Journal of Jilin University(Engineering and Technology Edition) ›› 2021, Vol. 51 ›› Issue (3): 977-988.doi: 10.13229/j.cnki.jdxbgxb20200557

Previous Articles Next Articles

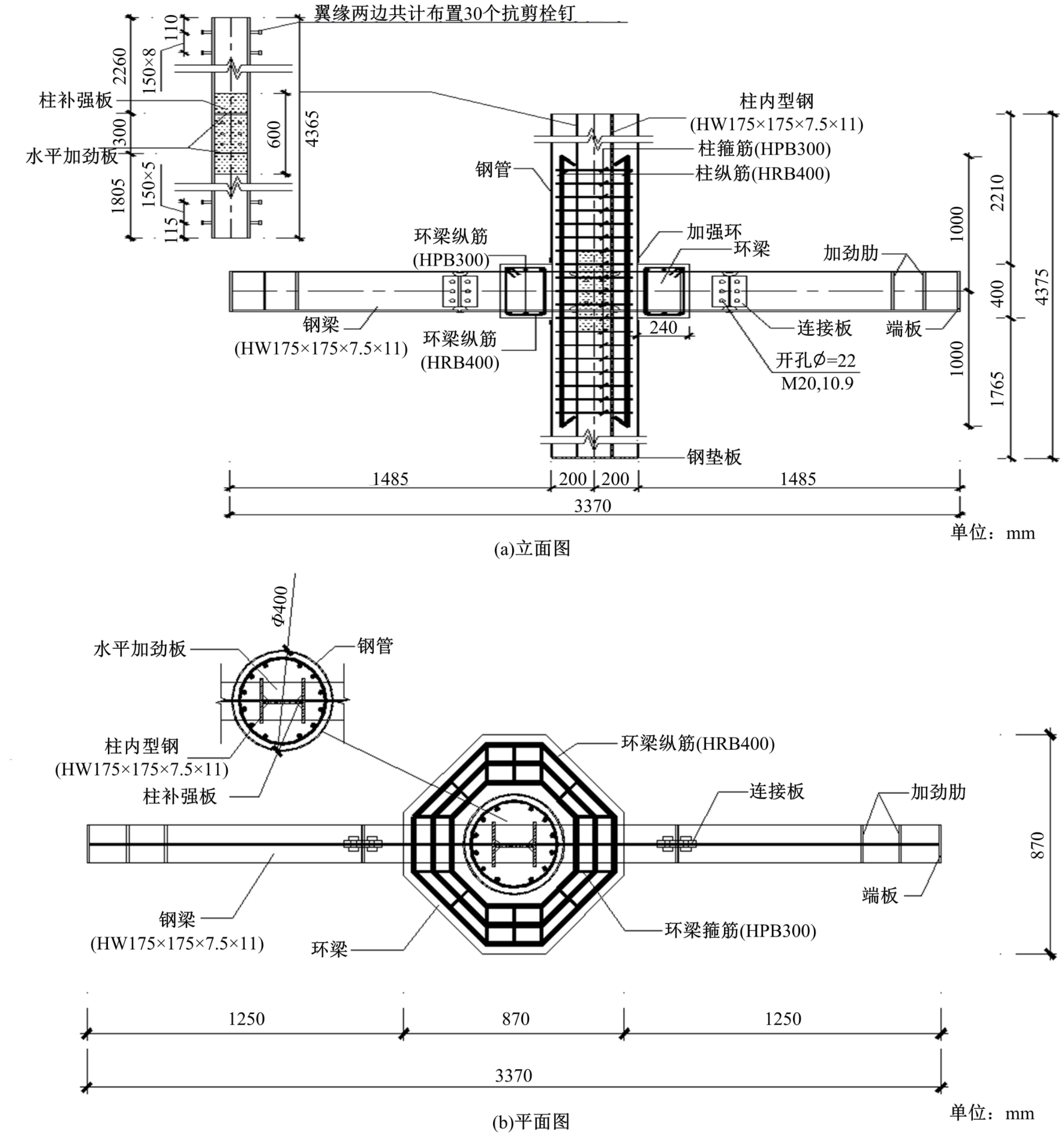

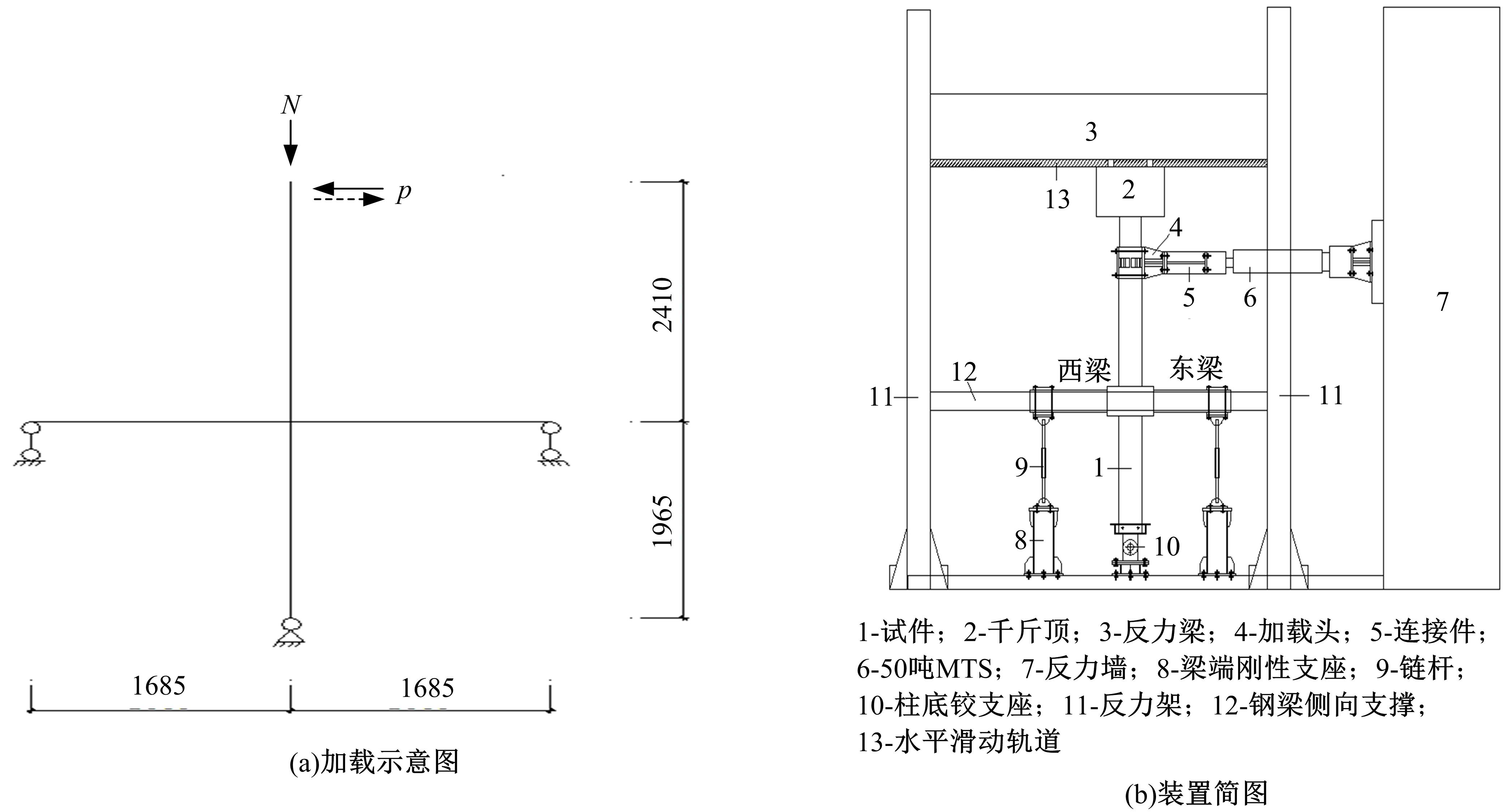

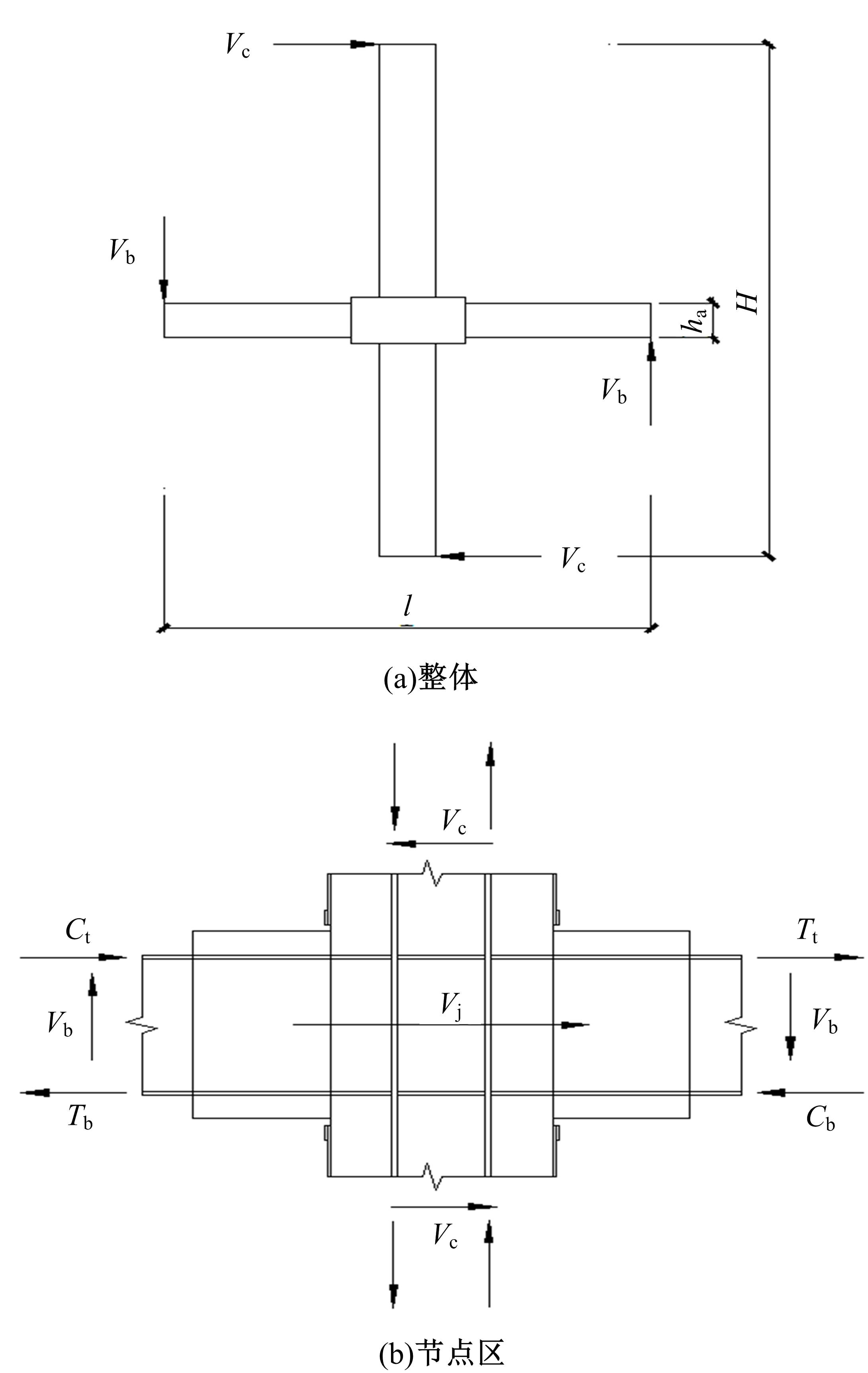

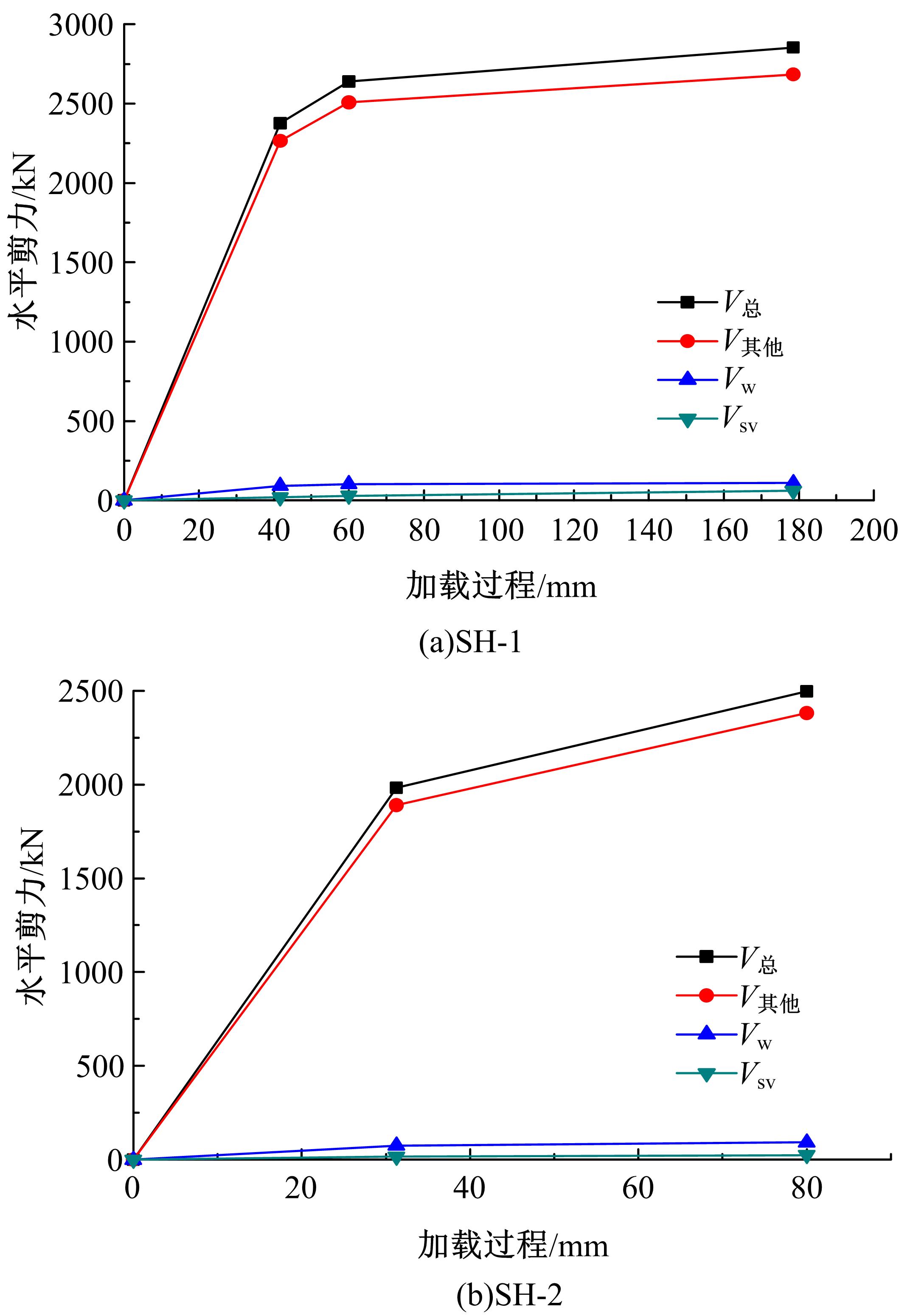

