Journal of Jilin University(Engineering and Technology Edition) ›› 2021, Vol. 51 ›› Issue (5): 1620-1627.doi: 10.13229/j.cnki.jdxbgxb20200538

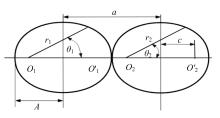

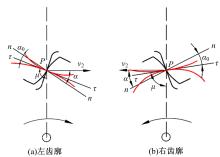

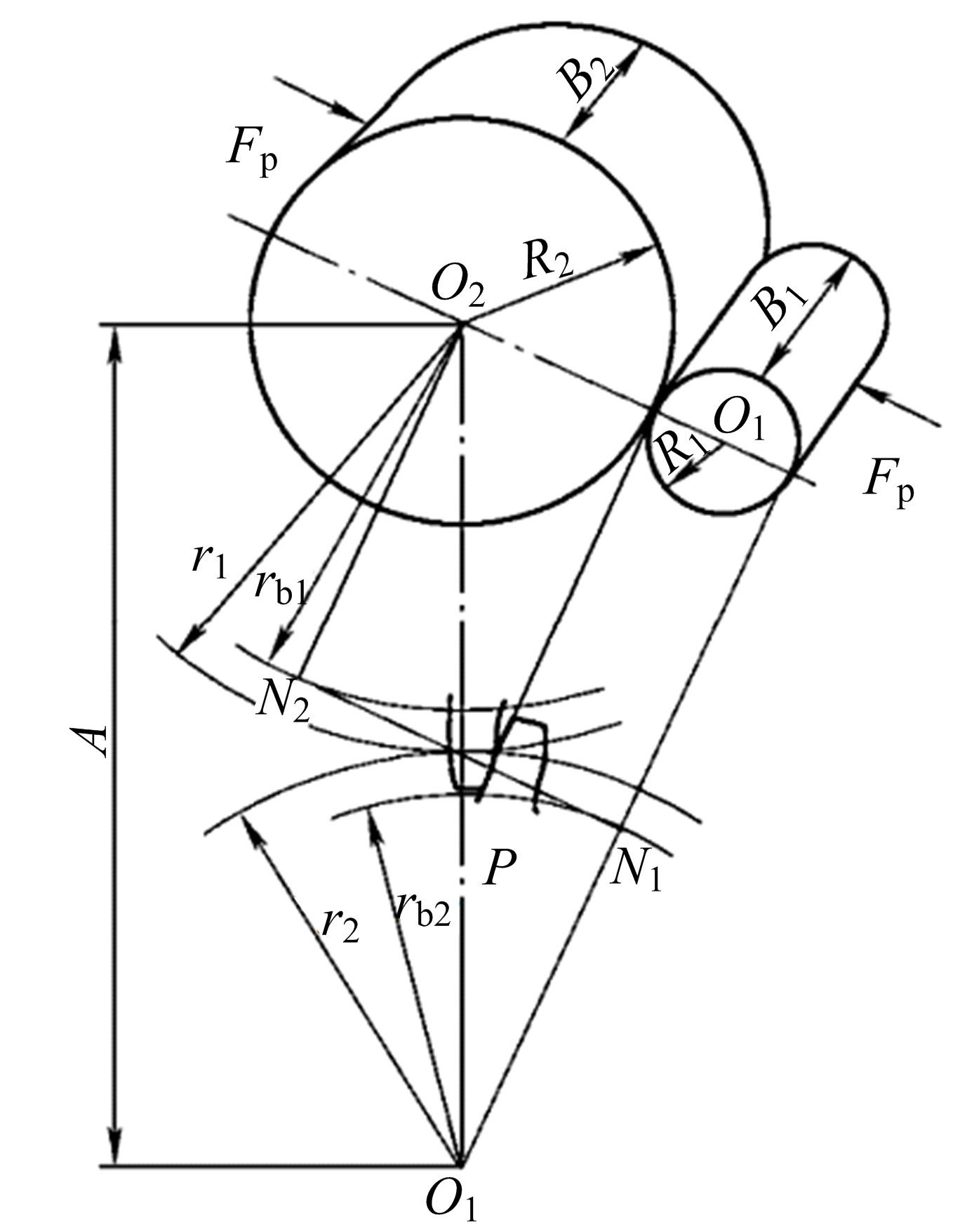

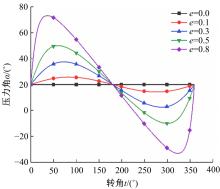

Analysis of tooth surface contact and dynamic wear of elliptic gear transmission system

