Journal of Jilin University(Engineering and Technology Edition) ›› 2024, Vol. 54 ›› Issue (1): 281-293.doi: 10.13229/j.cnki.jdxbgxb.20220194

Design and performance test of image transmission remote control mower in closed orchard

Fu-zeng YANG1,2( ),Jing-bin SUN1,2,Ya-nan LI1,2,Ya-zhou ZHANG1,2,Zhi-jie LIU1,3(

),Jing-bin SUN1,2,Ya-nan LI1,2,Ya-zhou ZHANG1,2,Zhi-jie LIU1,3( )

)

- 1.College of Mechanical and Electronic Engineering,Northwest A&F University,Yangling 712100,China

2.Apple Full Mechanized Scientific Research Base of Ministry of Agriculture and Rural Affairs,Yangling 712100,China

3.Scientific Observing and Experimental Station of Agricultural Equipment for the Northern China,Ministry of Agriculture and Rural Affairs,Yangling 712100,China

CLC Number:

- S224

| 1 | 秦喜田, 刘学峰, 任冬梅, 等. 我国果园生产机械化现状及其发展趋势[J]. 农业装备与车辆工程, 2019, 57(): 35-38. |

| Qin Xi-tian, Liu Xue-feng, Ren Dong-mei, et al. Present situation and development trend of orchard production mechanization in China[J]. Agricultural Equipment & Vehicle Engineering, 2019, 57(Sup.): 35-38. | |

| 2 | 李建平, 刘俊峰, 李杰银. 果园割草机割茬高度机构运动分析与设计[J]. 农机化研究, 2013, 35(8): 43-45, 49. |

| Li Jian-ping, Liu Jun-feng, Li Jie-yin, et al. The analysis and design of orchard mower stubble height of the mechanism motion[J]. Journal of Agricultural Mechanization Research, 2013, 35 (8): 43-45, 49. | |

| 3 | 李建平, 刘俊峰, 李杰银. 基于摇杆滑块机构的割草机割茬高度机构设计[J]. 农机化研究, 2013, 35(4): 96-99. |

| Li Jian-ping, Liu Jun-feng, Liu Jie-yin, et al. The design of mower stubble height mechanism based on the rocker slider mechanism[J]. Journal of Agricultural Mechanization Research, 2013, 35(4): 96-99. | |

| 4 | 杨鹏. 郁闭型果园遥控弥雾机的研制与试验[D]. 杨凌:西北农林科技大学, 2016. |

| Yang Peng.Development and experimental research of canopy type remote orchard mist sprayer[D]. Yangling: Northwest A&F University, 2016. | |

| 5 | 洪添胜, 王贵恩, 陈羽白, 等. 果树施药仿形喷雾关键参数的模拟试验研究[J]. 农业工程学报, 2004, 20(4): 104-107. |

| Hong Tian-sheng, Wang Gui-en, Chen Yu-bai, et al. Profile modeling of spray parameters of chemical solution application to fruit tree[J]. Transactions of the Chinese Society of Agricultural Engineering, 2004, 20(4): 104-107. | |

| 6 | 郑永军, 江世界, 陈炳太, 等. 丘陵山区果园机械化技术与装备研究进展[J]. 农业机械学报, 2020, 51 (11): 1-20. |

| Zheng Yong-jun, Jiang Shi-jie, Chen Bing-tai, et al. Review on technology and equipment of mechanization in hilly orchard[J]. Transactions of the Chinese society for Agricultural Machinery, 2020, 51(11): 1-20. | |

| 7 | 潘冠廷, 杨福增, 孙景彬, 等. 小型山地履带拖拉机爬坡越障性能分析与试验[J]. 农业机械学报, 2020, 51(9): 374-383. |

| Pan Guan-ting, Yang Fu-zeng, Sun Jing-bin, et al. Analysis and test of the obstacle negotiation performance of a small hillside crawler tractor during climbing process[J]. Transactions of the Chinese Society for Agricultural Machinery, 2020, 51(9): 374-383. | |

| 8 | 王金峰, 翁武雄, 鞠金艳, 等. 基于遥控转向的稻田行间除草机设计与试验[J]. 农业机械学报, 2021, 52(9): 97-105. |

| Wang Jin-feng, Weng Wu-xiong, Ju Jin-yan, et al. Design and experiment of weeder between rows in rice field based on remote control steering[J]. Transactions of the Chinese Society for Agricultural Machinery, 2021, 52(9): 97-105. | |

