Journal of Jilin University(Engineering and Technology Edition) ›› 2021, Vol. 51 ›› Issue (1): 96-106.doi: 10.13229/j.cnki.jdxbgxb20190861

Previous Articles Next Articles

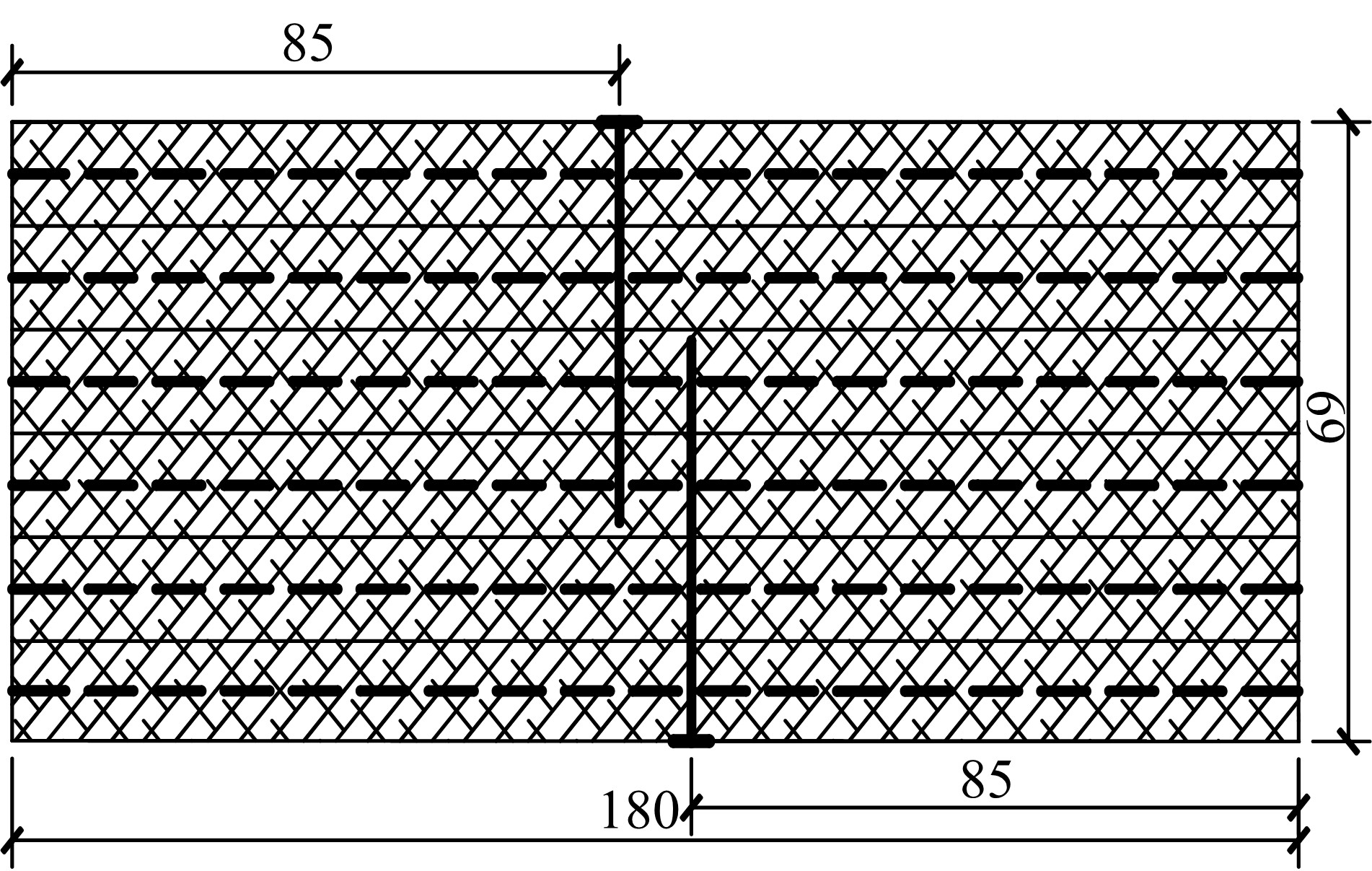

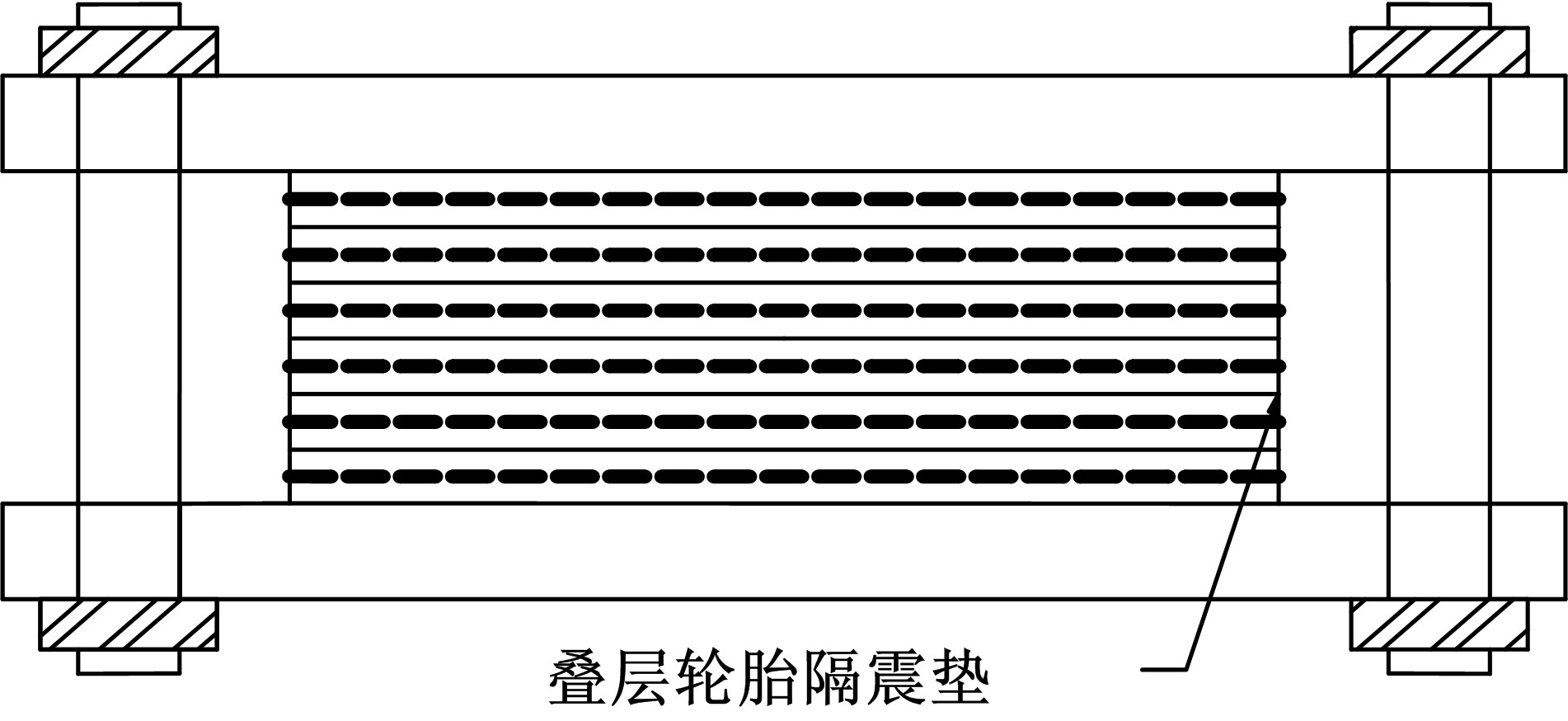

