Journal of Jilin University(Engineering and Technology Edition) ›› 2019, Vol. 49 ›› Issue (5): 1630-1635.doi: 10.13229/j.cnki.jdxbgxb20181222

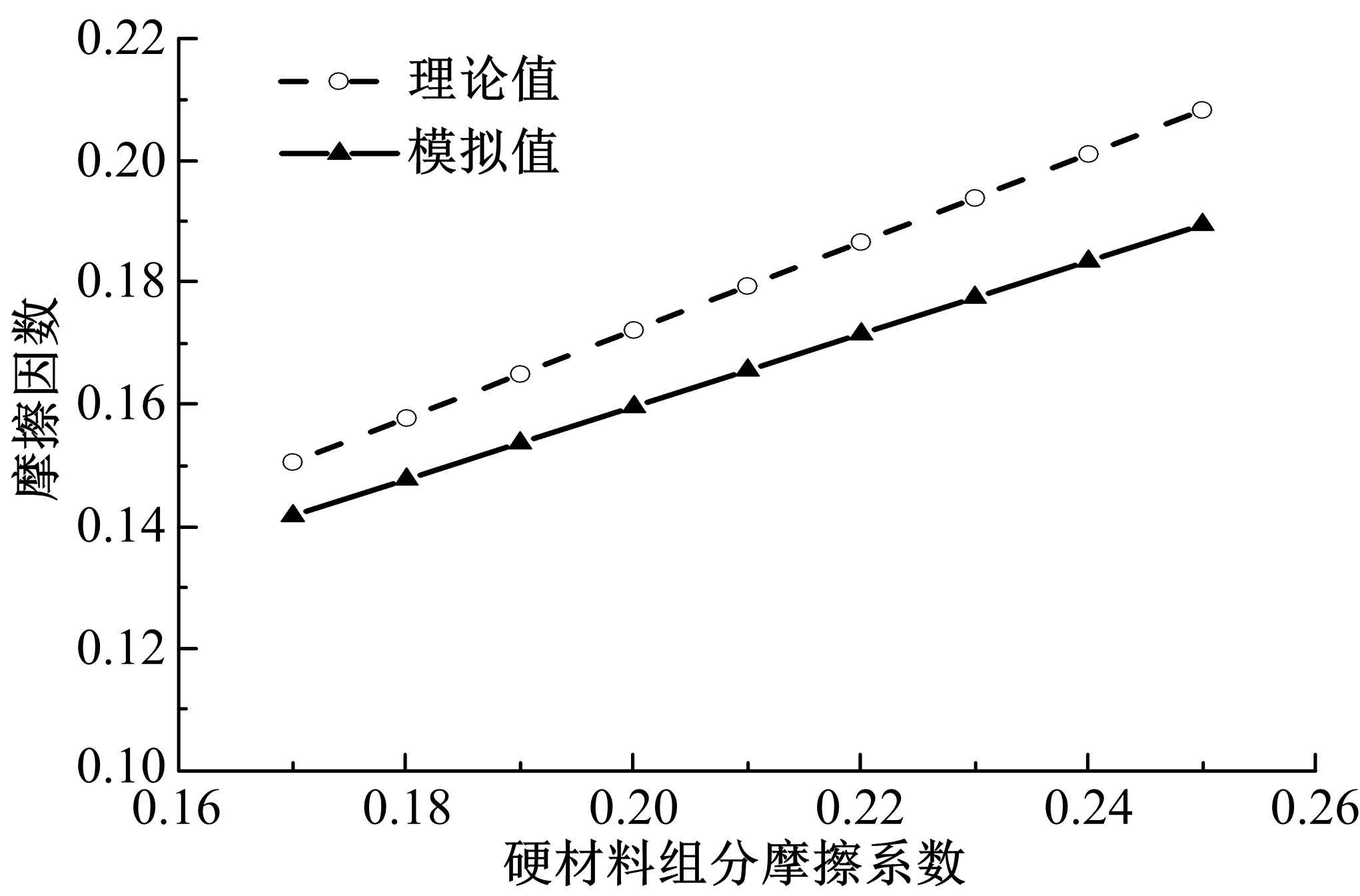

Influence factors upon friction coefficient of bioinspired materials with integrated soft and hard layers