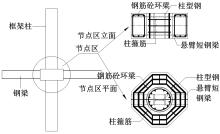

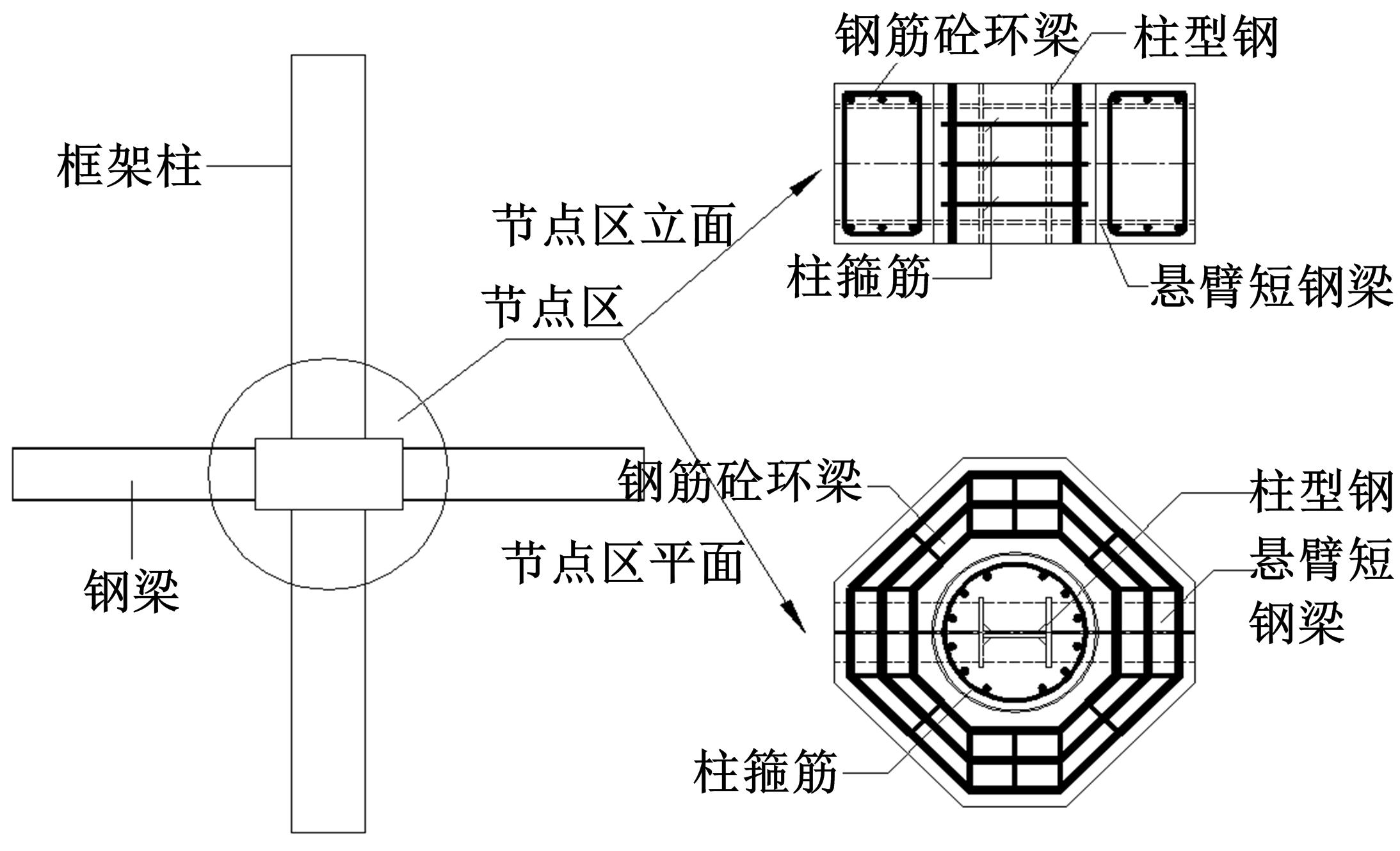

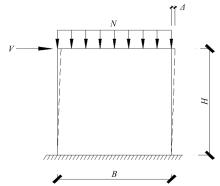

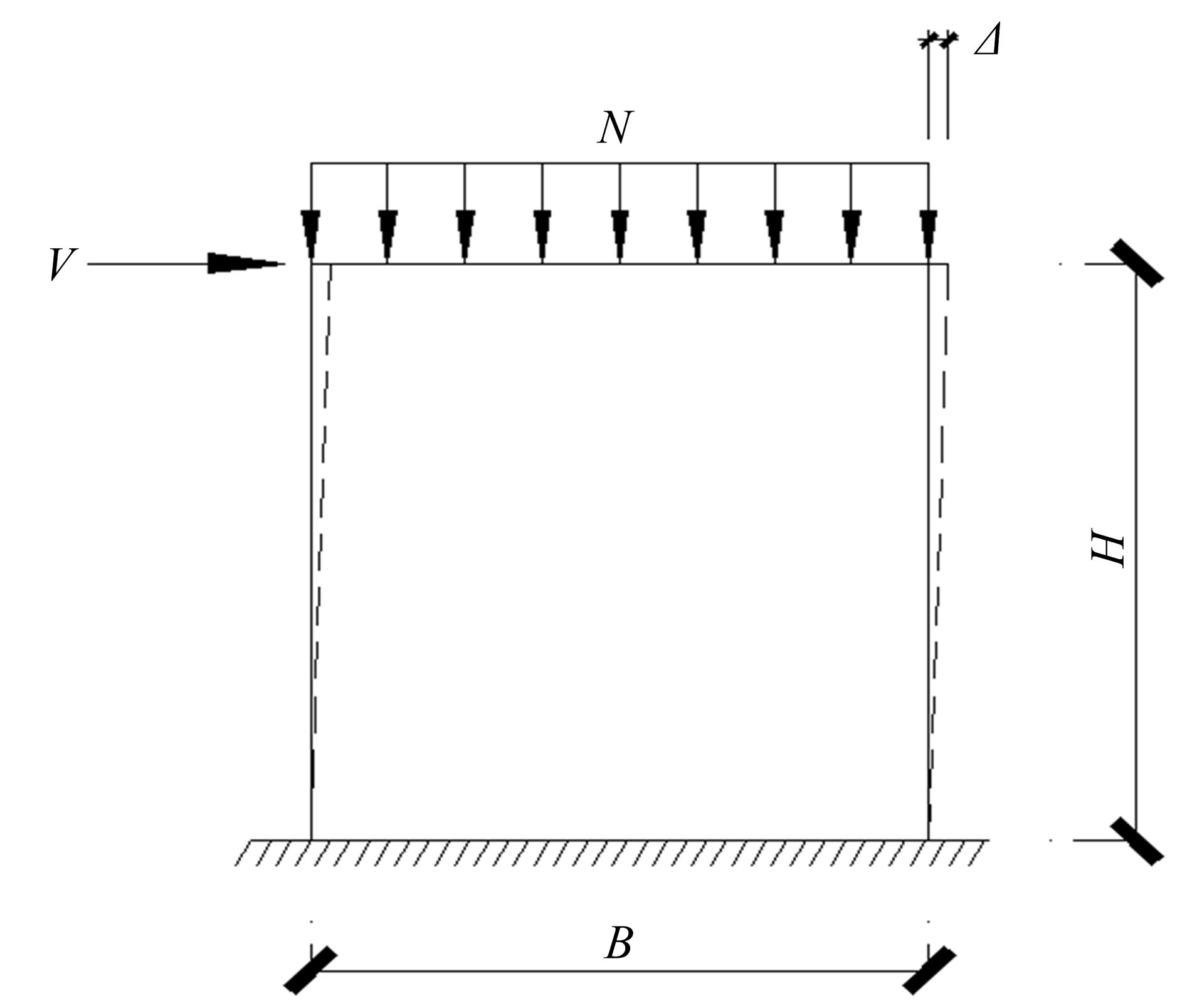

