Journal of Jilin University(Engineering and Technology Edition) ›› 2019, Vol. 49 ›› Issue (4): 1203-1211.doi: 10.13229/j.cnki.jdxbgxb20180105

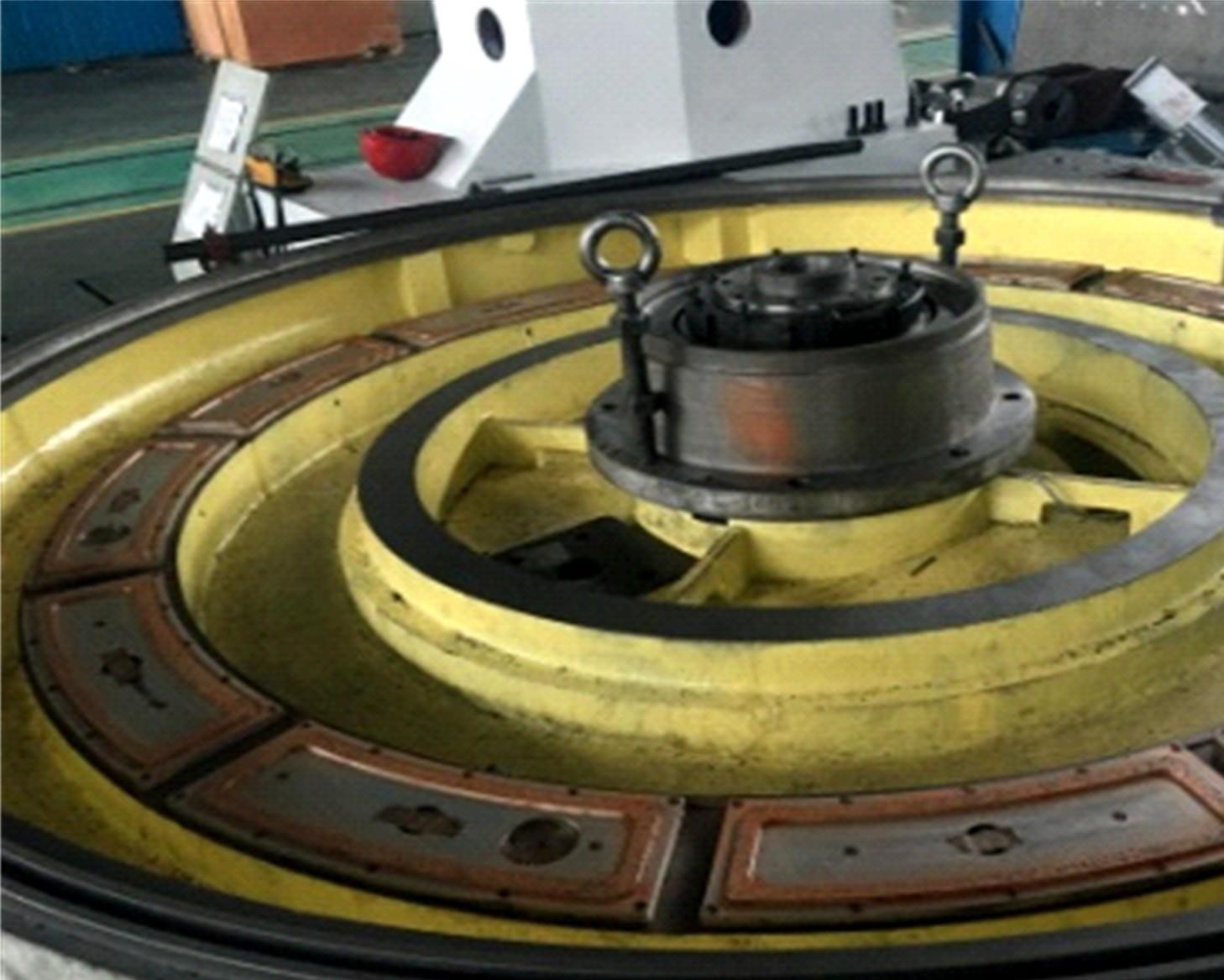

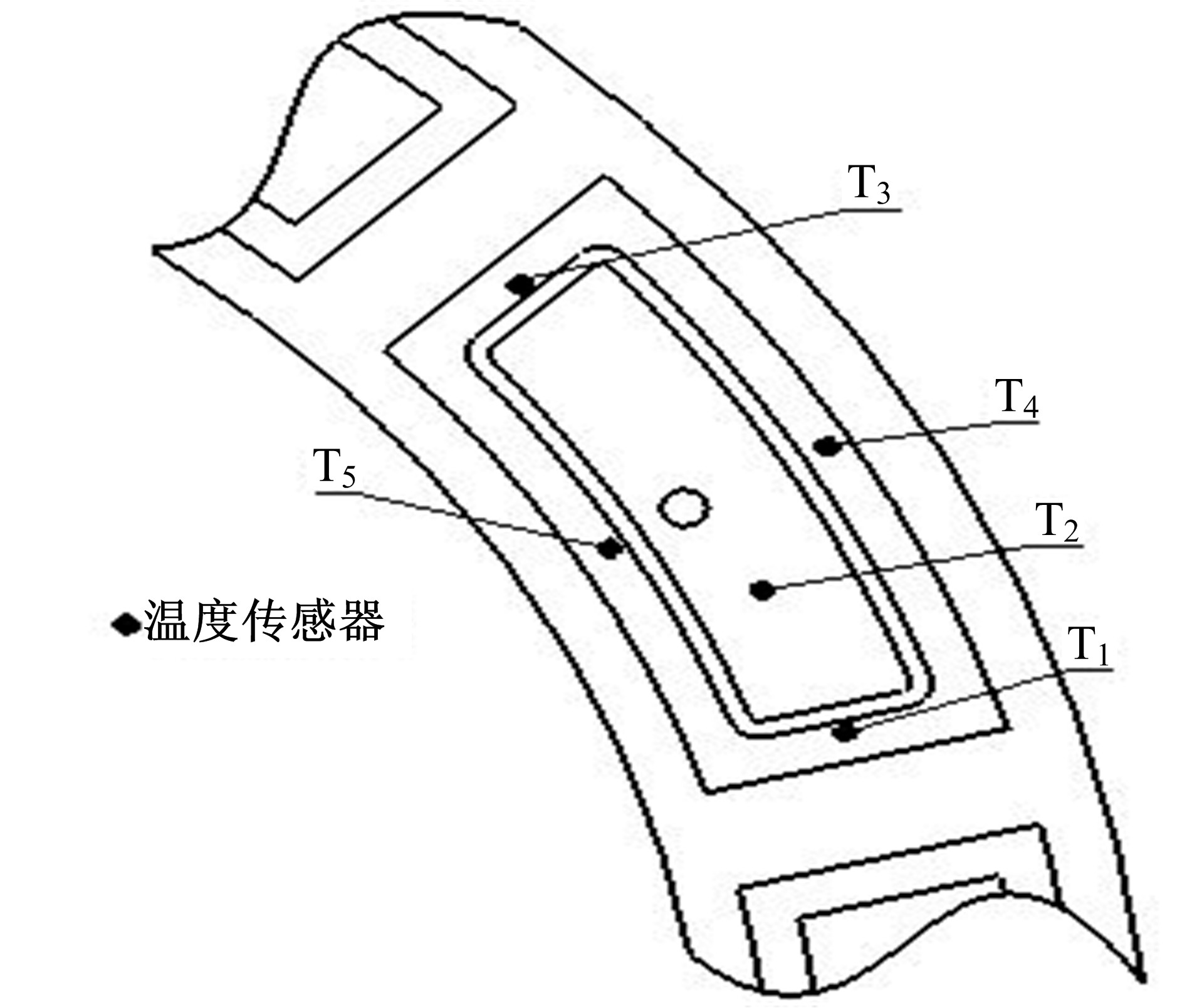

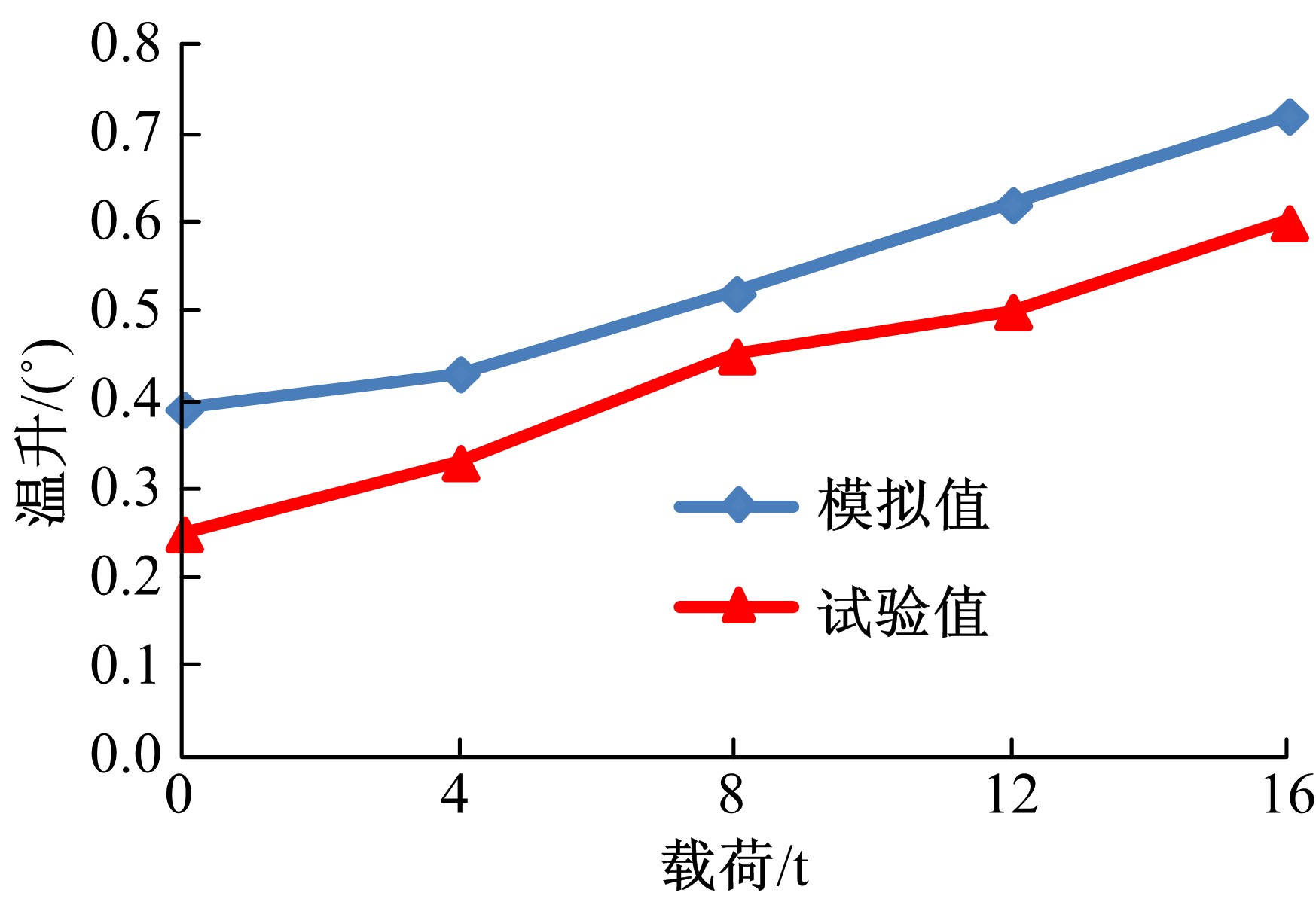

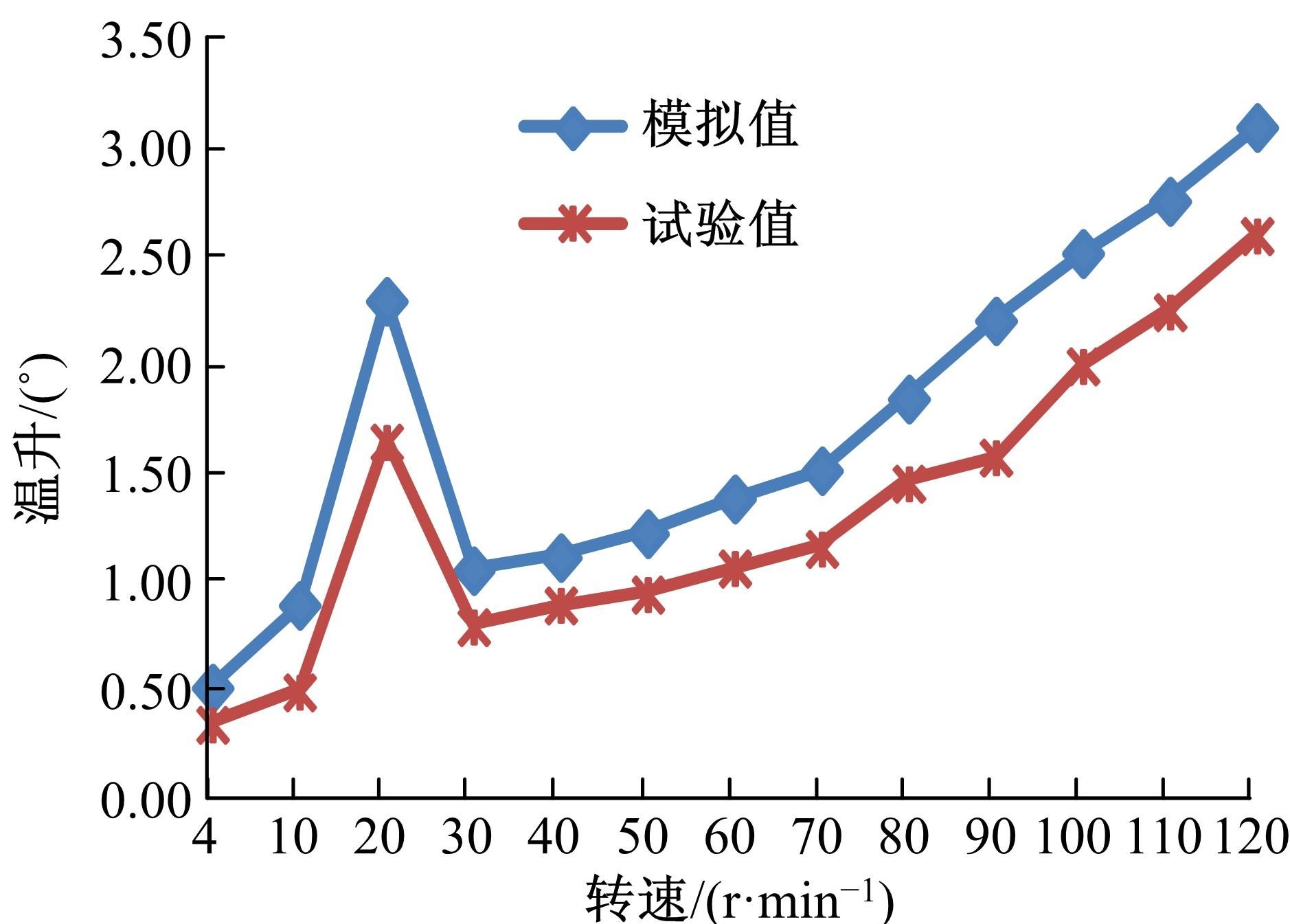

Temperature field and experiment of hydrostatic bearing oil film based on hot oil carrying

Yan-qin ZHANG1,2( ),Ya-nan FENG1,Peng-rui KONG1,Xiao-dong YU1,Xiang-bin KONG1

