Journal of Jilin University(Engineering and Technology Edition) ›› 2022, Vol. 52 ›› Issue (4): 773-780.doi: 10.13229/j.cnki.jdxbgxb20200895

Analysis on pressure fluctuation of hydraulic variable valve actuation

Zhao-hui JIN1( ),Le-qi GU1,Wei HONG1,Fang-xi XIE1(

),Le-qi GU1,Wei HONG1,Fang-xi XIE1( ),Tian YOU2

),Tian YOU2

- 1.State Key Laboratory of Automotive Simulation and Control,Jilin University,Changchun 130022,China

2.Engineering Branch,Changchun University of Technology,Changchun 130033,China

CLC Number:

- TK417

| 1 | Tong S, Li X, Liu S, et al. Effect of two-stage valve lift for fuel economy and performance on a PFI gasoline engine[C]∥SAE Paper, 2014-01-2874. |

| 2 | Xu J T, Chang S Q, Fan X Y, et al. Effects of electromagnetic intake valve train on gasoline engine intake charging[J]. Applied Thermal Engineering, 2016, 96: 708-715. |

| 3 | Knop V, Mattioli L. An analysis of limits for part load efficiency improvement with VVA devices[J]. Energy Conversion and Management, 2015, 105: 1006-1016. |

| 4 | Liang L, Luo X H, Liu Y S, et al. A numerical investigation in effects of inlet pressure fluctuations on the flow and cavitation characteristics inside water hydraulic poppet valves[J]. International Journal of Heat and Mass Transfer, 2016, 103: 684-700. |

| 5 | Lu X X, Wang D M, Shen W, et al. Experimental investigation of the propagation characteristics of an interface wave in a jet pump under cavitation condition[J]. Experimental Thermal and Fluid Science, 2015, 63: 74-83. |

| 6 | 陈飞. 全可变液压气门系统的建模仿真与试验研究[D]. 济南: 山东大学机械工程学院, 2018. |

| Chen Fei. Simulation and experiment research of a fully variable hydraulic valve system[D], Jinan: College of Mechanical Engineering, Shandong University, 2018. | |

| 7 | 韩志强,胡明艳,赵家辉,等. 电液可变气门系统液压油路瞬时压力的分析[J]. 内燃机工程, 2019, 40(2): 82-91. |

| Han Zhi-qiang, Hu Ming-yan, Zhao Jia-hui, et al. Analysis of instantaneous pressure of hydraulic circuit in electro-hydraulic variable valve timing system[J]. Chinese Internal Combustion Engine Engineering, 2019, 40(2): 82-91. | |

| 8 | 谢宗法, 秦磊, 王志明, 等. 全可变气门机构中的液压压力波动现象[J]. 内燃机学报, 2011, 29(5): 455-460. |

| Xie Zong-fa, Qin Lei, Wang Zhi-ming, et al. Hydraulic pressure fluctuation in fully variable valve train[J]. Transactions of CSICE, 2011, 29(5): 455-460. | |

