Journal of Jilin University(Engineering and Technology Edition) ›› 2022, Vol. 52 ›› Issue (2): 400-408.doi: 10.13229/j.cnki.jdxbgxb20211197

Reliability analysis of numerical control machine tools based on analytic network process and date enevalopment analys

Li-juan YU1,2,3( ),Ang LIU1,2,3,Zhao-jun YANG1,2,Hai-long TIAN1,2,3(

),Ang LIU1,2,3,Zhao-jun YANG1,2,Hai-long TIAN1,2,3( ),Chuan-hai CHEN1,2,3,Jing-wen GAO2

),Chuan-hai CHEN1,2,3,Jing-wen GAO2

- 1.Key Laboratory of CNC Equipment Reliability,Ministry of Education,Jilin University,Changchun 130022,China

2.College of Mechanical and Aerospace Engineering,Jilin University,Changchun 130022,China

3.Chongqing Research Institute,Jilin University,Chongqing 400037,China

CLC Number:

- TH17

| 1 | 杨兆军, 陈传海, 陈菲, 等. 数控机床可靠性技术的研究进展[J].机械工程学报, 2013, 49(20): 130-139. |

| Yang Zhao-jun, Chen Chuan-hai, Chen Fei, et al. Research progress on reliability technology of CNC machine tools[J]. Journal of Mechanical Engineering, 2013, 49(20): 130-139. | |

| 2 | 乔巍巍, 贾亚洲, 张海波, 等. 数控系统故障分析及可靠性提高措施[J]. 吉林大学学报: 工学版, 2006, 36(): 69-72. |

| Qiao Wei-wei, Jia Ya-zhou, Zhang Hai-bo, et al. Numerical control system fault analysis and reliability improvement measure[J].Journal of Jilin University(Engineering and Technology Edition), 2006, 36(Sup.2): 69-72. | |

| 3 | 陈颖, 康锐. FMECA技术及其应用[M]. 2版. 北京: 国防工业出版社, 2014. |

| 4 | Renjith V R,Jose K M, Kumar P H, et al. Fuzzy FMECA(failure mode effect and criticality analysis) of LNG storage facility[J]. Journal of Loss Prevention in the Process Industries, 2018, 56: 537-547. |

| 5 | Liu Yong-kui, Kong Zhao-jun, Zhang Qing. Failure modes and effects analysis(FMEA) for the security of the supply chain system of the gas station in China[J]. Ecotoxicology and Environmental Safety, 2018, 164: 325-330. |

| 6 | Gajanand G, Rajesh P M.Comparative analysis of traditional and fuzzy FMECA approach for criticality analysis of conventional lathe machine[J]. International Journal of System Assurance Engineering and Management, 2020, 11(2): 379-386. |

| 7 | 章浩然, 洪荣晶, 陈复兴, 等. 基于FMECA和模糊评判的数控机床可靠性分析方法[J]. 制造技术与机床, 2020(11): 125-129. |

| Zhang Hao-ran, Hong Rong-jing, Chen Fu-xing, et al.Reliability analysis method of CNC machine tools on FMECA and fuzzy evaluation[J]. Manufacturing Technology & Machine Tool, 2020(11): 125-129. | |

| 8 | 刘泽锐, 王红军, 李颖, 等. 基于数控机床FMECA与改进RPN的系统危害性评价方法[J]. 制造技术与机床, 2020(11): 40-45. |

| Liu Ze-rui, Wang Hong-jun, Li Ying, et al. System hazard evaluation method based on numerical control machine tool FMECA and improved RPN[J]. Manufacturing Technology & Machine Tool, 2020(11): 40-45. | |

| 9 | 申桂香, 贾亚洲, 马健, 等. CNC机床故障分析及其可靠性[J]. 中国机械工程, 1996(6): 67-69, 124. |

| Shen Gui-xiang, Jia Ya-zhou, Ma Jian, et al. Failure analysis and reliability of CNC machine tools[J]. China Mechanical Engineering, 1996(6): 67-69, 124. | |