| 9 | 郝朝会, 杨学军, 刘立晶, 等. 果园多功能动力底盘设计与试验[J]. 农业机械学报, 2018, 49(12): 66-73, 92. |

| Hao Zhao-hui, Yang Xue-jun, Liu Li-jing, et al. Design and experiment of multifunctional dynamic chassis for orchard[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(12): 66-73, 92. | |

| 10 | 洪添胜, 杨洲, 宋淑然, 等. 柑橘生产机械化研究[J]. 农业机械学报, 2010, 41(12): 105-110. |

| Hong Tian-sheng, Yang Zhou, Song Shu-ran, et al. Mechanization of citrus production[J]. Transactions of the Chinese Society for Agricultural Machinery, 2010, 41(12) : 105-110. | |

| 11 | 贠鑫, 吕猛, 王文彬, 等. 果园除草机研究现状与发展趋势[J]. 农业工程,2020, 10(1): 18-21. |

| Yun Xin, Meng Lü, Wang Wen-bin, et al. Research status and development trend of orchard weeder[J]. Agricultural Engineering, 2020, 10(1): 18-21. | |

| 12 | 日本罗宾 4W22割草机——果园机械化好帮手[J]. 西北园艺(果树), 2018(2): 53-54. |

| Japanese Robin 4W22 lawn mower——a good helper for orchard mechanization[J]. Northwest Horticulture, 2018(2): 53-54. | |

| 13 | 张雯. 果园小型圆盘式割草机的研究与设计[D].武汉:华中农业大学, 2019. |

| Zhang Wen. Research and design of orchard compact disc mower[D]. Wuhan: Huazhong Agricultural University, 2019. | |

| 14 | 祝露, 王德成, 尤泳, 等. 履带式林间草带收割机设计与试验[J]. 农业机械学报, 2021, 52(4): 126-133. |

| Zhu Lu, Wang De-cheng, You Yong, et al. Design and experiment of crawler-type grass belt harvester in forest[J]. Transactions of the Chinese Society of Agricultural Machinery, 2021, 52(4): 126-133. | |

