Journal of Jilin University(Engineering and Technology Edition) ›› 2025, Vol. 55 ›› Issue (2): 485-493.doi: 10.13229/j.cnki.jdxbgxb.20230504

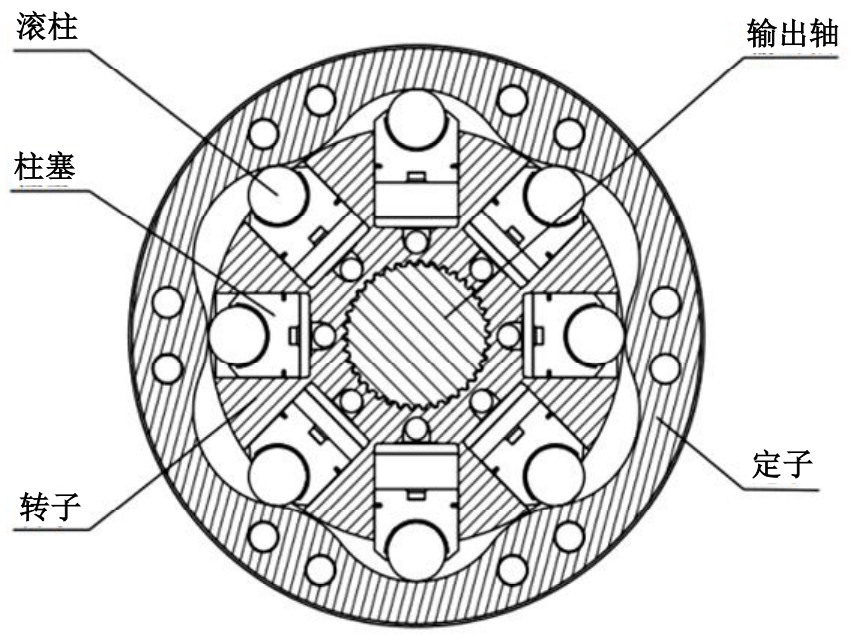

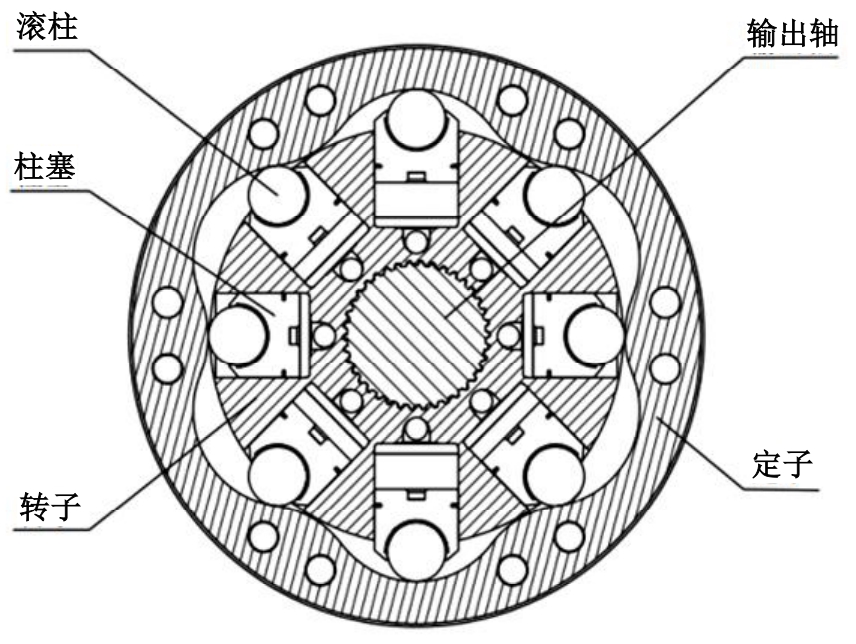

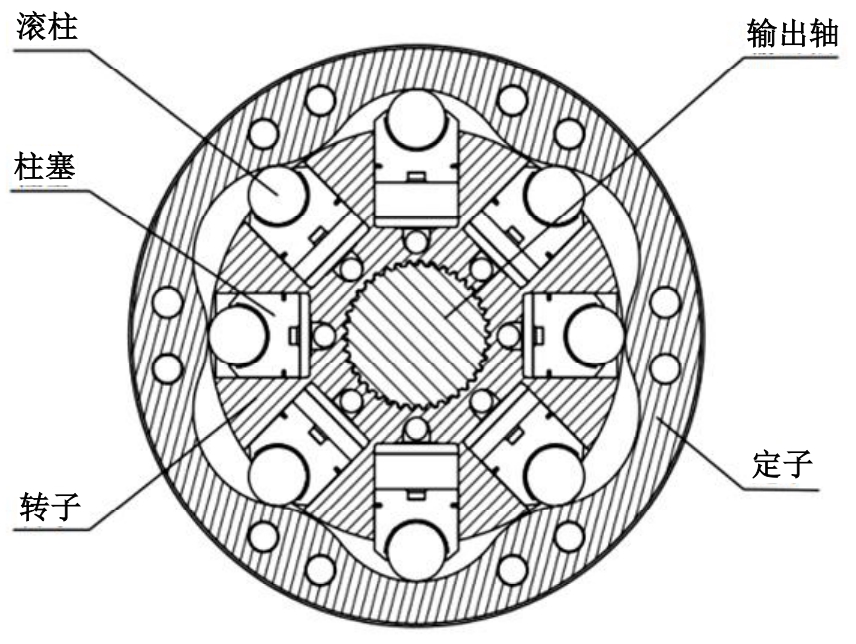

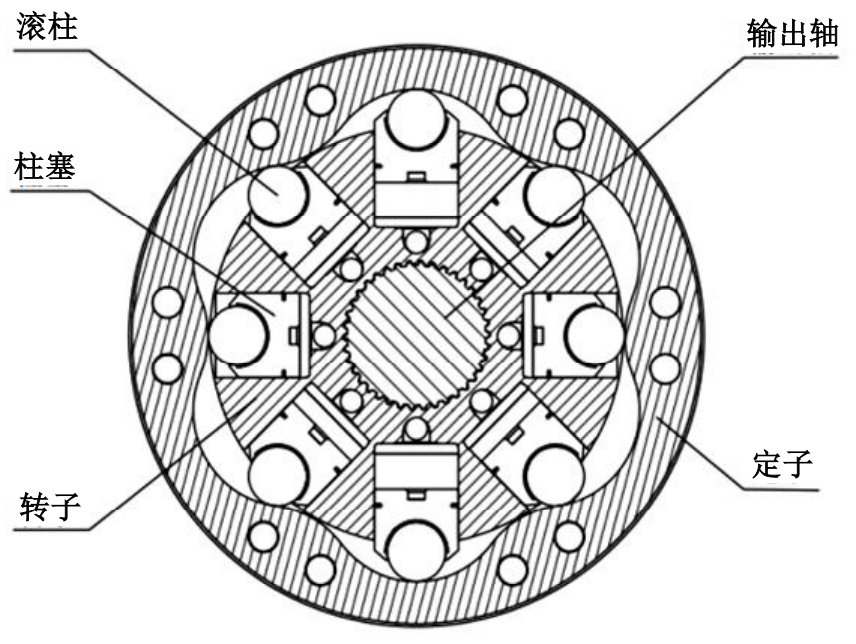

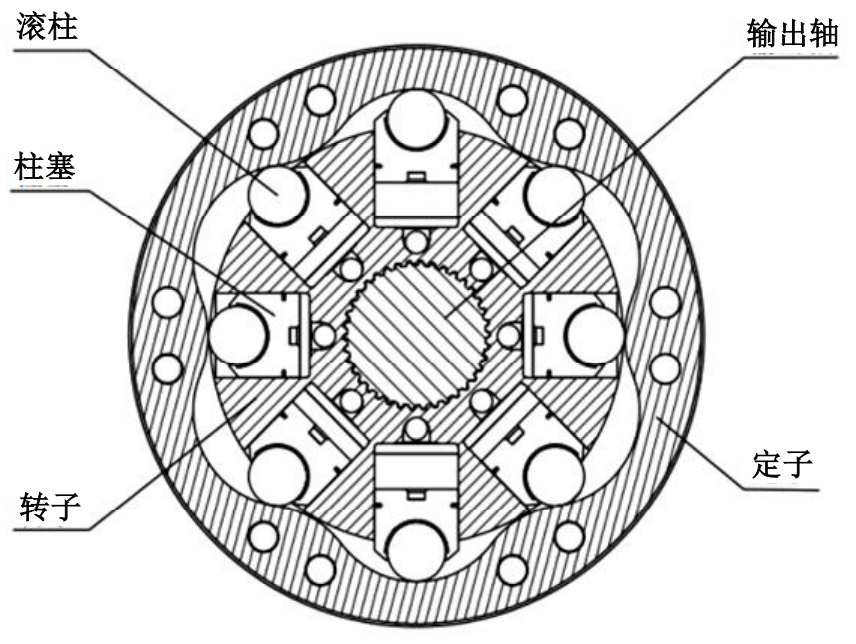

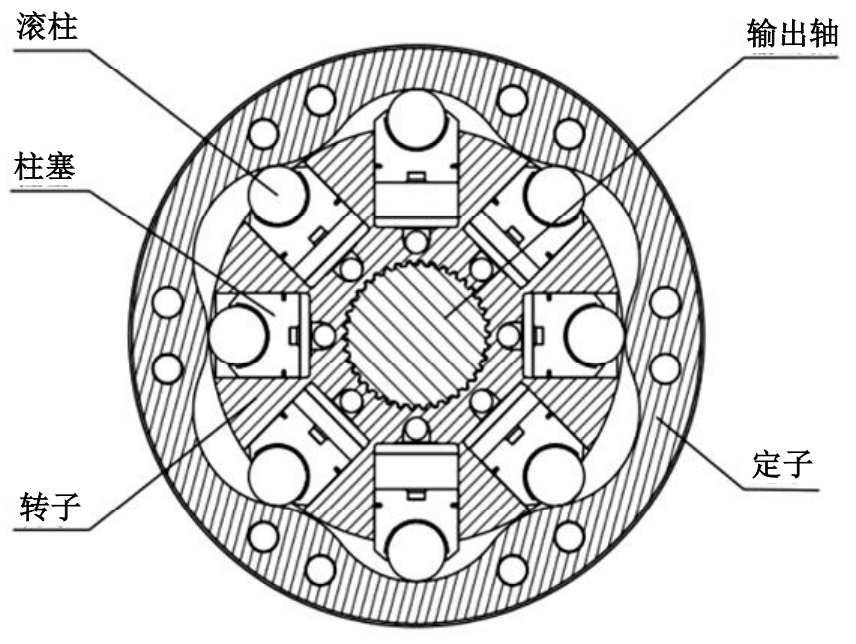

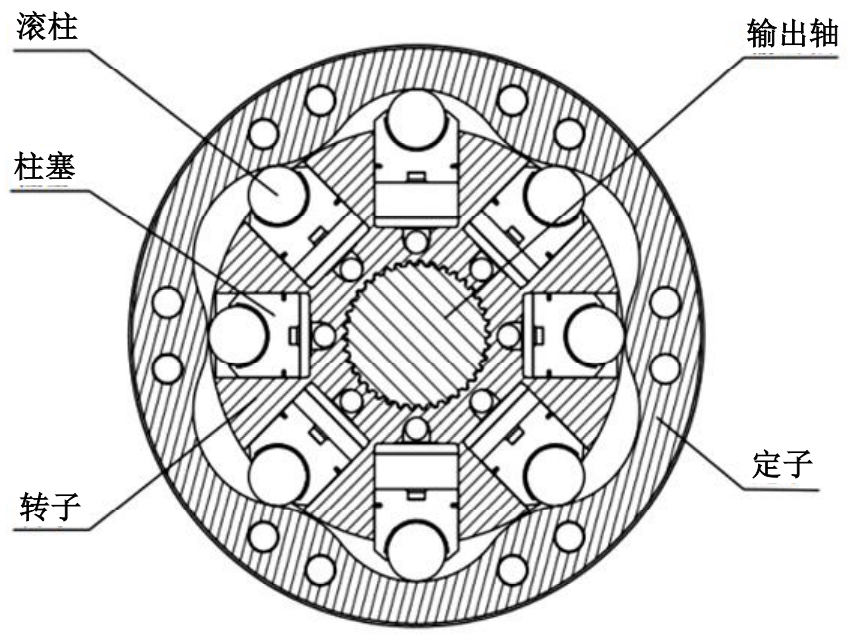

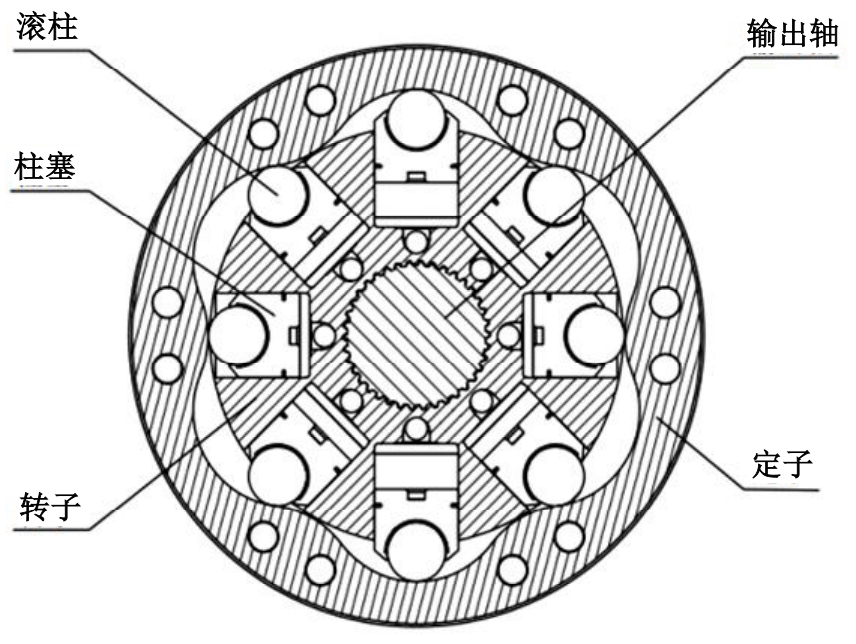

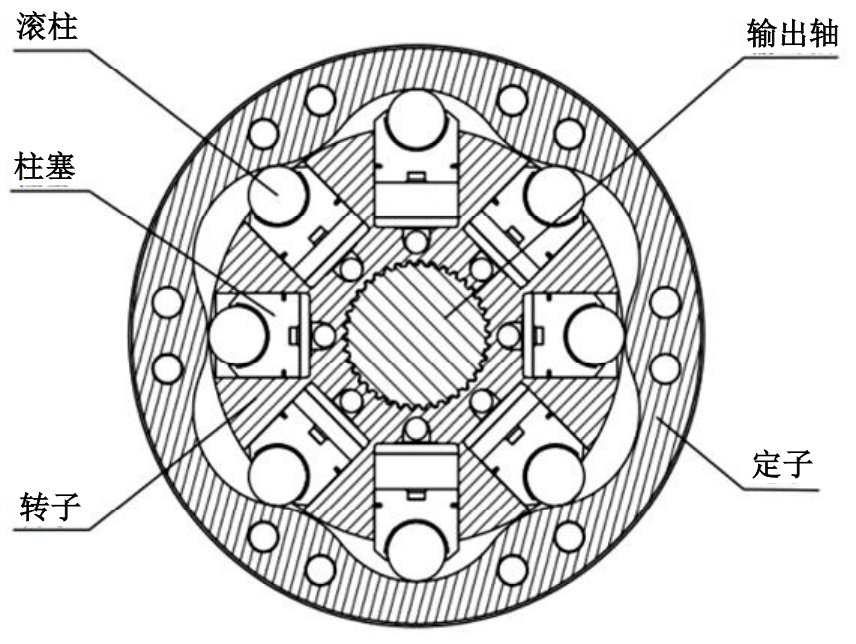

