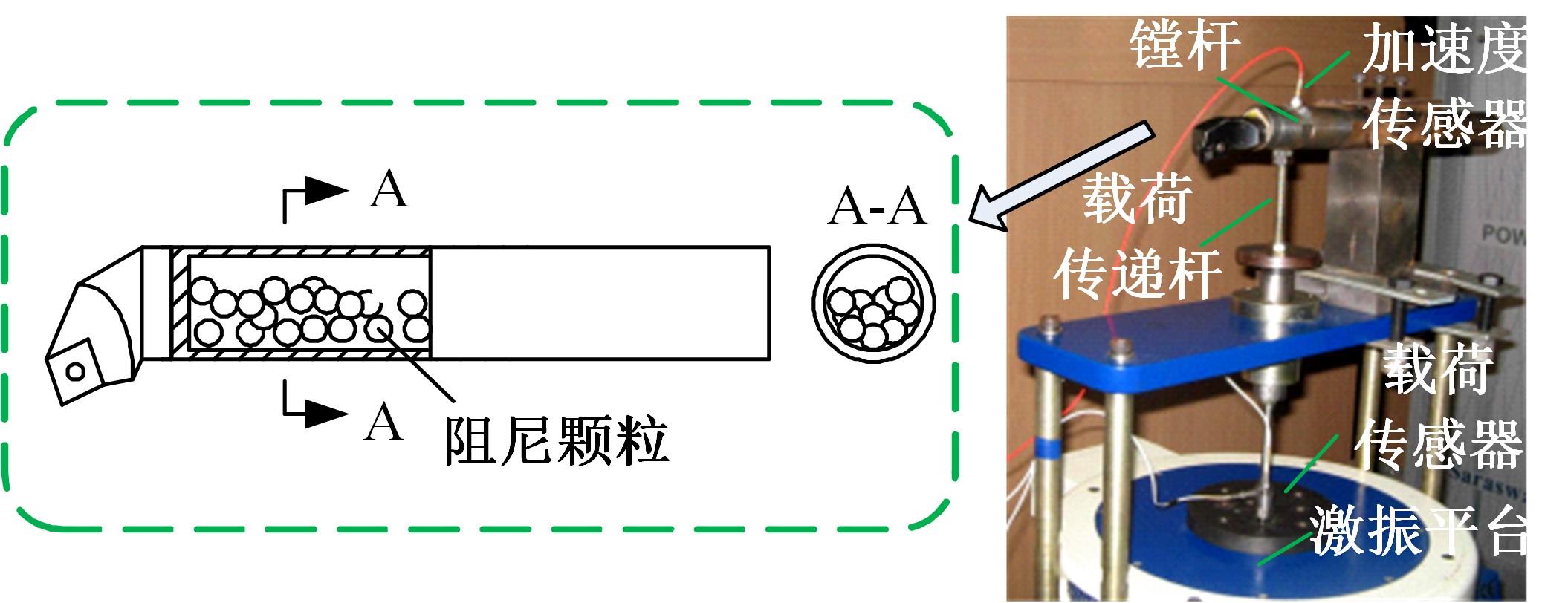

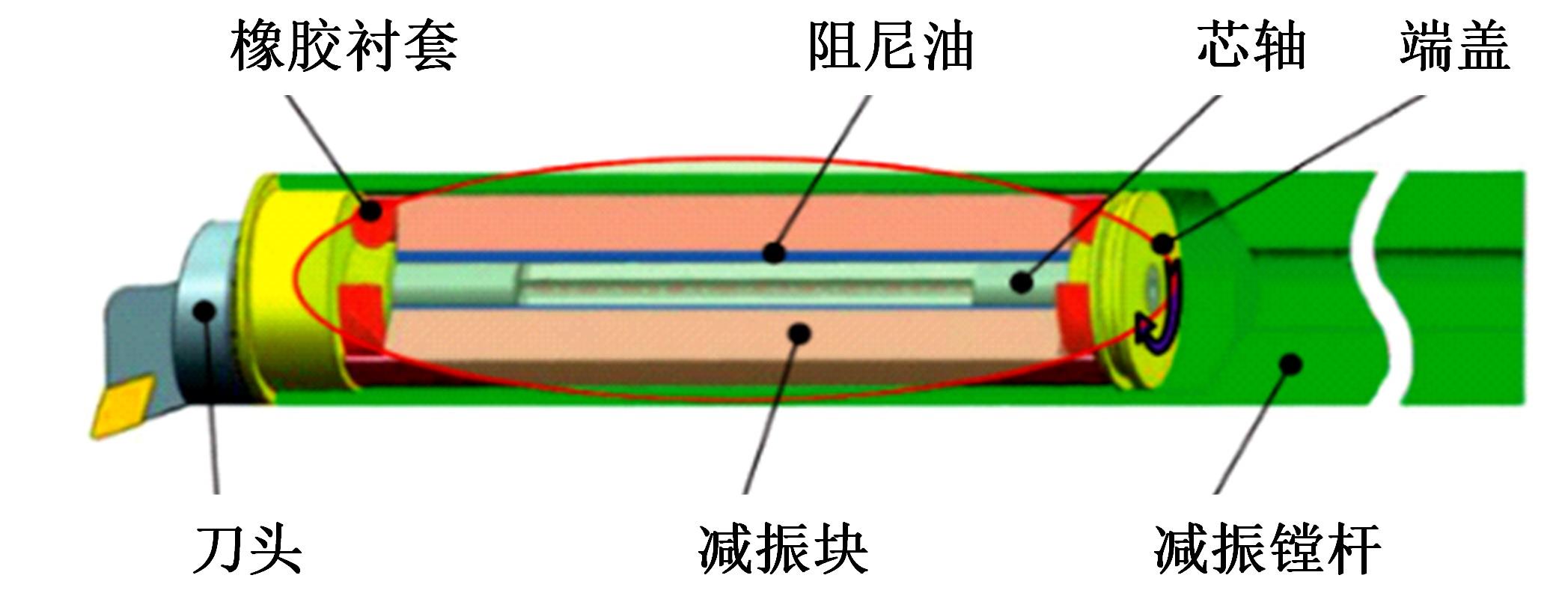

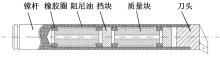

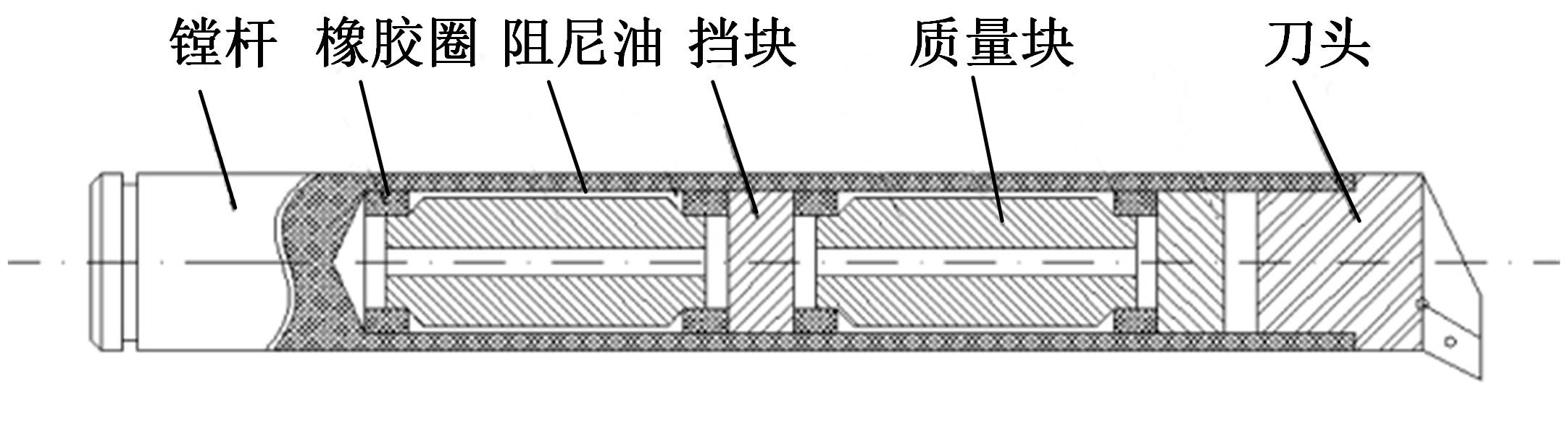

| 42 | 山特维克可乐满公司. 采用 Silent Tools减振刀具实现更平稳的加工[J]. 金属加工(冷加工),2013(2):45-46. |

| Coromant Sandvik. Use silent tools to achieve smoother machining[J]. Metal Working (Metal Cutting),2013(2):45-46. | |

