Journal of Jilin University(Engineering and Technology Edition) ›› 2019, Vol. 49 ›› Issue (4): 1221-1227.doi: 10.13229/j.cnki.jdxbgxb20180703

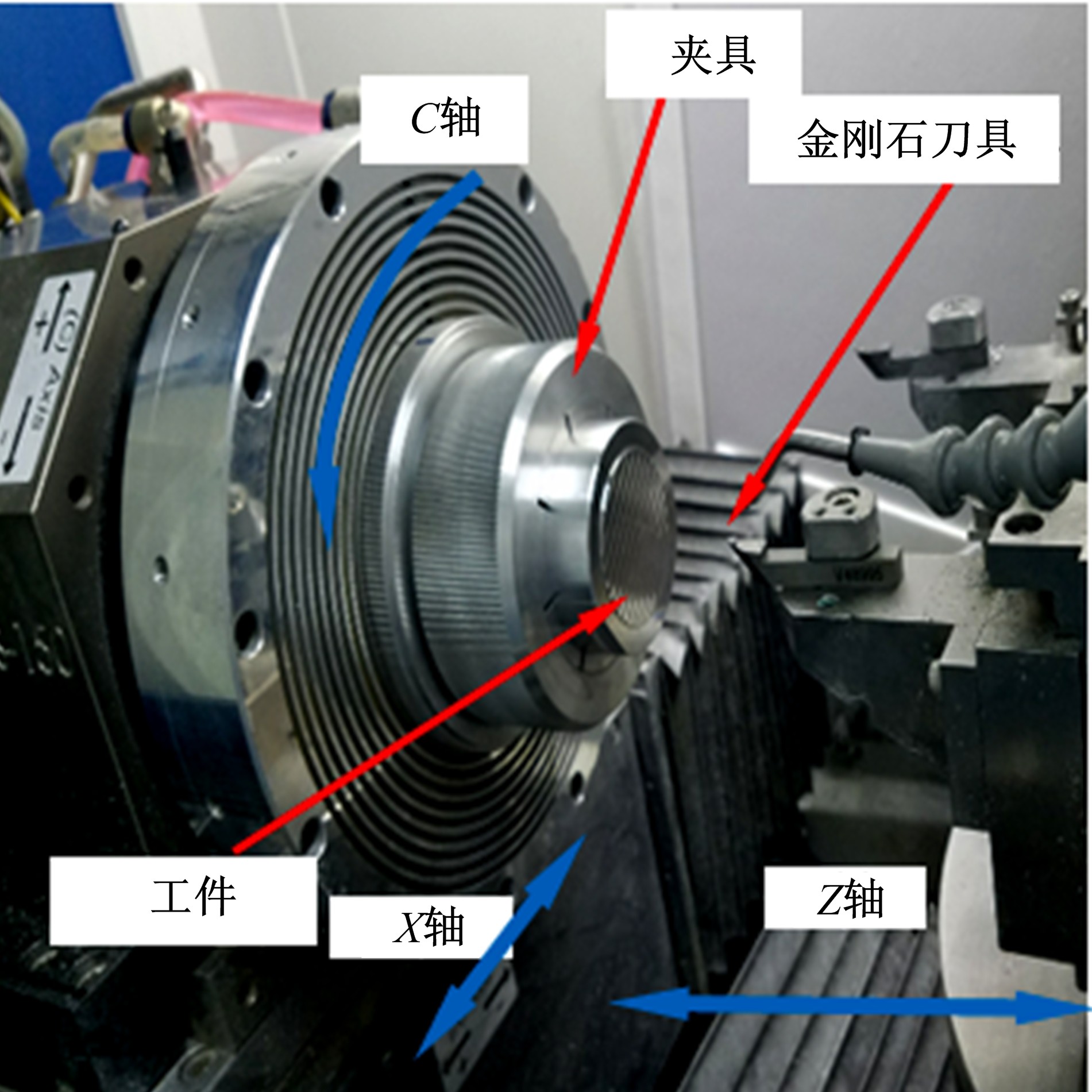

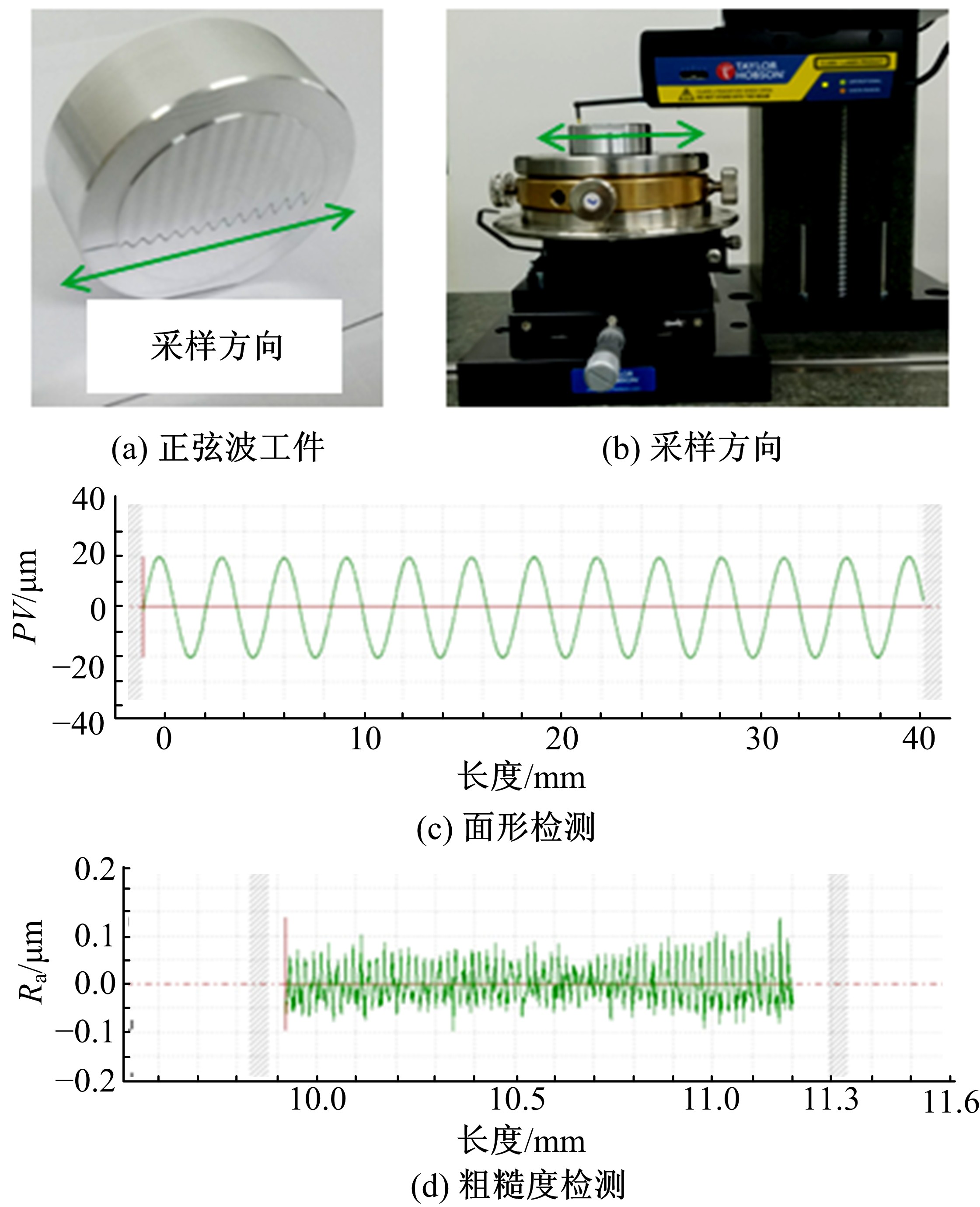

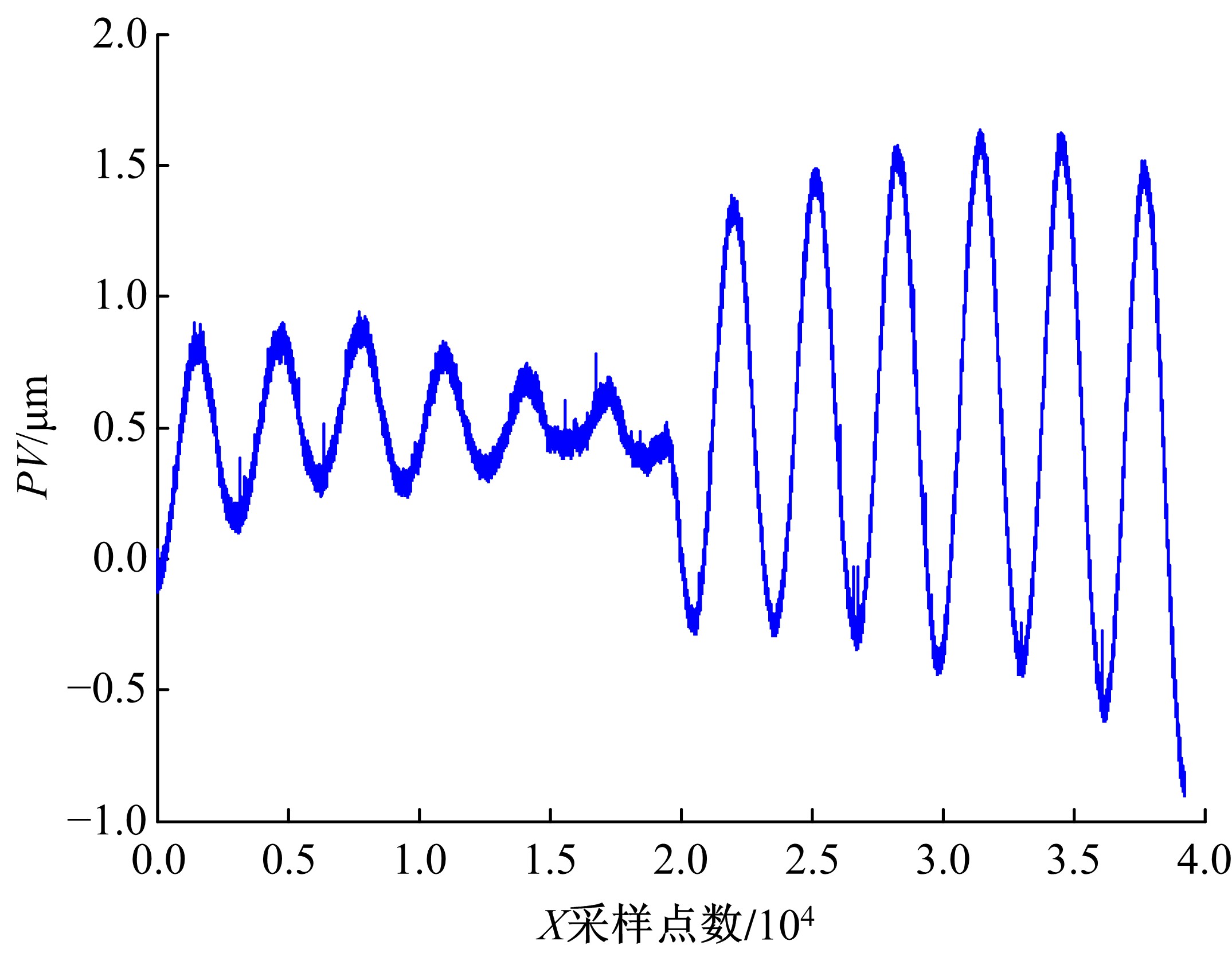

Tool path generation of slow tool servo for active control machining error

- College of Mechanical and Electric Engineering,Changchun University of Science and Technology,Changchun 130022,China

