吉林大学学报(工学版) ›› 2022, Vol. 52 ›› Issue (10): 2474-2485.doi: 10.13229/j.cnki.jdxbgxb20210309

• 农业工程·仿生工程 • 上一篇

果园多风机风送喷雾机作业参数优化与试验

- 河北农业大学 机电工程学院,河北 保定 071000

Operational parameter optimization and testing of an air-assisted multi-fan orchard sprayer

Jian-ping LI( ),Yong-liang BIAN,Xin YANG(

),Yong-liang BIAN,Xin YANG( ),Peng-fei WANG,Xin-hao LI,Chun-lin XUE

),Peng-fei WANG,Xin-hao LI,Chun-lin XUE

- College of Mechanical and Electrical Engineering,Hebei Agricultural University,Baoding 071000,China

摘要:

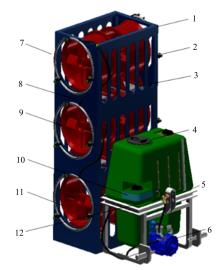

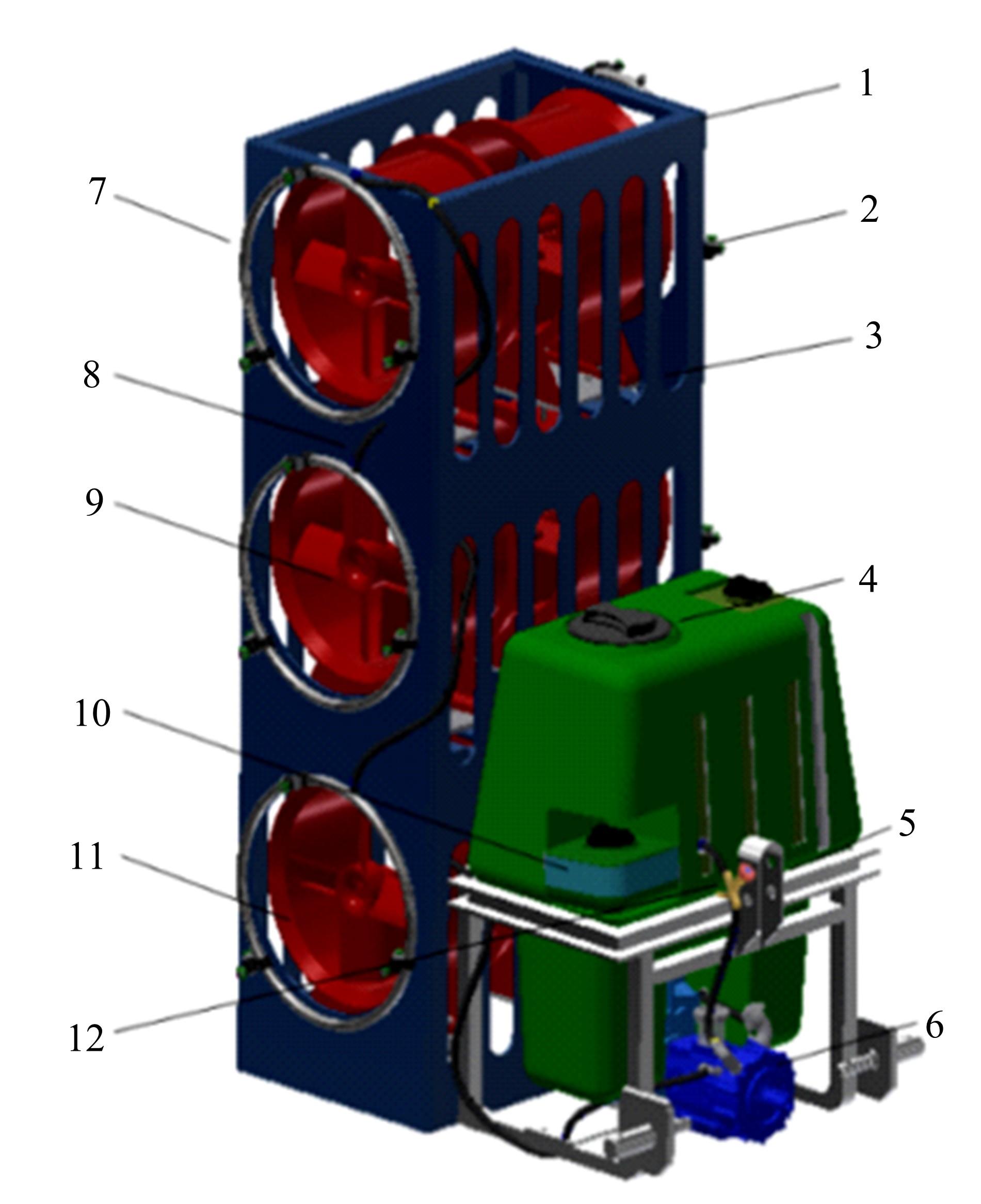

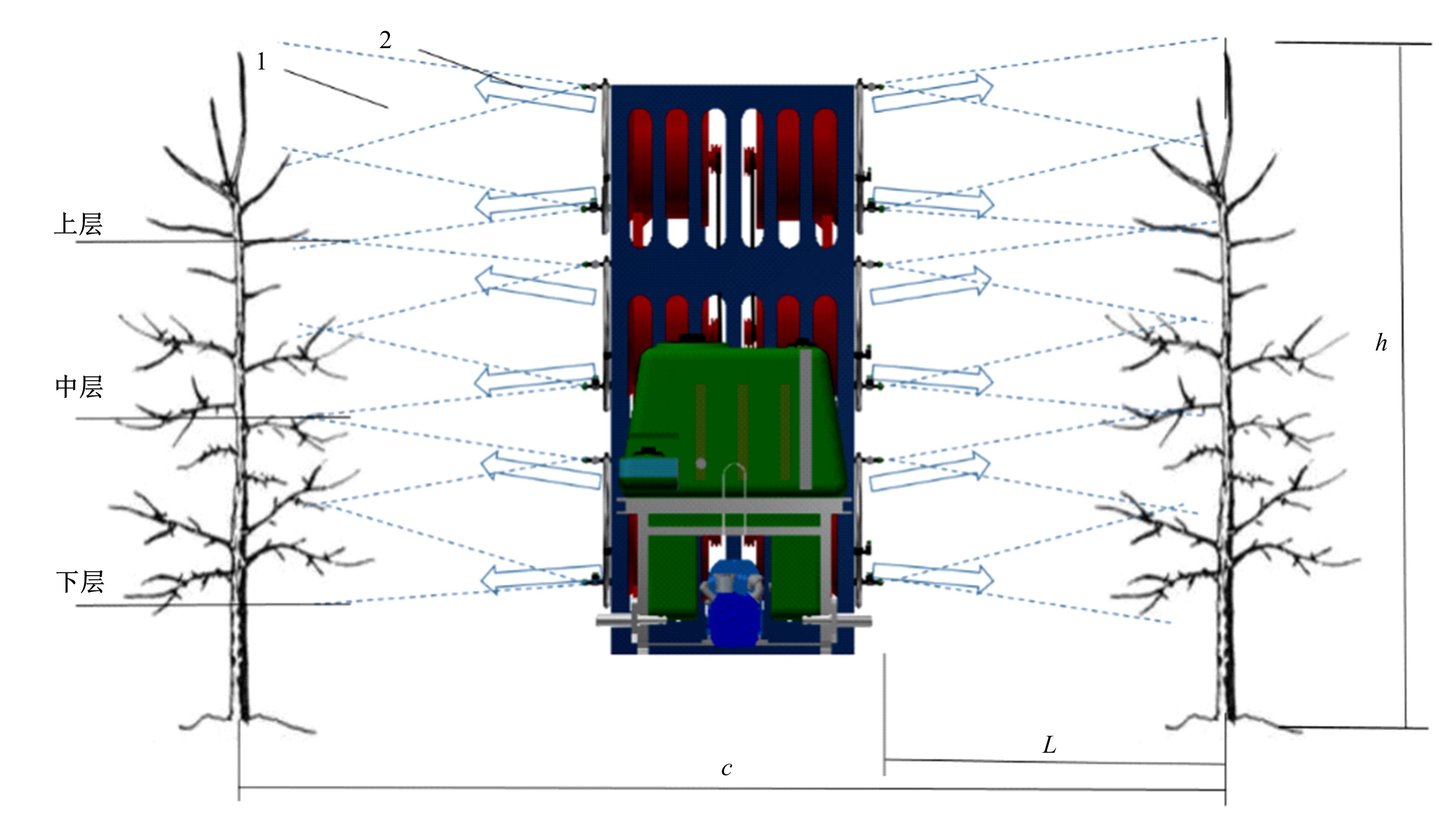

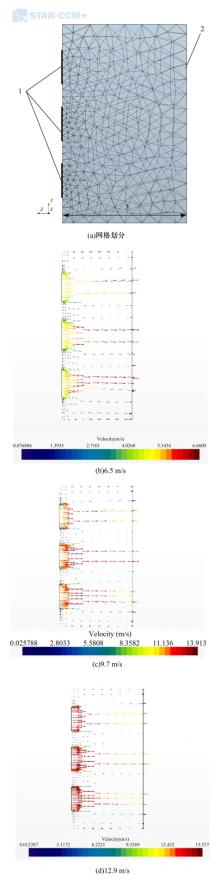

