Journal of Jilin University(Engineering and Technology Edition) ›› 2022, Vol. 52 ›› Issue (10): 2466-2473.doi: 10.13229/j.cnki.jdxbgxb20210317

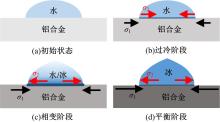

Stress characteristic of ice adhesion interface during freezing process

Yi-ying CHEN1,2( ),Jing-fu JIN1,2,Jia-xu WANG1,2,Ying-chun QI1,2,Lin WANG3,Ting-kun CHEN1,2(

),Jing-fu JIN1,2,Jia-xu WANG1,2,Ying-chun QI1,2,Lin WANG3,Ting-kun CHEN1,2( )

)

- 1.College of Biological and Agricultural Engineering,Jilin University,Changchun 130022,China

2.Key Laboratory of Bionic Engineering,Ministry of Education,Jilin University,Changchun 130022,China

3.State Key Laboratory of Power System of Tractor,Luoyang 471039,China

CLC Number:

- TB131

| 1 | Liu Y, Ma L Q, Wang W, et al. An experimental study on soft PDMS materials for aircraft icing mitigation[J]. Applied Surface Science, 2018, 447(1): 599-609. |

| 2 | Filomena P, Antonio C, Dariusz D, et al. Superhydrophobic coatings as anti-icing systems for small aircraft[J]. Aerospace, 2020, 7(1): No2. |

| 3 | Rustem M, Zhandos B, Saltanat B, et al. Numerical simulations on static vertical axis wind turbine blade icing[J]. Renewable Energy, 2021, 170: 997-1007. |

| 4 | Rossi A, Jubayer C, Koss H, et al. Combined effects of wind and atmospheric icing on overhead transmission lines[J]. Journal of Wind Engineering & Industrial Aerodynamics, 2020, 204: 104271. |

| 5 | 沈杰,白旭.风速对寒区船舶杆件结构霜冰结冰的影响分析[J].舰船科学技术,2020,42(5):56-60. |

| Shen Jie, Bai Xu. Analysis of the influence of wind speed on rime and ice formation of ship's pole structure in cold region[J]. Ship Science and Technology, 2020, 42(5): 56-60. | |

| 6 | 陈奕颖,丛茜,任露泉,等.冷藏设备防除冰表面非连续特征设计与试验[J].农业工程学报,2021,37(7):261-267. |

| Chen Yi-ying, Cong Qian, Ren Lu-quan, et al. Design and experiment of the non-continuous anti-icing surface for refrigeration equipment[J]. Transactions of the Chinese Society of Agricultural Engineering, 2021, 37(7): 261-267. | |

| 7 | 陈炳彬,张征,鲁聪达,等.复合材料层合结构在防覆冰/除冰系统中的应用[J].中国机械工程,2019, 30(7): 771-776. |

| Chen Bing-bin, Zhang Zheng, Lu Cong-da, et al. Applications of composite laminated structures in anti-icing and de-icing systems[J]. China Mechanical Engineering, 2019, 30(7): 771-776. | |

| 8 | Fay L, Shi X M. Environmental impacts of chemicals for snow and ice control: state of the knowledge[J]. Water, Air, & Soil Pollution, 2012, 223(5): 2751-2770. |

| 9 | Shi Z H, Zhao Y Q, Ma C K. Parametric study of ultrasonic de-icing method on a plate with coating[J]. Coatings, 2020, 10(7):No.631. |

| 10 | Li W, Zhan Y L, Yu S R. Applications of superhydrophobic coatings in anti-icing: theory, mechanisms, impact factors, challenges and perspectives[J]. Progress in Organic Coatings, 2021, 152: 106117. |

| 11 | Maghsoudi K, Vazirinasab E, Momen G, et al. Icephobicity and durability assessment of superhydrophobic surfaces: the role of surface roughness and the ice adhesion measurement technique[J]. Journal of Materials Processing Technology, 2021, 288: 116883. |