CLC Number:

- TH161

| 1 | 周晓勤, 侯强, 刘强, 等 . 微纳结构几何特征检测技术的研究现状与发展趋势[J]. 北京工业大学学报, 2015, 41(3): 327⁃339. |

| Zhou Xiao⁃qin , Hou Qiang , Liu Qiang , et al . Research status and tendency of measurement techniques for geometric features of micro/nano structures[J]. Journal of Beijing University of Technology, 2015, 41(3): 327⁃339. | |

| 2 | 樊成, 赵继, 张雷, 等 . 移动抛光自由曲面材料去除的理论建模与试验研究[J]. 机械工程学报, 2014, 50(5): 173⁃181. |

| Fan Cheng , Zhao Ji , Zhang Lei , et al . Modeling and experimental study on the material removal in the velocity⁃dwell⁃mode polishing process[J]. Journal of Mechanical Engineering, 2014, 50(5): 173⁃181. | |

| 3 | 刘源, 曹喜滨, 王永章, 等 . 具有自光顺功能的五坐标样条插补控制器[J]. 吉林大学学报: 工学版, 2011, 41(4): 1010⁃1014. |

| Liu Yuan , Cao Xi⁃bin , Wang Yong⁃zhang , et al . Spline interpolation controller with fairing function for five⁃axis machining[J]. Journal of Jilin University (Engineering and Technology Edition), 2011, 41(4): 1010⁃1014. | |

| 4 | 王兴盛, 康敏 . 基于Hermite插值的复杂光学曲面车削加工路径规划[J]. 机械工程学报, 2012, 48(11): 191⁃198. |

| Wang Xing⁃sheng , Kang Min . Cutting path planning for complex optical surface using hermite interpolation[J]. Journal of Mechanical Engineering, 2012, 48(11): 191⁃198. | |

| 5 | 车翔玖, 刘大有, 王钲旋 . 两张 NURBS 曲面间G1光滑过渡曲面的构造[J]. 吉林大学学报: 工学版, 2007, 37(4): 838⁃841. |

| Che Xiang⁃jiu , Liu Da⁃you , Wang Zheng⁃xuan . Construction of joining surface with G1 continuity for two NURBS surfaces[J]. Journal of Jilin University (Engineering and Technology Edition), 2007, 37(4): 838⁃841. | |

| 6 | Chrisp M P , Primeau B , Echter M A . Imaging freeform optical systems designed with NURBS surfaces[J]. Optical Engineering, 2016, 55(7): 071208. |

| 7 | 李荣彬, 张志辉, 杜雪, 等 . 自由曲面光学的超精密加工技术及其应用[J]. 红外与激光工程, 2010, 39(1): 110⁃115. |

| Li Rong⁃bin , Zhang Zhi⁃hui , Du Xue , et al . Ultra⁃precision machining technology of freeform optics and its applications[J]. Infrared and Laser Engineering, 2010, 39(1): 110⁃115. | |

| 8 | 田欣, 丁辉, 程凯 . 光学自由曲面机床检测系统静态几何误差快速辨识方法研究[J]. 航空精密制造技术, 2018(3): 11⁃15. |

| Tian Xin , Ding Hui , Cheng Kai . Swift identification method for identifying static geometric errors of ultraprecision machine tool[J]. Aviation Precision Manufacturing Technology, 2018(3): 11⁃15. | |

| 9 | 姚红兵, 丁勇, 辛忠华, 等 . 独立自由曲面LED汽车前雾灯的光学设计[J]. 应用光学, 2018, 39(3):423⁃428. |

| Yao Hong⁃bing , Ding Yong , Xin Zhong⁃hua , et al . Optical design of independent freeform surface LED automotive front fog lamp[J]. Journal of Applied Optics, 2018, 39(3): 423⁃428. | |