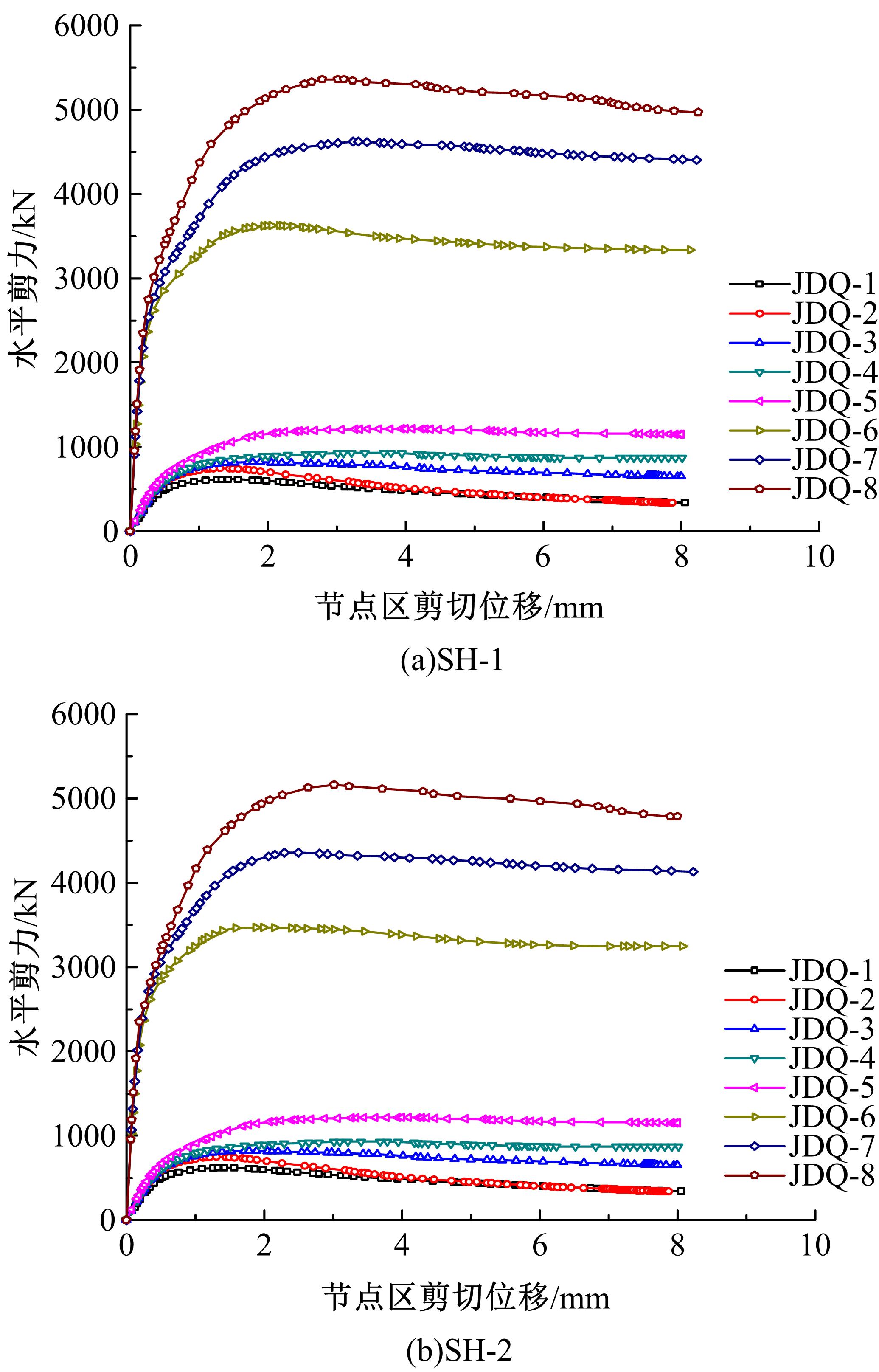

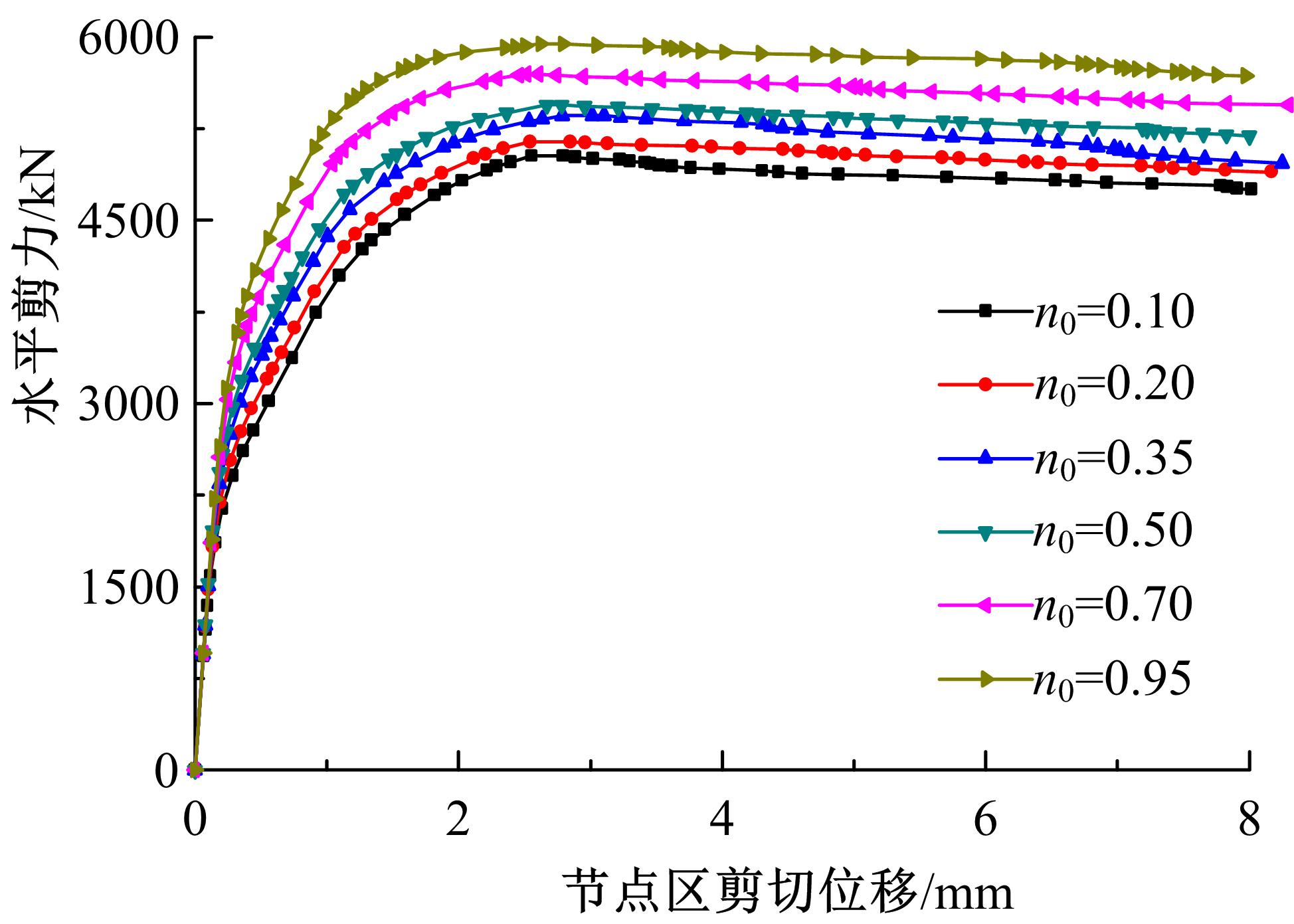

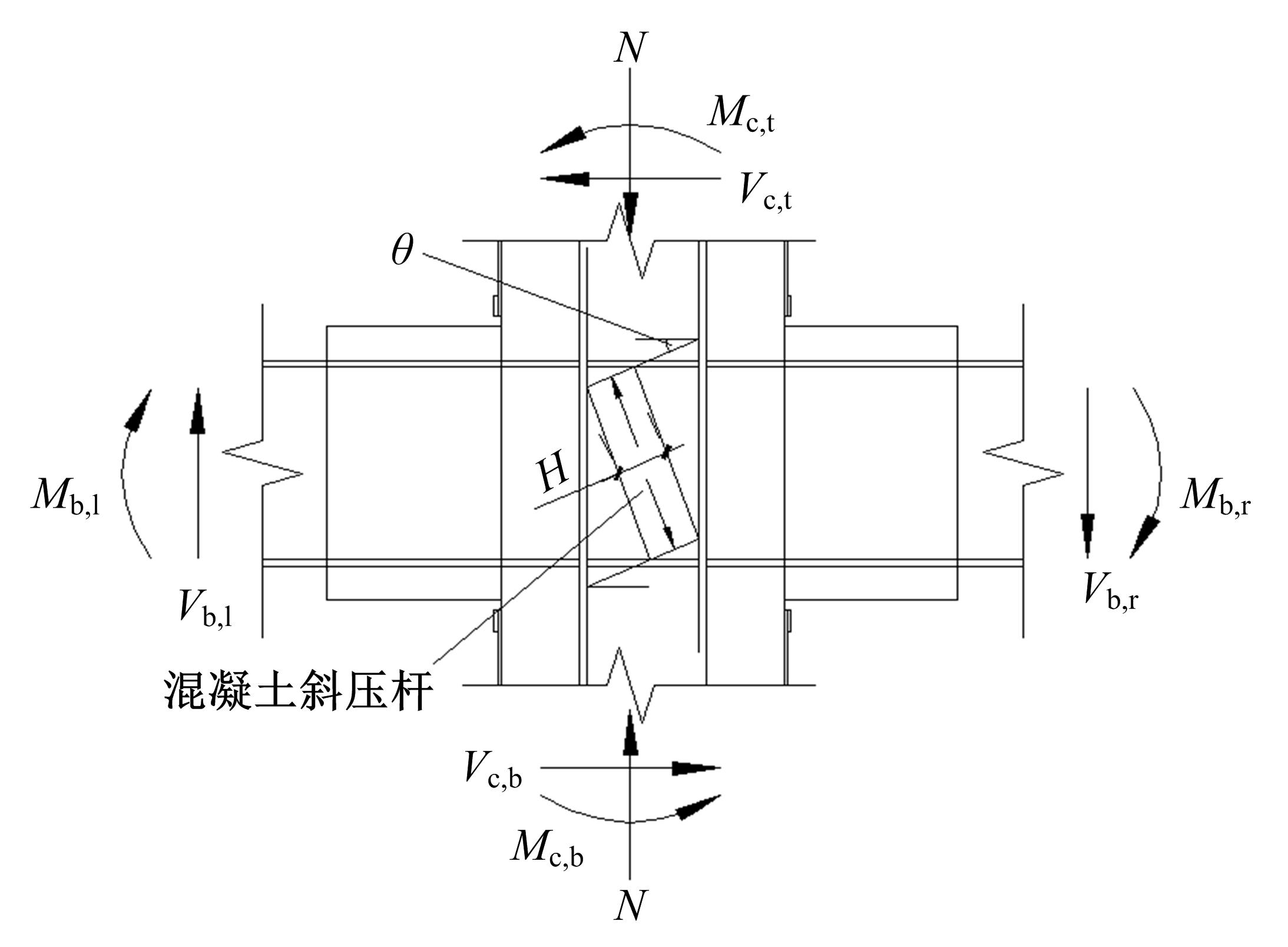

Shear capacity of circular steel tube confined H⁃SRC concrete column steel beam joint with ring beam

Yan DAI1( ),Shao-feng NIE2,Tian-hua ZHOU2

),Shao-feng NIE2,Tian-hua ZHOU2

- 1.Shaanxi Key Laboratory of Safety and Durability of Concrete Structures,Xijing University,Xi'an 710123,China

2.School of Civil Engineering,Chang'an University,Xi'an 710061,China

CLC Number:

