Journal of Jilin University(Engineering and Technology Edition) ›› 2022, Vol. 52 ›› Issue (12): 2883-2891.doi: 10.13229/j.cnki.jdxbgxb20210420

Previous Articles Next Articles

Pneumatic impact test on rib⁃to⁃diaphragm fatigue crack of steel box girder

Zhi-yuan YUANZHOU( ),Bo-hai JI(

),Bo-hai JI( ),Jun-yuan XIA,Tong SUN

),Jun-yuan XIA,Tong SUN

- College of Civil and Transportation Engineering,Hohai University,Nanjing 210098,China

CLC Number:

- U443.32

| 1 | Pfeil M S, Battista R C, Mergulhao A J R. Stress concentration in steel bridge orthotropic decks[J]. Journal of Constructional Steel Research, 2005, 61(8): 1172-1184. |

| 2 | Xiao Z G, Yamada K, Inoue J, et al. Fatigue cracks in longitudinal ribs of steel orthotropic deck[J]. International Journal of Fatigue, 2006, 28(4): 409-416. |

| 3 | Guo T, Li A Q, Li J H. Fatigue life prediction of welded joints in orthotropic steel decks considering temperature effect and increasing traffic flow[J]. Structural Health Monitoring, 2008, 7(3): 189-202. |

| 4 | Fisher J W, Barsom J M. Evaluation of cracking in the rib-to-deck welds of the bronx—whitestone bridge[J]. Journal of Bridge Engineering, 2015, 21(3): 1-10. |

| 5 | 张允士, 李法雄, 熊锋, 等. 正交异性钢桥面板疲劳裂纹成因分析及控制[J]. 公路交通科技, 2013, 30(8): 75-80. |

| Zhang Yun-shi, Li Fa-xiong, Xiong Feng, et al. Cause analysis and control measures of fatigue cracks in orthotropic steel deck[J]. Highway Traffic Science and Technology, 2013, 30(8): 75-80. | |

| 6 | 李传习, 李游, 陈卓异, 等. 基于实测车流的钢箱梁横隔板疲劳特性[J]. 长安大学学报:自然科学版, 2019, 39(5): 48-58. |

| Li Chuan-xi, Li You, Chen Zhuo-yi, et al. Fatigue characteristics of steel box girder based on measured vehicle flow[J]. Journal of Chang'an University(Natural Science Edition), 2019, 39(5): 48-58. | |

| 7 | 刘益铭, 张清华, 崔闯, 等. 正交异性钢桥面板三维疲劳裂纹扩展数值模拟方法[J]. 中国公路学报, 2016, 29(7): 89-95. |

| Liu Yi-ming, Zhang Qing-hua, Cui Chuang, et al. Numerical simulation method for 3D fatigue crack propagation of orthotropic steel bridge deck[J]. China Journal of Highway and Transport, 2016, 29(7): 89-95. | |

| 8 | 汪珍, 王莹. 正交异性钢桥面板的疲劳裂纹扩展规律[J]. 中南大学学报:自然科学版, 2020, 51(7): 1873-1882. |

| Wang Zhen, Wang Ying. Analysis of fatigue crack propagation on orthotropic steel bridge deck[J]. Journal of Central South University(Science and Technology), 2020, 51(7): 1873-1882. | |

| 9 | Choi J H, Kim D H. Stress characteristics and fatigue crack behaviour of the longitudinal rib-to-cross beam joints in an orthotropic steel deck[J]. Advances in Structural Engineering, 2008, 11(2): 189-198. |

| 10 | Gao W, Dai S, Xiao T, et al. Failure process of rock slopes with cracks based on the fracture mechanics method[J]. Engineering Geology, 2017, 231:190-199. |

| 11 | Patel A B, Pandey R K. Fatigue crack growth under mixed-mode loading[J]. Fatigue & Fracture of Engineering Materials & Structures, 2007, 4(1): 65-77. |

| 12 | 马世骧, 胡泓. CTS试件中复合型疲劳裂纹扩展[J]. 力学学报, 2006, 38(5): 698-704. |

| Ma Shi-xiang, Hu Hong. Compound fatigue crack propagation in CTS specimen[J]. Chinese Journal of Theoretical and Applied Mechanics, 2006, 38(5): 698-704. | |

| 13 | 房亮, 傅中秋, 王益逊, 等. 钢桥面板横隔板疲劳裂纹维修对未开裂侧的影响[J]. 南昌大学学报:工科版, 2019, 41(4): 336-344. |

| Fang Liang, Fu Zhong-qiu, Wang Yi-xun, et al. Effect of fatigue crack maintenance on uncracked side stress of steel bridge deck diaphragm[J]. Journal of Nanchang University (Engineering & Technology), 2019, 41(4): 336-344. | |

