Journal of Jilin University(Engineering and Technology Edition) ›› 2021, Vol. 51 ›› Issue (4): 1306-1316.doi: 10.13229/j.cnki.jdxbgxb20191055

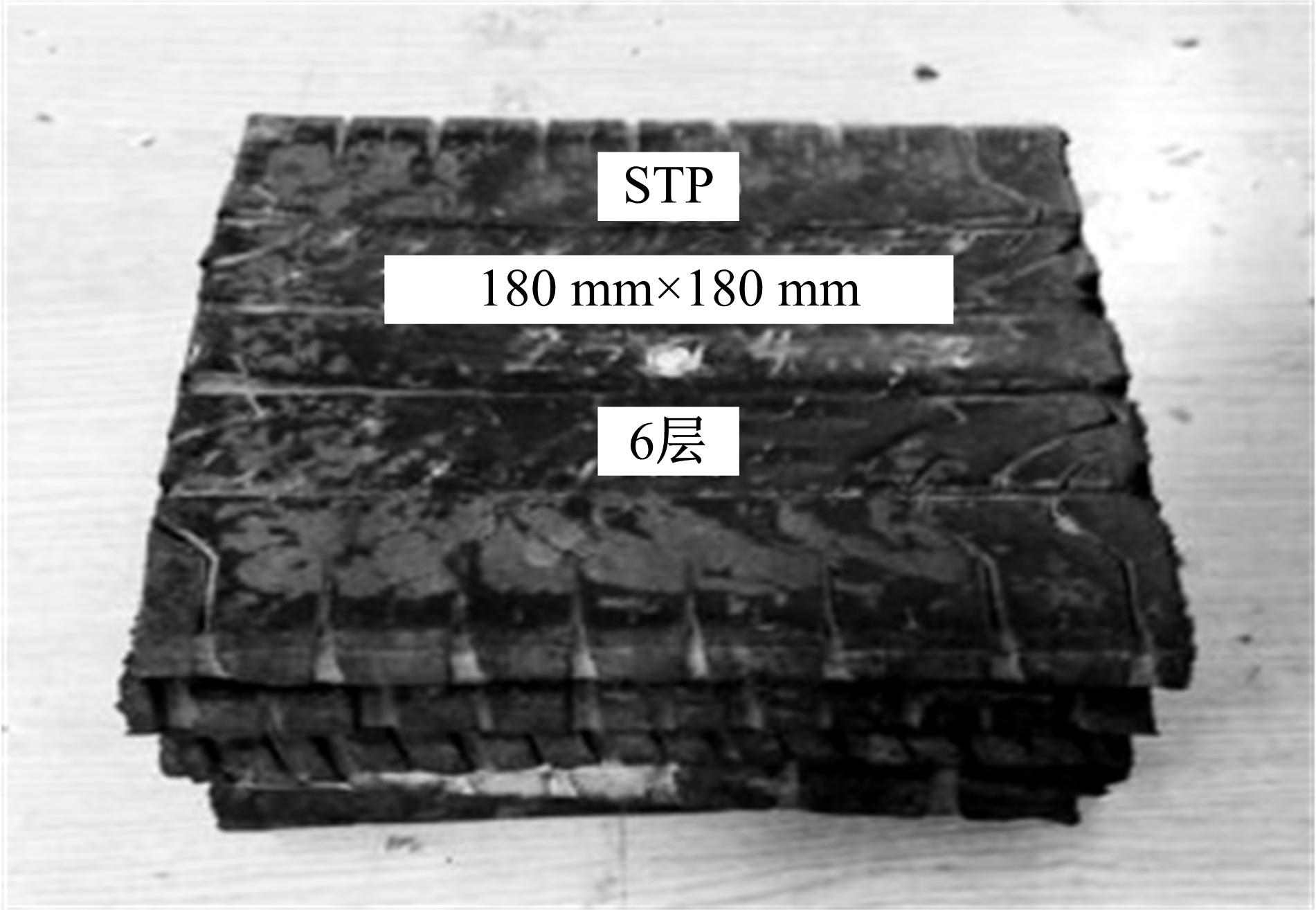

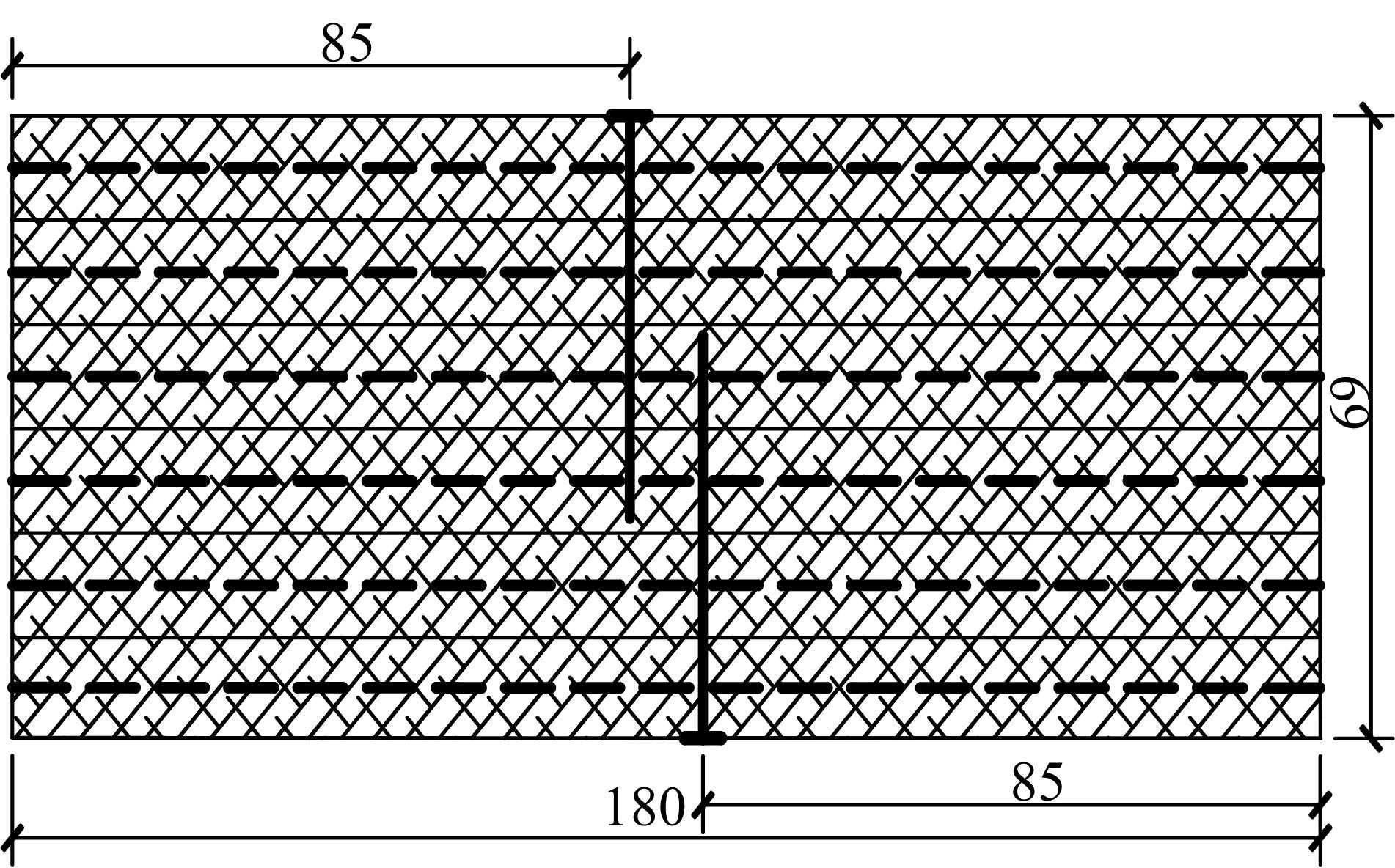

Scarp tire rubber pads′s practical restoring force model under the effect of thermal oxidation aging

Guang-tai ZHANG1( ),Ming-yang WANG1,Qiao-jun GUO1,Jin-peng ZHANG1,Dong-liang LU2

),Ming-yang WANG1,Qiao-jun GUO1,Jin-peng ZHANG1,Dong-liang LU2

- 1.School of Architecture and Engineering,Xinjiang University,Urumqi 830047,China

2.Wulanchabu Electric Power Survey and Design Institute Co. ,Ltd. ,Wulanchabu 012000,China

CLC Number:

- TU352.12

| 1 | Ahmet T, Bayezid Ö. Seismic base isolation using low-cost scrap tire pads (STP)[J]. Materials and Structures, 2008, 41(5):891-908. |

| 2 | 张广泰,陆东亮,魏飞来,等.热氧老化条件下废旧叠层轮胎隔震垫的力学性能[J].华南理工大学学报:自然科学版,2019,47(8):16-22. |

| Zhang Guang-tai,Lu Dong-liang,Wei Fei-lai,et al.Mechanial properties of scarp tire rubber pads based on thermal oxygen aging[J].Journal of South China University of Techology(Nature Science Edition),2019,47(8):16-22. | |

| 3 | 孟庆利,冯浩.铅芯废旧轮胎隔震垫(LRTP)力学性能试验研究[J].土木工程学报,2018,51(1):58-67. |

| Meng Qing-li,Feng Hao. The experimental study on mechnical behavior of Lead Recycle Tire Pads (LRTP)[J]. China Civil Engineering Journal, 2018,51(1):58-67. | |

| 4 | 张广泰,陆东亮,章金鹏,等.老化-荷载耦合下叠层轮胎隔震垫的竖向力学性能[J].材料导报,2019(18):3140-3146. |

| Zhang Guang-tai,Lu Dong-liang,Zhang Jin-peng,et al.Vertical mechanical properties of scrap tire rubber pads under aging-loading[J]. Materials Reports,2019(18): 3140-3146. | |

| 5 | 熊世树,周正华,王补林.铅芯橡胶隔震支座恢复力模型的分析方法[J].华中科技大学学报:城市科学版,2003(2):28-31. |

| Xiong Shi-shu,Zhou Zheng-hua,Wang Bu-lin. Analysis of hysteresis model of lead-rubber laminated bearing[J]. Journal of Wuhan Urban Construction Institute, 2003(2):28-31. | |

| 6 | 金建敏,周福霖,谭平.铅芯橡胶支座微分型恢复力模型屈服前刚度的研究[J].工程力学,2010,27(10):7-13. |

| Jin Jian-min,Zhou Fu-lin,Tan Ping. Study on pre-yield shear stiffness of differential restoring force model for lead rubber bearing[J]. Engineering Mechanics, 2010,27(10):7-13. | |

| 7 | 汪新明.橡胶隔震支座非线性建模及参数识别研究[D].南京:南京航空航天大学航空宇航学院,2018. |

| Wang Xin-ming. Research on nonlinear modeling and parameter identification of rubber isolation bearings[D]. Nanjing:College of Aerospace Engineering,Nanjing Aerospace University,2018. | |

| 8 | Pan T C,Yang G.Nonlinar analysis of base-isolated MOOF structures[J].Proceedings of the 11th Word Conference on Earthquake Engineering, Mexico,1996:No.1534. |

| 9 | Robert J.Noninear rate dependent model of high damping rubber bearing[J]. Bulletion of Earthquake Engineering,2004, 8(1):397-403. |

| 10 | Koh CG,Kelly J M.A simple mechanical model for elastomeric bearings used in based isolation[J]. International Journal of Mechanical Sciences, 1998,30(12):933-943. |

| 11 | Kikuchi M,Yamamoto S,Aiken I D.An analytical model for lead-rubber bearing sunder large demations[J]. Proceedings of the 8th Pacific Conference on Eartuquake Engineering,Singpore, 2007:222. |

| 12 | Dall Asta A,Ragni L.Experimental tests analytical model of high damping rubber d isspating devices[J]. Engineering Structures,2006,28(13):1874-1884. |

| 13 | Bhuiyan A R,Okui Y,Mitamura H,et al.A rheology model of high damping rubber bearings for seismic analysis:Identification of nonlinear viscosity[J].International Journal of Solids and Structures,2009,46(7,8):1778-1792. |

| 14 | 中国建筑标准设计研究所.建筑隔震橡胶支座:JG118—2000[M].北京:中国建筑工业出版社,2000. |

| 15 | 中华人民共和国国家标准.公路桥梁板式橡胶支座第一部分:橡胶隔震支座试验方法[S].北京:中国标准出版社,2007. |

| [1] | Guang-tai ZHANG,Jin-peng ZHANG,Ming-yang WANG,Dong-liang LU,Mei ZHANG. Seismic isolation performance of waste scrap tire pads under aging-loading coupling [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(1): 96-106. |

|

||