Journal of Jilin University(Engineering and Technology Edition) ›› 2025, Vol. 55 ›› Issue (4): 1225-1231.doi: 10.13229/j.cnki.jdxbgxb.20240399

Previous Articles Next Articles

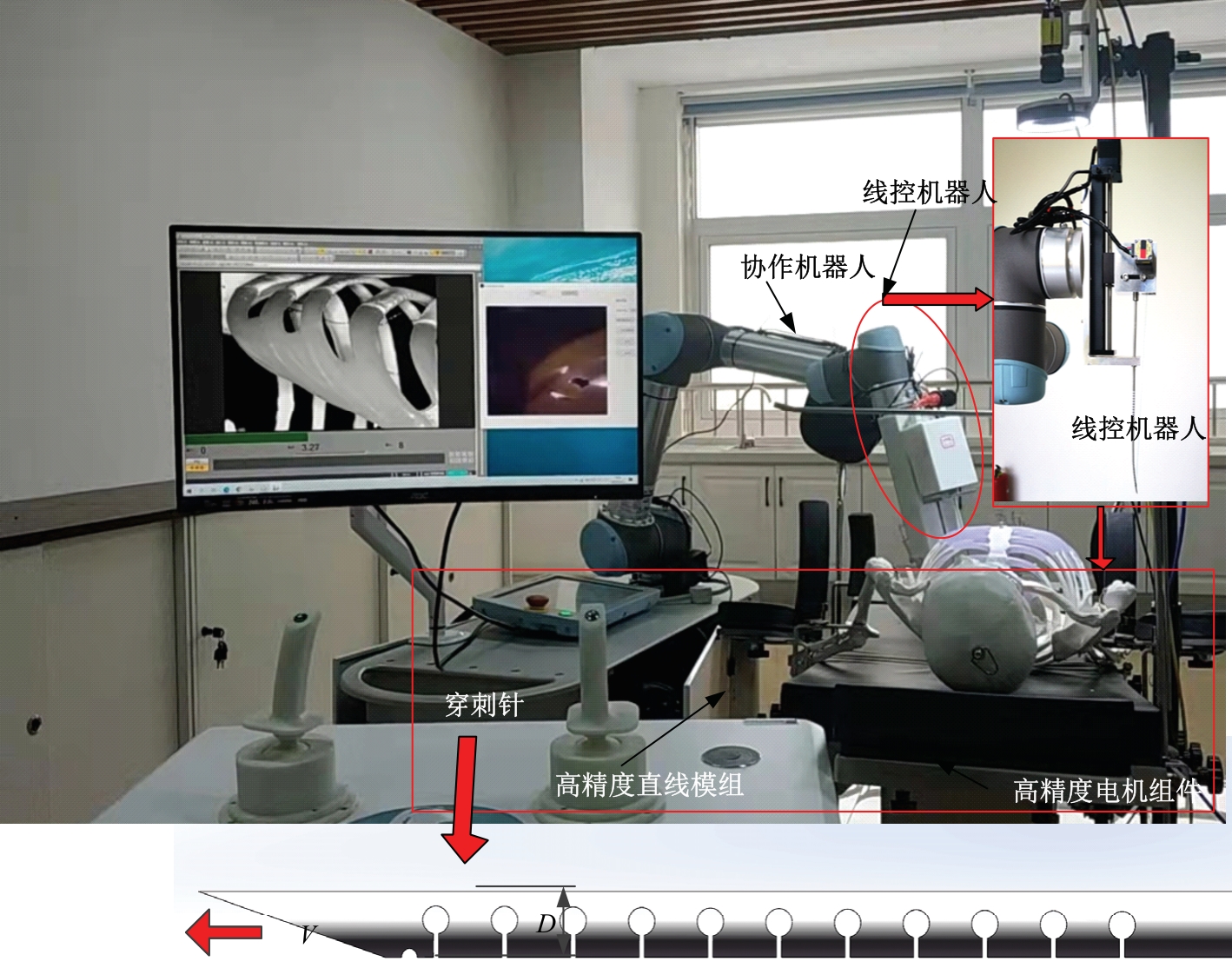

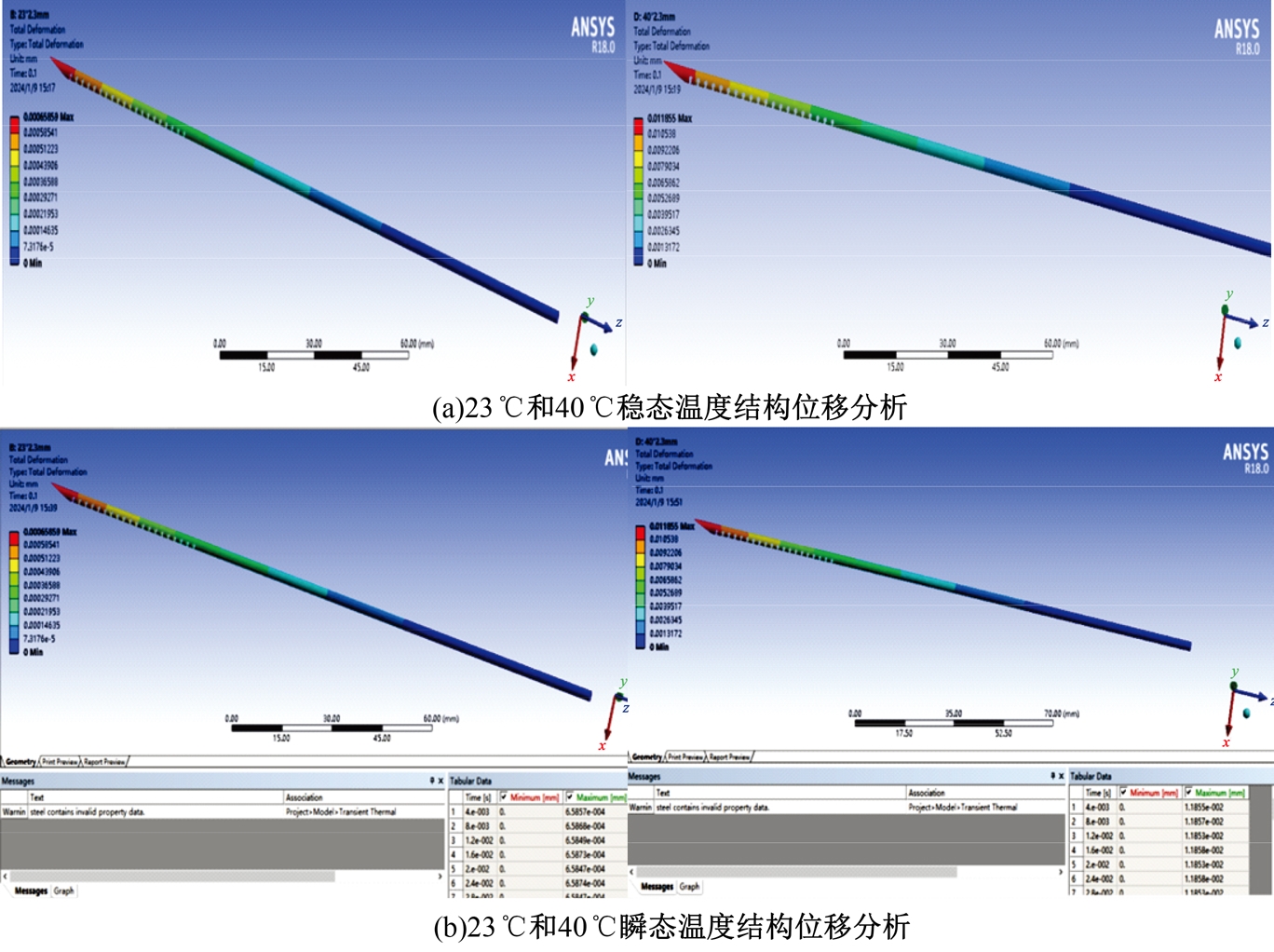

Influence of thermal factors on precision stability of wire-controlled puncture robot