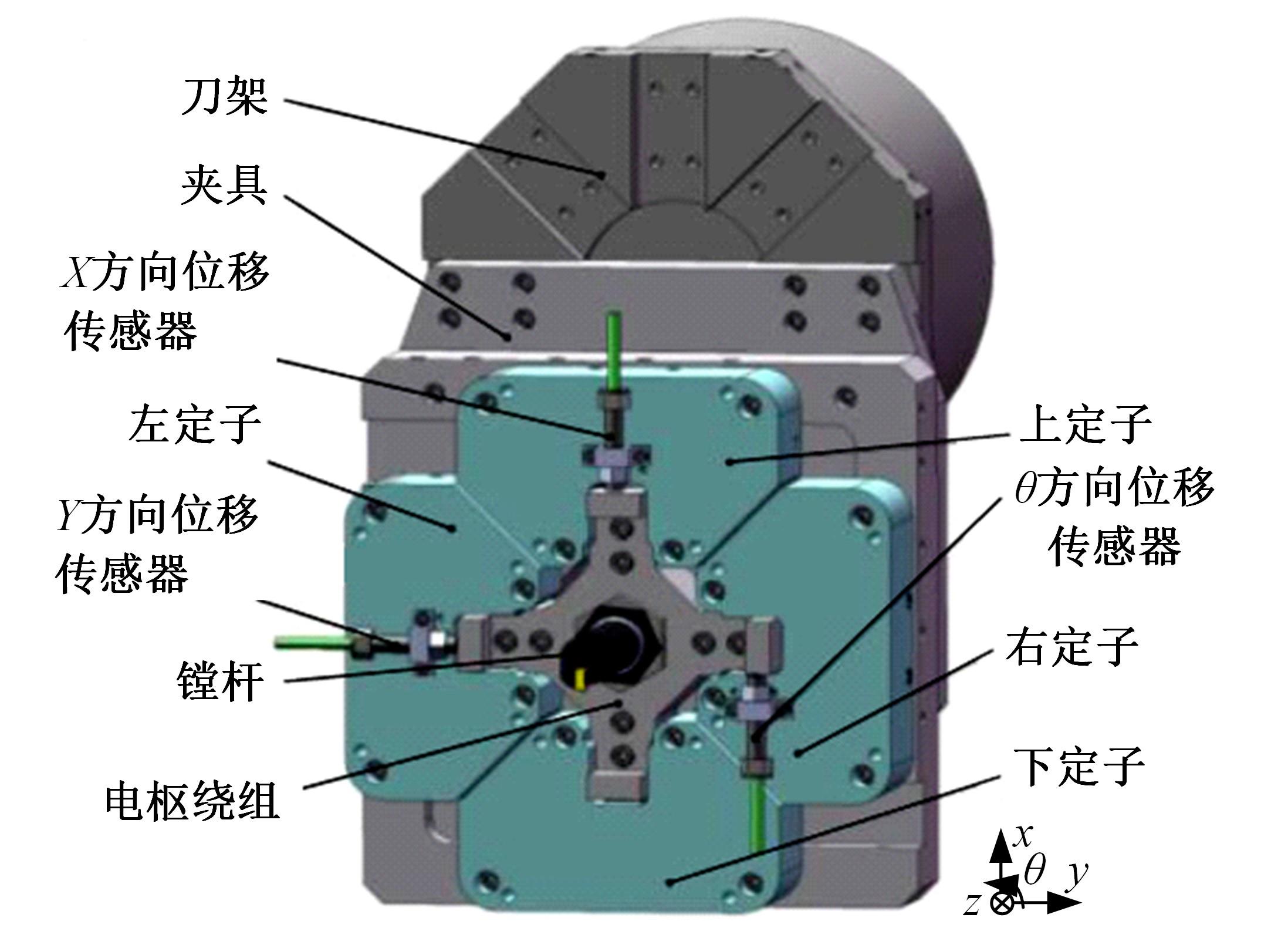

| 43 | 山高刀具有限公司. 山高新品 SteadylineTM [J]. 航空制造技术,2009(21):98-99. |

| Seco Cutting Tools CO,. Ltd,. Seco new steadylineTM [J]. Aeronautical Manufacturing Technology,2009(21):98-99. | |

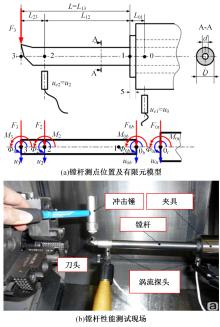

| 44 | 任违,孔金星,岳晓斌,等. 减振镗杆动态特性的对比实验分析[J]. 工具技术,2010,44(11):45-48. |

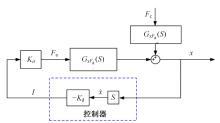

| Ren Wei, Kong Jin-xing, Yue Xiao-bin,et al. Comparative experimental analysis of dynamic characteristics of damping boring bars[J]. Tool Engineering,2010,44(11):45-48. | |

| 45 | 王茂华,于骏一. 电流变技术在机床颤振控制中应用的研究[J]. 机械工程学报,2000(11):94-97. |

| Wang Mao-hua, Yu Jun-yi. Research on the application of electrorheological technology in machine tool chatter control[J]. Journal of Mechanical Engineering,2000(11):94-97. | |

| 46 | 张永亮,于骏,王茂华. 电流变液减振器及其在切削颤振控制中应用的研究现状[J]. 振动与冲击,2003(2):16-19, 100. |

| Zhang Yong-liang, Yu Jun, Wang Mao-hua. Research status of electrorheological fluid damper and its application in cutting chatter control[J]. Vibration and Shock,2003(2):16-19, 100. | |

| 47 | 张永亮,于骏一,侯东霞,等. 基于电流变效应的车削颤振预报控制技术的研究[J]. 机械工程学报,2005(4):206-211. |

| Zhang Yong-liang, Yu Jun-yi, Hou Dong-xia,et al. Research on chatter prediction and control technology for turning based on electrorheological effect[J]. Journal of Mechanical Engineering, 2005(4):206-211. | |

| 48 | Jacob Rabinow.The magnetic fluid clutch[J]. Electrical Engineering,1951,67(12):1167-1167. |

| 49 | 史文库,张曙光,张友坤,等. 基于改进海鸥算法的磁流变减振器模型辨识[J]. 吉林大学学报:工学版,2022,52(4):764-772. |

| Shi Wen-ku, Zhang Shu-guang, Zhang You-kun,et al. Parameter identification of magnetorheological damper model with modified seagull optimization algorithm[J]. Journal of Jilin University (Engineering and Technology Edition),2022,52(4):764-772. | |

| 50 | Wang M, Fei R Y. Chatter suppression based on nonlinear vibration characteristic of electrorheological fluids[J]. International Journal of Machine Tools & Manufacture,1999,39(12):1925-1934. |