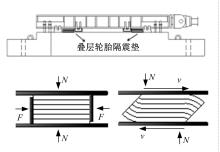

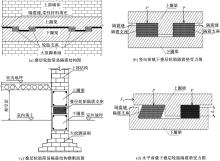

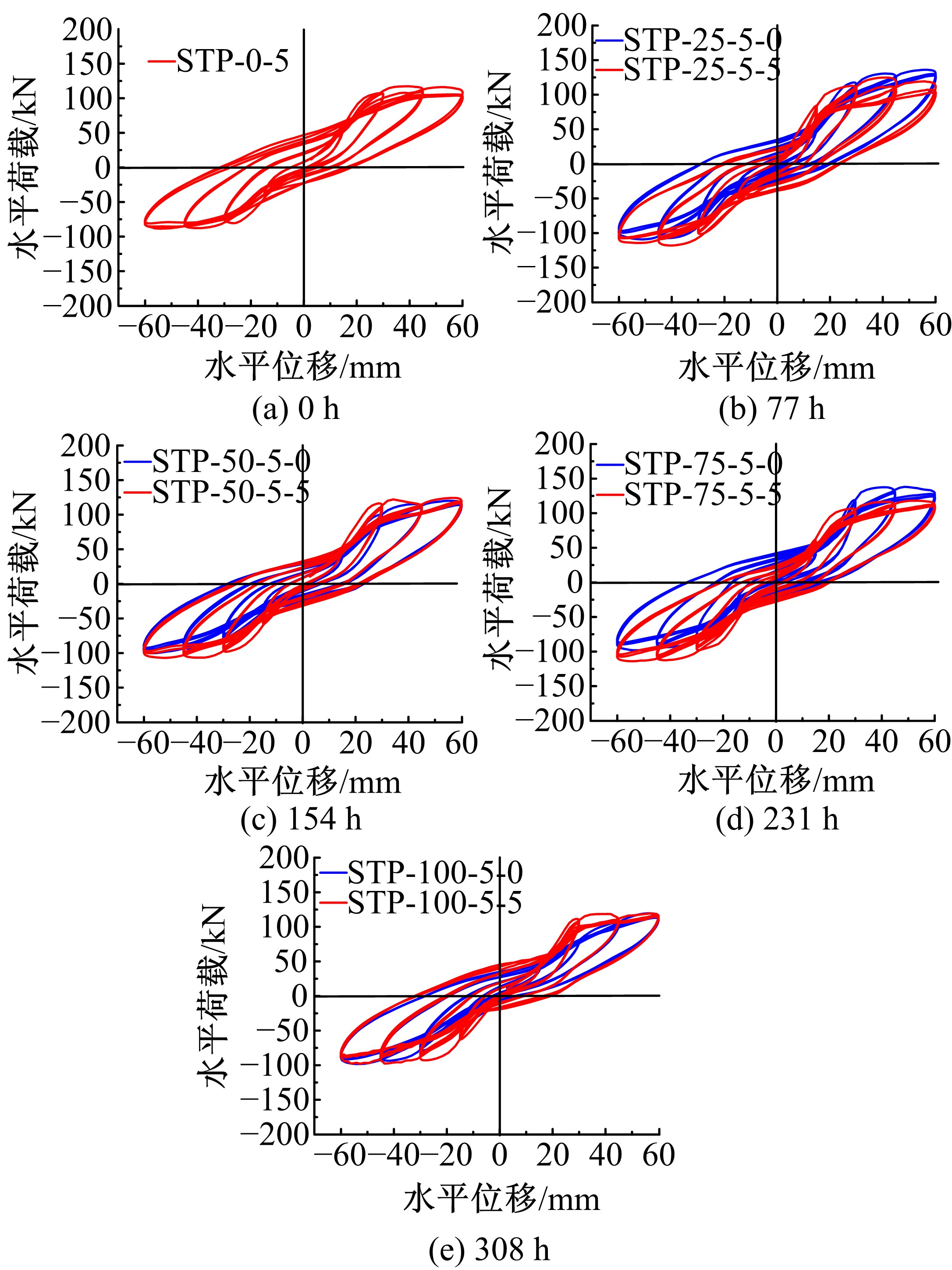

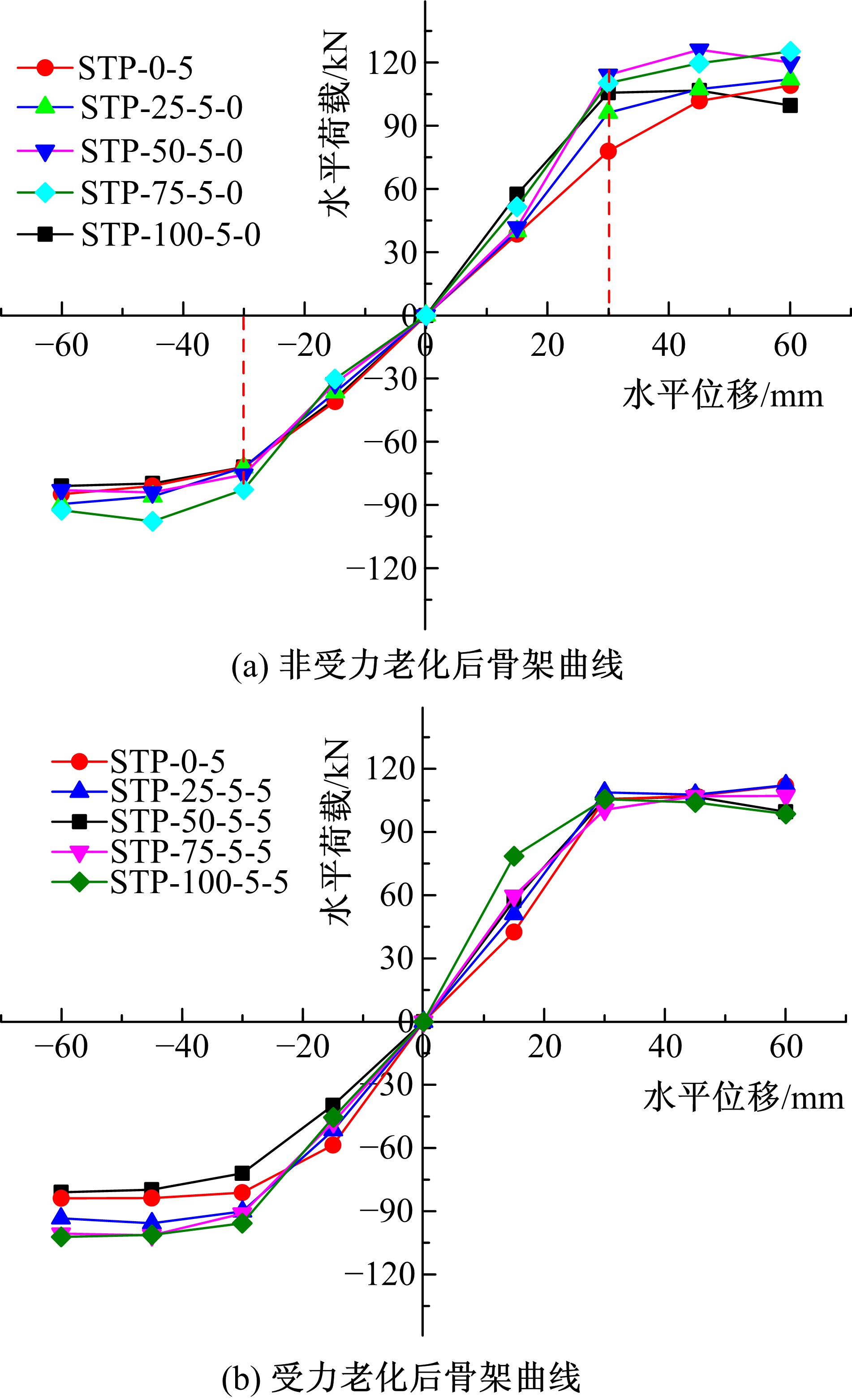

Seismic isolation performance of waste scrap tire pads under aging-loading coupling

Guang-tai ZHANG( ),Jin-peng ZHANG,Ming-yang WANG,Dong-liang LU,Mei ZHANG

),Jin-peng ZHANG,Ming-yang WANG,Dong-liang LU,Mei ZHANG

- School of Architecture and Engineering,Xinjiang University,Urumqi 830047,China

CLC Number:

- TU352.12

| 1 | 孟庆利, 冯浩. 铅芯废旧轮胎隔震垫(LRTP)力学性能试验研究[J]. 土木工程学报, 2018, 51(1): 58-67. |

| Meng Qing-li, Feng Hao. The experimental study on mechnical behavior of lead recycle tire pads(LRTP)[J]. China Civil Engineering Journal, 2018, 51(1): 58-67. | |

