Journal of Jilin University(Engineering and Technology Edition) ›› 2020, Vol. 50 ›› Issue (5): 1627-1634.doi: 10.13229/j.cnki.jdxbgxb20190588

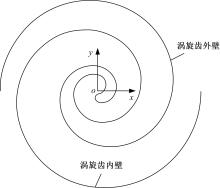

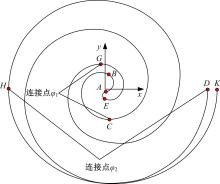

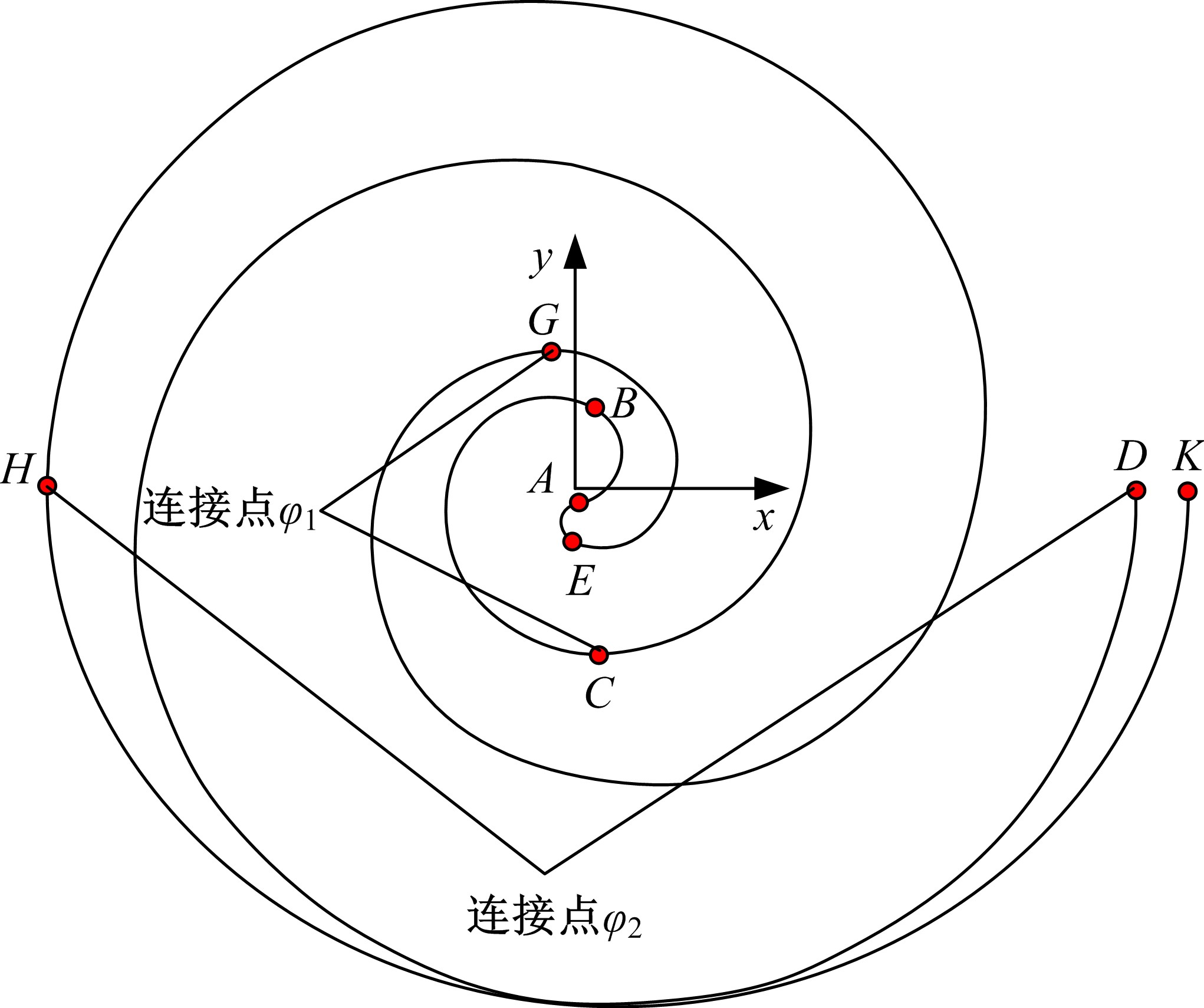

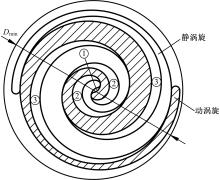

Construction theories of a new type of variable wall thickness scroll profile

Cai-sheng HOU( ),Tao LIU(

),Tao LIU( ),Li-xian GUO

),Li-xian GUO

- School of Mechanical and Electrical Engineering,Lanzhou University of Technology,Lanzhou 730050,China