- TU398

| 1 | 周绪红, 刘界鹏. 钢管约束混凝土柱的性能与设计[M]. 北京:科学出版社, 2010. |

| 2 | Zhou X, Liu J. Seismic behavior and strength of tubed steel reinforced-concrete(SRC)short columns[J]. Journal of Constructional Steel Research, 2010, 66(7):885-896. |

| 3 | Liu F, Gardner L, Yang H. Post-fire behavior of reinforced concrete stub columns confined by circular steel tubes[J]. Journal of Consturctional Steel Research, 2014, 102:82-103. |

| 4 | 甘丹, 周绪红, 闫标, 等. 圆钢管约束钢筋混凝土环筋式节点受力性能试验研究[J]. 建筑结构学报, 2018, 39(4):91-101. |

| Gan Dan, Zhou Xu-hong, Yan Biao, et al. Experimental studies on mechanical behavior of circular tubed reinforced concrete joints with ring ribs[J]. Journal of Building Structure, 2018, 39(4):91-101. | |

| 5 | 戴岩, 聂少锋, 周天华. 带环梁的方钢管约束钢骨混凝土柱-钢梁节点滞回性能有限元分析[J]. 吉林大学学报:工学版, 2018, 48(5):1426-1435. |

| Dai Yan, Nie Shao-feng, Zhou Tian-hua. Finite element analysis of hysteretic behavior of square steel tube confined steel reinforced concrete column steel frame ring beam joint[J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(5):1426-1435. | |

