吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (3): 657-662.doi: 10.13229/j.cnki.jdxbgxb.20220518

• 材料科学与工程 • 上一篇

基于层次分析过程的厚板T形接头弧焊焊接位置自主决策

何银水1( ),肖贺1,罗沧海1,张宇1,余卓骅2(

),肖贺1,罗沧海1,张宇1,余卓骅2( ),袁海涛3

),袁海涛3

- 1.南昌大学 资源与环境学院,南昌 330031

2.南昌交通学院 智能制造学院,南昌 330100

3.南昌大学 先进制造学院,南昌 330031

Autonomous decision⁃making of welding positions based on analytic hierarchy process in T⁃joint arc welding

Yin-shui HE1( ),He XIAO1,Cang-hai LUO1,Yu ZHANG1,Zhuo-hua YU2(

),He XIAO1,Cang-hai LUO1,Yu ZHANG1,Zhuo-hua YU2( ),Hai-tao YUAN3

),Hai-tao YUAN3

- 1.School of Resources & Environment,Nanchang University,Nanchang 330031,China

2.School of Intelligent Manufacturing,Nanchang Jiao Tong Institute,Nanchang 330100,China

3.School of Advanced Manufacturing,Nanchang University,Nanchang 330031,China

摘要:

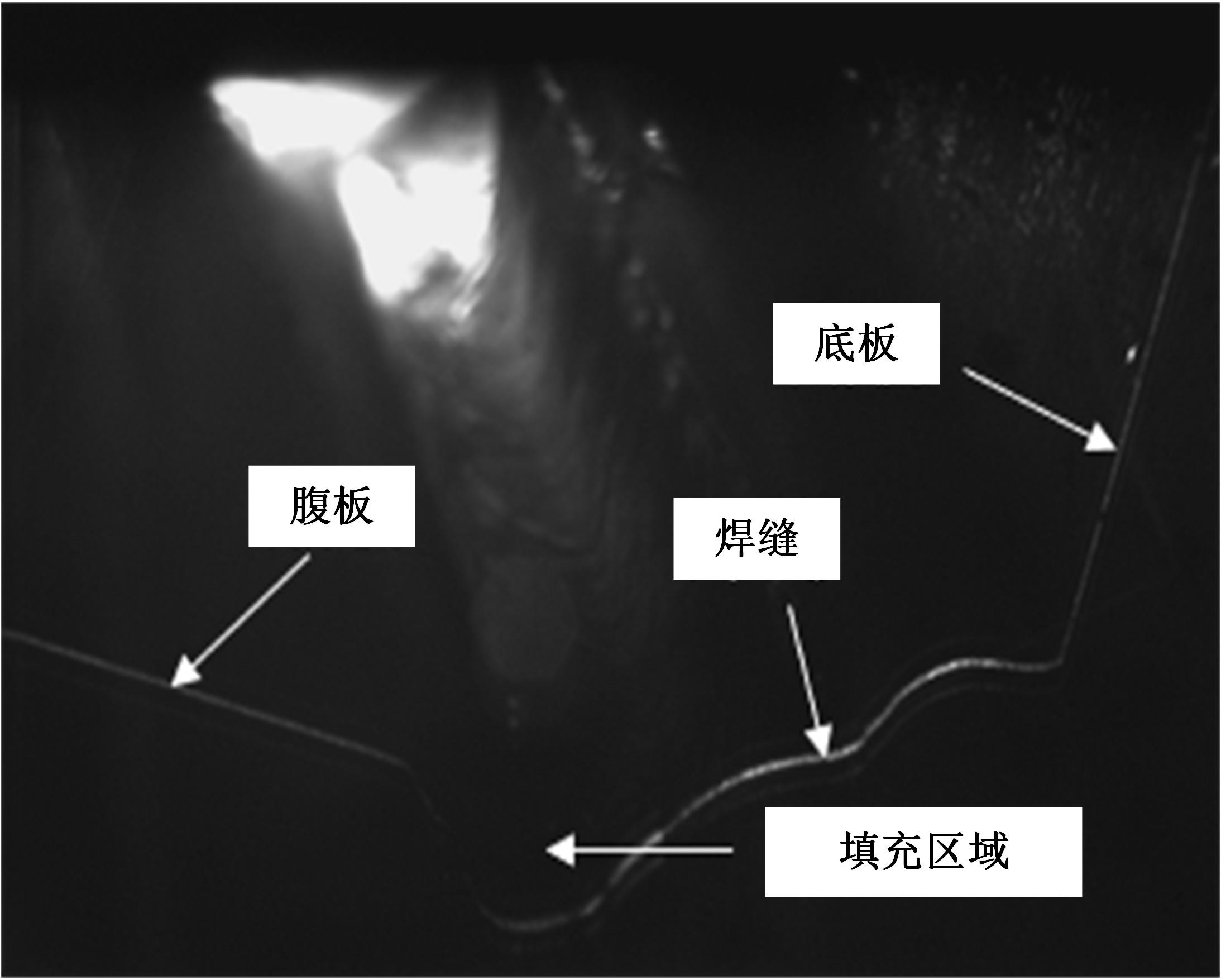

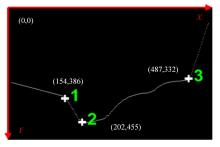

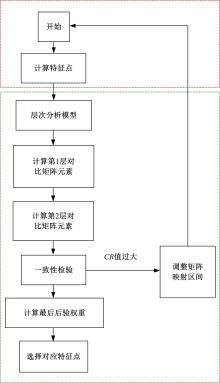

提出了一种基于层次分析过程的T形接头多道平角焊焊接位置自主决策方法。首先,利用视觉传感检测坡口的特征点,并将其他特征点与最右侧特征点之间在水平、垂直方向的相对距离作为因素,建立了层次分析模型。其次,基于平角焊腹板角变形控制经验设计了一种比较矩阵元素计算方法。最后,基于最大后验权重原则建立了焊接位置自主选定方法。不同板厚的多道填充焊焊接位置自主决策试验显示,本文方法在满足接头角变形控制的前提下,决策的正确率达到90%以上,抗干扰能力强。

中图分类号:

- TG409

| 1 | 周晓,梁燚杰,奚中轩,等. 白车身 B 柱焊接变形模拟及预变形控制方法[J]. 吉林大学学报:工学版,2023,53(8): 2212-2218. |

| Zhou Xiao, Liang Yi-jie, Xi Zhong-xuan, et al. Welding deformation and compensation method of B-pillar in body-in-white[J]. Journal of Jilin University (Engineering and Technology Edition), 2023, 53(8): 2212-2218. | |

| 2 | Zhang Chao-hua, Li Suo, Sun Jia-min, et al. Controlling angular distortion in high strength low alloy steel thick-plate T-joints[J]. Journal of Materials Processing Technology, 2019, 267: 257-267. |

| 3 | Liu Yan, Shi Lei, Tian Xin-cheng. Weld seam fitting and welding torch trajectory planning based on NURBS in intersecting curve welding[J]. International Journal of Advanced Manufacturing Technology, 2018, 95(5): 2457-2471. |