CLC Number:

- TH45

| 1 | Wang J, Liu Q, Cao C Y, et al. Design methodology and geometric modeling of complete meshing profiles for scroll compressors[J]. International Journal of Refrigeration, 2018, 91: 199-210. |

| 2 | 程哲铭, 欧阳新萍, 雷蓉. 涡旋式压缩机涡旋型线的研究综述与前景[J]. 流体机械, 2015, 43(1): 51-56. |

| Cheng Zhe-ming, Ouyang Xin-ping, Lei Rong. Overview and prospect of the research on profile of scroll compressor [J]. Fluid Machinery, 2015, 43(1): 51-56. | |

| 3 | Ivlev V I, Misyurin S Y. Calculated and experimental characteristics of a scroll machine operating in the air motor mode[J]. Doklady Physics, 2017, 62(1): 42-45. |

| 4 | Emhardt S, Tian G H, Chew J. A review of scroll expander geometries and their performance[J]. Applied Thermal Engineering, 2018, 141: 1020-1034. |

| 5 | Byrne P, Ghoubali R, Miriel J. Scroll compressor modelling for heat pumps using hydrocarbons as refrigerants[J]. International Journal of Refrigeration, 2014, 41: 1-13. |

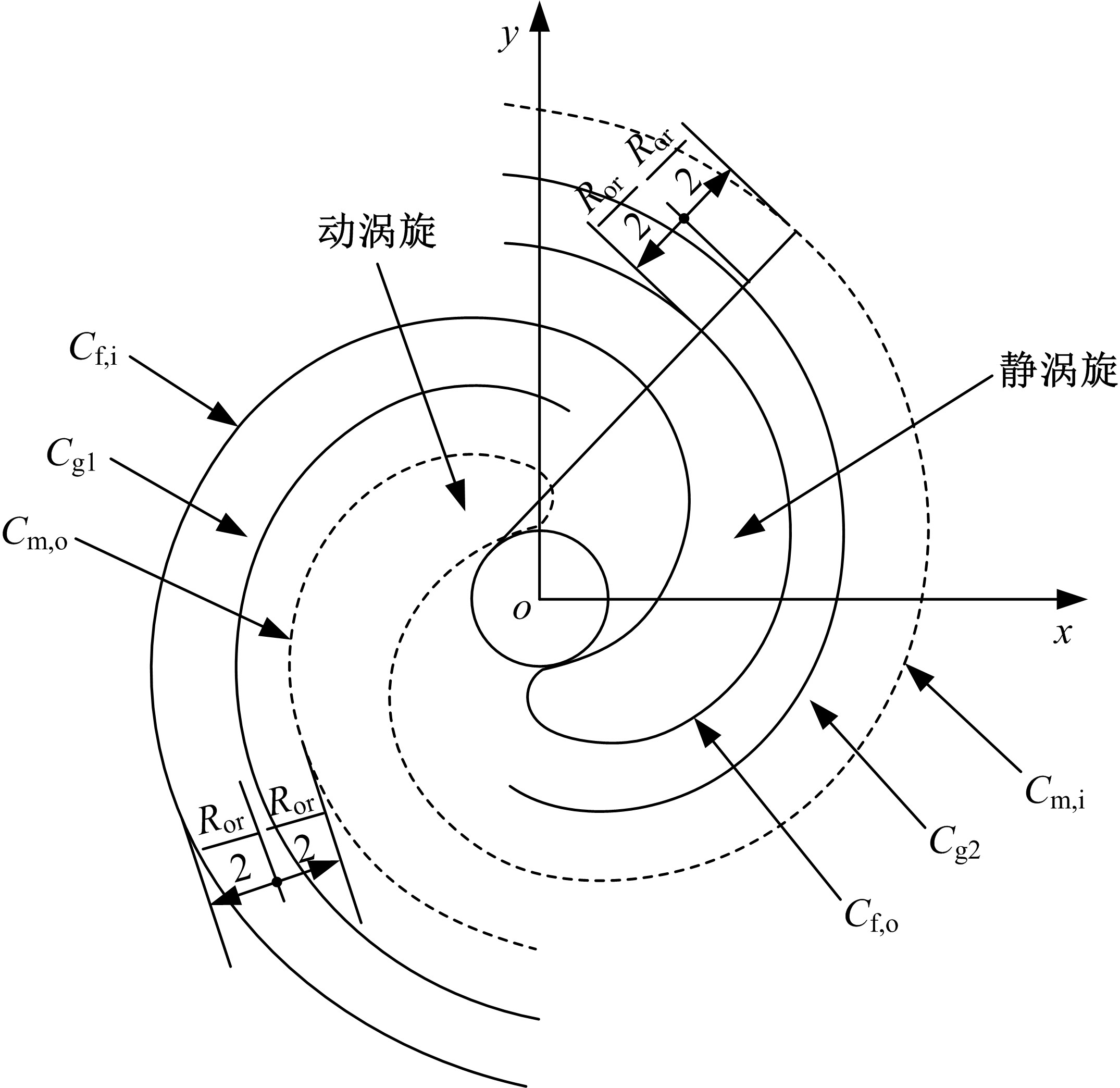

| 6 | 王君, 查海滨, 张晓慧, 等. 一种渐变啮合间隙的变壁厚涡旋齿型线研究[J]. 工程热物理学报, 2013, 34(8): 1453-1456. |

| Wang Jun, Zha Hai-bin, Zhang Xiao-hui, et al. Investigation of tapered meshing clearance and thickness scroll wrap[J]. Journal of Engineering Thermophysics, 2013, 34(8): 1453-1456. | |

| 7 | 刘涛, 侯富勇, 李传恒. 三段基圆渐开线涡旋型线的多目标遗传算法优化[J]. 流体机械, 2015, 43(8): 32-35. |

| Liu Tao, Hou Fu-yong, Li Chuan-heng. Multi-objective genetic algorithm based optimization of scroll wraps with three involutes of circle[J]. Fluid Machinery, 2015, 43(8): 32-35. | |

| 8 | 彭斌, 孙迎. 变截面涡旋压缩机数学模型及试验研究[J]. 机械工程学报, 2015, 51(14): 185-191. |

| Peng Bin, Sun Ying. Investigation of mathematical modeling and experiment for variable thickness scroll compressor[J]. Journal of Mechanical Engineering, 2015, 51(14): 185-191. | |