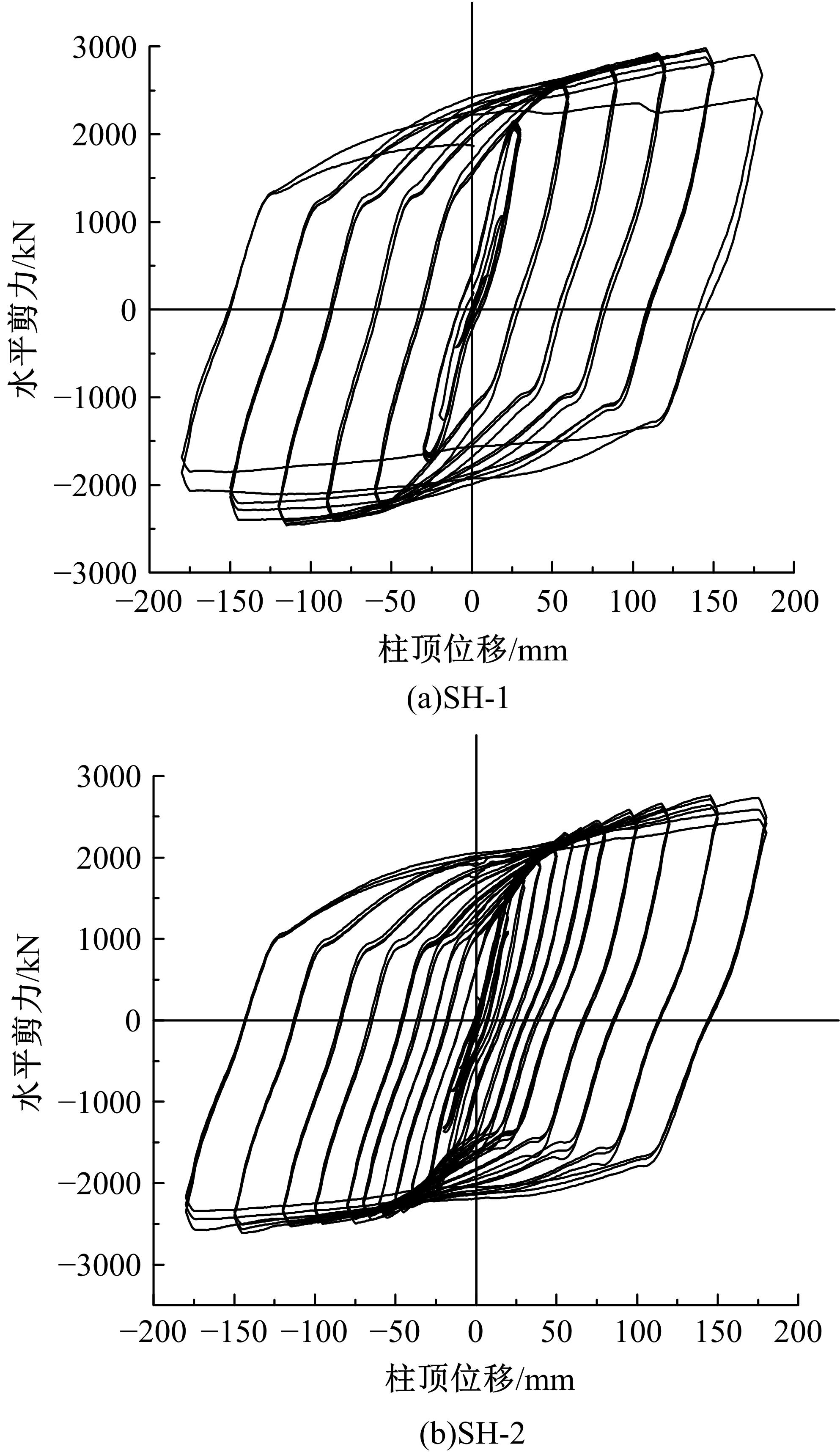

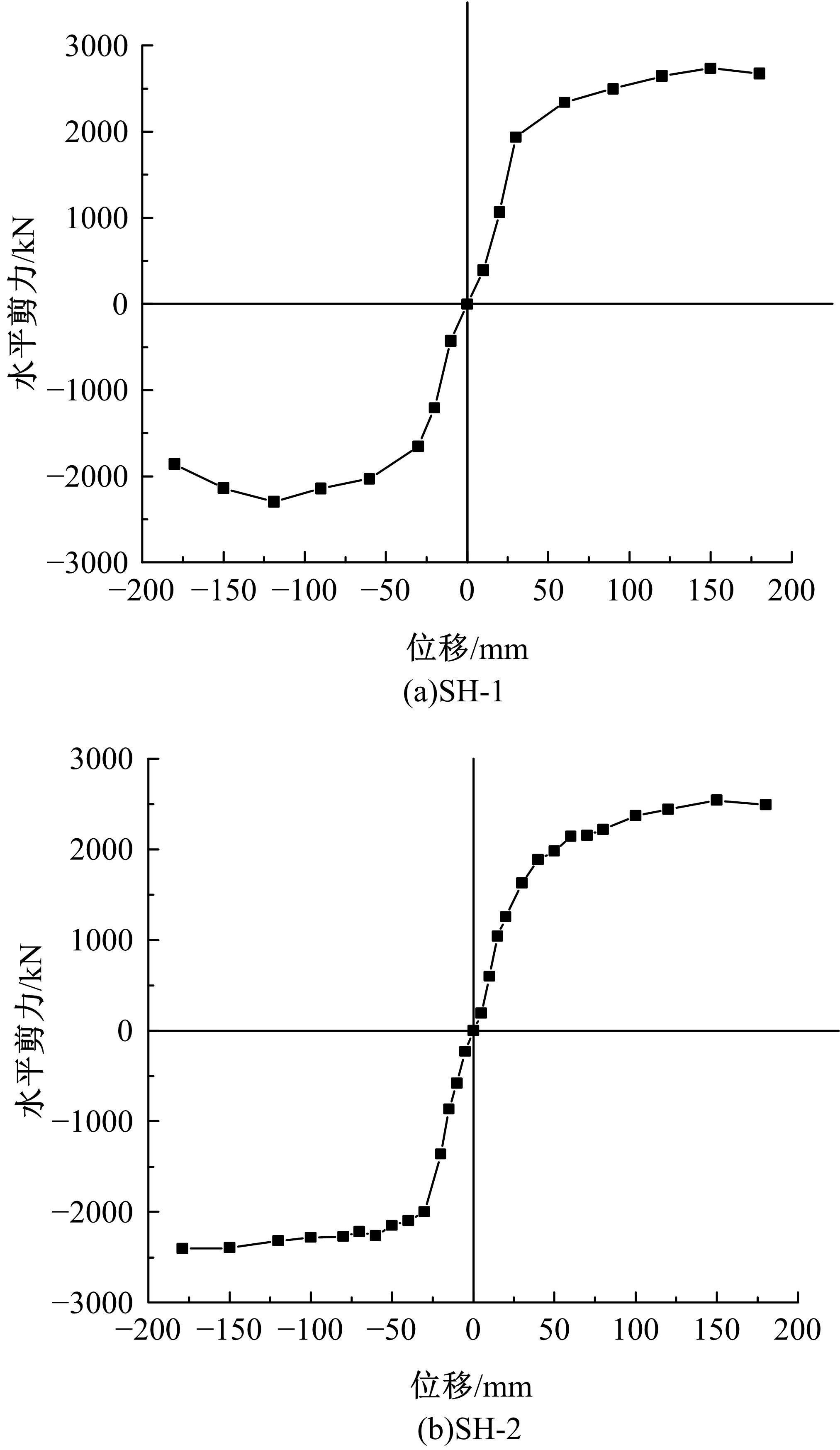

| 6 | 戴岩, 聂少锋, 周天华. 环梁式圆钢管约束H型钢混凝土柱-钢梁节点的抗震性能[J]. 华南理工大学学报:自然科学版, 2019, 47(5):110-122. |

| Dai Yan, Nie Shao-feng, Zhou Tian-hua. Seismic behavior of Circular steel tube confined H steel reinforced concrete column steel frame ring beam joint[J]. Journal of South China University of Technology(Natural Science Edition), 2019, 47(5):110-122. | |

| 7 | 赵鸿铁. 钢与混凝土组合结构[M]. 北京:科学出版社, 2001. |

| 8 | . 组合结构设计规范[S]. |

| 9 | 钟善桐, 白国良. 高层建筑组合结构框架梁柱节点分析与设计[M]. 北京:人民交通出版社, 2006. |

| 10 | 曾磊. 型钢高强高性能混凝土框架节点抗震性能及设计计算理论研究[D]. 西安:西安建筑科技大学土木工程学院, 2008. |

| Zeng Lei. Research on seismic behaviors and design method of steel reinforced high strength and high performance concrete frame joints[D]. Xi'an:School of Civil Engineering, Xi'an University of Architecture and Technology, 2008. | |

| 11 | . 混凝土结构设计规范[S]. |

| 12 | 苏小卒, 刘庆文, 陆余年, 等. 预应力混凝土水平加腋框架节点抗震性能研究[J]. 同济大学学报:自然科学版, 2008, 36(6):717-721. |

| Su Xiao-zu, Liu Qing-wen, Lu Yu-nian, et al. Experiment on seismic behavior of prestressed concrete frame joints with spread-ended beams[J]. Journal of Tongji University(Natural Science), 2008, 36(6):717-721. |

| [1] | Guang-tai ZHANG,Lu-yang ZHANG,Guo-hua XING,Yin-long CAO,Bao YI. Seismic performance of steel⁃polypropylene hybrid fiber reinforced concrete shear wall [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(3): 946-955. |

| [2] | Er-gang XIONG,Han XU,Ci TAN,Jing WANG,Ruo-yu DING. Shear strength of reinforced concrete beams based on elastoplastic stress field theory [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(1): 259-267. |

| [3] | DAI Yan, NIE Shao-feng, ZHOU Tian-hua. Finite element analysis of hysteretic behavior of square steel tube confined steel reinforced concrete column steel frame ring beam joint [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(5): 1426-1435. |

| [4] | SU Ying-she, YANG Yuan-yuan. Seismic compression performance of the concrete under high temperature [J]. 吉林大学学报(工学版), 2015, 45(5): 1436-1442. |

| [5] | GUO Jun-ping, DENG Zong-cai, LU Hai-bo, LIN Jin-song. Experiment on shear behavior of reinforced concrete beams strengthened with prestressed high strength steel wire mesh [J]. 吉林大学学报(工学版), 2014, 44(4): 968-977. |

| [6] | YANG Ai-wu,ZHOU Jin,KONG Ling-wei. Experiment on mechanical properties of stabilized soft dredger fill [J]. 吉林大学学报(工学版), 2014, 44(3): 661-667. |

|

||