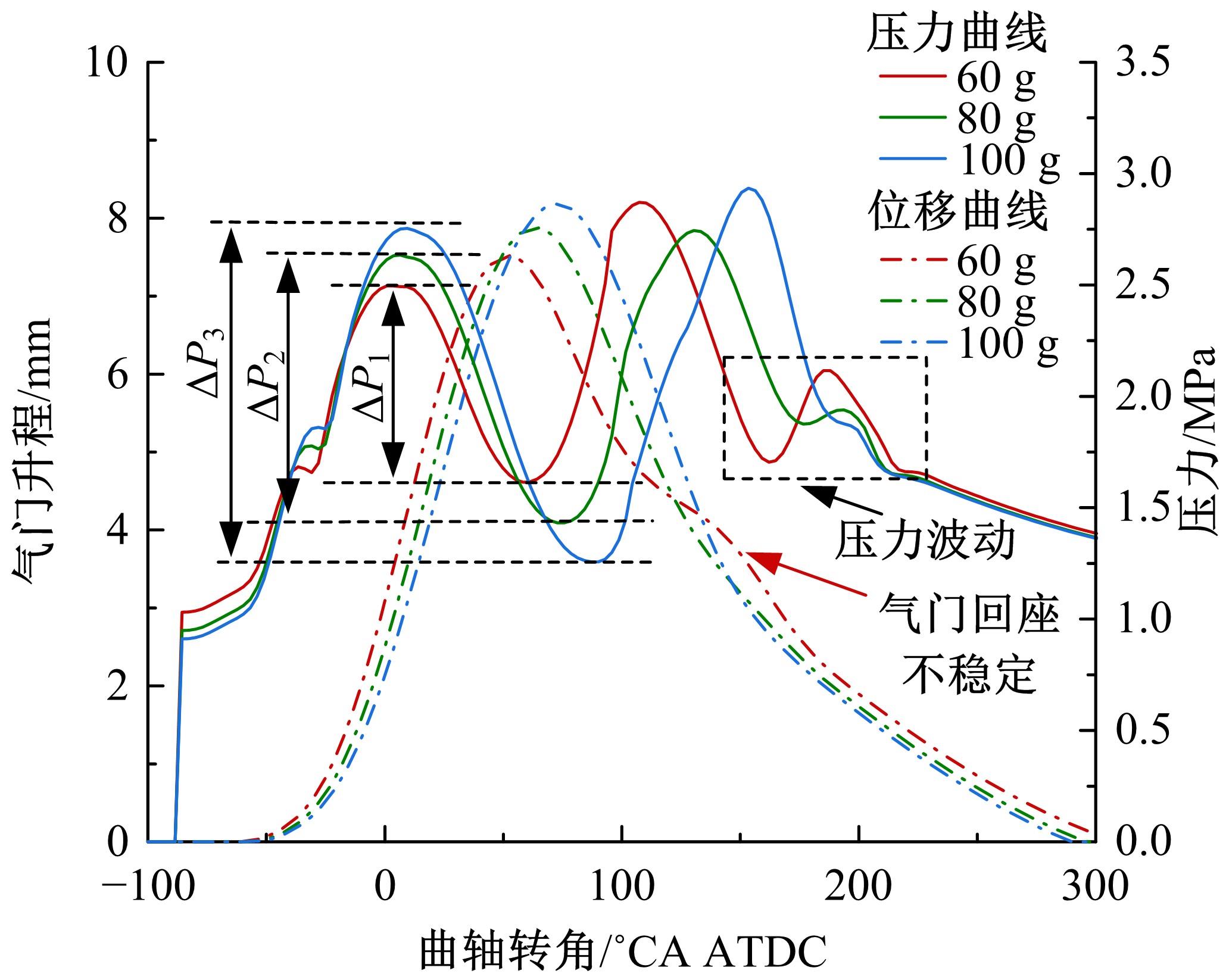

| 9 | 钟兵, 洪伟, 杨国志, 等. 液压可变气门机构压力波动及动作循环变动[J]. 吉林大学学报: 工学版, 2020, 50 (3): 796 - 803. |

| Zhong Bing, Hong Wei, Yang Guo-zhi, et al. Pressure fluctuation and cyclic variation of movement of hydraulic variable valve mechanism[J]. Journal of Jilin University (Engineering and Technology Edition), 2020, 50(3): 796- 803. | |

| 10 | 钟兵, 洪伟, 金兆辉, 等. 进气门早关液压可变气门机构运动特性[J]. 吉林大学学报: 工学版, 2018, 48(3): 727-734. |

| Zhong Bing, Hong Wei, Jin Zhao-hui, et al. Movement characteristics of hydraulic variable valve train with early intake valve closing[J]. Journal of Jilin University (Engineering and Technology Edition), 2018, 48(3): 727-734. | |