Yong-ping LIU( ),Chang-bin DONG,Yong-qiao WEI

),Chang-bin DONG,Yong-qiao WEI

- School of Mechanical and Electrical Engineering,Lanzhou University of Technology,Lanzhou 730050,China

CLC Number:

- TH132.424

| 1 | Smith W C. The math of noncircular gearing[J]. Gear Technology, 2000, 17(4): 18-21. |

| 2 | 董长斌, 刘永平, 魏永峭. 不同载荷条件下椭圆柱齿轮动态接触特性分析[J]. 华中科技大学学报: 自然科学版, 2019, 47(8): 103-107. |

| Dong Chang-bin, Liu Yong-ping, Wei Yong-qiao. Dynamic contact characteristics analysis of elliptic cylinder gear under different load conditions[J]. Journal of Huazhong University of Science and Technology(Natural Science Edition), 2019, 47(8): 103-107. | |

| 3 | 李波涛, 陈定方. 非圆齿轮设计、制造、检测及应用[J]. 机械工程学报, 2020, 56(9): 55-72. |

| Li Bo-tao, Chen Ding-fang. Design, manufacture, inspection and application of non-circular gears[J].Journal of Mechanical Engineering,2020,56(9):55-72. | |

| 4 | 董长斌, 刘永平, 魏永峭, 等. 椭圆齿轮传动系统非线性动态特性分析[J]. 吉林大学学报: 工学版, 2020, 50(2): 483-493. |

| Dong Chang-bin, Liu Yong-ping, Wei Yong-qiao, et al. Analysis of nonlinear dynamic characteristic of elliptic gear transmission system[J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 483-493. | |

| 5 | 周长江, 雷玉英, 汪红兵, 等. 准静态与动态载荷下斜齿轮齿面粘着磨损计算[J]. 机械工程学报, 2018, 54(23): 24-36. |

| Zhou Chang-jiang, Lei Yu-ying, Wang Hong-bing, et al. Adhesive wear models for helical gears under quasi-static and dynamic loads[J]. Journal of Mechanical Engineering, 2018, 54(23): 24-36. | |

| 6 | 潘冬, 赵阳, 李娜, 等. 齿轮磨损寿命预测方法[J]. 哈尔滨工业大学学报, 2012, 44(9): 29-33, 39. |

| Pan Dong, Zhao Yang, Li Na, et al. The wear life prediction method of gear system[J]. Journal of Harbin Institute of Technology, 2012, 44(9): 29-33, 39. | |

| 7 | 张俊, 卞世元, 鲁庆, 等. 准静态工况下渐开线直齿轮齿面磨损建模与分析[J]. 机械工程学报, 2017, 53(5): 136-145. |

| Zhang Jun, Bian Shi-yuan, Lu Qing, et al. Quasi-static-model-based wear analysis of spur gears[J]. Journal of Mechanical Engineering, 2017, 53(5): 136-145. | |

| 8 | Archard J F. Contact and rubbing of flat surfaces[J]. Journal of Applied Physics, 1953, 24(8): 981-998. |

| 9 | Wu S, Cheng H S. A sliding wear model for partial-EHL contacts[J]. Journal of Tribology, 1991, 113(1): 134. |

| 10 | Wu S, Cheng H S. Sliding wear calculation in spur gears[J].Journal of Tribology,1993,115(3): 493-500. |

| 11 | Zhang J, Liu X Z. Effects of misalignment on surface wear of spur gears[J]. Proceedings of the Institution of Mechanical Engineers Part J Journal of Engineering Tribology, 2015, 229(9): 1-14. |

| 12 | 王晓笋, 巫世晶, 陈杰, 等. 考虑动载荷与动态磨损系数的直齿轮传动系统动态磨损特性[J]. 中南大学学报: 自然科学版, 2014: 45(2): 408-413. |

| Wang Xiao-sun, Wu Shi-jing, Chen Jie, et al. Dynamic surface wear characteristics in spur gear transmission system with dynamic loads and wear coefficients[J]. Journal of Central South University(Science and Technology), 2014, 45(2): 408-413. | |

| 13 | 何泽银,唐伟迤,林腾蛟,等.增速齿轮副非均匀磨损时变啮合刚度研究[J].机械传动,2019,43(12): 1-6. |

| He Ze-yin, Tang Wei-yi, Lin Teng-jiao, et al. Study on the time-varying mesh stiffness of speed-increasing gear pair with non-uniform wear[J]. Journal of Mechanical Transmission, 2019, 43(12): 1-6. | |