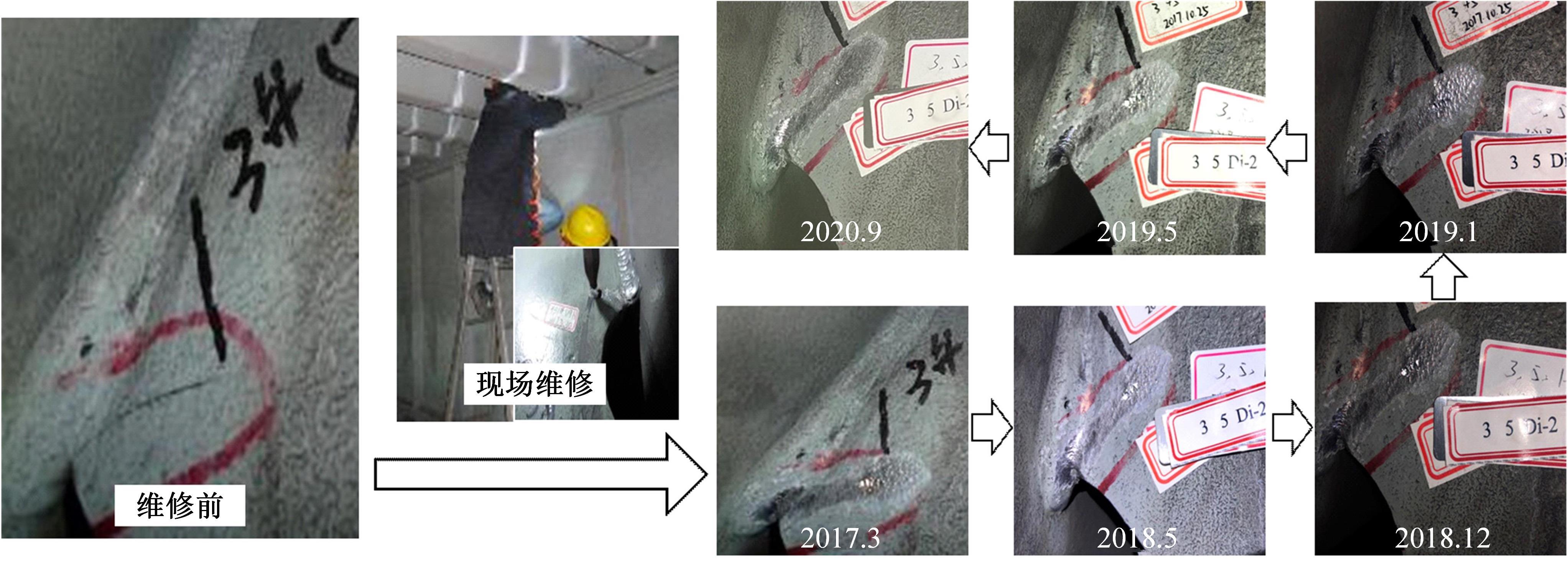

| 14 | 陈卓异, 李传习, 柯璐, 等. 某悬索桥钢箱梁疲劳病害及处治方法研究[J]. 土木工程学报, 2017, 50(3): 91-100. |

| Chen Zhuo-yi, Li Chuan-xi, Ke Lu, et al. Study on fatigue damages and retrofit methods of steel box girder in a suspension bridge[J]. China Civil Engineering Journal, 2017, 50(3): 91-100. | |