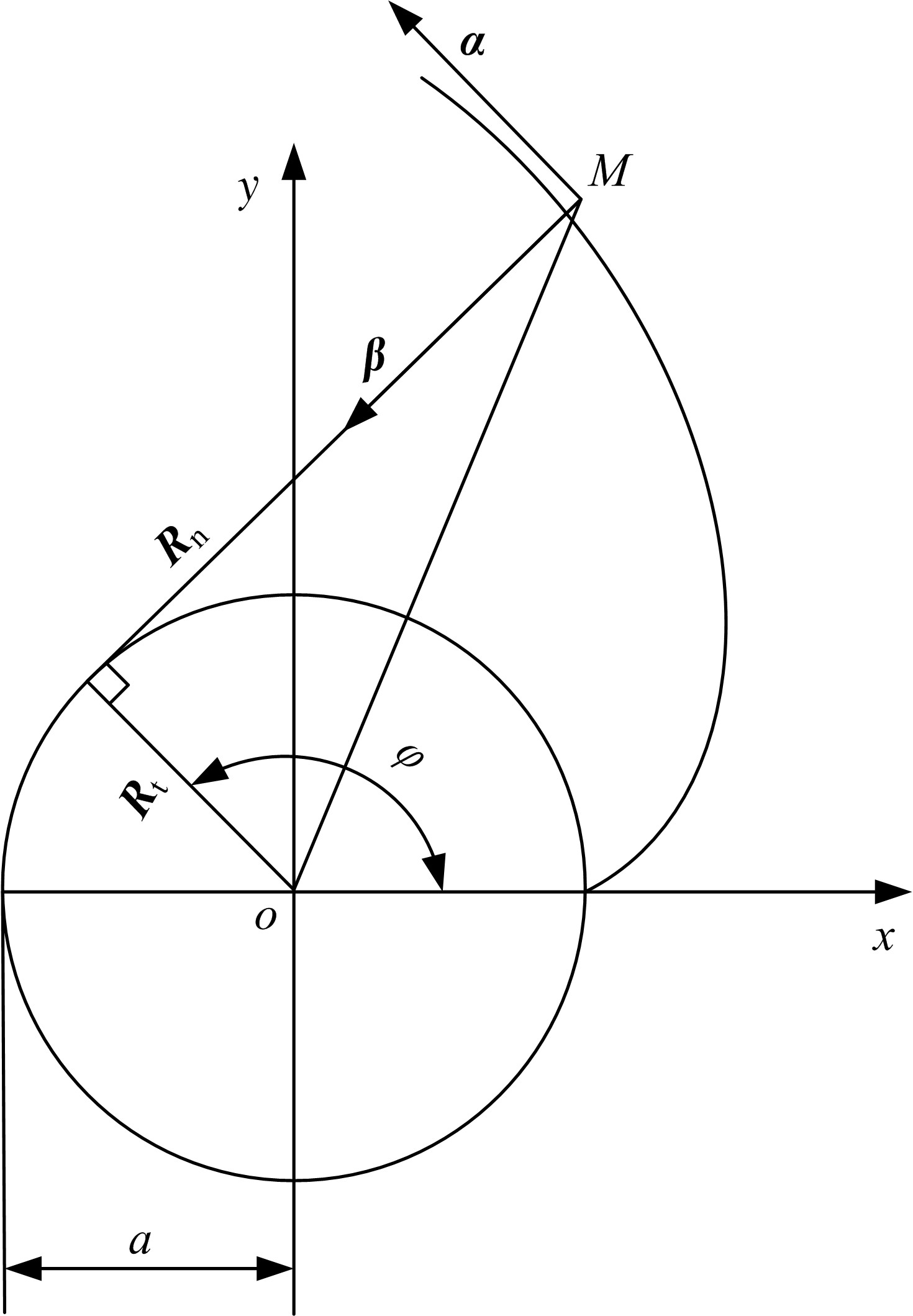

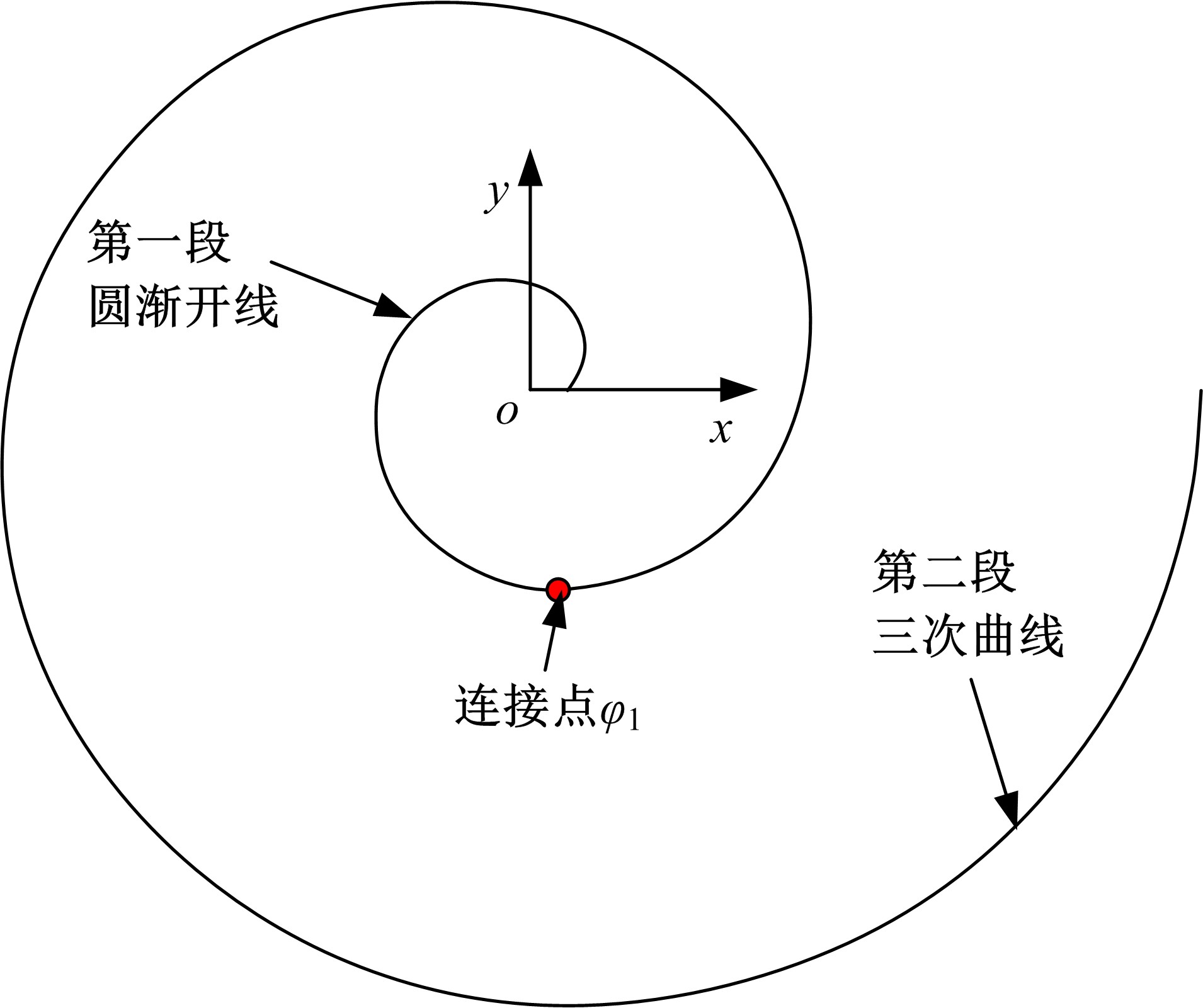

| 9 | 侯才生, 刘涛. 基于Frenet标架的变截面涡旋压缩机型线的研究[J]. 华中科技大学学报: 自然科学版, 2019, 47(2): 76-80. |

| Hou Cai-sheng, Liu Tao. Investigation of scroll profiles for variable cross-section scroll compressor based on Frenet frame[J]. Journal of Huazhong University of Science and Technology(Natural Science Edition), 2019, 47(2): 76-80. | |

| 10 | 陈进, 张永栋, 宋立权, 等. 基于多目标遗传算法的涡旋型线形状优化[J]. 机械工程学报, 2005, 41(1): 172-175. |

| Chen Jin, Zhang Yong-dong, Song Li-quan, et al. Profile optimization of scrolls based on multiobjective genetic algorithms[J]. Chinese Journal of Mechanical Engineering, 2005, 41(1): 172-175. | |

| 11 | 刘涛, 智建超. 型线曲率半径变化对涡旋压缩机性能的影响[J]. 压缩机技术, 2016(4): 1-5, 11. |

| Liu Tao, Zhi Jian-chao. Effect of profile curvature on performance of scroll compressor[J]. Compressor Technology, 2016(4): 1-5, 11. | |

| 12 | 邬再新, 杜文武, 刘涛, 等. 渐开线—高次曲线组合型线涡旋压缩机的设计及有限元分析[J]. 压缩机技术, 2011(2): 5-9. |

| Wu Zai-xin, Du Wen-wu, Liu Tao, et al. Design of involute-higher curve combined profile for scroll compressor and finite element analysis[J]. Compressor Technology, 2011(2): 5-9. |

| [1] | Yan-qin ZHANG,Ya-nan FENG,Peng-rui KONG,Xiao-dong YU,Xiang-bin KONG. Temperature field and experiment of hydrostatic bearing oil film based on hot oil carrying [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1203-1211. |

| [2] | CHI Xue-fen, WU Di, LIU Dan. IBP+MMBP/Geo/1/K vacation queuing system with threshold [J]. 吉林大学学报(工学版), 2013, 43(03): 781-787. |

|

||