Mi WANG1,2( ),Zhi-yuan LI1,Wen-xuan FAN1,Jia-yi LI1,Zhen-ning LIU1,Guo-long LU1(

),Zhi-yuan LI1,Wen-xuan FAN1,Jia-yi LI1,Zhen-ning LIU1,Guo-long LU1( )

)

- 1. Key Laboratory for Bionic Engineering Ministry of Education, Jilin University, Changchun 130022, China

2. College of Engineering, Changchun Normal University, Changchun 130032, China

CLC Number:

- TB33

| 1 | 史正良, 刘金龙, 宋明, 等. 人工髋关节摩擦学的研究现状[J]. 中国组织工程研究, 2008, 12(4): 731-734. |

| ShiZheng-liang, LiuJin-long, SongMing, et al. Research progress in tribology of artificial hip joint[J]. Journal of Clinical Rehabilitative Tissue Engineering Research, 2008, 12(4): 731-734. | |

| 2 | GeorgeM. Rigid biological systems as models for synthetic composites[J]. Science, 2005, 310(5751): 1144-1147. |

| 3 | AbbaM T, HungerP M, KalidindiS R, et al. Nacre-like hybrid films: structure, properties, and the effect of relative humidity[J]. Journal of the Mechanical Behavior of Biomedical Materials, 2015, 55: 140-150. |

| 4 | KatharineS. Structure: artificial armour[J]. Nature, 2015, 519(7455): 14,15. |

| 5 | GongS, CuiW, ZhangQ, et al. Integrated ternary bioinspired nanocomposites via synergistic toughening of reduced graphene oxide and double-walled carbon nanotubes[J]. Acs Nano, 2015, 9(12): 11568-11573. |

| 6 | KeC, ShiB, YueY, et al. Binary synergy strengthening and toughening of bio-inspired nacre-like graphene oxide/sodium alginate composite paper[J]. Acs Nano, 2015, 9(8): 8165-8175. |

| 7 | 陈莉. 激光仿生非光滑表面热作模具的磨料磨损性能研究[D]. 长春: 吉林大学材料科学与工程学院, 2007. |

| ChenLi. Study on the grinding abrasion of hot die with bionic non-smooth surface[D]. Changchun: College of Materials Science and Engineering, Jilin University, 2007. | |

| 8 | ShanH, ZhouH, SunN, et al. Study on adhesion resistance behavior of sample with striated non-smooth surface by laser processing technique[J]. Journal of Materials Processing Technology, 2008, 199(1-3): 221-229. |

| 9 | 孙娜. 不同仿生耦合单元体对蠕墨铸铁摩擦磨损性能的影响[D]. 长春: 吉林大学材料科学与工程学院, 2010. |

| SunNa. Influences of various biomimetic coupling units on the friction and wear behaviors of compacted graphite cast iron[D].Changchun: College of Materials Science and Engineering, Jilin University, 2010. |

| [1] | ZHAO Jian, ZHANG Jin, ZHU Bing. Fuzzy sliding mode traction control based on road friction coefficient estimation [J]. 吉林大学学报(工学版), 2015, 45(4): 1036-1042. |

| [2] | ZHENG Hong-yu, CHEN Guo-ying, SUN Lin-lin, KONG Fan-sen, HE Lei, ZONG Chang-fu. Tire-road friction coefficient estimation based on steer-by-wire system [J]. 吉林大学学报(工学版), 2014, 44(2): 292-295. |

| [3] | ZHANG Kuo, TAN Qing-chang, WANG Shun, WANG Cong-hui, Bian Li-juan. Friction coefficient in rough soft contact lubrication [J]. 吉林大学学报(工学版), 2012, 42(增刊1): 86-90. |

|

||