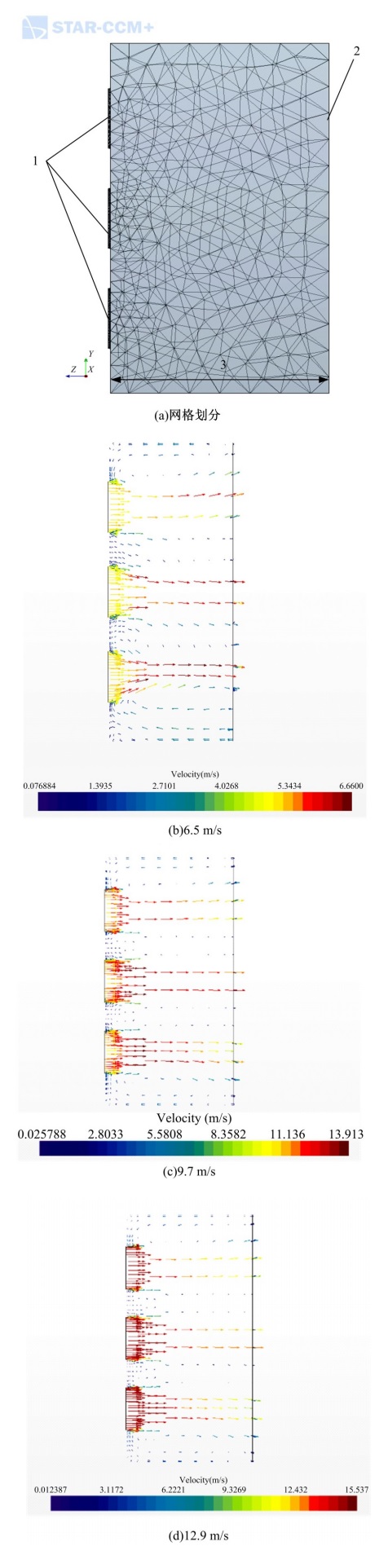

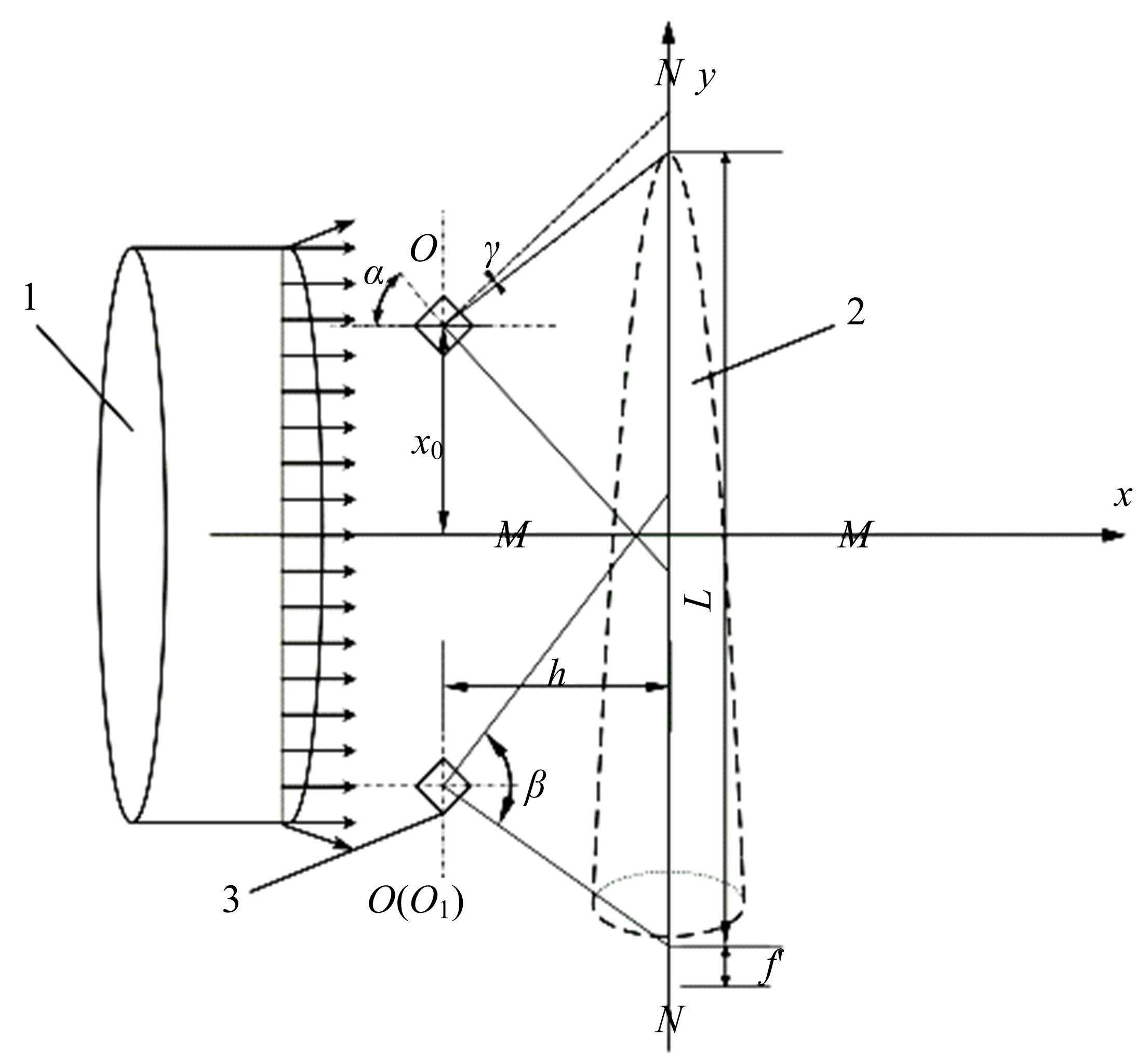

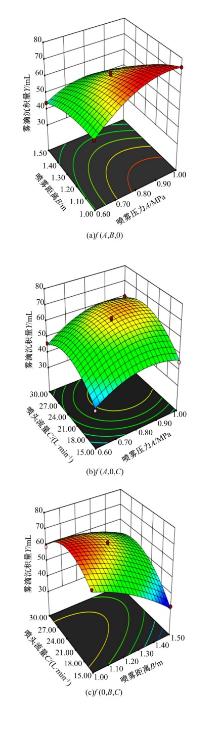

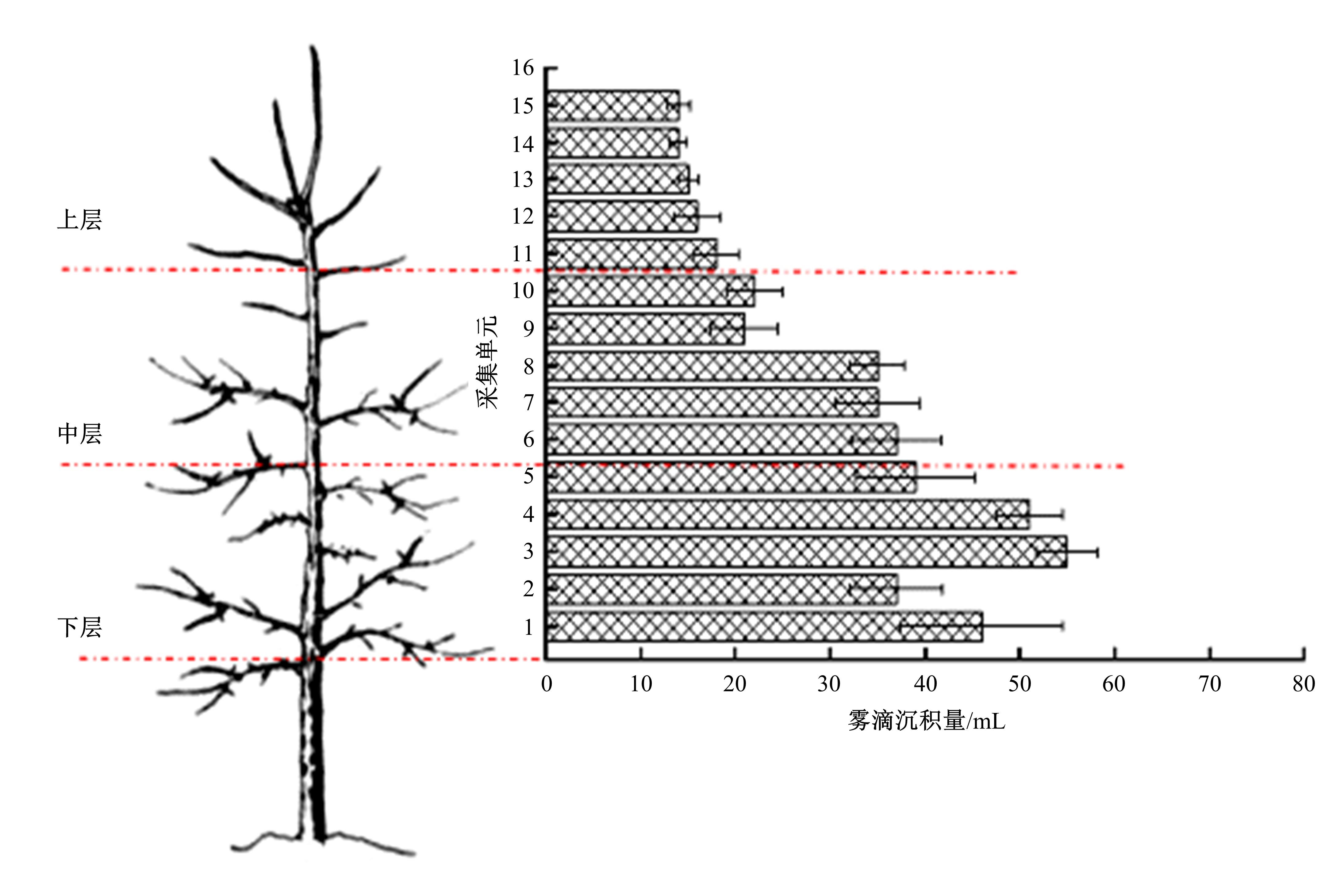

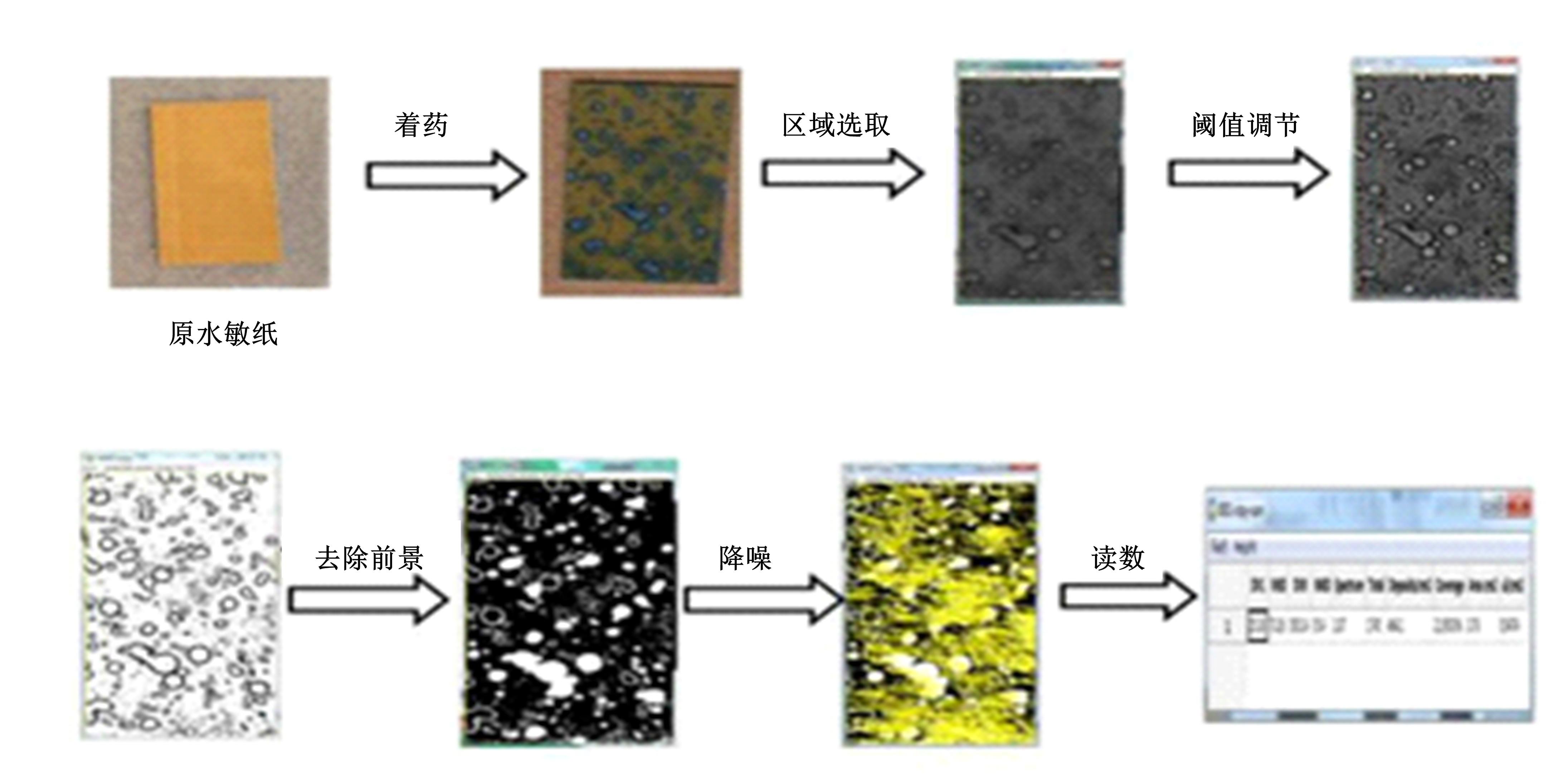

针对当前传统风送喷雾机在矮砧密植果园病虫害防治作业时存在药液浪费严重、雾滴难以穿透到果树冠层内部的问题,设计了一种风机对称布置的新型果园多风机风送喷雾机。