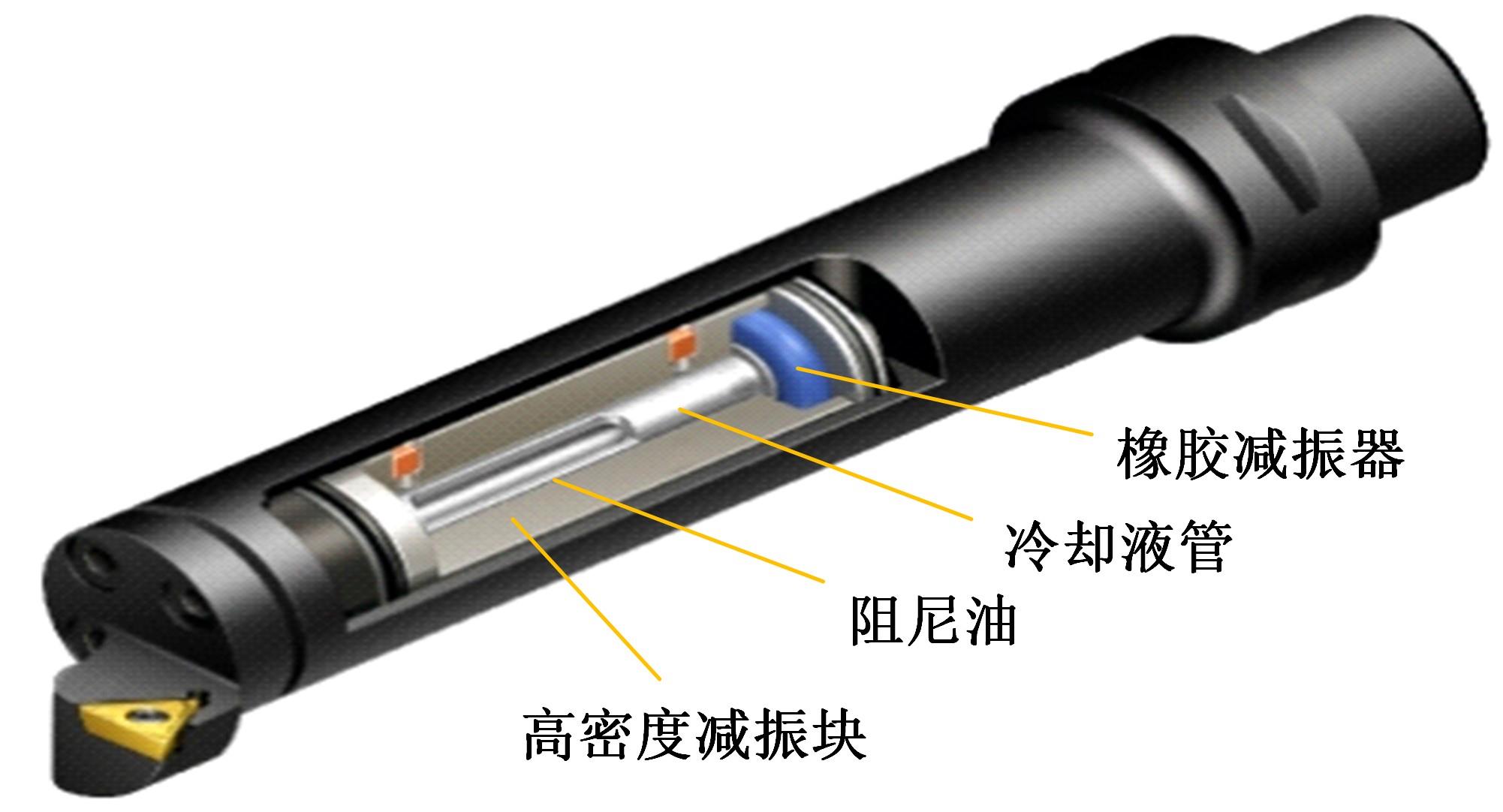

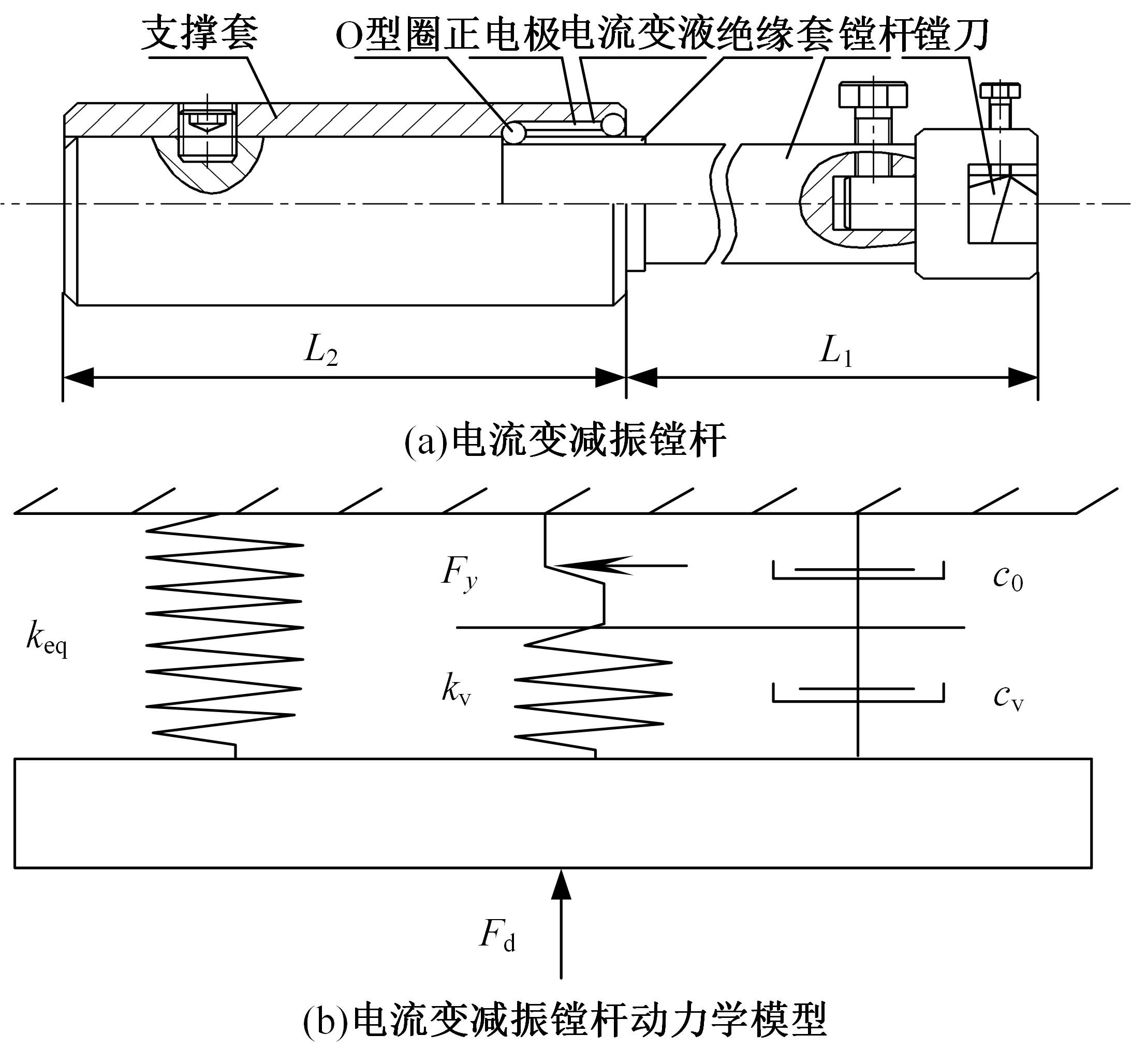

| 51 | 王民,费仁元,杨建武,等. 应用电流变材料改变镗杆动态特性的研究[J]. 中国机械工程,1999(12):39-42, 5. |

| Wang Min, Fei Ren-yuan, Yang Jian-wu,et al. Research on the application of electrorheological materials to change the dynamic characteristics of boring bars[J]. China Mechanical Engineering,1999(12):39-42, 5. | |

| 52 | 王民,费仁元. 基于电流变材料的切削颤振在线监控技术研究[J]. 机械工程学报,2002(12):93-97. |

| Wang Min, Fei Ren-yuan. Research on online monitoring technology of cutting chatter based on electrorheological materials[J]. Journal of Mechanical Engineering, 2002(12):93-97. | |