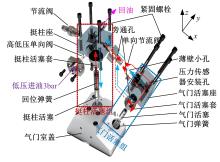

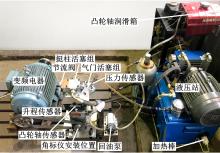

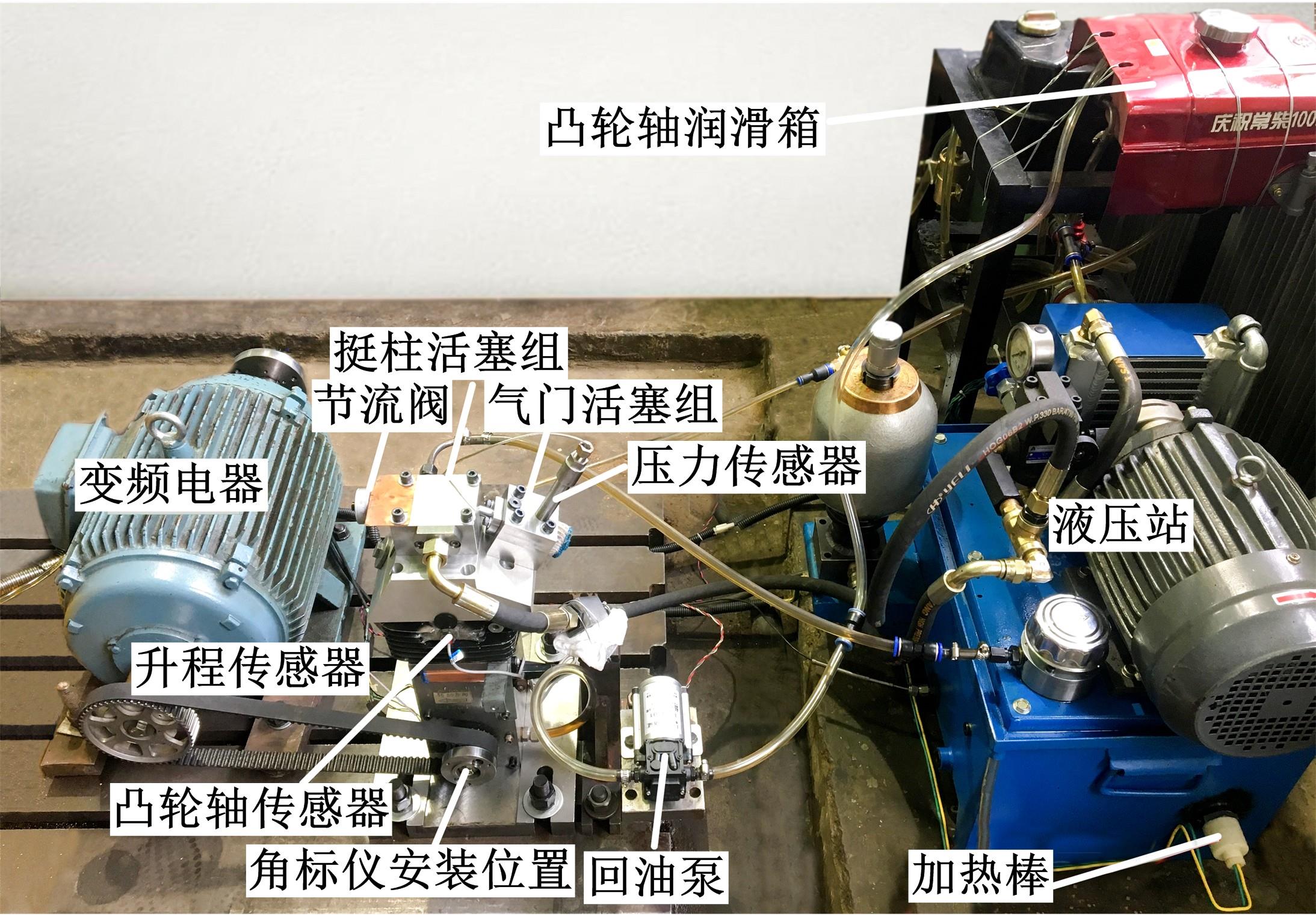

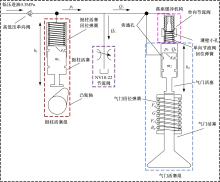

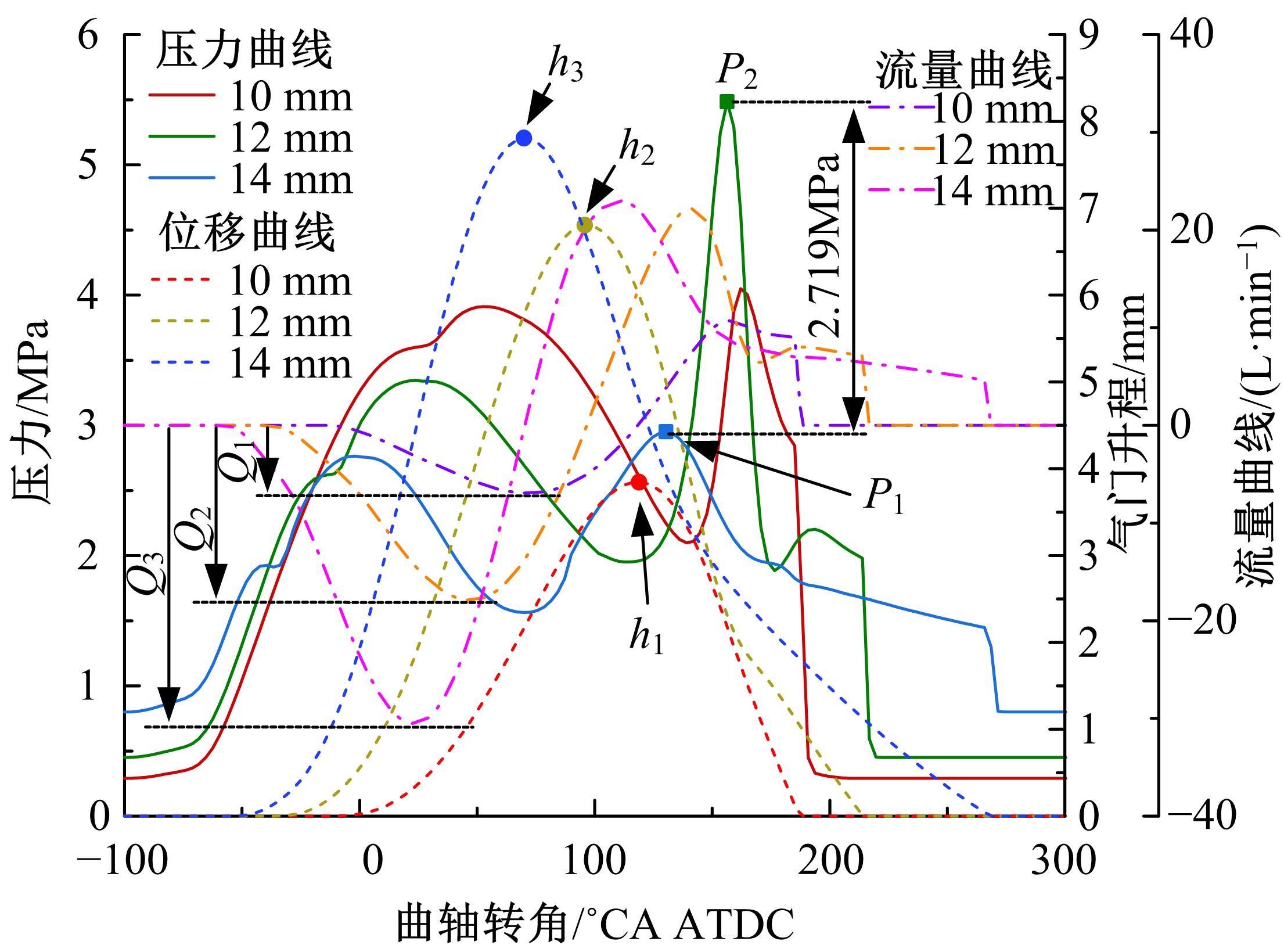

| 11 | 解方喜, 钟兵, 杨国志, 等. 凸轮驱动式液压可变气门机构设计及运动特性[J]. 汽车工程, 2020, 42(3): 307-314. |

| Xie Fang-xi, Zhong Bing, Yang Guo-zhi, et al. Design and motion characteristics of cam-driven hydraulic variable valve mechanism[J]. Automotive Engineering, 2020, 42(3): 307-314. | |

| 12 | Jin Z H, Hong W, You T, et al. Effect of multi-factor coupling on the movement characteristics of the hydraulic variable valve actuation[J]. Energies, 2020, 13(11): 2870. |

| 13 | ZlobinA V, Tarasevich S É. Hydraulic resistance of pipes with uniform continuous roughness of varying profile[J]. Journal of Engineering Physics and Thermophysics, 2020, 93(3): 725-732. |

| 14 | Boretti Alberto. Use of variable valve actuation to control the load in a direct injection, turbocharged, spark-ignition engine[C]∥SAE Paper, 2010-01-2225. |