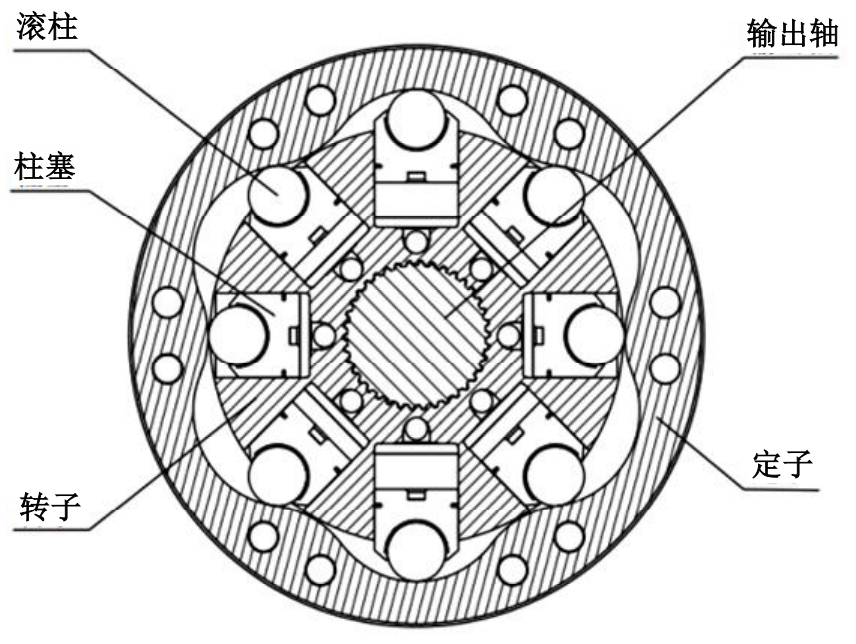

Design and analysis of guide curve of radial piston motor with low argument distribution coefficient

Gao-cheng AN( ),Zhen-hua HU,Hong-quan DONG,Bao-yu LIU,Kai GAO,Wen-kang WANG

),Zhen-hua HU,Hong-quan DONG,Bao-yu LIU,Kai GAO,Wen-kang WANG

- School of Mechanical Engineering,Taiyuan University of Science and Technology,Taiyuan 030024,China

CLC Number:

- TH137.51

| 1 | 李壮云. 液压元件与系统[M]. 北京: 机械工业出版社,2011. |

| 2 | 贺辉,宋大凤,杨南南,等. 轮毂马达液驱系统控制与仿真[J]. 吉林大学学报: 工学版,2012,42(): 27-31. |