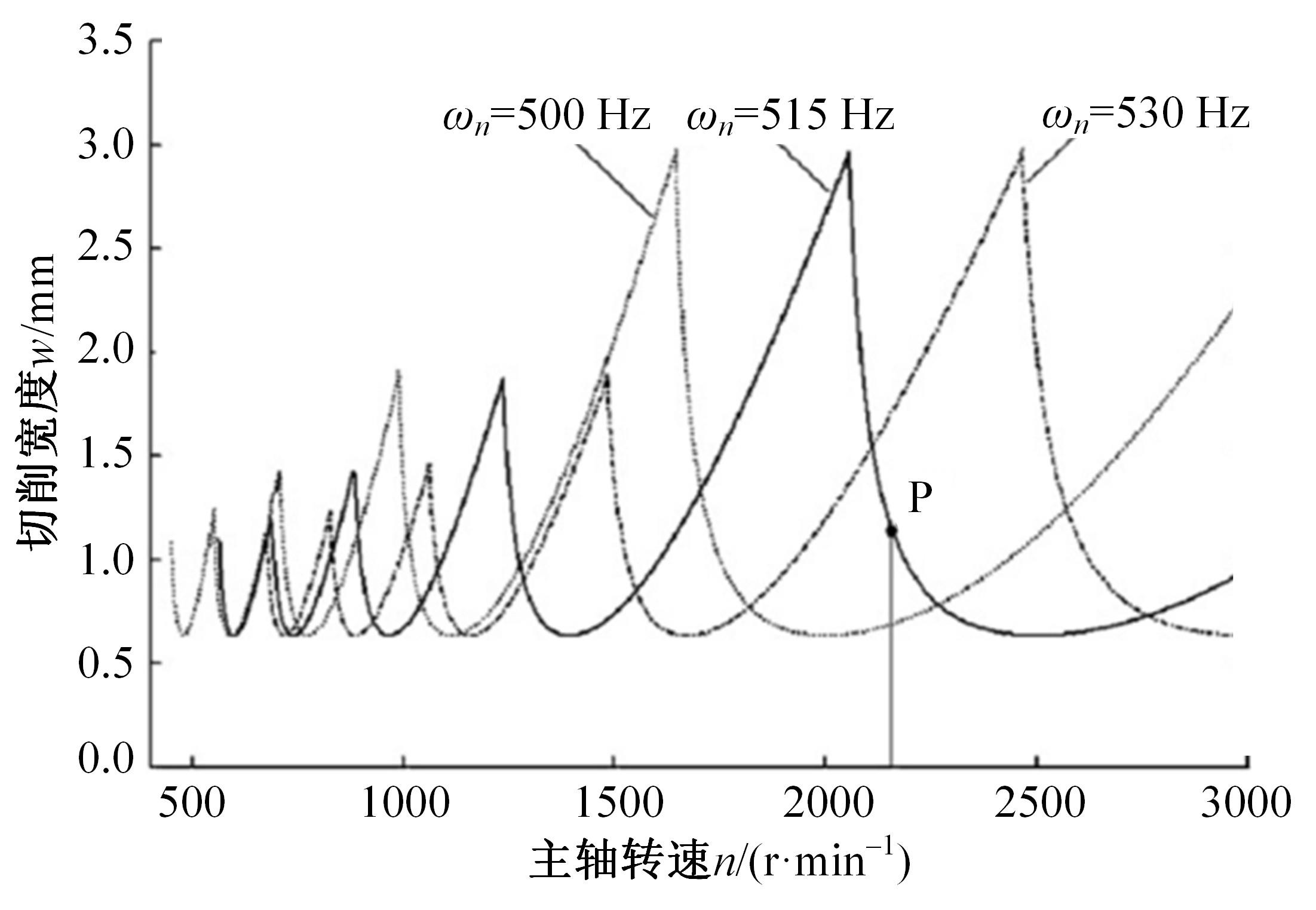

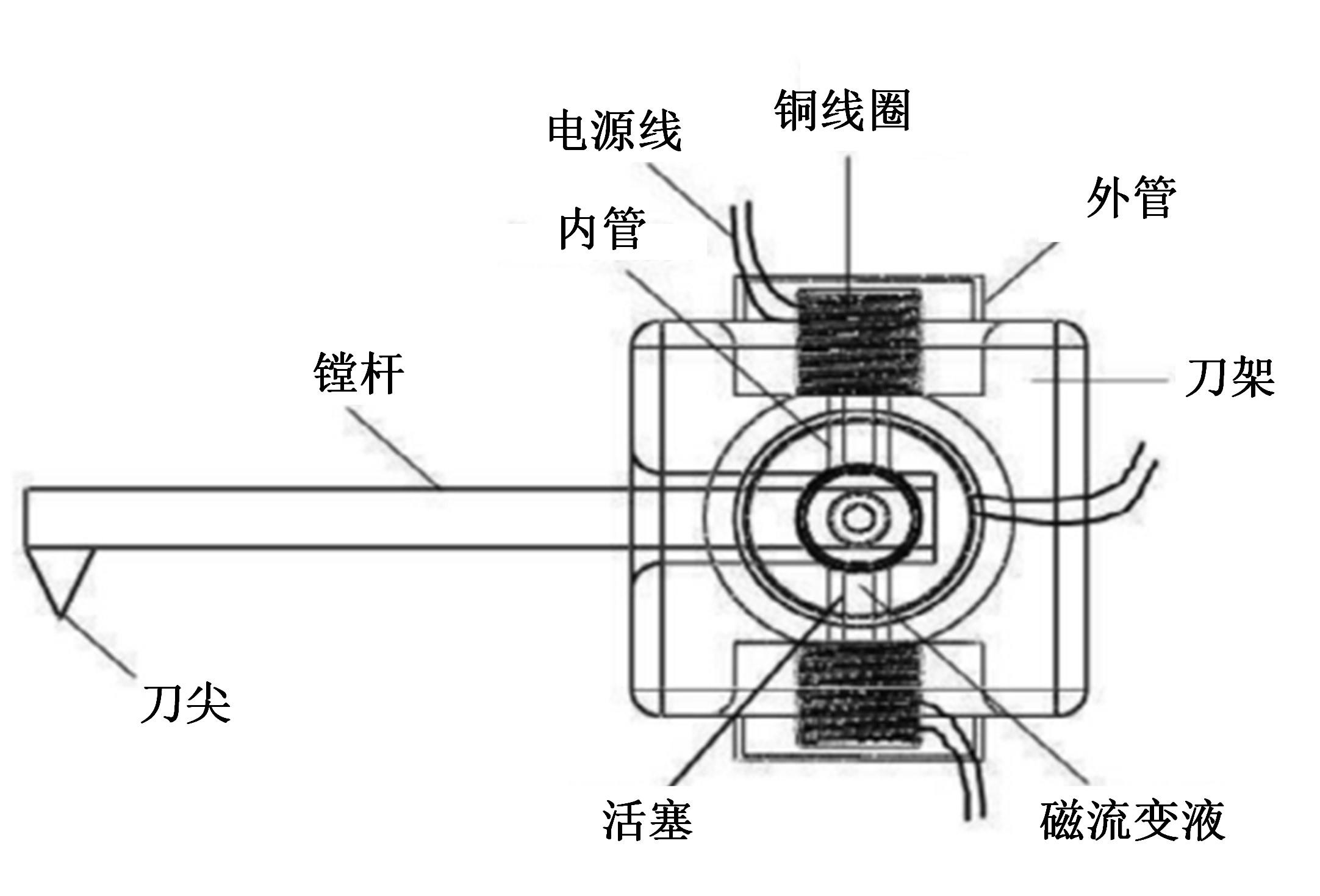

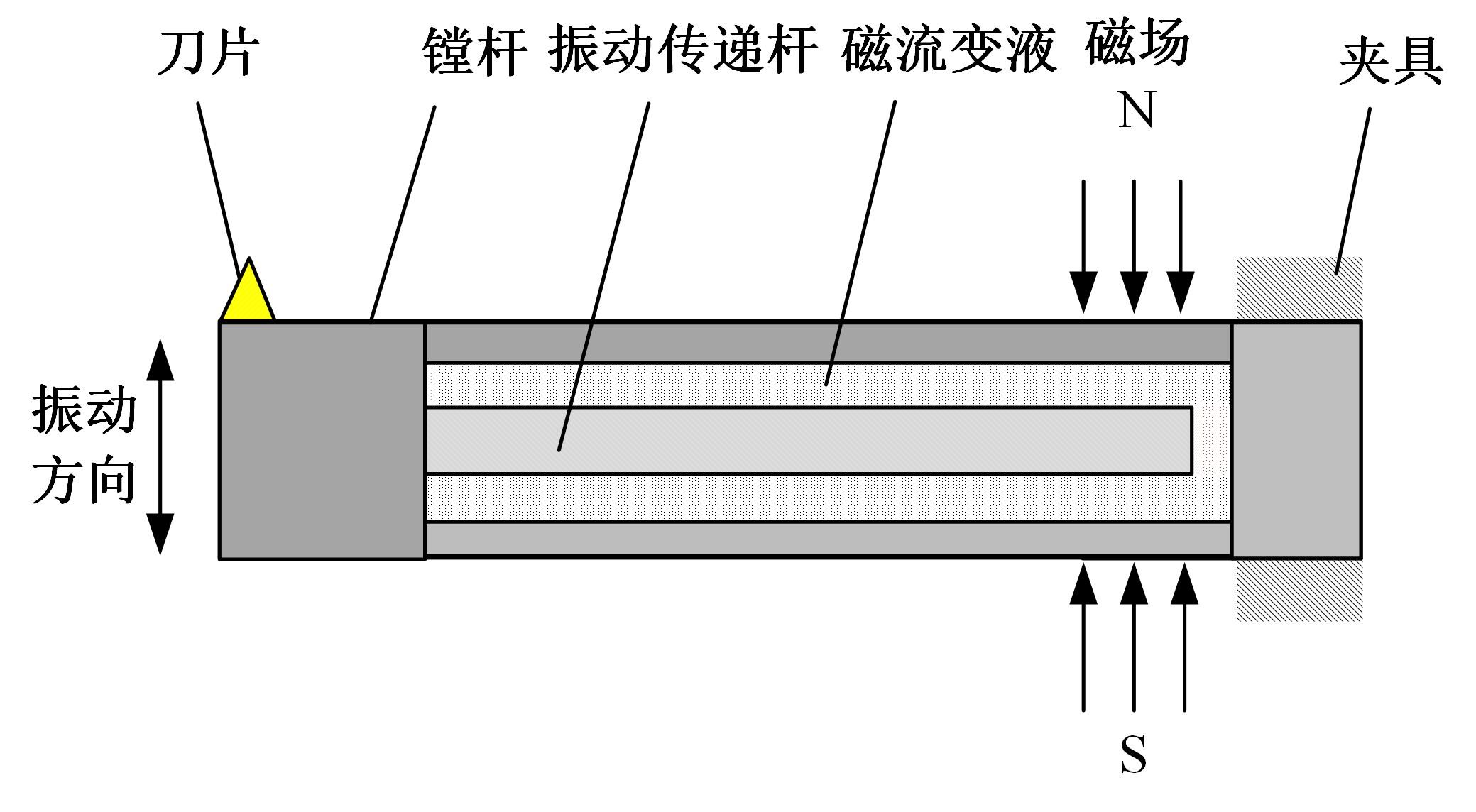

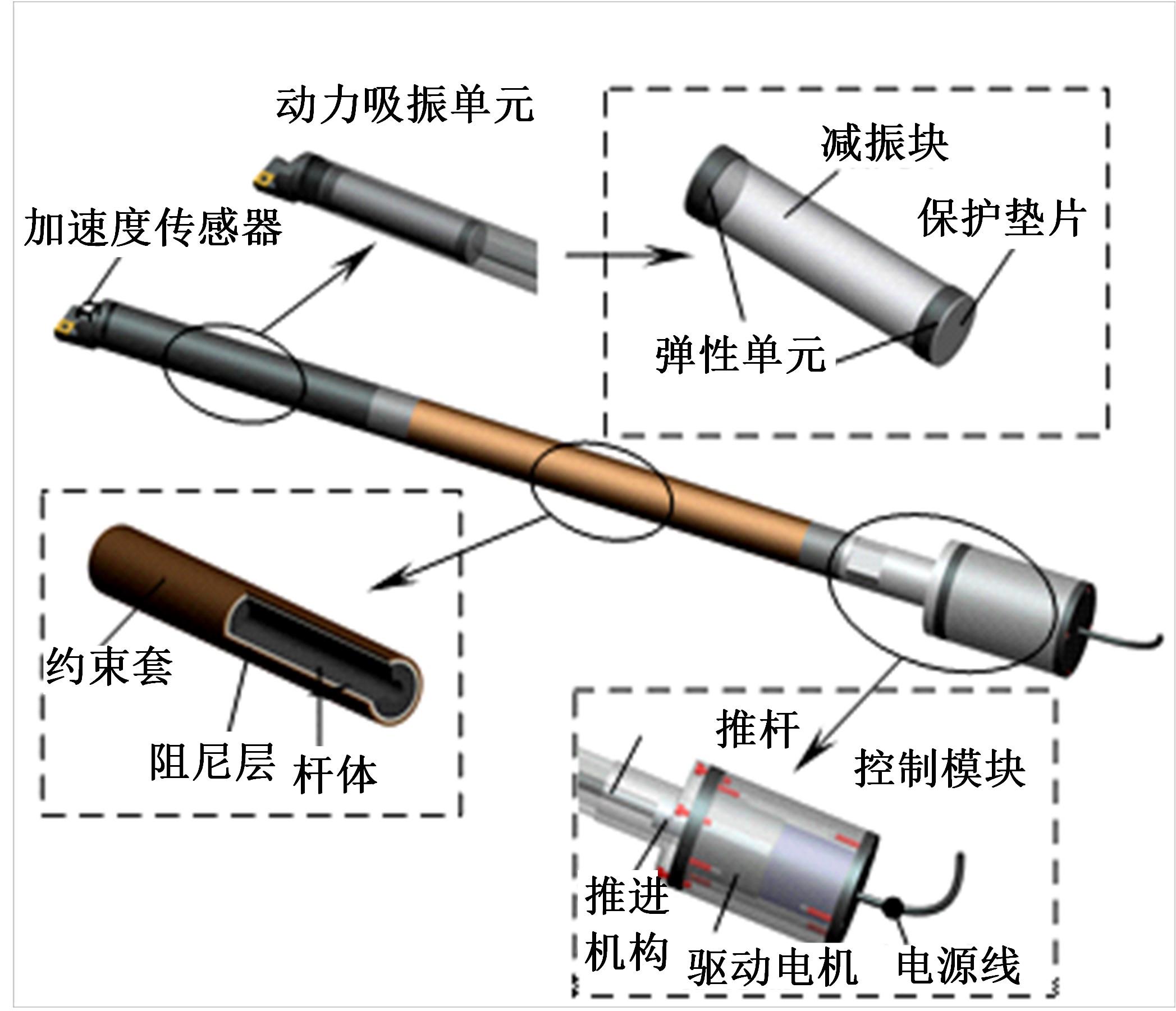

| 53 | Mei D, Kong T, Shih A J,et al. Magnetorheological fluid-controlled boring bar for chatter suppression[J]. Journal of Materials Processing Technoloygy,2009,209(4):1861-1870. |

| 54 | Mei D, Yao Z, Kong T,et al. Parameter optimization of time-varying stiffness method for chatter suppression based on magnetorheological fluid-controlled boring bar[J]. International Journal of Advanced Manufacturing Technology,2010,46(9-12):1071-1083. |

| 55 | 李欣,梅德庆,陈子辰. 基于ICA的镗削过程颤振征兆信号分离方法研究[J]. 振动与冲击,2013,32(9):5-9. |

| Li Xin, Mei De-qing, Chen Zi-chen. Research on ICA-based flutter signal separation method in boring process[J]. Journal of Vibration and Shock,2013,32(9): 5-9. | |

| 56 | Srilatha,Shalaja, Kumar S. Investigation of magnetorheolgical fulid (MRF) boring bar for chatter stablity[J]. International Journal of Mechanical Engineering and Technology,2016,7(4):75-182. |

| 57 | Prabhu L, Kumar S S, Dinakaran D,et al. Improvement of chatter stability in boring operations with semi active magneto-rheological fluid damper[J]. Materials Today: Proceedings, 2020,33(10):651-659. |

| 58 | Biju C V, Shunmugam M S. Development of a boring bar with magneto rheological fluid damping and assessment of its dynamic characteristics[J]. Journal of Vibration and Control,2017,24(14):3094-3106. |