),Ya-nan FENG1,Peng-rui KONG1,Xiao-dong YU1,Xiang-bin KONG1

- 1. College of Mechanical and Power Engineering, Harbin University of Science and Technology, Harbin 150080, China

2. College of Mechanical Engineering, Nanjing Institute of Technology, Nanjing 211167, China

CLC Number:

- TH122

| 1 | 杜威 . 重型龙门数控机床静压导轨的热特性研究[D]. 北京: 北京工业大学机械工程与应用电子工程学院, 2013. |

| Du Wei . The thermal characteristic research of heavy-duty gantry cnc machine tool’ hydrostatic guideway[D]. Beijing: College of Mechanical Engineering and Applied Electronics Technology, Beijing University of Technology, 2013. | |

| 2 | 陈玲, 黄智, 衡凤琴, 等 . 大型车铣磨复合机床静压转台油膜热特性分析及其优化研究[J]. 机床与液压, 2016, 44(19): 109-114. |

| Chen Ling , Huang Zhi , Heng Feng-qin , et al . Thermal characteristics analysis and optimization study of hydrostatic rotary table oil film for large lathe milling and grinder compound machine tool[J]. Machine Tool & Hydraulics, 2016, 44(19): 109-114. | |

| 3 | Nelias D , Antaluca E , Boucly V . Rolling of an elastic ellipsoid upon an elastic-plastic flat[J]. Journal of Tribology, 2007, 129(4): 791-800. |

| 4 | Kim S , Cho J W . Thermal characteristic analysis of a high-precision centerless grinding machine for machining ferrules[J]. International Journal of Precision Engineering and Manufacturing, 2007, 8(1): 32-39. |

