Journal of Jilin University(Engineering and Technology Edition) ›› 2021, Vol. 51 ›› Issue (5): 1926-1932.doi: 10.13229/j.cnki.jdxbgxb20210445

Influence of media with different low freezing points on ice adhesion strength

Yi-ying CHEN1( ),Jing-fu JIN1,Qian CONG2,3,Ting-kun CHEN1,2(

),Jing-fu JIN1,Qian CONG2,3,Ting-kun CHEN1,2( ),Lu-quan REN2

),Lu-quan REN2

- 1.College of Biological and Agricultural Engineering,Jilin University,Changchun 130022,China

2.Key Laboratory of Bionic Engineering,Ministry of Education,Jilin University,Changchun 130022,China

3.State Key Laboratory of Automotive Simulation and Control,Jilin University,Changchun 130022,China

CLC Number:

- TB131

| 1 | Lv J Y, Song Y L, Jiang L, et al. Bio-inspired strategies for anti-icing[J]. ACS Nano, 2014, 8(4): 3152-3169. |

| 2 | Wang J B, Zhang J, Zhang Y, et al. Impact of rotation of wheels and bogie cavity shapes on snow accumulating on the bogies of high-speed trains[J]. Cold Regions Science and Technology, 2019, 159: 58-70. |

| 3 | Cao Y H, Wu Z L, Su Y, et al. Aircraft flight characteristics in icing conditions[J]. Progress in Aerospace Science, 2015, 74: 62-80. |

| 4 | Fakorede O, Feger Z, Ibrahim H, et al. Ice protection systems for wind turbines in cold climate: characteristics, comparisons and analysis[J]. Renewable & Sustainable Energy Reviews, 2016, 65: 662-675. |

| 5 | Lan C Y, Li C, Wang S L. Parabolic antenna snow melting and removal using heat from the transmitter room[J]. Energy, 2019, 181: 738-744. |

| 6 | Zhu Y C, Huang X B, Jia J Y, et al. Experimental study on the thermal conductivity for transmission line icing[J]. Cold Regions Science and Technology, 2016, 129: 96-103. |

| 7 | Bao L Y, Huang Z Y, Priezjev N V, et al. A significant reduction of ice adhesion on nanostructured surfaces that consist of an array of single-walled carbon nanotubes: a molecular dynamics simulation study[J]. Applied Surface Science, 2018, 437: 202-208. |

| 8 | Borrebaek P O A, Jelle B P, Zhang Z L. Avoiding snow and ice accretion on building integrated photovoltaics-challenges, strategies, and opportunities[J]. Solar Energy Materials and Solar Cells, 2020, 206: 110306. |

| 9 | Wang Z J. Recent progress on ultrasonic de-icing technique used for wind power generation, high-voltage transmission line and aircraft[J]. Energy and Buildings, 2017, 140: 42-49. |

| 10 | Fakorede O, Feger Z, Ibrahim H, et al. Ice protection systems for wind turbines in cold climate characteristics, comparisons and analysis[J]. Renewable & Sustainable Energy Reviews, 2016, 65: 662-675. |

| 11 | 金敬福, 李杨, 陈廷坤, 等. 涂层弹性模量对结冰附着强度的影响[J]. 吉林大学学报: 工学版, 2017, 47(5): 1548-1553. |

| Jin Jing-fu, Li Yang, Chen Ting-kun, et al. Effect of elastic modulus of coating on ice-adhesion strength on substrate[J]. Journal of Jilin University(Engineering and Technology Edition), 2017, 47(5): 1548-1553. | |

| 12 | 金敬福, 韩丽曼, 曹敏, 等. 水滴结冰相变体积膨胀规律[J]. 吉林大学学报: 工学版, 2016, 46(5): 1546-1551. |

| Jin Jing-fu, Han Li-man, Cao Min, et al. Volume expansion rule of water droplets during freezing process[J]. Journal of Jilin University(Engineering and Technology Edition), 2016, 46(5): 1546-1551. | |

| 13 | Parent O, Ilinca A. Anti-icing and de-icing techniques for wind turbines: critical review[J]. Cold Regions Science and Technology, 2011, 65: 88-96. |