| 10 | 牛东晓, 李金超. 电力能源综合评价理论[M]. 北京: 中国电力出版社, 2014. |

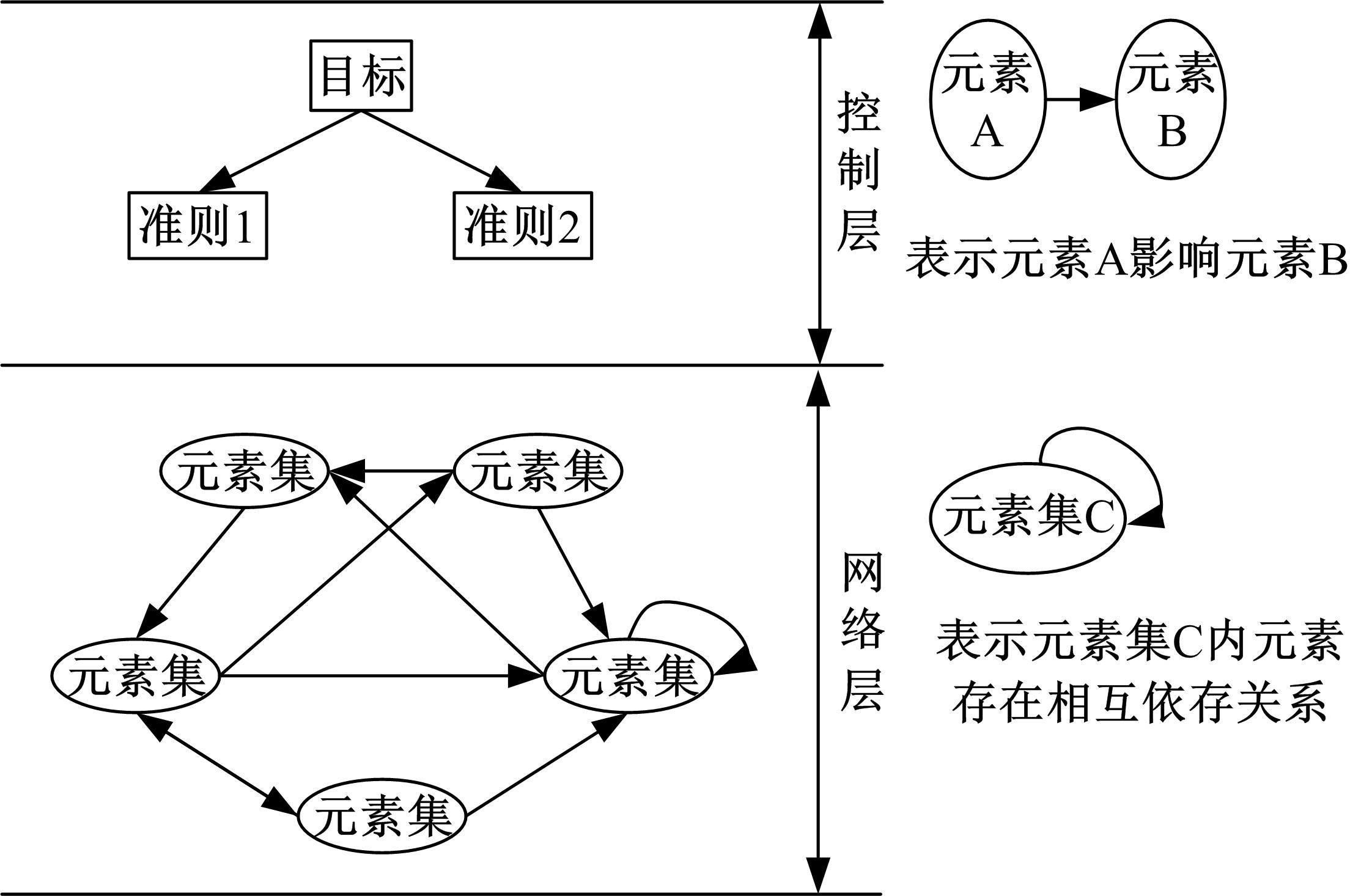

| 11 | 唐小丽, 冯俊文. ANP原理及其运用展望[J]. 统计与决策, 2006(12): 138-140. |

| Tang Xiao-li, Feng Jun-wen. ANP principle and its application prospects[J]. Statistics and Decision, 2006(12): 138-140. | |