| 12 | Maghsoudi K, Momen G, Jafari R, et al. Rigorous testing to assess the self-cleaning properties of an ultra-water repellent silicone rubber surface[J]. Surface & Coatings Technology, 2019, 374: 557-568. |

| 13 | Jiang G, Chen L, Zhang S D, et al. Superhydrophobic SiC/CNTs coatings with photothermal deicing and passive anti-icing properties[J]. ACS Applied Materials and Interfaces, 2018, 10(42): 36505-36511. |

| 14 | Zhao Z H, Chen H W, Liu X L, et al. Development of high-efficient synthetic electric heating coating for anti-icing/de-icing[J]. Surface and Coatings Technology, 2018, 349: 340-346. |

| 15 | Zeng X C, Yan Z X, Lu Y C, et al. Reduction of ice adhesion using surface acoustic waves: nanoscale vibration and interface heating effects[J]. Langmuir, 2021, 37(40): 11851-11858. |

| 16 | Koji M, Tomoastu K. Fundamental study on adhesion of ice to cooling solid surface[J]. International Journal of Refrigeration, 2007, 30(5): 851-860. |

| 17 | Kirill A E, Alexandre M E, Ludmila B B. Water and ice adhesion to solid surfaces: Common and specific, the Impact of temperature and surface wettability[J]. Coatings, 2020, 10(7): No.648. |

| 18 | Chen T K, Cong Q, Sun C B, et al. Influence of substrate initial temperature on adhesion strength of ice on aluminum alloy[J]. Cold Regions Science and Technology, 2018, 148: 142-147. |

| 19 | Vercillo V, Tonnicchia S, Romano J, et al. Design rules for laser-treated icephobic metallic surfaces for aeronautic applications[J]. Advanced Functional Materials, 2020, 30(16): 1-12. |

| 20 | Beemer D L, Wang W, Kota A K. Durable gels with ultra-low adhesion to ice[J]. Journal of Materials Chemistry A, 2016, 4(47): 18253-18258. |