| 10 | Tan Gao⁃shan , Zhang Li⁃yuan , Liu Sheng⁃lan , et al . A fast and differentiated localization method for complex surfaces inspection[J]. International Journal of Precision Engineering and Manufacturing, 2015, 16(13): 2631⁃2639. |

| 11 | Kawabata K , Tanaka F , Onosato M . A study on tool path generation for freeform surface by iso⁃scallop strategy using tensor analysis[C]∥JSPE Semestrial Meeting, Osaka, Japan, 2017. |

| 12 | Yang T , Zhu J , Wu X F , et al . Direct design of freeform surfaces and freeform imaging systems with a point⁃by⁃point three⁃dimensional construction⁃iteration method[J]. Optics Express, 2015, 23(8): 10233⁃10246. |

| 13 | Yu D P , Gan S W , Wong Y S , et al . Optimized tool path generation for fast tool servo diamond turning of micro⁃structured surfaces[J]. International Journal of Advanced Manufacturing Technology, 2012, 63(9): 1137⁃1152. |

| 14 | Wang Xing⁃sheng , Fu Xiu⁃qing , Li Chun⁃lin , et al . Tool path generation for slow tool servo turning of complex optical surfaces[J]. The International Journal of Advanced Manufacturing Technology, 2015, 79(1): 437⁃448. |

| 15 | Ji Shi⁃jun , Yu Hui⁃juan , Zhao Ji , et al . Ultra⁃precision machining of a large amplitude sinusoidal ring surface based on slow tool servo[J]. Strojniski Vestnik, 2016, 62(4): 213⁃219. |

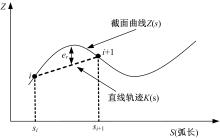

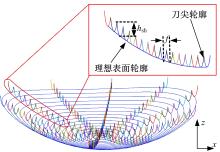

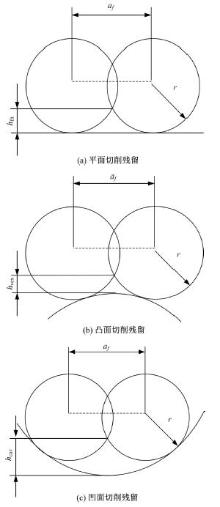

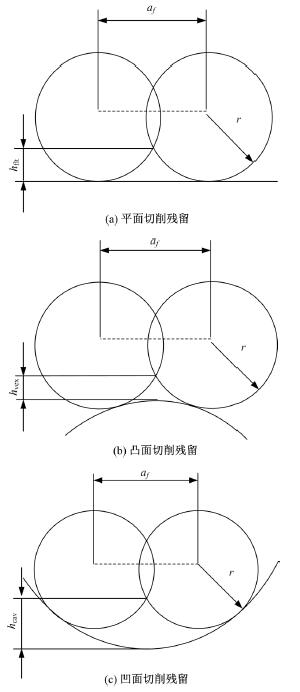

| 16 | Neo D W K , Kumar A S , Rahman M . A novel surface analytical model for cutting linearization error in fast tool/slow slide servo diamond turning[J]. Precision Engineering, 2014, 38(4): 849⁃860. |

| 17 | Kong L B , Cheung C F , To S , et al . A theoretical and experimental investigation of design and slow tool servo machining of freeform progressive addition lenses (PALs) for optometric applications[J]. International Journal of Advanced Manufacturing Technology, 2014, 72(1):33⁃40. |

| 18 | Liu Qiang , Zhou Xiao⁃qin , Xu Peng⁃zi . A new tool path for optical freeform surface fast tool servo diamond turning[J]. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 2014, 228(12): 1721⁃1726. |

| [1] | ZHENG Yu-bin, YANG Bin, WANG Xiao-feng, SHEN Gui-xiang, ZHAO Xian-zhuo, QIN Meng-meng. Test time design of motorized spindle accelerated life test based on Weibull distribution [J]. 吉林大学学报(工学版), 2018, 48(3): 767-772. |