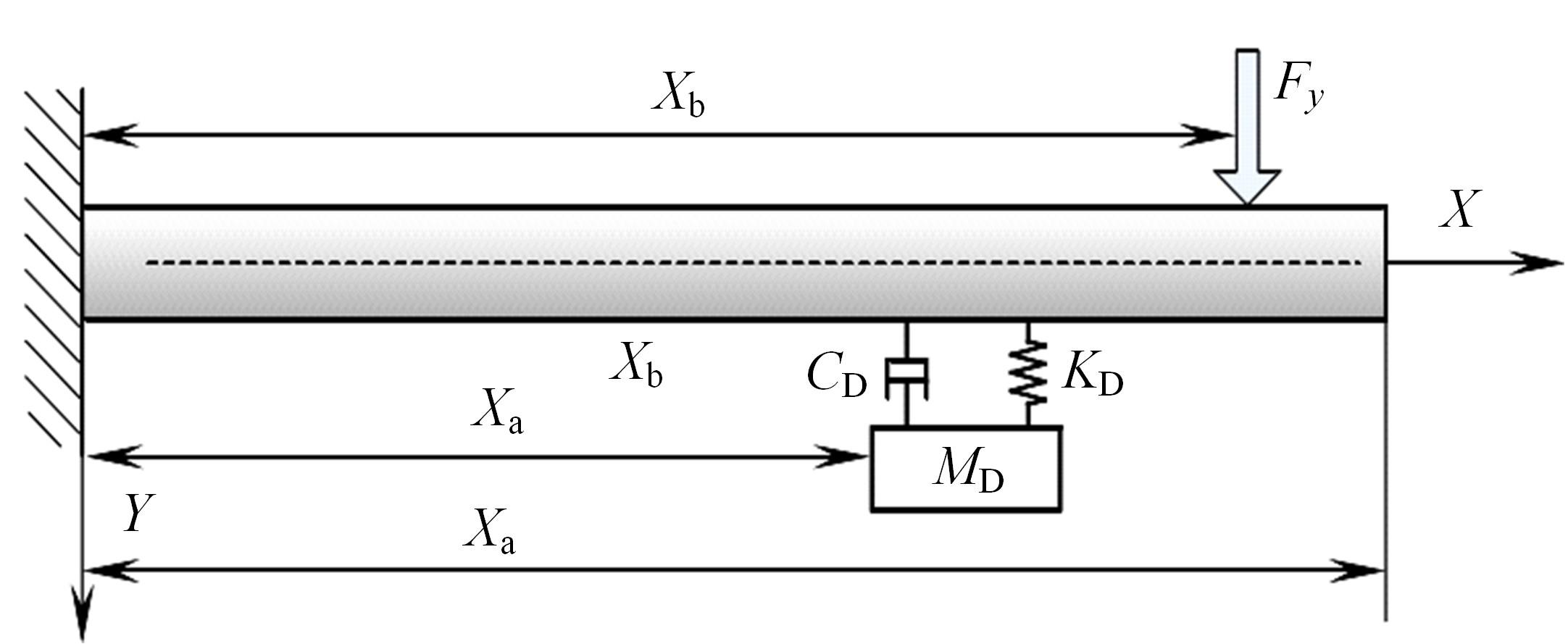

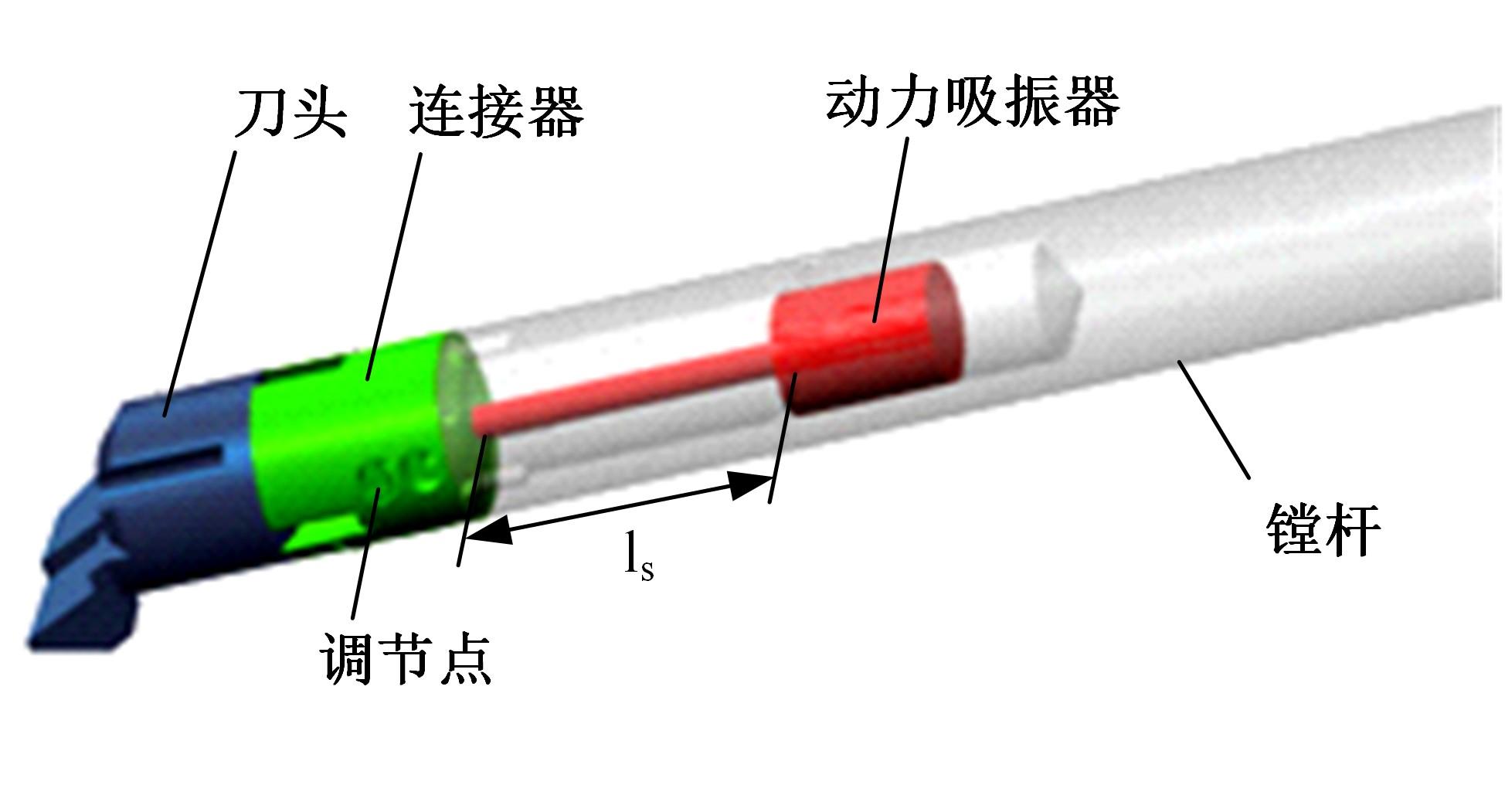

| 59 | Liu X, Liu Q, Wu S,et al. Analysis of the vibration characteristics and adjustment method of boring bar with a variable stiffness vibration absorber[J]. International Journal of Advanced Manufacturing Technology,2017,98(9):95-105. |

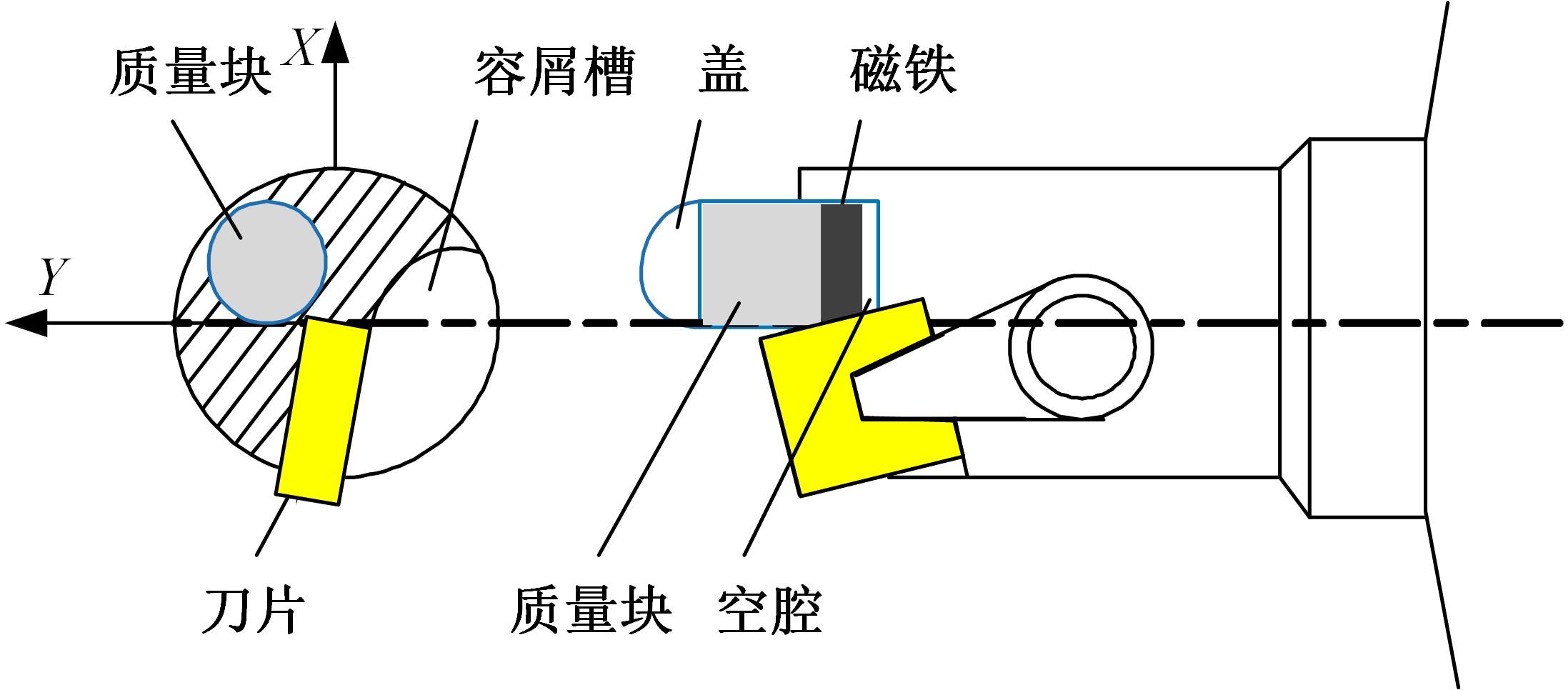

| 60 | 刘立佳. 变刚度-约束阻尼减振镗杆设计及特性研究[D]. 哈尔滨:哈尔滨理工大学机械动力工程学院,2016. |

| Liu Li-jia. Design and characteristics research on damping boring bar with variable stiffness and constrained damping[D]. Harbin:Mechanical Manu-facture and Automation,Harbin University of Science and Technology,2016. | |

| 61 | 赵康,罗红波,李伟. 可调磁力减振镗杆动力学模型参数优化[J]. 组合机床与自动化加工技术,2016(1):94-97. |

| Zhao Kang, Luo Hong-bo, Li Wei. Parameters optimization of controllable magnetic damping boring bar's kinetic model[J]. Modular Machine Tool and Automatic Manufacturing Technology,2016(1):94-97. | |