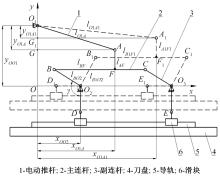

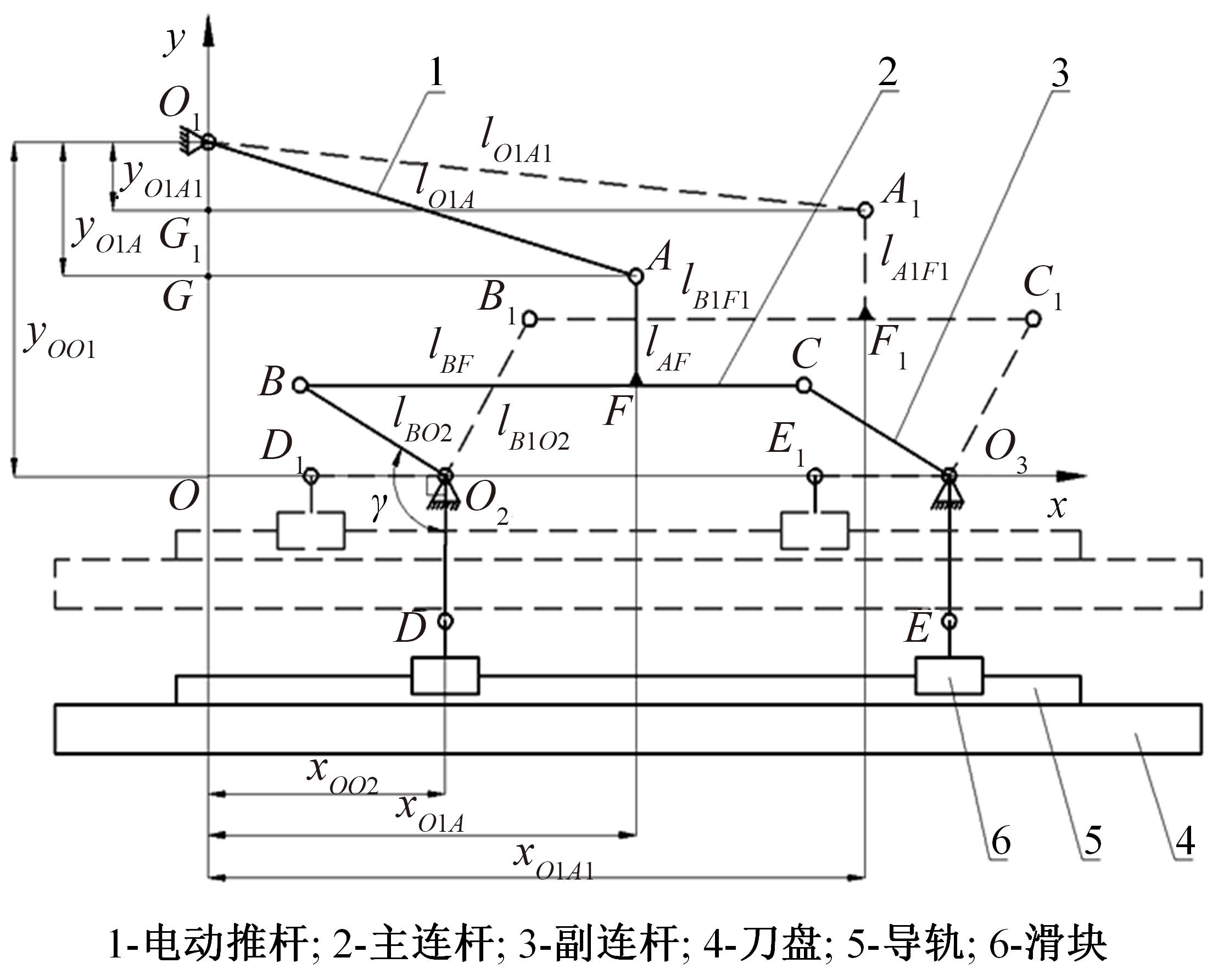

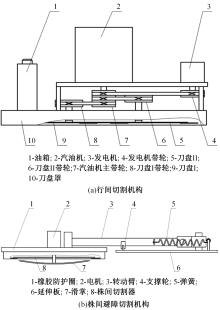

| 15 | 徐丽明, 于畅畅, 刘文, 等. 篱架式栽培葡萄株间除草机自动避障机构优化设计[J]. 农业工程学报, 2018, 34(7): 23-30. |

| Xu Li-ming, Yu Chang-chang, Liu Wen, et al. Optimal design of intra-row weeder's auto obstacle avoidance mechanism for trellis grape[J]. Transactions of the Chinese Society of Agricultural Engineering, 2018, 34(7): 23-30. | |

| 16 | 于畅畅, 徐丽明, 王庆杰, 等. 篱架式栽培葡萄双边作业株间自动避障除草机设计与试验[J]. 农业工程学报, 2019, 35(5): 1-9. |

| Yu Chang-chang, Xu Li-ming, Wang Qing-jie, et al. Design and experiment of bilateral operation intra-row auto obstacle avoidance weeder for trellis cultivated grape[J]. Transactions of the Chinese Society of Agricultural Engineering, 2019, 35(5): 1-9. | |

| 17 | 田甜. 四轮独立驱动电动底盘设计及试验研究[D]. 北京: 中国农业机械化科学研究院, 2012. |

| Tian Tian. Design and experimental research of four wheel independent drive chassis[D]. Beijing: Chinese Academy of Agricultural Mechanization Sciences, 2012. | |