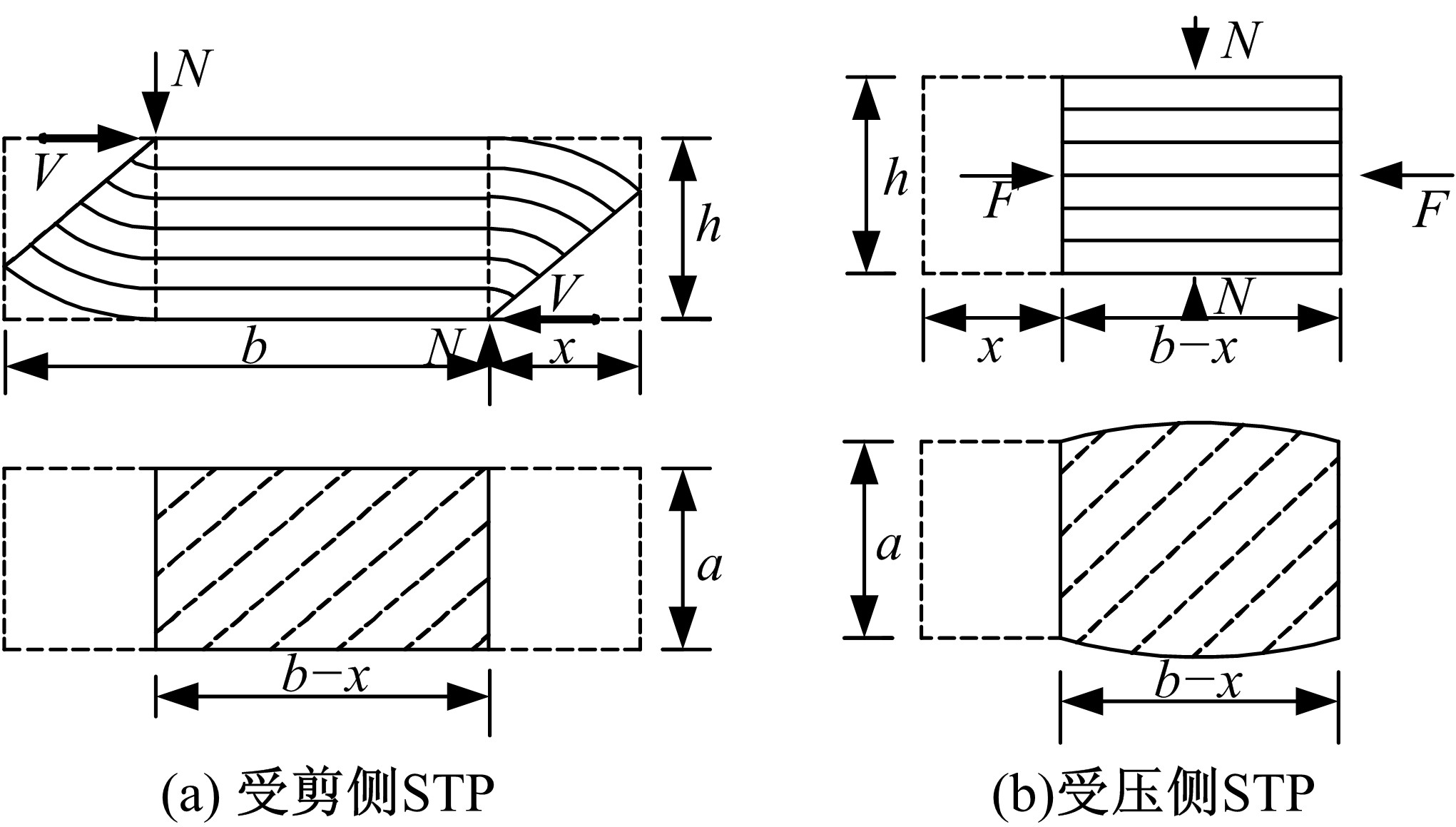

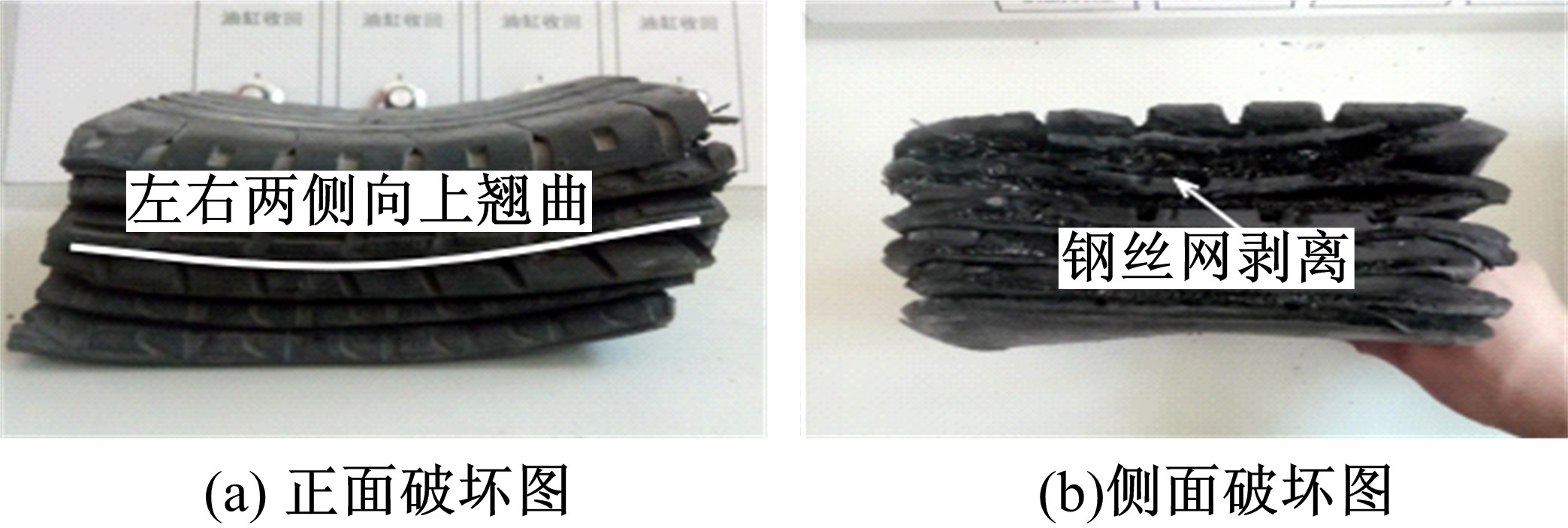

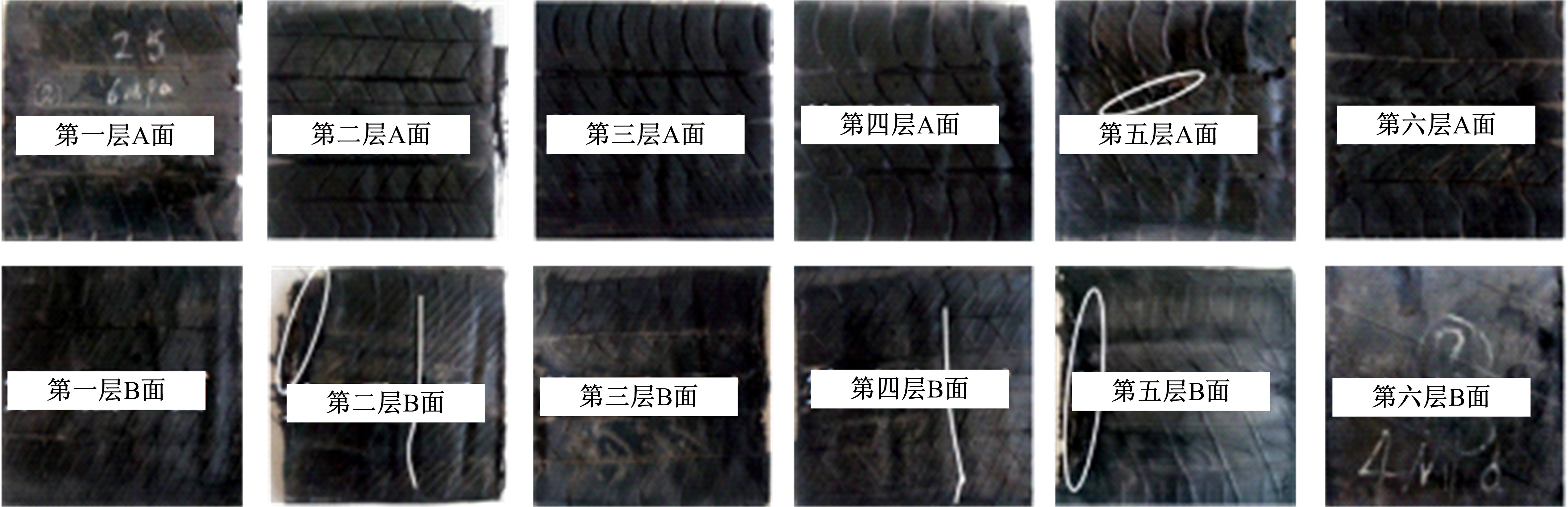

| 2 | 陆东亮, 张广泰, 魏飞来, 等. 叠层轮胎隔震垫轴压状态下的破坏准则[J]. 河南科技大学学报:自然科学版, 2019, 40(2):70-75. |

| Lu Dong-liang, Zhang Guang-tai, Wei Fei-lai, et al. Failure criterion of scrap tire rubber pads under axial compression[J]. Journal of Henan University of Science and Technology(Natural Science), 2019, 40(2):70-75. | |

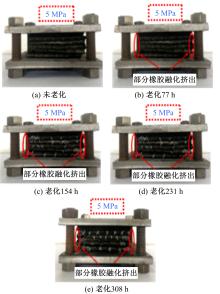

| 3 | 张广泰, 陆东亮, 章金鹏, 等. 老化-荷载耦合下叠层轮胎隔震垫的竖向力学性能[J]. 材料导报, 2019, 33(18): 3140-3146. |

| Zhang Guang-tai, Lu Dong-liang, Zhang Jin-peng, et al.Vertical mechanical properties of scrap tire rubber pads under aging-loading[J]. Materials Reports, 2019, 33(18): 3140-3146. | |

| 4 | Mishra H K, Igarashi A, Dang J, et al. Pseudo-Dynamic testing for seismic performance assessment of buildings with seismic isolation system using scrap tire rubber pad isolators[J]. Journal of Civil Engineering and Architecture, 2014, 8(1):73-88. |

| 5 | 张国荣. 不同压缩比下橡胶老化松弛机理的研究[D]. 北京:北京化工大学材料与工程学院, 2011. |

| Zhang Guo-rong. Study on the aging relaxation mechanism of rubber at differrnt compression rations[D]. Beijing: School of Materials and Engineering, Beijing University of Chemical Technology, 2011. | |

| 6 | 蒋沙沙. 硅橡胶加速老化及失效机理研究[D]. 哈尔滨:哈尔滨工业大学航天学院, 2013. |

| Jiang Sha-sha. Study on accelerated aging and failure mechanism of silicone rubber[D]. Harbin: School of Astronautics, Harbin Institute of Technology, 2013. | |