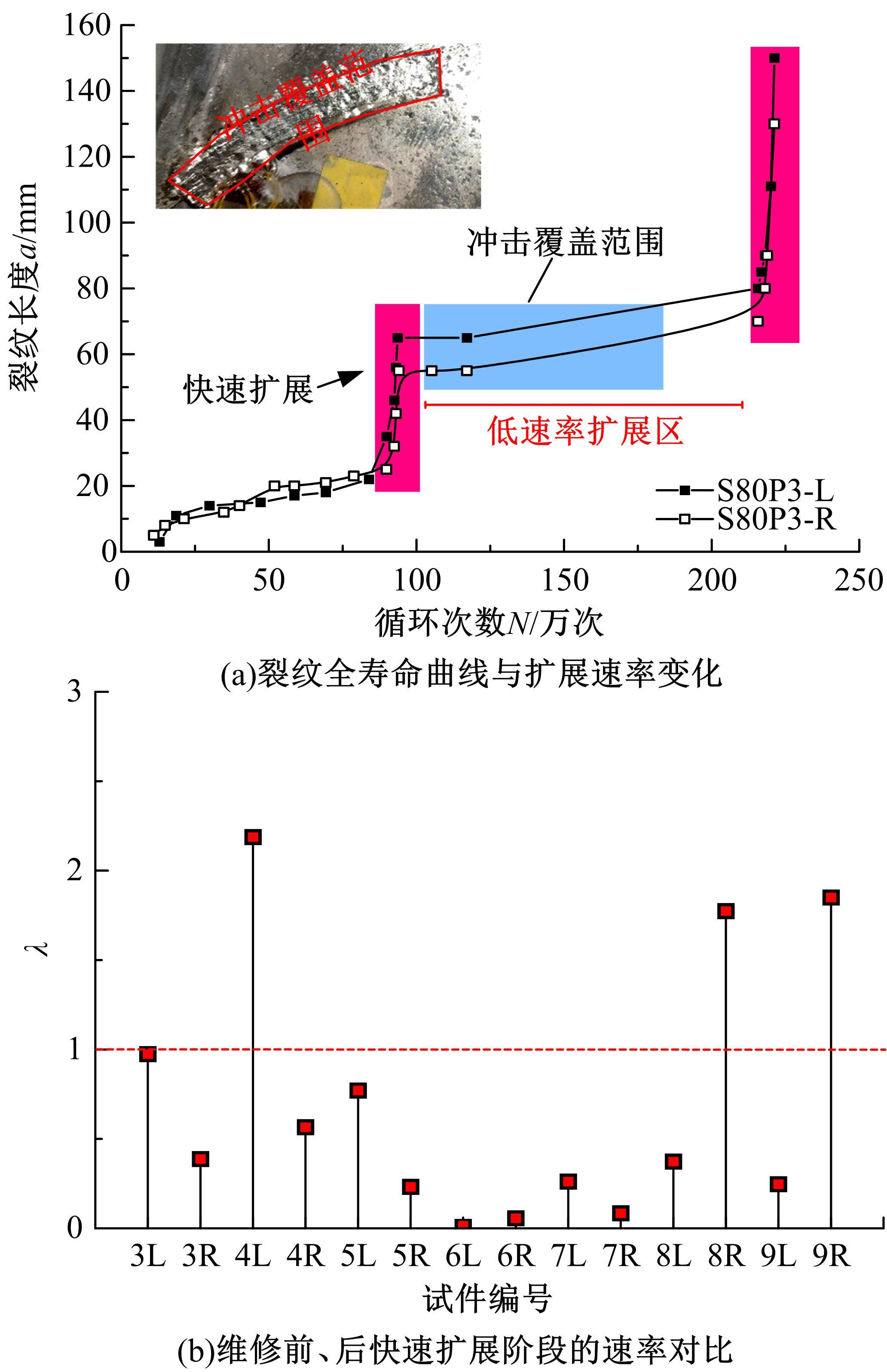

| 15 | Yuanzhou Z Y, Ji B H, Fu Z Q, et al. Retarding effects on crack propagation by closing crack surface using ICR treatment[J]. Journal of Constructional Steel Research, 2018, 143: 11-17. |

| 16 | Yamada K, Ishikawa T, Kakiichi T. Rehabilitation and improvement of fatigue life of welded joints by ICR treatment[J]. Advanced Steel Construction, 2015, 11(3): 294-304. |