| [2] | SHEN Gui-xiang, ZENG Wen-bin, ZHANG Ying-zhi, WU Mao-kun, ZHENG Yu-bin. Determination of average maintenance time of CNC machine tools under minimum failure rate [J]. 吉林大学学报(工学版), 2017, 47(5): 1519-1526. |

| [3] | QU Xing-tian, ZHAO Yong-bing, LIU Hai-zhong, WANG Xin, YANG Xu, CHEN Hang-de. Modeling and experiment of spatial geometric errors of hybrid serial-parallel machine tool [J]. 吉林大学学报(工学版), 2017, 47(1): 137-144. |

| [4] | ZHANG Ying-zhi, LIU Jin-tong, SHEN Gui-xiang, QI Xiao-yan, LONG Zhe. Reliability modeling of CNC machine tools system based on failure correlation analysis [J]. 吉林大学学报(工学版), 2017, 47(1): 169-173. |

| [5] | MENG Shu, SHEN Gui-xiang, ZHANG Ying-zhi, LONG Zhe, ZENG Wen-bin. Replacement time of system components of NC machine tools based on time-correlation [J]. 吉林大学学报(工学版), 2016, 46(6): 1946-1952. |

| [6] | LI Hong-zhou, YANG Zhao-jun, XU Bin-bin, WANG Yan-kun, JIA Yu-hui, HOU Chao. Design of testing period for reliability assessment of NC machine tools [J]. 吉林大学学报(工学版), 2016, 46(5): 1520-1527. |

| [7] | WANG Jian-jian, FENG Ping-fa, ZHANG Jian-fu, WU Zhi-jun, ZHANG Guo-bin, YAN Pei-long. Modeling of centering accuracy of chuck and its maintaining characteristics and restoration method [J]. 吉林大学学报(工学版), 2016, 46(2): 487-493. |

| [8] | WANG Yan-zhong, HOU Liang-wei, LYU Qing-jun, ZHAO Xing-fu, WU Can-hui. Processing technology of face gear complex surface based on bus control [J]. 吉林大学学报(工学版), 2015, 45(6): 1836-1843. |

| [9] | YANG Zhao-jun, YANG Chuan-gui, CHEN Fei, HAO Qing-bo, ZHENG Zhi-tong, WANG Song. Parameter estimation of reliability model of machining center based on particle swarm optimization and support vector regression [J]. 吉林大学学报(工学版), 2015, 45(3): 829-836. |

| [10] |

WANG Xiao-yan,SHEN Gui-xiang,ZHANG Ying-zhi, SUN Shu-guang,QI Xiao-yan,RONG Feng. Dependent coefficient model for complex system based on failure chains [J]. 吉林大学学报(工学版), 2015, 45(2): 442-447. |

| [11] | ZHAO Guo-juan, ZHANG Lei, LU Lei, HAN Fei-fei, ZHAO Ji. Modeling and analysis of the volumetric errors of four-axis polishing platform [J]. 吉林大学学报(工学版), 2014, 44(6): 1676-1683. |

| [12] | on improved EM algorithm. Reliability modeling of finite Weibull distribution based [J]. 吉林大学学报(工学版), 2014, 44(4): 1010-1015. |

| [13] | YANG Zhao-jun, YANG Chuan-gui, CHEN Fei, WANG Dong-liang, MA Shuai, LIU Bo. Optimization of the electro-hydraulic servo loading based on least square and SVDUKF algorithms [J]. 吉林大学学报(工学版), 2014, 44(2): 392-397. |

| [14] | CHEN Chuan-hai, YANG Zhao-jun, CHEN Fei, HAO Qing-bo, XU Bin-bin, KAN Ying-nan. Reliability modeling of machining center spindle based on Boosttrap-Bayes [J]. 吉林大学学报(工学版), 2014, 44(01): 95-100. |

| [15] | SHEN Gui-xiang, MENG Shu, ZHANG Ying-zhi, QI Xiao-yan, LUAN Lan, SONG Qi. Application of average rank time method in reliability modeling for subsystems [J]. 吉林大学学报(工学版), 2014, 44(01): 101-105. |

|

||