| 7 | 许斌, 唐家祥. 基础隔震叠层橡胶支座耐久性试验研究[J]. 工程抗震与加固改造, 1995(4): 41-44. |

| Xu Bing, Tang Jia-xiang. Experimental Study on durability of base-isolated laminated rubber bearings[J]. Earthquake Resistant Engineering and Retrofitting, 1995(4): 41-44. | |

| 8 | 裴若娟, 唐家祥. 叠层橡胶隔震器的耐久性[J]. 工程抗震与加固改造, 1993(3): 36-39. |

| Pei Ruo-juan, Tang Jia-xiang. Durability of laminated rubber isolators[J]. Earthquake Resistant Engineering and Retrofitting, 1993(3): 36-39. | |

| 9 | 庄学真, 周福霖, 沈朝勇, 等. 600型建筑叠层橡胶隔震装置温度相关性及耐老化性能研究[J]. 北京工业大学学报, 2011, 37(7): 993-999. |

| Zhuang Xue-zhen, Zhou Fu-lin, Shen Chao-Yong, et al. Research on temperature dependence and aging rigidity of 600 laminated steel-plate-laminated-rubber-bearing isolation[J]. Journal of Beijing Polytechnic University, 2011, 37(7): 993-999. | |

| 10 | 庄学真, 周福霖, 徐丽, 等. 大直径建筑叠层橡胶隔震装置温度相关性及老化性能研究[J]. 西安建筑科技大学学报:自然科学版, 2009, 41(6): 791-798. |

| Zhuang Xue-zhen, Zhou Fu-Lin, XU Li, et al. Research on temperature dependence and aging rigidity of lead steel-plate-laminated-rubber-bearing isolation bearings for building[J]. Journal of Xi'an University of Architecture & Technology(Natural Science Edition), 2009, 41(6): 791-798. | |

| 11 | 刘文光, 杨巧荣, 周福霖. 天然橡胶隔震支座温度相关性能试验研究[J]. 广州大学学报:自然科学版, 2002, 1(6): 51-56. |

| Liu Wen-guang, Yang Qiao-rong, Zhou Fu-Lin. Temperature properties of natural rubber bearings[J]. Journal of Guangzhou University(Natural Science Edition), 2002, 1(6): 51-56. | |

| 12 | 刘文光, 李峥嵘, 周福霖, 等. 低硬度橡胶隔震支座各种相关性及老化徐变特性[J]. 地震工程与工程振动, 2002, 22(6): 115-121. |

| Liu Wen-guang,Li Zheng-rong,Zhou Fu-lin,et al. Various dependence and duration properties of low stiffness rubber bearings[J]. Earthquake Engineering and Engineering Vibration, 2002, 22(6): 115-121. | |

| 13 | 顾浩声, 伊藤義人. 天然橡胶隔震支座的内部老化特性及预测方法[J]. 北京工业大学学报, 2012, 38(2): 186-193. |

| Gu Hao-sheng, Yoshito Itoh. Aging inside natural rubber bearings and prediction method[J]. Journal of Beijing University of Technology, 2012, 38(2):186-193. | |

| 14 | 顾浩声, 伊藤義人. 老化后天然橡胶隔震支座的性能预测[J]. 北京工业大学学报, 2012, 38(10): 1515-1521. |

| Gu Hao-sheng, Yoshito Itoh. Prediction of aged natural rubber isolation bearings' performances[J]. Journal of Beijing University of Technology, 2012, 38(10): 1515-1521. | |

| 15 | Chou H W, Huang J S. Fatigue life prediction for circular rubber bearings subjected to cyclic compression[J]. Journal of Applied Polymer Science, 2011, 123(4): 2194-2203. |

| 16 | Chou H W, Huang J S, Li S T. Effects of thermal aging on fatigue of carbon black–reinforced EPDM rubber[J]. Journal of Applied Polymer Science, 2010, 103(2): 1244-1251. |

| 17 | Celina M, Wise J, Ottesen D K, et al. Correlation of chemical and mechanical property changes during oxygen dative degradation of neoprene[J]. Polymer Degradation & Stability, 2000, 68(2): 171-184. |

| 18 | Gu H S, Itoh Y. Aging behaviors of natural rubber in isolation bearings[J]. Advanced Materials Research, 2011, 163-167: 3343-3347. |

| 19 | 张广泰, 陆东亮, 魏飞来, 等. 热氧老化条件下废旧叠层轮胎隔震垫的力学性能[J]. 华南理工大学学报:自然科学版, 2019, 47(8): 16-22. |

| Zhang Gung-tai, Lu Dong-liang, Wei Fei-lai, et al. Mechanial properties of scarp tire rubber pads based on thermal oxygen aging[J]. Journal of South China University of Techology(Nature Science Edition), 2019, 47(8): 16-22. | |