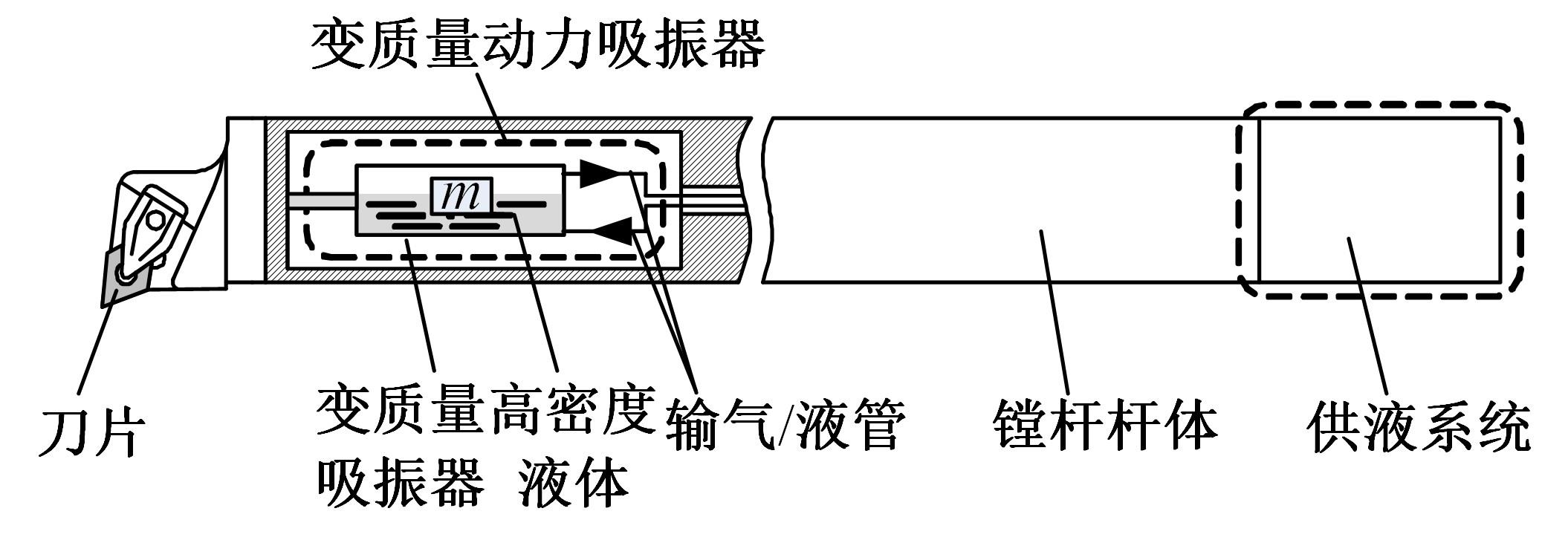

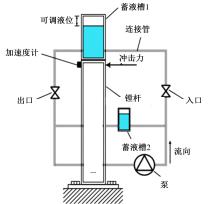

| 62 | 刘强,刘献礼,吴石,等. 变质量动力吸振器减振镗杆减振性能研究[J]. 哈尔滨理工大学学报,2018,23(5):25-29. |

| Liu Qiang, Liu Xian-li, Wu Shi,et al. Analysis of the vibration reduction characteristics of boringbar with a variable mass dynamic vibration absorber[J]. Journal of Harbin University of Science and Technology,2018,23(5):25-29. | |

| 63 | Alammari Y, Sanati M, Freiheit T,et al. Investigation of boring bar dynamics for chatter suppression[J]. Procedia Manufacturing,2015(1):768-778. |

| 64 | Teti R, Jemielniak K, O'Donnell G,et al. Advanced monitoring of machining operations[J]. CIRP Annals-Manufacturing Technology,2010,59(2):717-739. |

| 65 | 刘献礼,刘强,岳彩旭,等. 切削过程中的智能技术[J].机械工程学报,2018,54(16):45-61. |

| Liu Xian-li, Liu Qiang, Yue Cai-xu,et al. Intelligent technology in the cutting process[J]. Journal of Mechanical Engineering,2018,54(16):45-61. | |

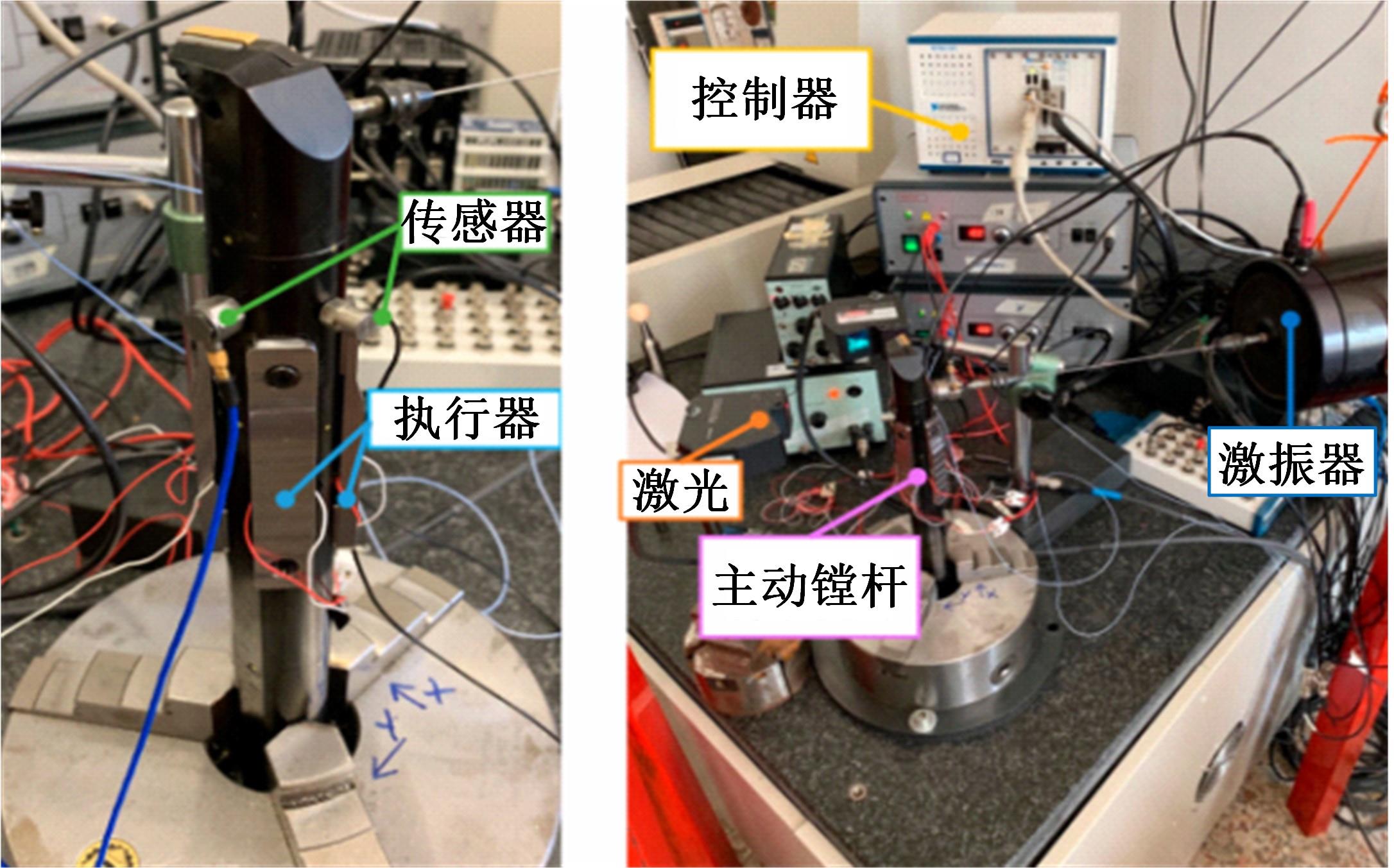

| 66 | Niccolo G, Croppi L, Scippa A,et al. A dedicated design strategy for active boring bar[J]. Applied Sciences,2019,9(17):35-41. |

| 67 | Yamada K, Matsuhisa H, Utsuno H. Enhancement of efficiency of vibration suppression using piezoelectric elements and LR circuit by amplification of electrical resonance[J]. Journal of Sound & Vibration,2014,333(5):1281-1301. |

| 68 | Matsubara A, Maeda M, Yamaji I. Vibration suppression of boring bar by piezoelectric actuators and LR circuit[J]. CIRP Annals-Manufacturing Technology,2014,63(1):373-376. |

| 69 | 刘春颖. 镗杆振动的主动最优控制仿真研究[D]. 长春:吉林大学机械与航空航天工程学院,2007. |

| Liu Chun-ying. Research of simulation on active optimal control of boring bar vibration[D]. Changchun:School of Mechanical and Aerospace Engineering,Jilin University,2007. | |

| 70 | 孔繁森,刘鹏,刘春颖. 基于压电智能结构的镗削振动主动控制的仿真与实验研究[J]. 振动与冲击,2010,29(3):142-146,210-211. |

| Kong Fan-sen, Liu Peng, Liu Chun-ying. Simulation and experimental research on active control of boring vibration based on piezoelectric smart structure[J]. Journal of Vibration and Shock, 2010, 29(3): 142-146,210-211. | |

