Journal of Jilin University(Engineering and Technology Edition) ›› 2026, Vol. 56 ›› Issue (1): 86-95.doi: 10.13229/j.cnki.jdxbgxb.20240669

Previous Articles Next Articles

Controlling aerodynamic noise of macroscopic point array structure on leading edge of airfoil

Chun SHEN1( ),Zhuang LI1,Jin MENG1,Xiao-wei SUN2,Cheng-chun ZHANG2(

),Zhuang LI1,Jin MENG1,Xiao-wei SUN2,Cheng-chun ZHANG2( ),Zheng-wu CHEN3,Dong LIANG4

),Zheng-wu CHEN3,Dong LIANG4

- 1.College of Automotive Engineering,Jilin University,Changchun 130022,China

2.Key Laboratory of Engineering Bionics,Ministry of Education,Jilin University,Changchun 130022,China

3.Key Laboratory of Aerodynamic Noise Control,China Aerodynamics Research and Development Center,Mianyang 621000,China

4.Aero-Engine Academy of China,Aero-Engine Corporation of China,Beijing 101304,China

CLC Number:

- TP27

| [1] | Fish F E, Battle J M. Hydrodynamic design of the humpback whale flipper[J]. Journal of Morphology, 1995, 225(1): 51-60. |

| [2] | Hansen K, Kelso R, Doolan C. Reduction of flow induced tonal noise through leading edge tubercle modifications[C]∥AIAA Paper, 2010-3700. |

| [3] | Wang J, Zhang C, Wu Z, et al. Numerical study on reduction of aerodynamic noise around an airfoil with biomimetic structures[J]. Journal of Sound and Vibration, 2017, 394: 46-58. |

| [4] | Howe M S. Aerodynamic noise of a serrated trail- ing edge[J]. Journal of Fluids and Structures, 1991, 5(1): 33-45. |

| [5] | Howe M S. Noise produced by a sawtooth trailing edge[J]. The Journal of the Acoustical society of America, 1991, 90(1): 482-487. |

| [6] | Arina R, Rinaldi R D R, Iob A, et al. Numerical study of self-noise produced by an airfoil with trailing-edgeserrations[C]∥AIAA Paper, 2012-2184. |

| [7] | Jones L, Sandberg R. Numerical investigation of airfoil self-noise reduction by addition of trailing-edge serrations[C]∥AIAA Paper,2010-3703. |

| [8] | 黄琪琪, 陈二云, 杨爱玲, 等. 倾斜锯齿尾缘轴流风机降噪的实验研究[J]. 动力工程学报, 2020, 40(9): 735-741. |

| Huang Qi-qi, Chen Er-yun, Yang Ai-ling, et al. Experimental study on noise reduction of axial fan with inclined serrated tail edge[J]. Journal of Chinese Society of Power Engineering, 2020, 40(9): 735-741. | |

| [9] | 陈伟杰, 乔渭阳, 仝帆, 等. 尾缘锯齿结构对叶片边界层不稳定噪声的影响[J]. 航空学报, 2016, 37(11): 3317-3327. |

| Chen Wei-jie, Qiao Wei-yang, Tong Fan, et al. Effect of trailing edge serrated structure on unstable noise of blade boundary layer[J]. Journal of Aeronautics, 2016, 37(11): 3317-3327. | |

| [10] | 汪瑞欣, 赵振宙, 王同光, 等. 锯齿尾缘DU91-W2-250风力机翼型气动及噪声特性分析[J]. 太阳能学报, 2020, 41(12): 221-228. |

| Wang Rui-xin, Zhao Zhen-zhou, Wang Tong-guang, et al. Analysis of aerodynamic and noise charac-teristics of sawtooth trailing edge DU91-W2-250 wind turbine airfoil[J]. Journal of Solar Energy, 2020, 41(12): 221-228. | |

| [11] | Wang J, Zhang C C, Wu Z Y, et al. Numerical study on reduction of aerodynamic noise around an airfoil with biomimetic structures[J]. Journal of Sound and Vibration, 2017, 394: 46-58. |

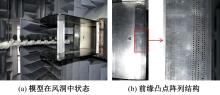

| [12] | Zhang C C, Cheng W, Du T Y, et al. Experimental and numerical study on noise reduction of airfoil with the bioinspired ridge-like structure[J]. Applied Acoustics. 2023, 203: 109190. |

| [13] | Epikhin A, Evdokimov I, Kraposhin M, et al. Development of a dynamic library for compu-tational aeroacoustics applications using the openFOAM Open Source Package[J]. Procedia Computer Science, 2016, 66: 150-157. |