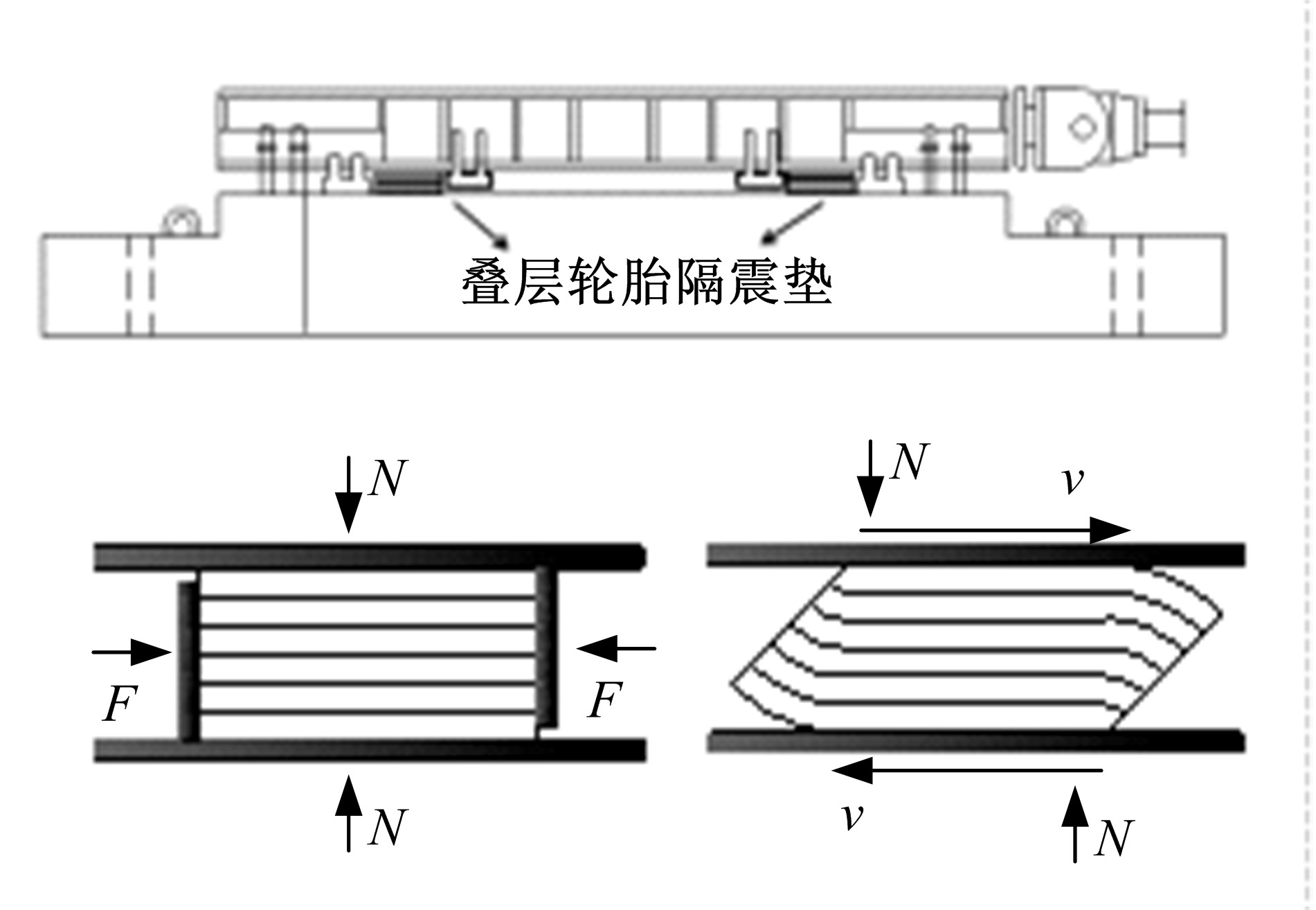

| 20 | 谭平, 徐凯, 王斌, 等. 基于新型简易隔震支座的村镇建筑隔震性能研究[J]. 土木工程学报, 2013, 46(5): 64-70. |

| Tan Ping, Xu Kai, Wang Bing, et al. Performance study of isolated rural buildings using novel simple isolators[J]. China Civil Engineering Journal, 2013, 46(5): 64-70. |

| [1] | DENG Cheng-jiang, HE Xiao-cong, XING Bao-ying, WANG Yu-qi, ZENG Kai, DING Yan-fang. Mechanical properties of self-piercing riveted lap joints in dissimilar metal sheets of aluminum and copper [J]. 吉林大学学报(工学版), 2015, 45(2): 473-480. |

|

||