Guan-bin WANG1,2( ),Ye-wang SUN1,2(

),Ye-wang SUN1,2( ),Peng-kai GAO1,2,Lu-wei YANG1,2

),Peng-kai GAO1,2,Lu-wei YANG1,2

- 1.Technical Institute of Physics and Chemistry,Chinese Academy of Sciences,Beijing 100190,China

2.University of Chinese Academy of Sciences,Beijing 101408,China

CLC Number:

- TP242

| 1 | 段星光, 温浩, 何睿, 等.胸腹腔经皮穿刺机器人研究进展及关键技术分析[J]. 机器人, 2021, 43(5): 567-584. |

| Duan Xing-guang, Wen Hao, He Rui, et al. Research progress and key technology analysis of thoracoabdominal percutaneous puncture robot[J]. Robot,2021,43(5):567-584. | |

| 2 | Donder A, Baena F R. 3-D path-following control for steerable needles with fiber Bragg gratings in multi-core fibers[J]. IEEE Transactions on Biomedical Engineering, 2022, 70(3): 1072-1085. |

| 3 | 张帆, 何彦霖, 周康鹏, 等. 穿刺手术柔性针路径规划技术现状和展望[J]. 电子测量与仪器学报, 2023, 37(6): 1-13. |

| Zhang Fan, He Yan-lin, Zhou Kang-peng, et al. The current status and prospects of flexible needle path planning technology for puncture surgery[J]. Journal of Electronic Measurement and Instrumentation, 2023,37(6):1-13. | |

| 4 | Goh G S, Yue W M, Guo C M. Comparative demographics and outcomes of minimally invasive transforaminal lumbar interbody fusion in Chinese, Malays, and Indians[J]. Clinical Spine Surgery, 2021, 34(2): 66-72. |

| 5 | 王乃堃, 骆敏舟, 陆丽娟. 穿刺机器人在微创外科手术中的应用进展[J]. 中国疼痛医学杂志, 2020, 26(5): 376-380. |

| Wang Nai-kun, Luo Min-zhou, Lu Li-juan.Progress in the application of puncture robots in minimally invasive surgery[J]. Chinese Journal of Pain Medicine, 2020,26(5):376-380. | |

| 6 | Kim J E, Yoo H S, Choi D J. Comparison of minimal invasive versus biportal endoscopic transforaminal lumbar interbody fusion for single-level lumbar disease[J]. Clinical Spine Surgery, 2021, 34(2): 64-71. |

| 7 | 田伟. 我国医用机器人的研究现状及展望[J]. 骨科临床与研究杂志, 2018, 3(4): 193-197. |

| Tian Wei. The current research status and prospects of medical robots in China[J]. Journal of Clinical and Research Orthopedics, 2018, 3(4): 193-197. | |

| 8 | 李霞. 机器人辅助柔性针软组织穿刺系统研究[D].湘潭: 湘潭大学自动化与电子信息学院, 2016. |

| Li Xia. Research on robot assisted flexible needle soft tissue puncture system[D]. Xiangtan: School of Automation and Electronic Information,Xiangtan University, 2016. | |

| 9 | 王田苗, 郝雨飞, 杨兴帮, 等. 软体机器人: 结构、驱动、传感与控制[J]. 机械工程学报, 2017, 53(13): 1-12. |

| Wang Tian-miao, Hao Yu-fei, Yang Xing-bang, et al. Soft robot: structure, drive, sensing and control [J]. Journal of Mechanical Engineering, 2017, 53(13): 1-12. | |

| 10 | 霍本岩, 赵新刚, 韩建达, 等. 基于可达性决策的柔性针穿刺控制方法[J]. 控制理论与应用, 2014, 31(10):1423-1424. |

| Huo Ben-yan, Zhao Xin-gang, Han Jian-da, et al. Flexible needle puncture control method based on accessibility decision[J]. Control Theory and Application, 2014, 31(10):1423-1424. | |

| 11 | 雷静桃, 王洋, 程利亚, 等. 基于复位路径包络误差和改进人工势力场法的复位机器人安全策略[J]. 机械工程学报,2020, 56(1): 9-19. |