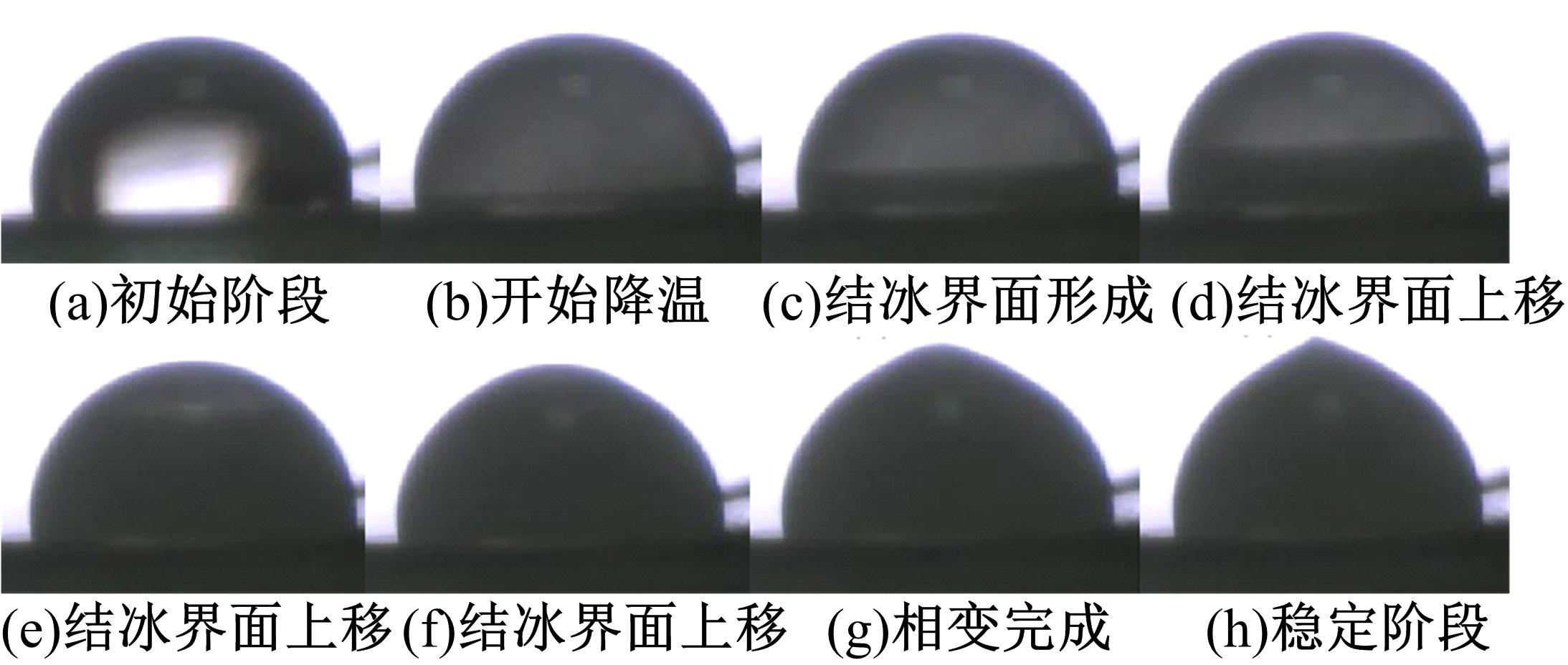

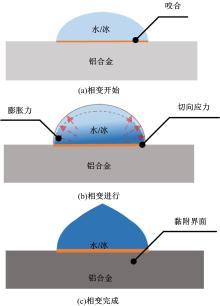

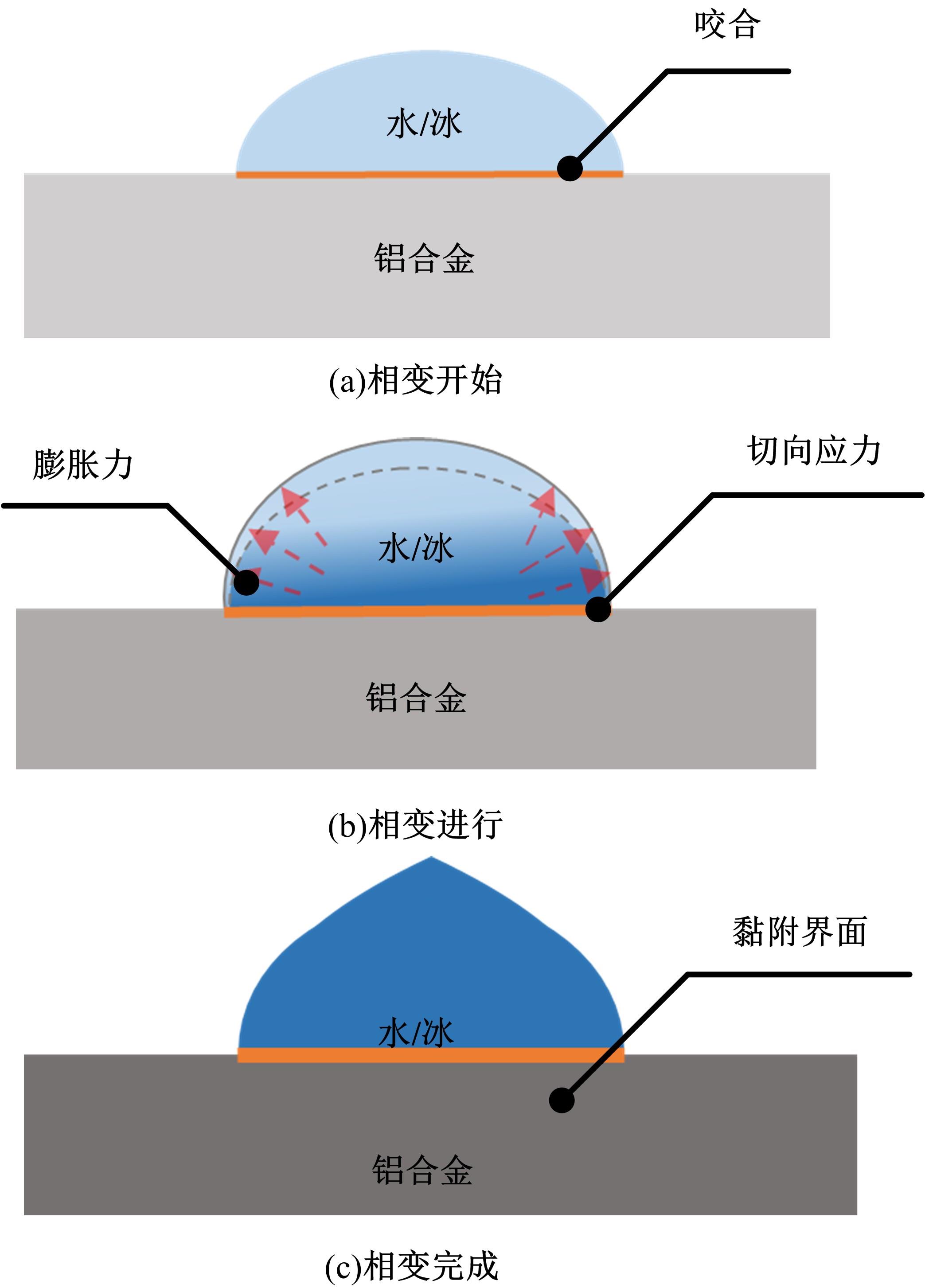

| 21 | 金敬福,韩丽曼,曹敏,等.水滴结冰相变体积膨胀规律[J].吉林大学学报:工学版,2016,46(5):1546-1551. |

| Jin Jing-fu, Han Li-man, Cao Min, et al. Volume expansion rule of water drops during the freezing process[J]. Journal of Jilin University(Engineering and Technology Edition),2016, 46(5): 1546-1551. | |

| 22 | 张受谦.化工手册[M].济南:山东科学技术出版社,1986. |

| 23 | Zhang X, Liu X, Min J C, et al. Shape variation and unique tip formation of a sessile water droplet during freezing[J]. Applied Thermal Engineering, 2019, 147: 927-934. |

| 24 | Song M J, Dang C B, Higashi T, et al. Review of experimental data associated with the solidification characteristics of water droplets on a cold plate surface at the early frosting stage[J]. Energy & Buildings, 2020, 223: 110113. |

| 25 | 曹敏,陈廷坤,丛茜,等.表面形态对结冰附着强度的影响[J].吉林大学学报:工学版,2013,43(5):1314-1319. |

| Cao Min, Chen Ting-kun, Cong Qian, et al. Influence of PMMA surface morphology on ice adhesion strength[J]. Journal of Jilin University(Engineering and Technology Edition), 2013, 43(5): 1314-1319. | |

| 26 | Cong Q, Xu J, Ren L Q, et al. Changes of water/ice morphological, thermodynamic, and mechanical parameters during the freezing process[J]. Arabian Journal for Science and Engineering, 2021, 46(11): 10631-10639. |

| 27 | 秦大同,谢里阳.现代机械设计手册(第一卷)[M].北京:化学工业出版社,2011. |

| 28 | 陈廷坤.基于干扰冰-固界面粘附稳定性的主动防/除冰方法研究[D].长春:吉林大学生物与农业工程学院,2019. |

| Chen Ting-kun. Research on active anti/de-icing method based on disturbing the adhesion stability of ice-solid interface[D]. Changchun: College of Biological and Agricultural Engineering, Jilin University, 2019. |

| [1] | Yi-ying CHEN,Jing-fu JIN,Qian CONG,Ting-kun CHEN,Lu-quan REN. Influence of media with different low freezing points on ice adhesion strength [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(5): 1926-1932. |

|

||