| 17 | Yuanzhou Z Y, Ji B H, Fu Z Q, et al. Fatigue performance of cracked rib-deck welded joint retrofitted by ICR technique[J]. International Journal of Steel Structures, 2016, 16(3): 735-742. |

| 18 | Wang Q D, Ji B H, Fu Z Q, et al. Effect of crack-closure treatment on fatigue durability of cracked rib-to-deck welded joints in steel bridge decks[J]. Journal of Central South University, 2019, 26(9): 2554-2568. |

| 19 | . 桥梁用结构钢 [S]. |

| 20 | 孔祥明, 吉伯海, 傅中秋, 等. 钢桥面板典型细节疲劳应力及变形特征分析[J]. 工业建筑, 2017, 47(5):6-11. |

| Kong Xiang-ming, Ji Bo-hai, Fu Zhong-qiu, et al. Research on fatigue stress and deformation characteristics of typical details of steel bridge deck[J]. Industrial Construction, 2017, 47(5):6-11. | |

| 21 | . 公路桥梁钢箱梁疲劳裂纹检测、评定与维护规范 [S]. |

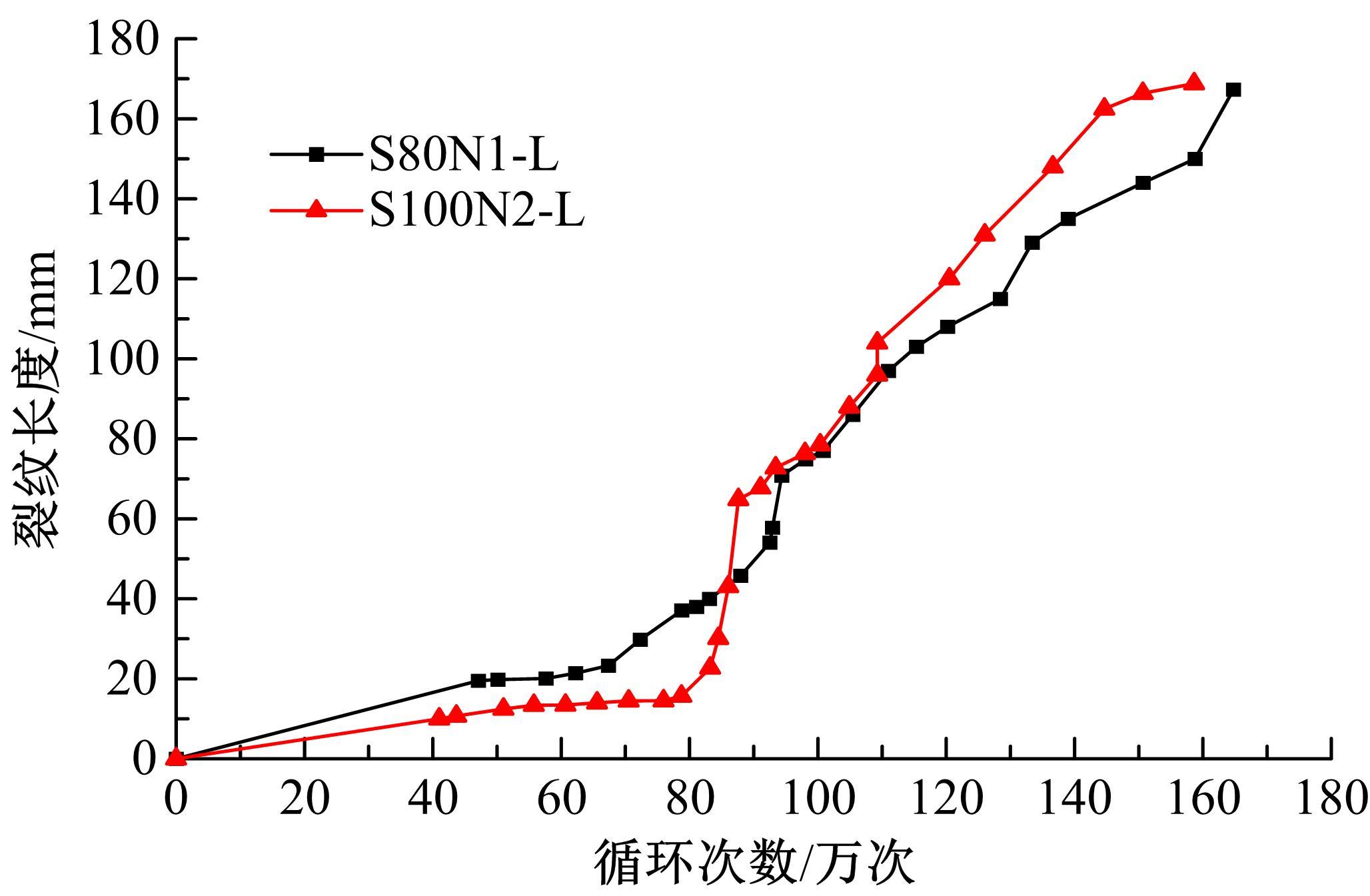

| 22 | 宗亮. 基于断裂力学的钢桥疲劳裂纹扩展与寿命评估方法研究[D]. 北京: 清华大学土木水利学院, 2015: 73-74. |

| Zong Liang. Investigation on fatigue crack propagation and life prediction of steel bridges based on fracture mechanics[D]. Beijing: School of Civil Engineering, Tsinghua University, 2015: 73-74. | |

| 23 | . 公路钢结构桥梁设计规范 [S]. |

| 24 | 陈一馨, 吕彭民, 李大涛. U肋与横隔板焊接构造细节疲劳强度研究[J]. 桥梁建设, 2014, 44(3): 63-68. |

| Chen Yi-xin, Peng-min Lü, Li Da-tao. Study of fatigue strength of structural details of u-rib and diaphragm welding joints[J]. Bridge Construction, 2014, 44(3): 63-68. | |

| 25 | 陈念念. 钢箱梁U肋与横隔板连接部位疲劳开裂钢板加固技术研究[D]. 南京: 河海大学土木与交通学院,2021. |

| Chen Nian-nian. Study on fatigue cracking steel plate reinforcement technology of connection between u-rib and diaphragm on steel box girder[D]. Nanjing: College of Civil and Transportation Engineering, Hohai University, 2021. |