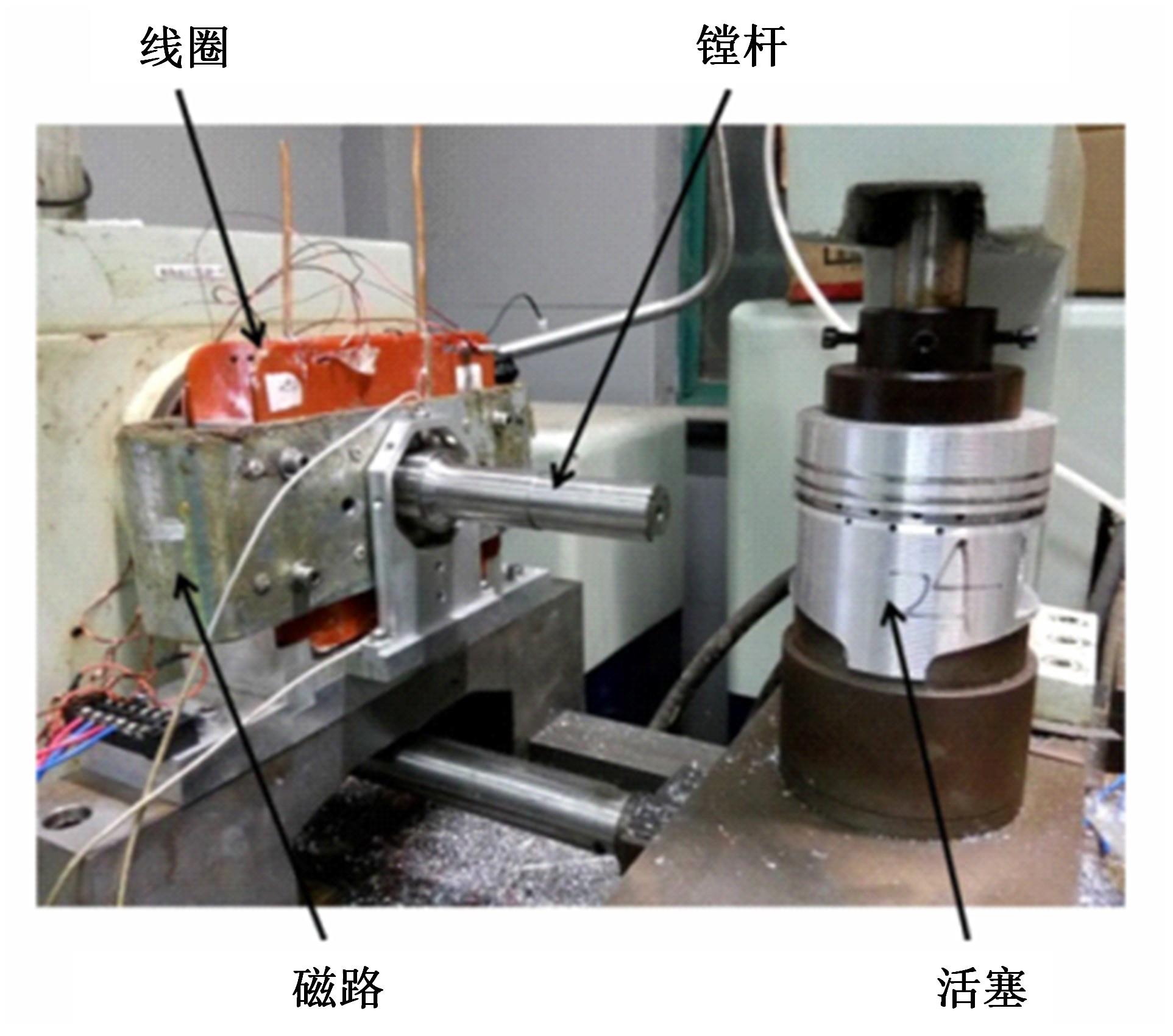

| 71 | Peng H, Xu H, Wu Y,et al. Research on multi-parametric coupling design method of deformable boring bar in embedded giant magnetostrictive actuator[J]. International Journal of Precision Engineering and Manufacturing,2020,21(9-12):2234-2245. |

| 72 | Saleh M, Nejatpour M, Acar H Y,et al. A new magnetorheological damper for chatter stability of boring tools[J]. Journal of Materials Processing Technology,2020,289(1):116931. |

| 73 | Lu X, Chen F, Altintas Y. Magnetic actuator for active damping of boring bars[J]. CIRP Annals—Manufacturing Technology,2014,63(1):369-372. |

| 74 | Chen F, Lu X, Altintas Y. A novel magnetic actuator design for active damping of machining tools[J]. International Journal of Machine Tools & Manufacture,2014,85(7):58-69. |

| 75 | Chen F, Hanifzadegan M, Altintas Y,et al. Active damping of boring bar vibration with a magnetic actuator[J]. IEEE/ASME Transactions on Mechatronics,2015,20(6):2783-2794. |

| 76 | Chen F, Liu G. Active damping of machine tool vibrations and cutting force measurement with a magnetic actuator[J]. The International Journal of Advanced Manufacturing Technology,2017,89(1):691-700. |

| 77 | Aimini P N, Moetakef-Imani B. High-performance controller design and evaluation for active vibration control in boring[J]. Scientia Iranica,2019,29(5):2839-2853. |

| 78 | Fallah M, Moetakef-Imani B.Investigation on nonlinear dynamics and active control of boring bar chatter[J]. Journal of the Brazilian Society of Mechanical Sciences and Engineering,2021,43(3):1116-1143. |

| 79 | 刘强,张海军,刘献礼,等. 智能刀具研究综述[J].机械工程学报,2021,57(21):248-268. |

| Liu Qiang, Zhang Hai-jun, Liu Xian-li,et al. A review of research on intelligent cutting tools[J]. Journal of Mechanical Engineering,2021,57(21):248-268. | |

| 80 | 刘献礼,李雪冰,丁明娜,等. 面向智能制造的刀具全生命周期智能管控技术[J].机械工程学报,2021,57(10):196-219. |

| Liu Xian-li, Li Xue-bing, Ding Ming-na,et al. Intelligent management and control technology of cutting tool life-cycle for intelligent manufacturing[J]. Journal of Mechanical Engineering,2021,57(10):196-219. | |

| 81 | Liu X, Liu S, Li X,et al. Intelligent tool wear monitoring based on parallel residual and stacked bidirectional long short-term memory network[J]. Journal of Manufacturing Systems,2021,60:608-619. |

| 82 | Li X B, Liu X J, Yue C X,et al. A data-driven approach for tool wear recognition and quantitative prediction based on radar map feature fusion[J].Measurement,2021,185:1172-1186. |

| [1] | WANG Pan, LU Jun, DENG Zhao-xiang, LIAO Hai-chen, WANG Zheng-ya, YANG Xiao-guang. Modal control of smart constrained layer damping plate based on state observer [J]. 吉林大学学报(工学版), 2016, 46(4): 1057-1064. |

| [2] | MA Jian-Ming, HE Jing-Feng, XIONG Hai-Guo, HAN Jun-Wei. Vibration control strategy for sixDOF motion simulator [J]. 吉林大学学报(工学版), 2010, 40(02): 511-0516. |

| [3] | Song Min, Chen Yudong, Chen Suhuan. Robustness analysis of responses of vibration control structures with uncertain parameters [J]. 吉林大学学报(工学版), 2006, 36(增刊1): 38-0041. |

| [4] | Song Min,, Chen Yudong, Chen Suhuan. Stability Robustness of Closedloop System with Uncertain Parameters Using Interval Analysis [J]. 吉林大学学报(工学版), 2006, 36(01): 5-0009. |

|

||