Journal of Jilin University(Engineering and Technology Edition) ›› 2021, Vol. 51 ›› Issue (3): 840-846.doi: 10.13229/j.cnki.jdxbgxb20200109

Previous Articles Next Articles

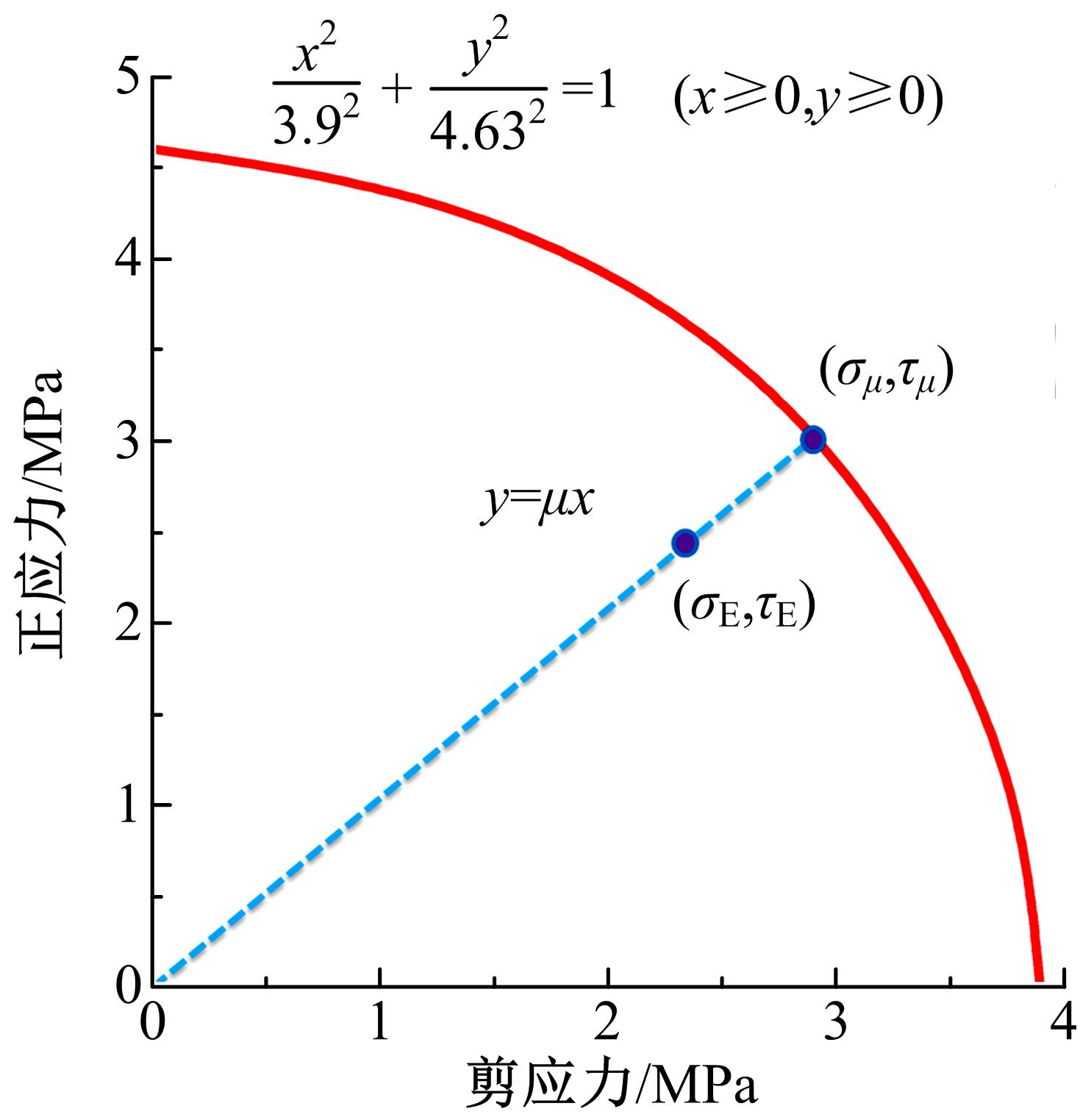

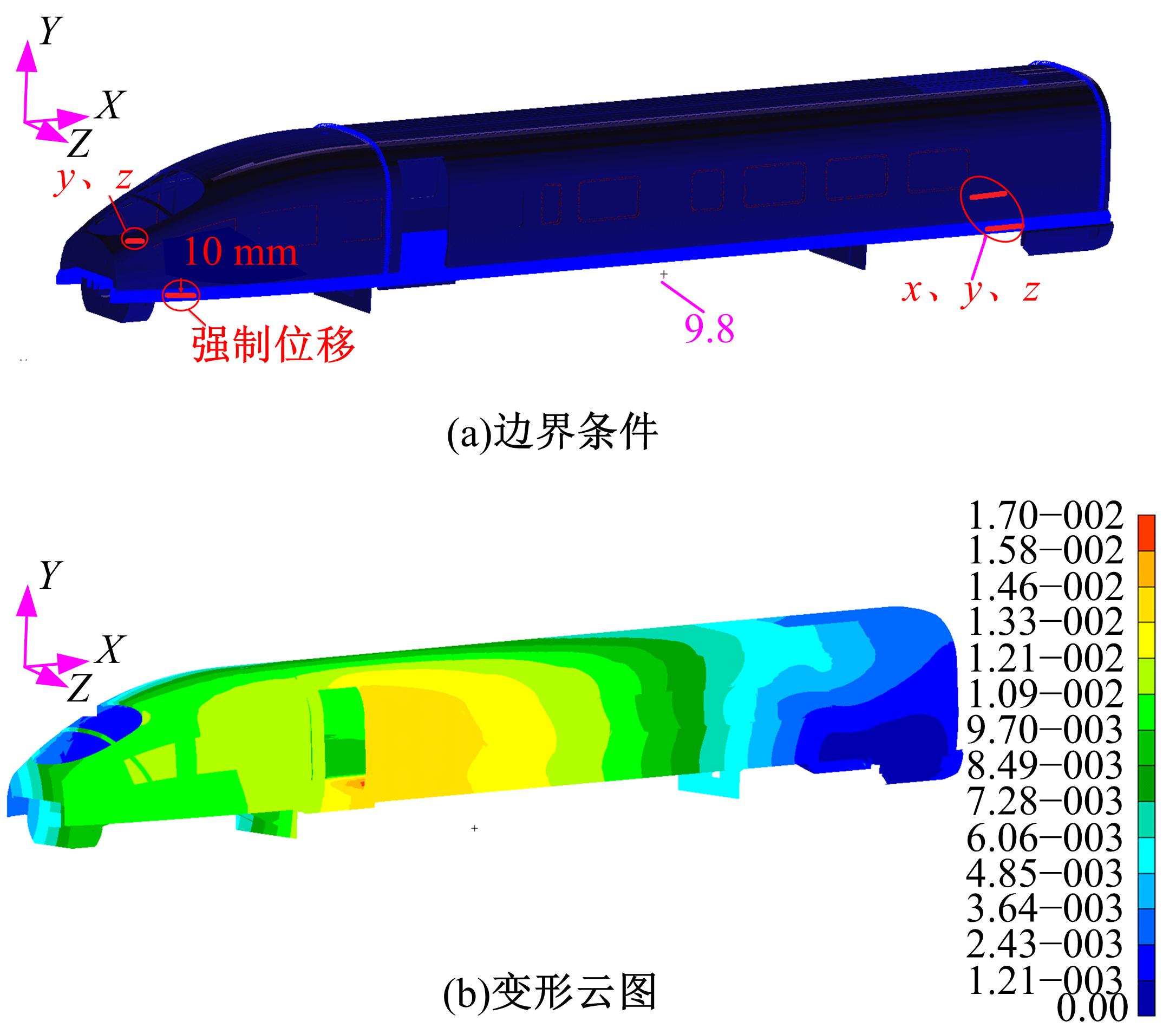

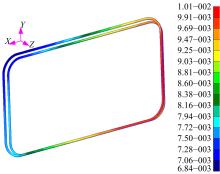

Method for checking bonding strength of high⁃speed EMU side window based on residual strength

Yi-sa FAN1( ),Jing-xin NA2,Lin-jian SHANGGUAN1(

),Jing-xin NA2,Lin-jian SHANGGUAN1( )

)

- 1.School of Mechanical Engineering,North China University of Water Resources and Electric Power,Zhengzhou 450045,China

2.State Key Laboratory of Automotive Simulation and Control,Jilin University,Changchun 130022,China

CLC Number:

- U266.2

| 1 | Marques E A S, da Silva L F M, Banea M D, et al. Adhesive joints for low-and high-temperature use: an overview[J]. The Journal of Adhesion, 2015,91(7):556-585. |

| 2 | Xu W, Wei Y G. Assessments for impact of adhesive properties: modeling strength of metallic single lap joints[J]. Journal of Adhesion Science and Technology, 2013, 27(1):1-21. |

| 3 | 庄蔚敏, 施宏达, 解东旋,等. 钢铝异质无铆钉粘铆复合连接胶层厚度分布[J]. 吉林大学学报:工学版, 2020, 50(1):100-106. |

| Zhuang Wei-min,Shi Hong-da,Xie Dong-xuan, et al. Thickness distribution of adhesive layer in dissimilar clinch-adhesive hybrid joint with steel and aluminum alloy[J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(1):100-106. | |