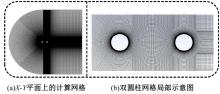

| [14] | Lockard D. Summary of the tandem cylinder sol- utions from the benchmark problems for airframe noise computations——I workshop[C]∥AIAA Paper, 2011-3053. |

| [15] | 陈武, 周毅. 基于K-FWH声比拟方法的串列双圆柱气动噪声研究[J]. 北京航空航天大学学报, 2021, 47(10): 2118-2128. |

| Chen Wu, Zhou Yi. Research on pneumatic noise of tandem double cylindrical based on K-FWH acoustic analogy method[J]. Journal of Beijing University of Aeronautics and Astronautics, 2021, 47(10): 2118-2128. | |

| [16] | 杜天宇. 基于仿生流动控制的无人机螺旋桨降噪研究[D]. 长春: 吉林大学生物与农业工程学院, 2022. |

| Du Tian-yu. Research on noise reduction of UAV propeller based on bionic flow control[D]. Changchun: College of Biological and Agricultural Engineering, Jilin University, 2022. | |

| [17] | Amiet R K. Acoustic radiation from an airfoil in a turbulent stream[J]. Journal of Sound and Vibration 1975, 41(4): 407-420. |

| [1] | Wen CHENG,Cheng-chun ZHANG,Xiao-wei SUN,Chun SHEN,Zheng-yang WU,Zheng-wu CHEN. Experimental on self-noise control of airfoil with ridge-like structure [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(8): 2385-2392. |

| [2] | Jia-yi WANG,Xin-hui LIU,Zhan WANG,Jin-shi CHEN,Ya-fang HAN,Yu-qi WANG. Flow characteristics analysis of constant flow control valve based on AMESim [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(9): 2499-2507. |

| [3] | Yan-bo LI,Yu ZHANG,Wei-yu LIU,Qi-sheng WU,Biao WANG,Bo-bin YAO. Bipolar DC flow field⁃effect⁃transistor and its application in microfluidics [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(8): 1934-1942. |

| [4] | Tai-ming HUANG,Wei-ping LI,Tao-tao HU,Wan-hao YUE,Nian-zhou JI,Yu-bang LI. Aerodynamic noise optimization of vehicle claw-pole generator [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(10): 2244-2255. |

| [5] | Xin CHEN,Ning WANG,Chuan-liang SHEN,Xiao FENG,Chang-hai YANG. Effect of rearview mirror modeling on aerodynamic noise of front window [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 426-436. |

| [6] | Wei-ping SHI,Xu ZHAO,Xing-jun HU,Tian-ming YU,Bo-wen LIU,Yan DUAN. Design and numerical simulation of water restriction device AICD for natural gas exploitation [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 1986-1991. |

| [7] | ZUO Shu-guang, HAN Hui-jun, SU Hu, WEI Kai-jun, ZHAO Yuan-ling. Analysis of aerodynamic noise and influence factors of a regenerative blower used in air supply system of fuel cell cars [J]. 吉林大学学报(工学版), 2013, 43(06): 1453-1458. |

| [8] | SHI Lei, ZHANG Cheng-chun, WANG Jing, WANG Yong-hua,ZHANG Xue-peng, REN Lu-quan. Reduction of aerodynamic noise from NACA0018 airfoil model using bionic methods [J]. 吉林大学学报(工学版), 2011, 41(6): 1664-1668. |

| [9] | HAO Shuang-hui|SHI Jing-he, HAO Ming-hui, SONG Bao-yu, TANG Zi-li. Pressure and flow compound control of direct drive electro-hydraulic servo system [J]. 吉林大学学报(工学版), 2011, 41(4): 1113-1118. |

| [10] | YANG Bo,HU Xing-jun,WANG Fu-liang. Numerical simulation and verification of aerodynamic noise from side window region of minivan [J]. 吉林大学学报(工学版), 2010, 40(04): 915-0919. |

| [11] |

Yang Bo, Fu Li-min .

Application of steady state numerical simulation to prediction of sedan exterior aeroacoustic sources [J]. 吉林大学学报(工学版), 2007, 37(05): 1005-1008. |

|

||