| He Hui, Song Da-feng, Yang Nan-nan, et al. Control and simulation of hydraulic in-wheel motor propulsion system[J]. Journal of Jilin University(Engineering and Technology Edition), 2012, 42(Sup.1): 27-31. | |

| 3 | 黄方平,罗从宗,黄菲,等. 低速大扭矩多作用内曲线径向柱塞式液压马达的发展与应用[J]. 机床与液压,2015,43(4): 181-183. |

| Huang Fang-ping, Luo Cong-zong, Huang Fei, et al. Development and application of low-speed and high- torque multi-acting internal curve radial piston hydraulic motor[J]. Machine Tool & Hydraulics, 2015, 43(4): 181-183. | |

| 4 | Tao J, Wang H Y, Liao H H, et al. Mechanical design and numerical simulation of digital-displacement radial piston pump for multi-megawatt wind turbine drivetrain[J]. Renewable Energy, 2019, 143: 995-1009. |

| 5 | 陈卓如. 低速大扭矩液压马达理论、计算与设计[M]. 北京: 机械工业出版社,1989. |

| 6 | 杨国来,黄昭雪,李熙彬,等. 幅角分配对大排量径向柱塞泵性能的影响[J]. 液压与气动,2016(6): 1-7. |

| Yang Guo-lai, Huang Zhao-xue, Li Xi-bin, et al. Effect of argument distribution on performance of larger displacement radial piston pump[J]. Chinese Hydraulic & Pneumatics, 2016(6): 1-7. | |

| 7 | 高殿荣,王志强,赵一楠. 径向低速大转矩水液压马达定子曲线特性分析[J]. 机械设计,2012,29(9): 29-35. |

| Gao Dian-rong, Wang Zhi-qiang, Zhao Yi-nan. Analysis of stator curve characteristics of radial low-speed large torque hydraulic motor[J]. Journal of Mechanical Design, 2012, 29(9): 29-35. | |

| 8 | Wang Z Q, Yao H, Bao W J, et al. Motion simulation and statics analysis of the stator and rotor of low speed high torque water hydraulic motor[C]∥ Intelligent Robotics and Applications: 8th International Conference, Portsmouth, UK, 2015: 167-180. |