| 5 | Johansen P , Roemer D B , Pedersen H C , et al . Analytical thermal field theory applicable to oil hydraulic fluid film lubrication[C]∥Proceedings of the ASME/BATH Symposium on Fluid Power and Motion Control, Bath, England, 2014:1-8. |

| 6 | 彭育志, 明越, 肖金生, 等 . 活性炭/沸石层状床氢气纯化穿透曲线热效应[J]. 工程热物理学报, 2016, 37(7): 1511-1518. |

| Peng Yu-zhi , Ming Yue , Xiao Jin-sheng , et al . Thermal effects on hydrogen purification breakthrough curves of activated carbon/zeolite layered bed[J]. Journal of Engineering Thermophysics, 2016, 37(7): 1511-1518. | |

| 7 | 孟曙光, 熊万里, 王少力, 等 . 小孔节流深浅腔动静压轴承承载特性解析研究[J]. 机械工程学报, 2015, 51(22): 191-201. |

| Meng Shu-guang , Xiong Wan-li , Wang Shao-li , et al . Analytical research on characteristics of deep-shallow journal bearings with orifice restrictors[J]. Journal of Mechanical Engineering, 2015, 51(22): 191-201. | |

| 8 | 于晓东, 耿磊, 郑小军, 等 . 恒流环形腔多油垫静压推力轴承油膜刚度特性[J]. 哈尔滨工程大学学报, 2017, 38(12):1-6. |

| Yu Xiao-dong , Geng Lei , Deng Xiao-jun , et al . Oil film stiffness characteristics of constant fluid hydrostatic thrust bearing with annular cavity multi-pads[J]. Journal of Harbin Engineering University, 2017, 38(12):1-6. | |

| 9 | 于晓东, 高春丽, 邱志新, 等 . 高速重载静压推力轴承润滑性能研究[J].中国机械工程, 2013, 24(23): 3230-3234. |

| Yu Xiao-dong , Gao Chun-li , Qiu Zhi-xin , et al . Research on lubrication performance of high-speed heavy-duty hydrostatic thrust bearings[J]. China Mechanical Engineering, 2013, 24(23): 3230-3234. | |

| 10 | 于晓东, 孙丹丹, 吴晓刚, 等 . 环形腔多油垫静压推力轴承膜厚高速重载特性[J]. 推进技术, 2016, 37(7): 1350-1355. |

| Yu Xiao-dong , Sun Dan-dan , Wu Xiao-gang , et al . High speed and heavy load characteristic on oil film thickness of annular recess multi-pad hydrostatic thrust bearing[J]. Journal of Propulsion Technology, 2016, 37(7): 1350-1355. | |

| 11 | 谢方伟, 侯友夫, 张立强, 等 . 液粘传动变形界面间油膜温度场实验研究[J]. 中南大学学报, 2015, 34(11): 1733-1737. |

| Xie Fang-wei , Hou You-fu , Zhang Li-qiang , et al . Experimental research on oil film temperature field of hydro-viscous drive between deformed interfaces[J]. Journal of Central South University, 2015, 34(11): 1733-1737. | |

| 12 | Zhang Yan-qin , Fan Li-guo , Yu Xiao-dong , et al . Simulation and experimental analysis on supporting characteristics of multiple oil pad hydrostatic bearing disk[J]. Journal of Hydrodynamics, 2013, 25(2): 236-241. |

| 13 | Zhang Yan-qin , Fan Li-guo , Chen Yao . Simulation and experimental study of lubrication characteristics of vertical hydrostatic guide rail[J]. High Technology Letters, 2014, 20(3): 315-320. |

| 14 | Zhang Yan-qin , Fan Li-guo . Simulation and experimental analysis of influence of inlet flow on heavy hydrostatic bearing temperature field[J]. Asian Journal of Chemistry, 2014, 26(17): 5478-5482. |

| 15 | 张艳芹 . 重型静压推力轴承综合物理场研究[D]. 哈尔滨:哈尔滨理工大学机械动力工程学院, 2009. |

| Zhang Yan-qin . Integrated physical field research of heavy hydrostatic thrust bearing[D]. Harbin: School of Mechanical and Power Engineering, Harbin University of Science and Technology, 2009. | |

| 16 | 李海宁, 张晓青, 李奎, 等 . 动磁直线压缩机气体轴承特性的CFD模拟[J]. 工程热物理学报, 2013, 34(6): 1026-1030. |

| Li Hai-ning , Zhang Xiao-qing , Li Kui , et al . CFD simulation of gas bearing characteristic for a moving-magnet linear compressor[J]. Journal of Engineering Hermophysics, 2013, 34(6): 1026-1030. | |