| 15 | 宋佳彬. 变刚度气门弹簧设计方法研究[D]. 长春:吉林大学汽车工程学院, 2018. |

| Song Jia-bin. Research on design method of variable stiffness valve spring[D]. Changchun: College of Automotive Engineering, Jilin University, 2018. |

| [1] | WANG De-jun, LYU Zhi-chao, WANG Qi-ming, ZHANG Xian-da, WANG Zi-jian. Engine misfire fault diagnosis based on cylinder pressure identification [J]. 吉林大学学报(工学版), 2017, 47(3): 917-923. |

| [2] | HAN Lin-pei, HONG Wei, SU Yan, XIE Fang-xi, CHEN Jing, DU Wen-chang. Effect of GDI engine exhaust valve secondary open on refluent EGR stratification and combustion characteristics [J]. 吉林大学学报(工学版), 2017, 47(1): 113-121. |

| [3] | CHEN Jin-shi, WANG Guo-qiang, GONG Xun, WANG Xin, WANG Li, DU Yang. Characteristics of cartridge one-way relief valve [J]. 吉林大学学报(工学版), 2016, 46(2): 465-470. |

| [4] | TIAN Jing, LIU Zhong-chang, ZHANG Wen-jie, ZHANG Long-ping. Effect of load conditions on the performance of diesel engine under transient operation condition [J]. 吉林大学学报(工学版), 2015, 45(6): 1798-1803. |