| 14 | Rashid T, Khawaja H A, Edvardsen K. Review of marine icing and anti-/de-icing systems[J]. Journal of Marine Engineering and Technology, 2016, 15(2): 79-87. |

| 15 | Kulinich S A, Farhadi S, Nose K, et al. Superhydrophobic surfaces are they really ice-repellent?[J]. Langmuir, 2011, 27: 25-29. |

| 16 | Nosonovsky M, Hejazi V. Why superhydrophobic surfaces are not always icephobic[J]. ACS Nano, 2012, 6(10): 8488-8491. |

| 17 | Zheng S L, Li C, Fu Q T, et al. Development of stable superhydrophobic coatings on aluminum surface for corrosion-resistant, self-cleaning, and anti-icing applications[J]. Materials & Design, 2016, 93: 261-270. |

| 18 | 郭永刚, 张鑫, 耿铁, 等. 超疏水表面耐久性能的研究进展[J]. 中国表面工程, 2018, 31(5): 63-72. |

| Guo Yong-gang, Zhang Xin, Geng Tie, et al. Research progress on durability of superhydrophobic surfaces[J]. China Surface Engineering, 2018, 31(5): 63-72. | |

| 19 | 佟威, 熊党生. 仿生超疏水表面的发展及其应用研究进展[J]. 无机材料学报, 2019, 34(11):1133-1144. |

| Tong Wei, Xiong Dang-sheng. Bioinspired superhydrophobic materials: progress and functional application[J]. Journal of Inorganic Materials, 2019, 34(11): 1133-1144. | |

| 20 | 李国滨, 刘海峰, 李金辉, 等. 超疏水材料的研究进展[J]. 高分子材料科学与工程, 2020, 36(12): 142-150. |

| Li Guo-bin, Liu Hai-feng, Li Jin-hui, et al. Research progress of preparation of superhydrophobic[J]. Polymer Materials Science and Engineering, 2020, 36(12): 142-150. | |

| 21 | 丁金波, 董威. 表面粗糙度对冰冻黏强度影响试验研究[J]. 航空发动机, 2012, 38(4): 42-46. |

| Ding Jin-bo, Dong Wei. Experimental study of influence of surface roughness on ice adhesion[J]. Aeroengine, 2012, 38(4): 42-46. | |

| 22 | Hassan M F, Lee H P, Lim S P. The variation of ice adhesion strength with substrate surface roughness[J]. Measurement Science and Technology, 2010, 21: 075701. |

| 23 | Tarquini S, Antonini C, Amirfazli A, et al. Investigation of ice shedding properties of superhydrophobic coatings on helicopter blades[J]. Cold Regions Science and Technology, 2014, 100: 50-58. |

| 24 | 丁云飞, 唐珊, 吴会军. 表面微结构对冰粘附强度的影响[J]. 表面技术, 2015, 44(4): 74-78. |

| Ding Yun-fei, Tang Shan, Wu Hui-jun. Study on influence of surface microstructure on ice adhesion strength[J].Surface Technology, 2015, 44(4): 74-78. | |

| 25 | 翟广坤, 李曙林, 陈素素, 等. 氟化改性硅树脂制备的超疏水涂层防覆冰性能[J]. 工程科学学报, 2018, 40(7): 864-870. |

| Zhai Guang-kun, Li Shu-lin, Chen Su-su, et al. Anti-icing performance of superhydrophobic coating prepared by modified fluorinated silicone[J]. Chinese Journal of Engineering, 2018, 40(7): 864-870. | |

| 26 | Shen Y Z, Wu Y, Tao J, et al. Spraying fabrication of durable and transparent coatings for anti-icing application: dynamic water repellency, icing delay, and ice adhesion[J]. ACS Applied Materials & Interfaces, 2019, 11: 3590-3598. |

| 27 | Ghalmi Z, Farzaneh M. Durability of nanostructured coatings based on PTFE nanoparticles deposited on porous aluminum alloy[J]. Applied Surface Science, 2014, 314: 564-569. |

| 28 | Ghalmi Z, Farzaneh M. Experimental investigation to evaluate the effect of PTFE nanostructured roughness on ice adhesion strength[J]. Cold Regions Science and Technology, 2015, 115: 42-47. |