| 9 | 王志强. 内曲线式低速大扭矩水液压马达关键技术研究[D]. 秦皇岛:燕山大学机械工程学院,2014. |

| Wang Zhi-qiang. Research on key technology of incurve type water hydraulic motor with low speed high torque [D]. Qinhuangdao:School of Mechanical Engineering, Yanshan University, 2014. | |

| 10 | 武洪松. 低速大扭矩水液压马达定子曲线研究[D]. 秦皇岛:燕山大学机械工程学院,2016. |

| Wu Hong-song. Research on the stator curve of water- hydraulic motor with low speed high torque[D]. Qinhuangdao: School of Mechanical Engineering, Yanshan University, 2016. | |

| 11 | 于红英,钟汉田,李硕. 修正心形线式内曲线径向柱塞马达脉动分析[J]. 哈尔滨工业大学学报,2012,44 (3): 44-48. |

| Yu Hong-ying, Zhong Han-tian, Li Shuo. The analysis on the flow pulsation of radial piston motor with the modified heart-shaped curve as inner curve[J]. Journal of Harbin Institute of Technology, 2012, 44(3): 44-48. | |

| 12 | 辛剑波,柯尊荣,武艺. 径向双球塞柱塞马达广义椭圆定子曲线导轨的分析与设计[J]. 液压与气动, 2018, 2018(10): 87-91. |

| Xin Jian-bo, Ke Zun-rong, Wu Yi. Analysis and design on curved guide orbit of generalized elliptic stator for radial double ball plunger motor[J]. Chinese Hydraulic & pneumatics, 2018, 2018(10): 87-91. | |

| 13 | 辛剑波,柯尊荣,乐国鹏,等. 采用广义椭圆方程曲线导轨的径向球塞马达的输出特性[J]. 液压与气动,2019(6): 47-52. |

| Xin Jian-bo, Ke Zun-rong, Le Guo-peng, et al. Output characteristics of radial bulb stopper hydraulic motor using generalized elliptic equation curve orbits[J]. Chinese Hydraulic & Pneumatics, 2019(6): 47- 52. | |

| 14 | 黄菲,黄方平,沈萌红. 径向柱塞式液压马达等接触应力内曲线的精确绘制[J] . 机床与液压,2013,41(19): 148-150. |

| Huang Fei, Huang Fang-ping, Shen Meng-hong. Accurate drawing of equal contact stress inner curve for radial-piston hydraulic motor[J]. Machine Tool & Hydraulics, 2013, 41(19): 148-150. | |

| 15 | 程海林. 径向柱塞式液压马达等接触应力内曲线的研究[D]. 杭州:浙江工业大学机电工程学院,2004. |

| Cheng Hai-lin. Study on internal contact stress curve of radial piston hydraulic motor[D]. Hangzhou: School of Mechanical and Electrical Engineering, Zhejiang University of Technology, 2004. | |

| 16 | 刘为海. 径向柱塞式液压马达无脉动等应力导轨曲线设计与分析[D]. 武汉: 武汉理工大学机电工程学院, 2013. |

| Liu Wei-hai. Design and analysis of pulseless isostress guide curve for radical piston hydraulic motor[D]. Wuhan: School of Mechanical and Electrical Engineering, Wuhan University of Technology, 2013. | |

| 17 | 张小龙,张军辉,张红娟,等. 内曲线径向柱塞马达导轨曲线的优化设计[J]. 华中科技大学学报: 自然科学,2021, 49(10): 30-35. |

| Zhang Xiao-long, Zhang Jun-hui, Zhang Hong-juan, et al. Optimized design of cam ring curve of cam lobe radial- piston motor[J]. Journal of Huazhong University of Science and Technology (Natural Science), 2021, 49(10): 30-35. |

| [1] | Yong-ping LIU,Chang-bin DONG,Yong-qiao WEI. Analysis of tooth surface contact and dynamic wear of elliptic gear transmission system [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(5): 1620-1627. |

| [2] | DONG Li-chun, HAN Zhi-wu, ZHANG Lei, NIU Shi-chao, MA Rong-feng, REN Lu-quan. Numerical simulation on contact problem of ring model with bionic concave morphology [J]. 吉林大学学报(工学版), 2013, 43(增刊1): 543-546. |

|

||