| 4 | Kinloch A J. Toughening epoxy adhesives to meet today's challenges[J]. Mrs Bulletin, 2003, 28(6): 445-448. |

| 5 | Banea M D, da Silva L F M, Campilho R. Moulds design for adhesive bulk and joint specimens manufacturing[J]. Assembly Automation, 2012, 32(3):284-292. |

| 6 | 那景新, 刘浩垒, 范以撒, 等. 湿热环境对车用粘接剂拉伸强度的影响[J]. 吉林大学学报:工学版, 2019, 49(3):822-828. |

| Na Jing-xin,Liu Hao-lei,Fan Yi-sa, et al. Effect of hygrothermal environment on vehicle adhesive tensile strength[J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(3):822-828. | |

| 7 | Spiryagin M, Lee K S, Yoo H H, al et, Modeling of adhesion for railway vehicles[J]. Journal of Adhesive Science and Technology, 2008, 22(10):1017-1034. |

| 8 | Grant L D R, Adams R D, Silva L F M D. Effect of the temperature on the strength of adhesively bonded single lap and T joints for the automotive industry[J]. International Journal of Adhesion and Adhesives, 2009, 29(5):535-542. |

| 9 | He X, Gu F, Ball A. Fatigue behaviour of fastening joints of sheet materials and finite element analysis[J]. Advances in Mechanical Engineering, 2013, 2013(3):533-542. |

| 10 | Pulung N I, Arief B B, Muhammad A. Evaluation of bonding strength and fracture criterion for aluminum alloy-woven composite adhesive joint based on cohesive zone model[J]. International Journal of Adhesion and Adhesives, 2018, 85:193-201. |

| 11 | Hart-Smith L J. Adhesive-bonded single-lap joints[EB/OL]. [2020-02-02]. |

| 12 | Adams R D, Comyn J, Wake W C. Structural Adhesive Joints in Engineering[M]. Amsterdam: Elsevier Applied Science Publishers, 1997. |

| 13 | Adams R D, Harris J A. The influence of local geometry on the strength of adhesive joints[J]. International Journal of Adhesion and Adhesives, 1987, 7(2):69-80. |

| 14 | Alfano M, Furgiuele F, Leonardi A, et al. Mode I fracture of adhesive joints using tailored cohesive zone models[J]. International Journal of Fracture, 2009, 157(1):193-204. |

| 15 | Qiao Pi-zhong, Chen Ying. Cohesive fracture simulation and failure modes of FRP-concrete bonded interfaces[J]. Theoretical and Applied Fracture Mechanics, 2008, 49(2):213-225. |

| 16 | Feraren P, Jensen H M. Cohesive zone modelling of interface fracture near flaws in adhesive joints[J]. Engineering Fracture Mechanics, 2004, 71(15):2125-2142. |

| 17 | Moura M F S F D, Gonçalves J P M, Chousal J A G, et al. Cohesive and continuum mixed-mode damage models applied to the simulation of the mechanical behaviour of bonded joints[J]. International Journal of Adhesion and Adhesives, 2008, 28(8):419-426. |

| 18 | Abdel W M M, Ashcroft I A, Crocombe A D, et al. Prediction of fatigue thresholds in adhesively bonded joints using damage mechanics and fracture mechanics[J]. Journal of Adhesion Science and Technology, 2001, 15(7):763-781. |

| 19 | Abdel W M M, Hilmy I, Ashcroft I A, et al. Evaluation of fatigue damage in adhesive bonding: part 1: bulk adhesive[J]. Journal of Adhesion Science and Technology, 2010, 24(2):305-324. |

| 20 | Martiny P, Lani F, Kinloch A J, et al. A multiscale parametric study of mode I fracture in metal-to-metal low-toughness adhesive joints[J]. International Journal of Fracture, 2012, 173(2):105-133. |

| 21 | Weißgraeber P, Becker W. Finite fracture mechanics model for mixed mode fracture in adhesive joints[J]. International Journal of Solids and Structures, 2013, 50(14/15):2383-2394. |

| 22 | Hutchinson J W, Suo Z. Mixed mode cracking in layered materials[J]. Advances in Applied Mechanics, 1992, 29(8):63-191. |

| 23 | Wang C H, Rose L R F. Compact solutions for the corner singularity in bonded lap joints[J]. International Journal of Adhesion and Adhesives, 2000, 20(2):145-154. |