| 17 | Yadav S K , Sharma S C . Performance of hydrostatic tilted thrust pad bearings of various recess shapes operating with non-Newtonian lubricant[J]. Finite Elements in Analysis and Design, 2014, 87: 43-55. |

| [1] | Yu⁃peng LI,Da⁃qian SUN,Wen⁃biao GONG. Temperature fields in bobbin⁃tool friction stir welding for 6082⁃T6 aluminum alloy sheet [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(3): 836-841. |

| [2] | LIU Zhi-feng, ZHAO Dai-hong, WANG Yu-mo, HUN Lian-ming, ZHAO Yong-sheng, DONG Xiang-min. Relationship between bearing capacity of heavy machine hydrostatic rotary table and temperature field distribution of oil pad [J]. 吉林大学学报(工学版), 2018, 48(3): 773-780. |

| [3] | LIU Ying, ZHANG Kai, YU Xiang-jun. Multi-objective optimization of hydrostatic bearing of hollow shaft based on surrogate model [J]. 吉林大学学报(工学版), 2017, 47(4): 1130-1137. |

| [4] | WANG Guo-lin, SUN Yan-tian, LIANG Chen, YANG Jian, ZHOU Hai-chao. Contour design of radial tire based on full stress theory [J]. 吉林大学学报(工学版), 2017, 47(2): 365-372. |

| [5] | SHAO Qing, XU Tao, XU Cong-zhan, GUO Hao-tian, GUO Gui-kai, ZHANG Hai-bo. Simulation of angular contact ball bearing characteristics with PEEK cage [J]. 吉林大学学报(工学版), 2017, 47(1): 163-168. |

| [6] | JIANG Feng-guo, ZHAO Jing-lu, ZHENG Zhong-yuan. Reliability analysis of steel columns exposed to fire by load and resistance factor design [J]. 吉林大学学报(工学版), 2014, 44(4): 978-984. |

| [7] | SHI Dong-yong, YING Liang, HU Ping, SHEN Guo-zhe, WU Wen-hua, JIANG Da-xin. Numerical simulation of 3D temperature field in hot forming of high strength steel [J]. 吉林大学学报(工学版), 2014, 44(4): 946-952. |

| [8] | CHEN Yan-hong, WU Wei-jing, LIU Hong-wei, SHEN Shuai, LI Ce-yuan, GENG Huan-liang. Thermal characteristics of battery for pure electric vehicles [J]. 吉林大学学报(工学版), 2014, 44(4): 925-932. |

| [9] | JIANG Feng-guo, ZHAO Jing-lu. Reliability analysis of reinforced concrete member under fire load [J]. 吉林大学学报(工学版), 2013, 43(06): 1500-1503. |

| [10] | YUAN Zhe, MA Wen-xing, LIU Chun-bao, LIU Hao. Temperature field analysis of the open-type hydrodynamic retarder of heavy vehicle [J]. 吉林大学学报(工学版), 2013, 43(05): 1271-1275. |

| [11] | KOU Shu-Qing, WANG Jin-Wei, ZHAO Yong, YANG Shen-Hua. Numerical simulation of pulsed laser processing conrod fracture splitting notch [J]. 吉林大学学报(工学版), 2010, 40(05): 1256-1261. |

| [12] | LI Yong-qiang, ZHAO He, ZHAO Xi-hua, ZHANG Wei-hua. Numerical simulation of RSW temperature field during mild steel LB-RSW [J]. 吉林大学学报(工学版), 2010, 40(03): 709-0713. |

| [13] | Li Rui; Ma Hong-an; Han Qi-gang;Ren Guo-zhong;Yin Bin-hua; Liu Wan-qiang;Jia Xiao-peng . Analysis of temperature field in diamond synthetic chamber based on ANSYS [J]. 吉林大学学报(工学版), 2008, 38(03): 535-0538. |

| [14] |

Feng Wei, Wu Zhi-jun, Deng Jun, Li Li-guang .

Numerical simulation of temperature field in controllable active thermoatmosphere combustor [J]. 吉林大学学报(工学版), 2007, 37(03): 513-0517. |

| [15] |

Deng Jun,Wu Zhi-jun,Li Li-guang,Huang Cheng-jie,Feng Wei .

Development of experimental system of novel controllable active thermoatmosphere combustor [J]. 吉林大学学报(工学版), 2007, 37(02): 307-0312. |

|

||