| 29 | 陈绍纲. 轮机工程手册[M]. 1版. 北京: 人民交通出版社, 1992. |

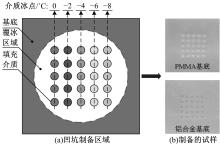

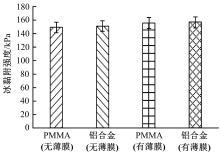

| 30 | 曹敏, 陈廷坤, 丛茜, 等. 表面形态对结冰附着强度的影响[J]. 吉林大学学报: 工学版, 2013, 43(5): 1314-1319. |

| Cao Min, Chen Ting-kun, Cong Qian, et al. Influence of PMMA surface morphology on ice adhesion strength[J]. Journal of Jilin University(Engineering and Technology Edition), 2013, 43(5): 1314-1319. |

| [1] | Kang WANG,Meng YAO,Li-ben LI,Jian-qiao LI,Xiang-jin DENG,Meng ZOU,Long XUE. Mechanical performance identification for lunar soil in lunar surface sampling [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(3): 1146-1152. |

| [2] | Zhi-hui QIAN,Si-jie WU,Qiang WANG,Xin-yan ZHOU,Jia-nan WU,Lei REN,Lu-quan REN. Design of bionic tensegrity leg and simulation analysis of its impact resistance [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 758-764. |

| [3] | TIAN Wei-jun, WANG Ji-yue, LI Ming, ZHANG Xing-wang, ZHANG Yong, CONG Qian. Observation of locomotion of water strider towards water strider robot [J]. 吉林大学学报(工学版), 2018, 48(3): 812-820. |