| 14 | 胡波, 黄平. 渐开线直齿圆柱齿轮磨损的数值计算与分析[J]. 润滑与密封, 2017, 42(12): 23-28, 33. |

| Hu Bo, Huang Ping. Numerical calculation and analysis of wear behavior of involute spur gear[J]. Lubrication Engineering, 2017, 42(12): 23-28, 33. | |

| 15 | Litvin F L. Noncircular Gears: Design and Generation[M]. Canbridge: Cambridge University Press, 2009. |

| 16 | 林超, 刘毅, 魏艳群, 等. 端曲面齿轮副复合运动规律及受力分析[J]. 吉林大学学报: 工学版, 2017, 47(1): 157-162. |

| Lin Chao, Liu Yi, Wei Yan-qun, et al. Composite motion law and force condition of curve-face gear pair[J]. Journal of Jilin University(Engineering and Technology Edition), 2017, 47(1): 157-162. |

| [1] | Chang-bin DONG,Yong-ping LIU,Yong-qiao WEI,Hai-qing DENG,Jie Xu. Analysis of nonlinear dynamic characteristic of elliptic gear transmission system [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 483-493. |

| [2] | REN Qing-lei, WEI Xin, XIE Xiao-zhu, HU Wei. Micro contact mechanism based on force in self rotation grinding of silicon wafer [J]. 吉林大学学报(工学版), 2018, 48(3): 796-802. |

| [3] | DONG Li-chun, HAN Zhi-wu, ZHANG Lei, NIU Shi-chao, MA Rong-feng, REN Lu-quan. Numerical simulation on contact problem of ring model with bionic concave morphology [J]. 吉林大学学报(工学版), 2013, 43(增刊1): 543-546. |

| [4] | TONG Jin, WANG Ya-hui, LU Ji-sheng, ZHANG Shu-jun, CHEN Dong-hui. Coaxiality measurement of large-size forged components based on CCD [J]. 吉林大学学报(工学版), 2013, 43(04): 945-950. |

| [5] | ZHANG Hua-jun, HUANG Qing-xue, QUAN Long. Servo control of the composite controller based on combined given curve [J]. 吉林大学学报(工学版), 2013, 43(02): 346-351. |

| [6] | SHI Yong-jie, ZHENG Di, HU Li-yong, WANG Long-shan. Force-position-posture decoupling technique for NC polishing of aspherical part [J]. 吉林大学学报(工学版), 2012, 42(01): 116-121. |

| [7] | ZHANG Ying-zhi, ZHENG Rui, SHEN Gui-xiang, WANG Zhi-qiong, LI Huai-yang, et al. Failure dependency of CNC equipment based on copula theory [J]. 吉林大学学报(工学版), 2011, 41(6): 1636-1640. |

| [8] | REN Di, WANG Zu-Wen, BAO Gang, YANG Qing-Jun. Static characteristic for |newstyle high stiffness externally pressurized spherical gas bearings [J]. 吉林大学学报(工学版), 2010, 40(06): 1599-1603. |

| [9] | KONG Fan-Sen, LIU Peng, CAO Yang-Hua, DAN Jin-Dan. Fuzzy comprehensive evaluation on work environment in a gearbox plant [J]. 吉林大学学报(工学版), 2010, 40(02): 475-0479. |

| [10] | CHEN Jun, HU Ping, MA Li-Li. Time buffer control mechanism based on drumbufferrope for remanufacturing system [J]. 吉林大学学报(工学版), 2009, 39(05): 1197-1201. |

| [11] | ZHAO Yang, ZHAO Ji, ZHANG Lei, JI Li-Zhe. Robotic blade grinding based on reverse engineering [J]. 吉林大学学报(工学版), 2009, 39(05): 1176-1180. |

| [12] | MENG Ling-qi,DU Yong,MA Sheng-biao,GUO Bin . Nonlinearity of vertical vibration of medium plate mill [J]. 吉林大学学报(工学版), 2009, 39(03): 712-0715. |

| [13] |

JI Shi-jun, WANG Yang, Lv Han-ming .

Parametrization of 3D foursided region on triangular mesh model [J]. 吉林大学学报(工学版), 2009, 39(02): 458-0462. |

| [14] | LI Jing-cai,WANG Tai-yong,HE Gai-yun,ZHENG Hui-jiang,FAN Sheng-bo . 3D solid accurate modeling of spiral bevel gear based on manufacture method and meshing theory [J]. 吉林大学学报(工学版), 2008, 38(06): 1315-1319. |

| [15] | He Qiu-wei;Wang Long-shan;Yu Zhong-dang;Li Guo-fa;Gao Li-guo. Defect detection for microgear based on image processing and support vector machine [J]. 吉林大学学报(工学版), 2008, 38(03): 565-0569. |

|

||