| [1] | Zhi-qiang HAN,Gang XIE,Yong-jun ZHOU,Shi-zhong LIU,Min-jie JIN. Numerical analysis method of vehicle⁃bridge coupling vibration of curved bridge [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(2): 515-522. |

| [2] | Guo-jun YANG,Qi-wei TIAN,Ming-hang LYU,Yong-feng DU,Guang-wu TANG,Zong-jian HAN,Yi-duo FU. Review of mechanic characteristics of tunnel⁃type anchorage of long⁃span suspension bridge [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(6): 1245-1263. |

| [3] | Chun-liang LI,Zhi-hao LIN,Luo-luo ZHAO. Effect of damaged hinge joint and damaged slab on transverse force of hollow slab bridge [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(2): 611-619. |

| [4] | YU Tian-lai, LIU Xing-guo, YAO Shuang, Muhammad Mansour. Fatigue performance of RC beams strengthened with externally prestressed CFRP tendons [J]. 吉林大学学报(工学版), 2016, 46(6): 1867-1873. |

| [5] | LIU Zhen-tao, SUN Zhao-hui, PAN Jun, HUANG Rui, CHEN Jun-xuan, YU Xiao-li. Effects of mechanical constraints on the cylinder head thermal fatigue simulation test [J]. 吉林大学学报(工学版), 2015, 45(5): 1450-1454. |

| [6] | LIU Ke-Ge, YAN Chu-Liang. Probability distribution of fatigue test data and fatigue life of aircraft structure [J]. 吉林大学学报(工学版), 2011, 41(02): 419-0423. |

| [7] | CHEN Jun, HUANG Xiao-Ming. Virtual fatigue test of asphalt mixture based on discrete element method [J]. 吉林大学学报(工学版), 2010, 40(02): 435-0440. |

| [8] | Shi Qi-yin,Lu Ming,Zhang Qing-zong,Li Ai-qun,Hui Zhuo . Bending fatigue behavior of RC crane beam strengthened with carbon fiber reinforced plastic [J]. 吉林大学学报(工学版), 2008, 38(01): 99-104. |

|