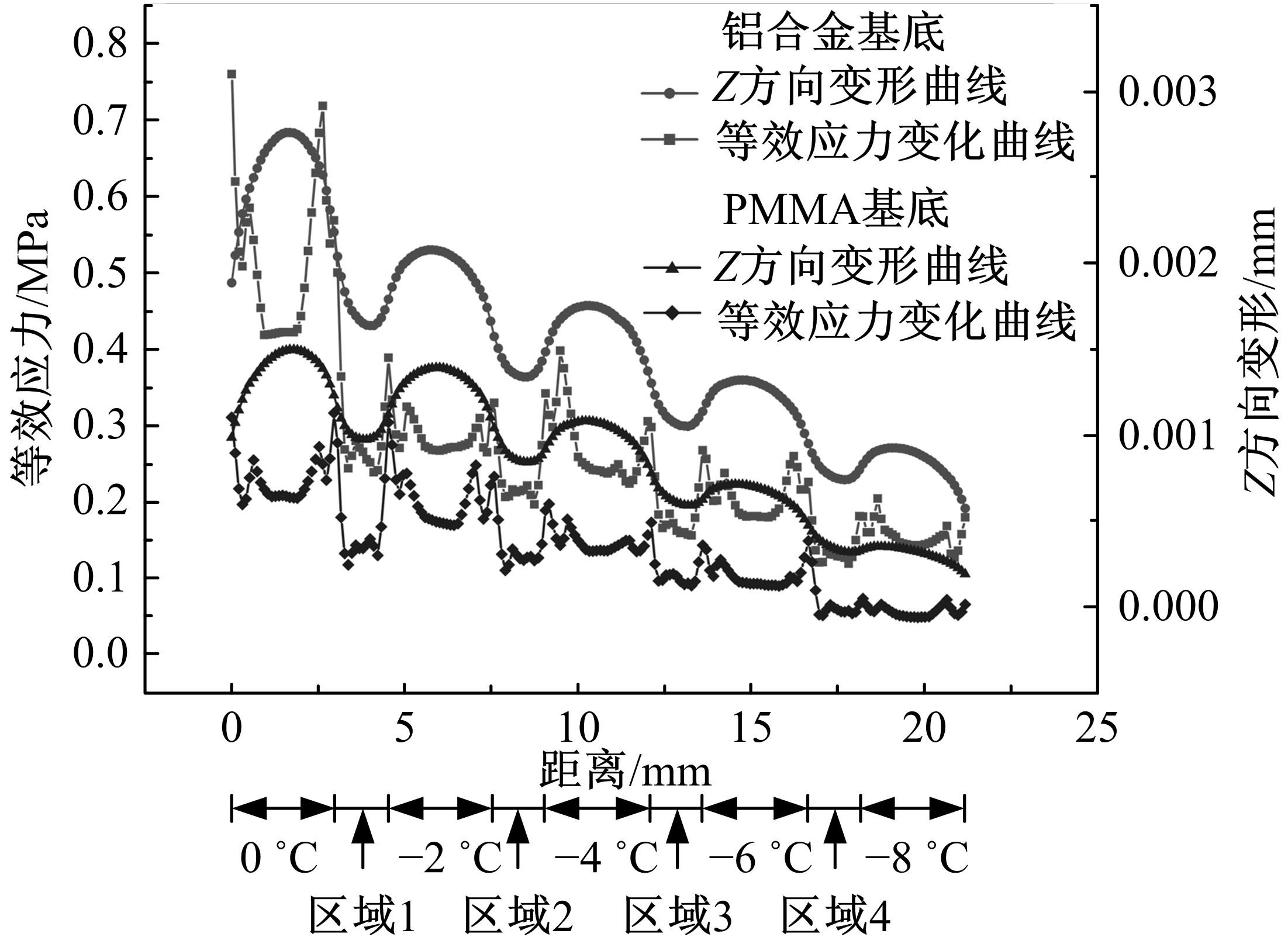

| [4] | JIN Jing-fu, LI Yang, CHEN Ting-kun, CONG Qian, QI Ying-chun. Effect of elastic modulus of coating on ice-adhesion strength on substrate [J]. 吉林大学学报(工学版), 2017, 47(5): 1548-1553. |

| [5] | CHEN Dong-hui, LIU Wei, LYU Jian-hua, CHANG Zhi-yong, WU Ting, MU Hai-feng. Bionic design of corn stubble collector based on surface structure of Patinopecten yessoensis [J]. 吉林大学学报(工学版), 2017, 47(4): 1185-1193. |

| [6] | TIAN Li-mei, WANG Yang-jun, LI Zi-yuan, SHANG Yan-geng. Development of drag-reduction test system of bionic functional surfaces with internal flow [J]. 吉林大学学报(工学版), 2017, 47(4): 1179-1184. |

| [7] | WANG Ying, LI Jian-qiao, ZHANG Guang-quan, HUANG Han, ZOU Meng. Mechanical characteristics of bionic walking foot in different media [J]. 吉林大学学报(工学版), 2017, 47(2): 546-551. |

| [8] | ZHANG Rui, YANG Ming-ming, LIU Hai-bao, ZENG Gui-yin, PAN Run-duo, LI Jian-qiao. Numerical simulation of sand flow fixation characteristics of plantar surface of ostrich didactyl foot [J]. 吉林大学学报(工学版), 2015, 45(2): 508-515. |

| [9] | TIAN Li-mei, SHANG Zhen, HU Guo-liang, LI Nan. Numerical simulation of the lift and drag characteristics of passenger car based on morphological bionics [J]. 吉林大学学报(工学版), 2014, 44(5): 1283-1289. |

| [10] | ZHANG Rui, ZHANG Si-hua, LIU Fang, LI Jian-qiao. Structure design and performance analysis of bionic desert hiking stick [J]. 吉林大学学报(工学版), 2013, 43(04): 976-982. |

| [11] | ZHANG Yan, HUANG He, REN Lu-quan. Drag reduction experiment of bionic excvavtor bucket teeth [J]. 吉林大学学报(工学版), 2012, 42(增刊1): 126-130. |

| [12] | CHANG Zhi-yong, CHEN Dong-hui, TONG Jin, TONG Yue-ying, XIE Jun. Human olfactory feature based bionic electronic nose technology for pork freshness detection [J]. 吉林大学学报(工学版), 2012, 42(增刊1): 131-134. |

| [13] | SHI Lei, ZHANG Cheng-chun, WANG Jing, WANG Yong-hua,ZHANG Xue-peng, REN Lu-quan. Reduction of aerodynamic noise from NACA0018 airfoil model using bionic methods [J]. 吉林大学学报(工学版), 2011, 41(6): 1664-1668. |

|

||