基于STAR-CCM+软件仿真分析了单侧组合3风机送风流场,当拖拉机动力输出(PTO)转速为540 r/min时,单风机风量为4397.1 m3/h、风速为9.7 m/s、风机动压为47.3 Pa,到达果树外侧冠层空气流速度大于5.5 m/s,满足药液抵达冠层中心的喷雾需要。利用Box-Behnken优化了喷雾系统参数组合,当喷雾压力为0.8 MPa、喷雾距离为1.25 m、喷头型号采用扇形02型时,经垂直雾滴分布仪模拟果树冠层垂直方向的药液附着性能试验表明,雾滴沉积量变异系数为10%~12%,雾滴分布较为均匀;经田间试验表明,多风机风送喷雾机喷雾作业后果树冠层垂直方向上、中、下3层的雾滴沉积总量分别为68、145、195 mL,总体标准差分别为1.61、3.72、5.29,叶片药液附着雾滴数大于等于70粒/cm2,达到了风送式果园喷雾机标准的规定,可实现果树冠层垂直方向药液的有效覆盖。

中图分类号:

- S224.3

| 1 | 李龙龙, 何雄奎, 宋坚利, 等. 果园仿形变量喷雾与常规风送喷雾性能对比试验[J]. 农业工程学报, 2017, 33(16): 56-63. |

| Li Long-long, He Xiong-kui, Song Jian-li, et al. Comparative experiment on profile variable rate spray and conventional air assisted spray in orchards[J]. Transactions of the Chinese Society of Agricultural Engineering, 2017, 33(16): 56-63。 | |

| 2 | 梁海忠, 范崇辉, 王琰, 等. 苹果高纺锤形树体枝量、果实产量与品质的研究[J]. 西北农林科技大学学报: 自然科学版, 2010, 38(7): 123-128. |

| Liang Hai-zhong, Fan Chong-hui, Wang Yan, et al. Research on shoot number, fruit yield and quality of high-spindle apple trees[J]. Journal of Northwest A & F University(Natural Science Edition), 2010, 38(7): 123-128. | |