| 12 | 王恒田, 杨晓龙. 基于网络层次分析法的平价上网光伏电站站址优选的决策研究[J]. 太阳能, 2020(12): 24-32. |

| Wang Heng-tian, Yang Xiao-long. Decision-making research on site selection of affordable photovoltaic power station based on network analytic hierarchy process [J]. Solar Energy, 2020(12): 24-32. | |

| 13 | 孙铭忆. 层次分析法(AHP)与网络层次分析法(ANP)的比较[J]. 中外企业家, 2014(10): 67-68. |

| Sun Ming-Yi. Comparison between AHP and network analytic hierarchy process(ANP)[J]. Chinese and Foreign Entrepreneurs, 2014(10): 67-68. | |

| 14 | 李学平. 用层次分析法求指标权重的标度方法的探讨[J]. 北京邮电大学学报: 社会科学版, 2001(1): 25-27. |

| Li Xue-ping. Discussion on the scaling method of using analytic hierarchy process to obtain index weight[J]. Journal of Beijing University of Posts and Telecommunications(Social Science Edition), 2001(1): 25-27. | |

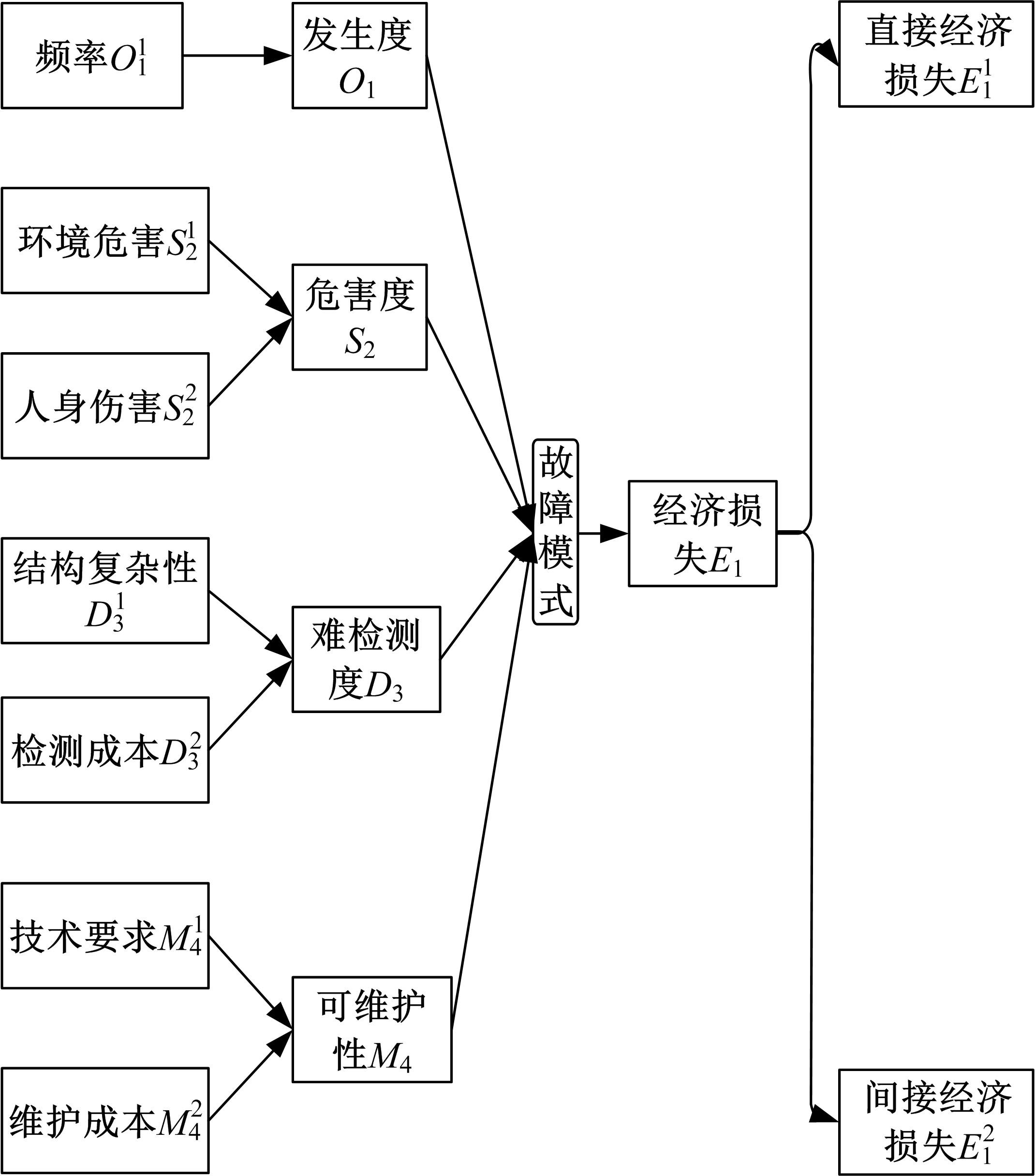

| 15 | 陈传海, 杨兆军, 陈菲, 等. 基于模糊数据包络分析的数控机床故障模式分析[J]. 吉林大学学报: 工学版, 2013, 43(6): 1523-1528. |

| Chen Chuan-hai, Yang Zhao-jun, Chen Fei, et al.Analysis of failure modes of CNC machine tools based on fuzzy data envelopment analysis[J].Journal of Jilin University(Engineering and Technology Edition), 2013, 43(6): 1523-1528. | |

| 16 | Kong W H, Fu T T. Assessing the performance of business colleges in Taiwan using data envelopment analysis and student based value added performance indicators [J]. Omega, 2012, 40(5): 541-549. |