| Lei Jing-tao, Wang Yang, Cheng Li-ya, et al. Safety strategy for reset robots based on reset path envelope error and improved artificial force field method[J]. Journal of Mechanical Engineering, 2020, 56(1): 9-19. | |

| 12 | 张少华. 微创穿刺手术系统关键技术及穿刺定位精度实验研究[D].北京:北京理工大学机械与车辆学院, 2012. |

| Zhang Shao-hua. Experimental study on key technologies and puncture positioning accuracy of minimally invasive puncture surgery system[D].Beijing: School of Mechanical and Vehicular Engineering,Beijing Institute of Technology, 2012. | |

| 13 | 孙椰望, 刘宇行. 腰椎神经微创机器人柔性进针控制技术设计[J]. 颈腰痛杂志, 2021, 42(2): 274-278. |

| Sun Ye-wang, Liu Yu-xing. Design of flexible needle insertion control technology for lumbar spine nerve minimally invasive robot[J]. Journal of Neck and Back Pain, 2021, 42(2):274-278. | |

| 14 | 殷谦, 尚建忠. 柔性波动鳍两栖机器人鳍面结构设计与运动仿真[J]. 工程热物理学报, 2021, 42(11):2954-2960. |

| Yin Qian, Shang Jian-zhong. Design and motion simulation of fin surface structure for flexible wave fin amphibious robot[J]. Journal of Engineering Thermophysics, 2021, 42 (11): 2954-2960. | |

| 15 | 嵇建成, 王玉峰, 付建军, 等.康复助行机器人倾覆稳定性分析[J]. 工业控制计算机, 2024, 37(2): 70-72. |

| Ji Jian-cheng, Wang Yu-feng, Fu Jian-jun, et al. Stability analysis of rehabilitation walking robot overturning[J]. Industrial Control Computer, 2024, 37 (2): 70-72. | |

| 16 | 刘泽华. 柔索驱动式主动柔性针穿刺机器人机构的设计及分析[D]. 哈尔滨: 哈尔滨理工大学机械动力工程学院, 2020. |

| Liu Ze-hua. Design and analysis of a flexible cable driven active flexible needle puncture robot mechanism[D]. Harbin:School of Mechanical and Power Engineering,Harbin University of Science and Technology, 2020. | |

| 17 | 董欣勃, 魏操兵, 商晋. 冷压缩机温度场仿真及其冷却参数优化分析[J]. 工程热物理学报, 2020, 41(8): 1851-1860. |

| Dong Xin-bo, Wei Cao-bing, Shang Jin.Simulation of temperature field and optimization analysis of cooling parameters for cold compressors[J]. Journal of Engineering Thermophysics, 2020, 41 (8): 1851-1860. | |

| 18 | 王文涛. RV减速器热——结构耦合分析[D]. 北京:北方工业大学机械与材料工程学院,2016. |

| Wang Wen-tao.Thermal structural coupling analysis of RV reducer[D].Beijing:School of Mechanical and Materials Engineering, North China University of Technology,2016. | |

| 19 | 董年鑫, 王希贵, 吴哲, 等. 基于热固耦合的林区原油管道机器人壳体优化分析[J]. 森林工程, 2022, 38(1): 101-107. |

| Dong Nian-xin, Wang Xi-gui, Wu Zhe, et al. Optimization analysis of robot shell for crude oil pipeline in forest areas based on thermal solid coupling[J]. Forest Engineering, 2022,38(1): 101-107. | |

| 20 | 卢博文. 摆线针轮传动系统热分析[D]. 大连: 大连交通大学机械工程学院,2021. |

| Lu Bo-wen. Thermal analysis of cycloid needle wheel transmission system[D].Dalian:School of Mechanical Engineering, Dalian Jiaotong University, 2021. |

| [1] | CHEN Yan-hong, WU Wei-jing, LIU Hong-wei, SHEN Shuai, LI Ce-yuan, GENG Huan-liang. Thermal characteristics of battery for pure electric vehicles [J]. 吉林大学学报(工学版), 2014, 44(4): 925-932. |

|