| 3 | 边永亮, 李建平, 薛春林, 等. 果园风送式喷雾机智能化发展现状与前景分析[J]. 东北农业大学学报, 2020, 51(2): 86-94. |

| Bian Yong-liang, Li Jian-ping, Xue Chun-lin, et al. Analysis on status quo and prospects of intelligent development of air-feed sprayer in orchard[J]. Journal of Northeast Agricultural University, 2020, 51(2): 86-94. | |

| 4 | 周良富, 张晓辛, 吕晓兰, 等. 圆盘雾化器风力性能数值模拟与试验[J]. 农业机械学报, 2012, 43(10): 72-75, 81. |

| Zhou Liang-fu, Zhang Xiao-xin, Xiao-lan Lü, et al. Numerical simulation and experiment on wind performanceof disc atomizer[J]. Transactions of the Chinese Society for Agricultural Machinery, 2012, 43(10): 72-75, 81. | |

| 5 | 宋淑然, 陈建泽, 洪添胜, 等. 远射程风送式喷雾机风场中雾滴粒径变化规律[J]. 农业工程学报, 2017, 33(6): 59-66. |

| Song Shu-ran, Chen Jian-ze, Hong Tian-sheng, et al. Variation of droplet diameter in wind field for long-range air-assisted sprayer[J]. Transactions of the Chinese Society of Agricultural Engineering, 2017, 33(6): 59-66. | |

| 6 | Gupta Pankaj. Air flow characteristics of an air-assisted sprayer through horizontal crop canopy[J]. International Journal of Agricultural & Biological Engineering, 2012, 5(1): 1-7. |

| 7 | Fuentes M A, Diezma G L J, Roldán B L G, et al. Testing the influence of the air flow rate on spray deposit, coverage and losses to the ground in a super-intensive olive orchard in southern Spain[C]∥The 13th Workshop on Spray Application in Fruit Growing. Germany: Julius-Kühn-Archiv, 2015, 448: 17-18. |

| 8 | Dekeyser D, Duga A T, Verboven P, et al. Assessment of orchard sprayers using laboratory experiments and computational fluid dynamics modelling[J]. Biosystems Engineering, 2013, 114(2): 157-169. |

| 9 | 宋雷洁, 李建平, 杨欣, 等. 塔型风送式果园喷雾机风场参数优化设计[J]. 农机化研究, 2020, 42(4): 12-17. |

| Song Lei-jie, Li Jian-ping, Yang Xin, et al. Optimization design of wind field parameters of tower type wind-driven orchard sprayer[J]. Journal of Agricultural Mechanization Research, 2020, 42(4): 12-17. | |

| 10 | 宋淑然, 夏侯炳, 卢玉华, 等. 风送式喷雾机导流器结构优化及试验研究[J].农业工程学报, 2012, 28(6): 7-12. |

| Song Shu-ran, Xia Hou-bing, Lu Yu-hua, et al. Structural optimization and experiment on fluid director of air-assisted sprayer[J]. Transactions of the Chinese Society of Agricultural Engineering, 2012, 28(6): 7-12. | |

| 11 | Reichard D L, Retzer H J, Liljedahl L A, et al. Spray droplet size distributions delivered by air blast orchard sprayers[J]. Transactions of the ASAE, 1977, 20(2): 232-237. |

| 12 | Mona Hassanzadeh Jobehdar. Experimental study of two-phase flow in a liquid cross-flow and an effervescent atomizer[D]. London(Canada):University of Western Ontario, 2017. |

| 13 | 周良富, 张玲, 薛新宇, 等. 3WQ-400型双气流辅助静电果园喷雾机设计与试验[J]. 农业工程学报, 2016, 32(16): 45-53. |

| Zhou Liang-fu, Zhang Ling, Xue Xin-yu, et al. Design and experiment of 3WQ-400 double air-assisted electrostatic orchard sprayer[J]. Transactions of the Chinese Society of Agricultural Engineering, 2016, 32(16): 45-53. | |

| 14 | Godyn A, Holownicki R, Doruchowski G, et al. Dual-fan orchard sprayer with reversed air-stream-preliminary trials[J]. Agricultural Engineering International: The CIGR Journal, 2008(1): 1-12. |