| 17 | Chen T Y. Measuring firm performance with DEA and prior information in Taiwan's banks[J]. Applied Economics Letters, 2002, 9(3): 201-204. |

| 18 | Banker R D, Charnes A, Cooper W W. Some models for estimating technical and scale inefficiencies in data envelopment analysis[J]. Management Science, 1984, 30(9): 1078-1092. |

| 19 | 马占新. 数据包络分析方法的研究进展[J]. 系统工程与电子技术, 2002, 24(3): 42-46. |

| Ma Zhan-xin. Research progress of data envelopment analysis methods[J]. System Engineering and Electronic Technology, 2002, 24(3): 42-46. | |

| 20 | 曹莉, 马占新, 马生昀. 复杂多层次指标合成技术及效率分析[J]. 运筹学学报, 2020, 24(4): 39-50. |

| Cao Li, Ma Zhan-xin, Ma Sheng-yun. Complex multi-level index synthesis technology and efficiency analysis[J]. Journal of Operations Research, 2020, 24(4): 39-50. |

| [1] | Chuan-hai CHEN,Cheng-gong WANG,Zhao-jun YANG,Zhi-feng LIU,Hai-long TIAN. Research status and development trend analysis of reliability modeling of CNC machine tools [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(2): 253-266. |

| [2] | XU Bin-bin, YANG Zhao-jun, CHEN Fei, HAO Qing-bo, ZHAO Hong-wei, LI Guo-fa. Reliability model of CNC machine tools based on non-homogenous poisson process [J]. 吉林大学学报(工学版), 2011, 41(增刊2): 210-214. |

|

||