| 18 | 高连兴, 师帅兵. 拖拉机汽车学(下册) 车辆底盘与理论[M]. 北京:中国农业出版社, 2009: 186-187. |

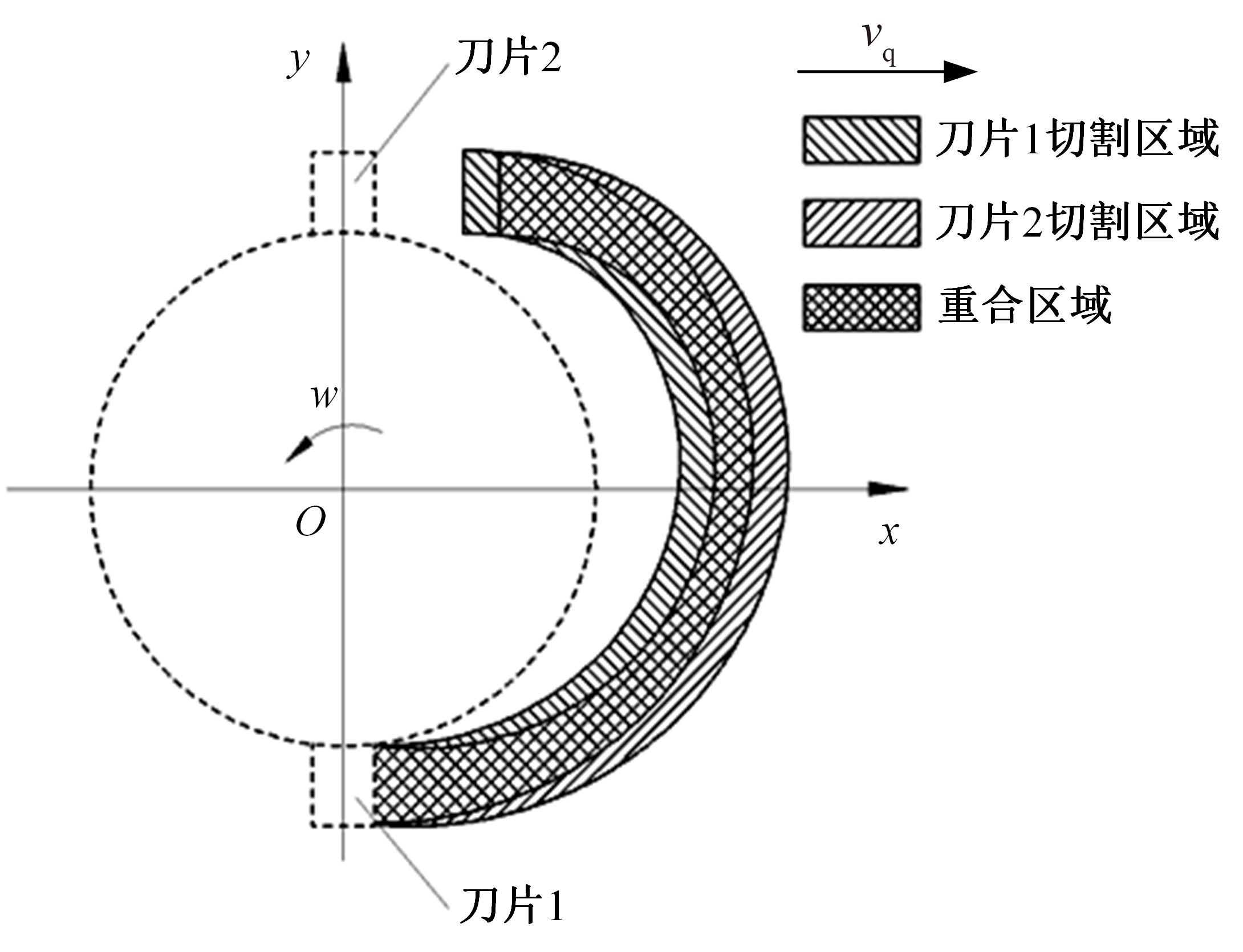

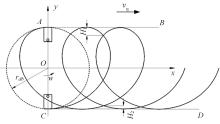

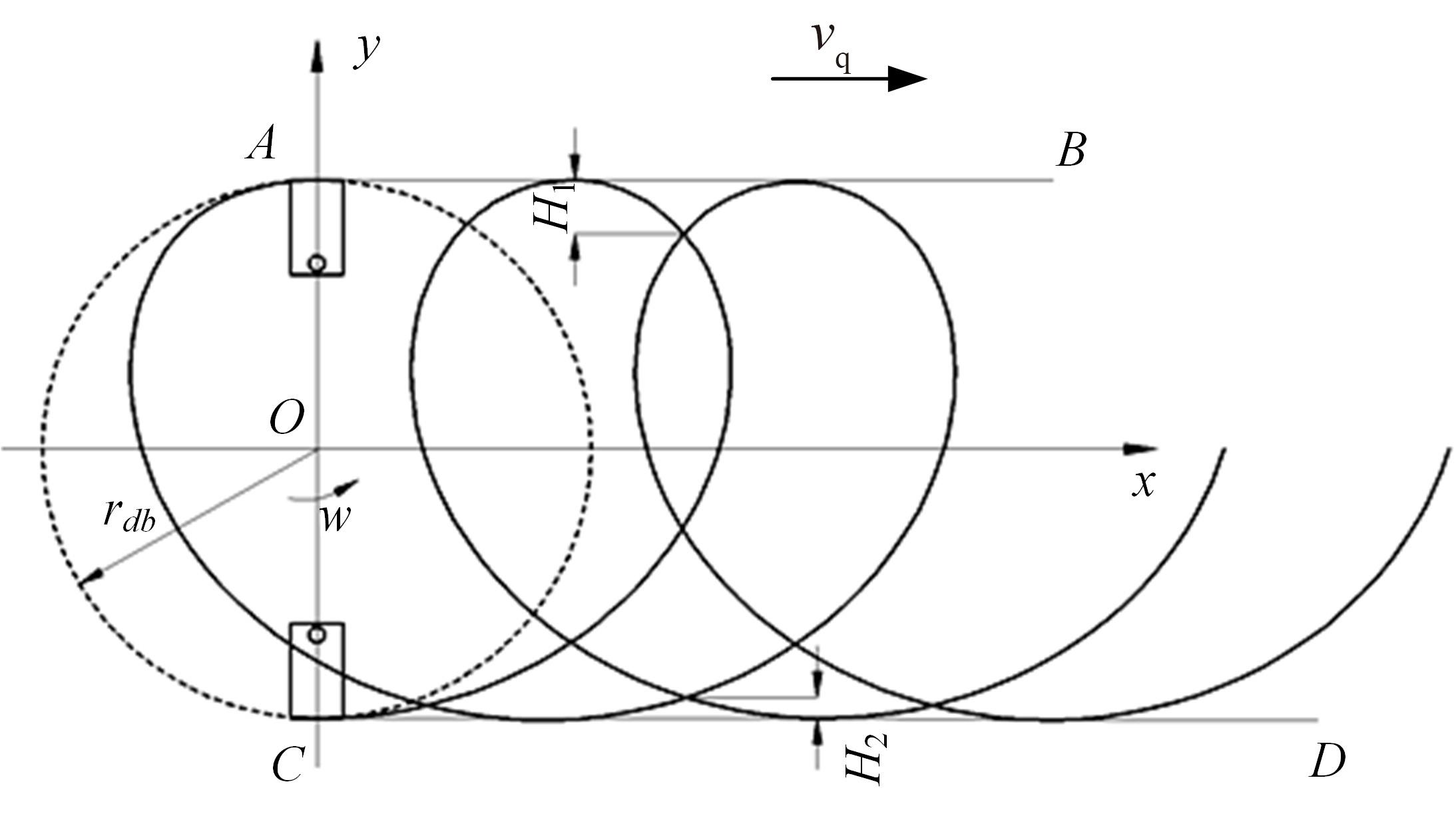

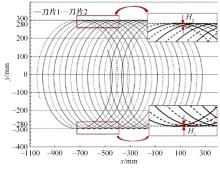

| 20 | 段天青. 双圆盘割草机的研制[D].兰州:甘肃农业大学工学院, 2007. |

| Duan Tian-qing. Development of double disc mower[D]. Lanzhou: College of Engineering,Gansu Agricultural University, 2007. | |

| 21 | 马攀宇. 山地果园仿形割草机的设计与试验[D]. 武汉: 华中农业大学工学院, 2019. |

| Ma Pan-yu. Design and test of mountain orchard profile mower[D]. Wuhan: College of Engineering,Huazhong Agricultural University, 2019. | |

| 22 | 宋建农. 农业机械与装备[M]. 北京: 中国农业出版社,2006. |

| 23 | 程小龙. 果园乘坐自走式割草机的设计与试验研究[D]. 保定: 河北农业大学机电工程学院, 2015. |

| Cheng Xiao-long. Design and experimental research of selfpropelled riding of orchard mower[D]. Baoding: College of Mechanical and Electrical Engineering,Hebei Agricultural University, 2015. | |

| 24 | 邬备. 苜蓿刈割压扁收获机械系统的优化和试验研究[D]. 北京: 中国农业大学工学院, 2017. |

| Wu Bei. Optimization and experimental study on mechanical system of alfalfa mower conditioner[D]. Beijing: College of Engineering,China Agricultural University, 2017. | |

| 25 | 白璐璐. 悬挂式调幅果园割草机设计与仿形研究[D].保定:河北农业大学机电工程学院, 2016. |

| Bai Lu-lu. Design and profiling research of suspending and width adjustable orchard mower[D].Baoding: College of Mechanical and Electrical Engineering,Hebei Agricultural University, 2016. | |