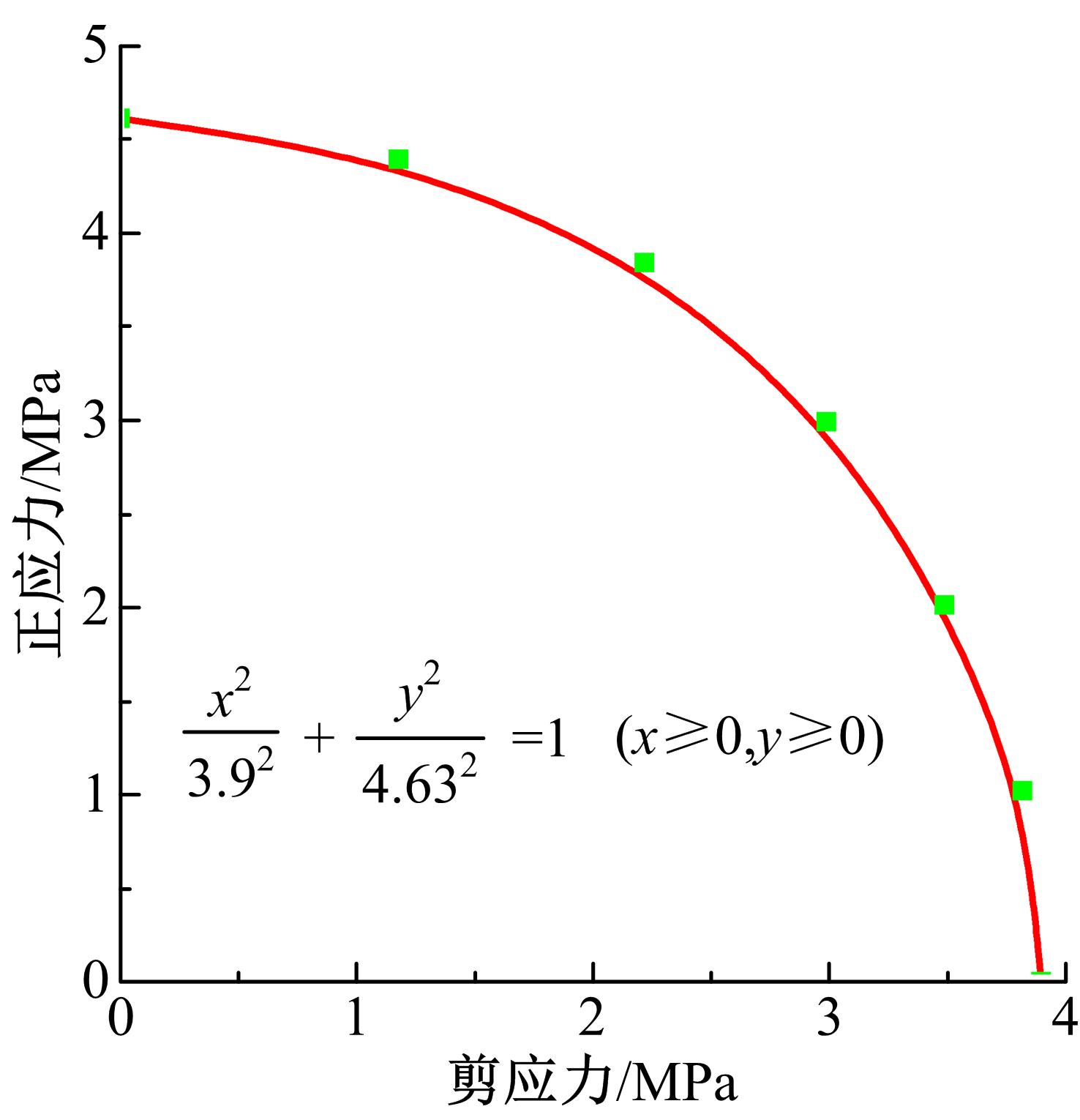

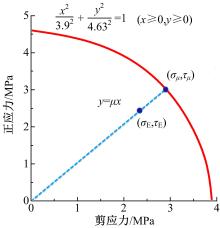

| 24 | Na J X, Liu Y, Cai L, et al. An adhesive joint strength evaluation method and its application in mechanical engineering[J]. Journal of Adhesive Science and Technology, 2015, 30(2):131-144. |

| 25 | . Ahesive bonding of railway vehicles and parts—part 2: qualification of manufacturer of adhesive bonded materials, quality assurance[S]. |

| 26 | Wang C H, Rose L R F. Compact solutions for the corner singularity in bonded lap joints[J]. International Journal of Adhesion and Adhesives, 2000, 20(20):145-154. |

| 27 | . 轨道车辆及部件的粘接[S]. |

| 28 | Na J X, Liu Y, Fan Y S, et al. Effect of temperature on the joint strength of a silyl modified polymer based adhesive[J]. The Journal of Adhesion, 2017,93(8): 626-639. |

| [1] | Wen-long MU,Jing-xin NA,Wei TAN,Guang-bin WANG,Hao SHEN,Jian-ze LUAN. Residual strength prediction of adhesive CFRP-aluminum alloy adhesively bonded joint based on FTIR analysis [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(1): 139-146. |

|

||