| 15 | Delele M A, Jaeken P, Debaer C, et al. CFD prototyping of an air-assisted orchard sprayer aimed at drift reduction[J]. Computers and Electronics in Agriculture, 2007, 55(1): 16-27. |

| 16 | Endalew A M, Debaer C, Rutten N, et al. Modelling pesticide flow and deposition from air-assisted orchard spraying in orchards: a new integrated CFD approach[J]. Agricultural and Forest Meteorology, 2010, 150(10): 1383-1392. |

| 17 | 丁天航, 曹曙明, 薛新宇, 等. 果园喷雾机单双风机风道气流场仿真与试验[J].农业工程学报, 2016, 32(14): 62-68, 315. |

| Ding Tian-hang, Cao Shu-ming, Xue Xin-yu, et al. Simulation and experiment on single-channel and double-channel airflow field of orchard sprayer[J]. Transactions of the Chinese Society of Agricultural Engineering, 2016, 32(14): 62-68, 315. | |

| 18 | Garciaramos F J, Vidal M, Bone A, et al. Analysis of the air flow generated by an air-assisted sprayer equipped with two axial fans using a 3D Sonic anemometer[J]. Sensors, 2012, 12(6): 7598-7613. |

| 19 | Garciaramos F J, Vidal M, Bone A, et al. Field evaluation of an air-assisted sprayer equipped with two reversed rotation fans[J]. Applied Engineering in Agriculture, 2009, 25(4): 481-494. |

| 20 | 戴奋奋. 风送喷雾机风量的选择与计算[J]. 植物保护, 2008, 45(6):124-127. |

| Dai Fenfen. Selection and calculation of the blowing rate of air-assisted sprayers[J]. Plant Protection,2008, 45(6):124-127. | |

| 21 | 续魁昌, 王洪强, 盖京方, 等. 风机手册[M]. 2版.北京:机械工业出版社,2011. |

| 22 | 周良富, 傅锡敏, 丁为民, 等. 组合圆盘式果园风送喷雾机设计与试验[J].农业工程学报, 2015, 31(10): 64-71. |

| Zhou Liang-fu, Fu Xi-min, Ding Wei-min, et al. Design and experiment of combined disc air-assisted orchard sprayer[J]. Transactions of the Chinese Society of Agricultural Engineering, 2015, 31(10): 64-71. | |

| 23 | 刘冬梅, 周宏平, 茹煜, 等. 扇形喷头结构和压力对微生物农药雾滴分布及活性的影响[J]. 农业工程学报, 2018, 34(21): 57-64. |

| Liu Dong-mei, Zhou Hong-ping, Ru Yu, et al. Effect of fan nozzle structure and pressure on distribution and activity of microbial pesticide droplets[J]. Transactions of the Chinese Society of Agricultural Engineering, 2018, 34(21): 57-64. | |

| 24 | 全国农业机械标准化技术委员会. 喷雾机( 器) 作业质量:NY /T 650—2013[M].北京:中华人民共和国农业部,2013. |

| 25 | 边永亮, 李建平, 薛春林, 等. 单旋翼油动无人机与圆形果园风送喷雾机作业性能对比试验研究[J]. 中国农业大学学报, 2020, 25(12): 134-141. |

| Bian Yong-liang, Li Jian-ping, Xue Chun-lin, et al. A comparative study on the performance of single-rotor oil-propelled UAV and circular air-fed orchard sprayer[J]. Journal of China Agricultural University, 2020, 25(12): 134-141. | |

| 26 | 全国农业机械标准化技术委员会. 风送式果园喷雾机作业质量:NY/T 992—2006[M].北京:中华人民共和国农业部,2006. |

| [1] | 袁哲, 周茜茜, 刘春宝, 马文星, 徐志轩. 基于BEM理论的兆瓦级风力机叶片设计及其气动性能[J]. 吉林大学学报(工学版), 2016, 46(4): 1142-1148. |

| [2] | 马文星,胡晶,褚亚旭,王松林,吴岳诗. 双涡轮液力变矩器超越离合器动载强度分析[J]. 吉林大学学报(工学版), 2014, 44(3): 675-679. |

| [3] | 李陆,郭庆,管明祥,井庆丰 . 基于跨层设计的卫星MAC协议[J]. 吉林大学学报(工学版), 2008, 38(06): 1458-1462. |

|

||