| [5] | LIU Xin-hui, LI Qian-wen, CHEN Jin-shi, ZHANG Peng, NIU Ping-jie. Mathematical modeling and simulation of load-sensing priority valve [J]. 吉林大学学报(工学版), 2015, 45(6): 1817-1824. |

| [6] | DONG Han, LIU Xin-hui, WANG Xin, ZHENG Bo-yuan, LIANG Wei-quan, WANG Jia-yi. Parallel hydraulic hybrid braking regenerative characteristics [J]. 吉林大学学报(工学版), 2014, 44(6): 1655-1663. |

| [7] | LI Li-feng, JIANG Wan-lu. Driving system of hydroforming die change vehicle [J]. 吉林大学学报(工学版), 2012, 42(增刊1): 81-85. |

| [8] | Zhu Bing, Zhao Jian, Li Jing, Li You-de, Liu Wei, Wei Qing . Co-simulation platform with AMESim and MATLAB for traction control system [J]. 吉林大学学报(工学版), 2008, 38(增刊): 23-0027. |

| [9] |

Wang Peng-yu,Wang Qing-nian,Hu An-ping,Yu Yuan-bin .

Analysis of regenerative brake system of hybrid bus based on SimulinkAMESim cosimulation [J]. 吉林大学学报(工学版), 2008, 38(增刊): 7-0011. |

|

||