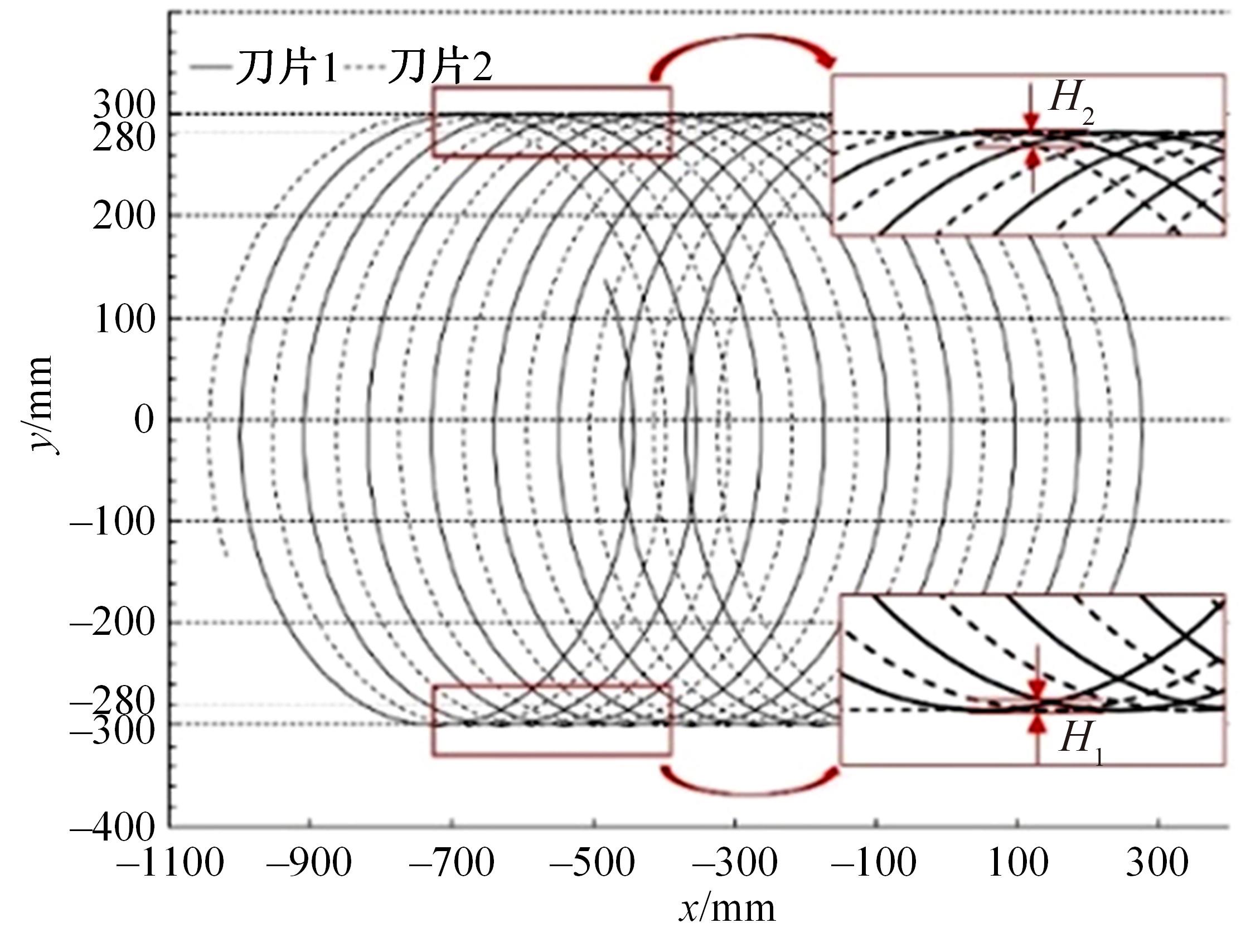

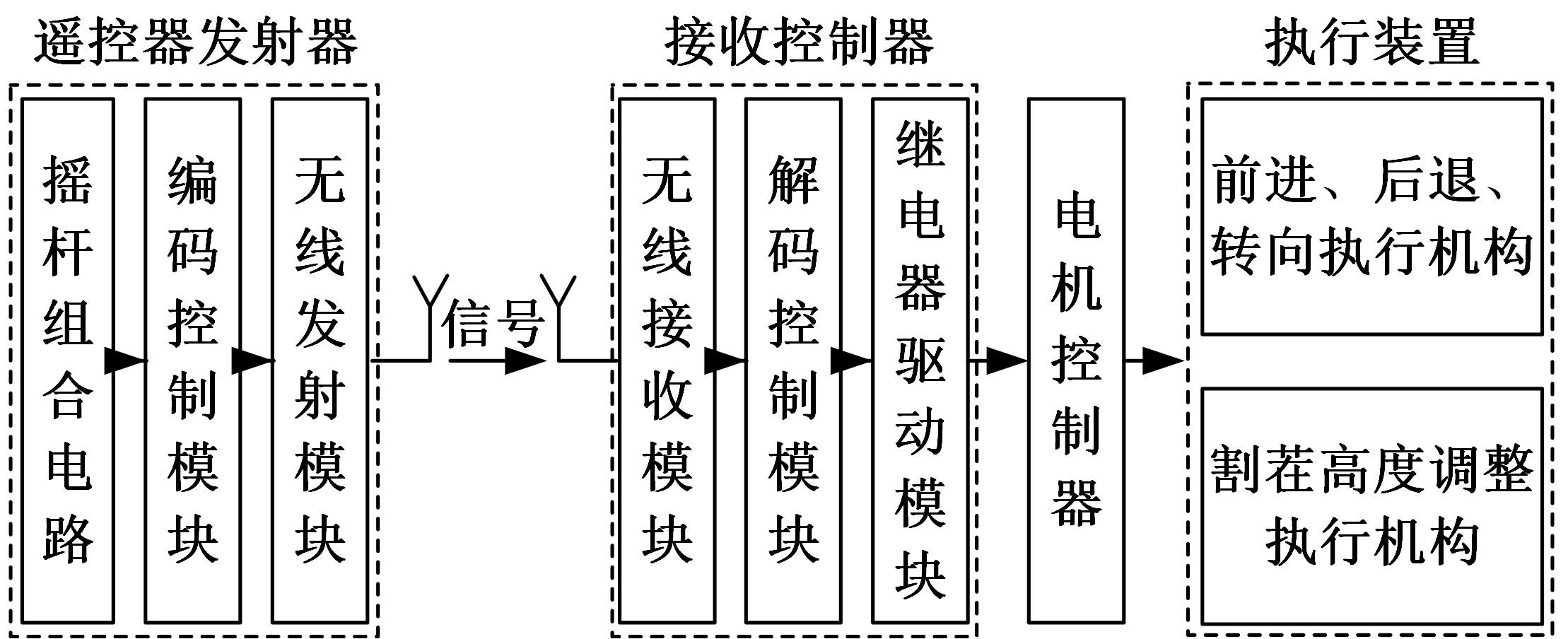

| 26 | 孙景彬, 楚国评, 潘冠廷, 等. 遥控全向调平山地履带拖拉机设计与性能试验[J]. 农业机械学报, 2021, 52(5): 358-369. |

| Sun Jing-bin, Chu Guo-ping, Pan Guan-ting, et al. Design and performance test of remote control omnidirectional leveling hillside crawler tractor[J]. Transactions of the Chinese Society of Agricultural Machinery, 2021, 52(5): 358-369. | |

| 27 | 王元杰, 刘永成, 杨福增, 等. 温室微型遥控电动拖拉机的研制与试验[J]. 农业工程学报, 2012, 28(22): 23-29. |

| Wang Yuan-jie, Liu Yong-cheng, Yang Fu-zeng, et al. Development and test of tiny remotely controlled electric tractor for greenhouses[J]. Transactions of the Chinese Society of Agricultural Engineering, 2012, 28(22): 23-29. | |

| 28 | 朱站伟, 汤智辉, 何义川, 等. 果园株间除草自动避障装置的设计与试验[J]. 农机化研究, 2020, 42(6): 147-153. |

| Zhu Zhan-wei, Tang Zhi-hui, He Yi-chuan, et al. Design and experiment of automatic obstacle avoidance device for weeding between plants[J]. Journal of Agricultural Mechanization Research, 2020, 42(6): 147-153. |

| [1] | Hai-yan CHEN. Design of remote switching control algorithm for multi-band signal source in distributed communication network [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(5): 1886-1893. |

| [2] | HUANG Xin-lin, WANG Gang, LIU Chun-gang, YU Ying-xin,SUN Qing-quan. Unequal error protection for progressive image transmission [J]. 吉林大学学报(工学版), 2011, 41(01): 235-0238. |

|

||