| 4 | Fang H C, Ong S K, Nee A Y C. Adaptive pass planning and optimization for robotic welding of complex joints[J]. Advances in Manufacturing, 2017, 5(2): 93-104. |

| 5 | Zhang Yang, Lv Xiao-qing, Xu Lian-yong, et al. A segmentation planning method based on the change rate of cross-sectional area of single V-groove for robotic multi-pass welding in intersecting pipe-pipe joint[J]. International Journal of Advanced Manufacturing Technology, 2019, 101(1): 23-38. |

| 6 | Liu Yan, Ren Li-juan, Tian Xin-cheng. A robot welding approach for the sphere-pipe joints with swing and multi-layer planning[J]. International Journal of Advanced Manufacturing Technology, 2019, 105(1): 265-278. |

| 7 | 刘成文, 彭安华, 杜爱民. 基于级别优序关系和层次分析法的铝合金焊接方法决策[J]. 数学的实践与认识, 2018, 48(11): 150-157. |

| Liu Cheng-wen, Peng An-hua, Du Ai-min. Decision-making of aluminum alloys welding method based on hierarchy and analytic hierarchy process[J]. Practice and Understanding of Mathematics, 2018, 48(11): 150-157. | |

| 8 | Bhattacharya A, Singla S. Dissimilar GTAW between AISI 304 and AISI 4340 steel: multi-response optimization by analytic hierarchy process[J]. Proceedings of the Institution of Mechanical Engineers, Part E: Journal of Process Mechanical Engineering, 2017, 231(4): 824-835. |

| 9 | 沈鸿源, 陈华斌, 林涛,等. 应用于铝合金焊接中的被动视觉获取[J]. 上海交通大学学报, 2015, 49(3):341-343. |

| Shen Hong-yuan, Chen Hua-bin, Lin Tao, et al. Passive visual technology in aluminum alloy welding[J]. Journal of Shanghai Jiaotong University, 2015, 49(3): 341-343. | |

| 10 | Zhang Chao-hua, Li Suo, Hu Long, et al. Effects of pass arrangement on angular distortion, residual stresses and lamellar tearing tendency in thick-plate T-joints of low alloy steel[J]. Journal of Materials Processing Technology, 2019, 274: No. 116293. |

| 11 | He Yin-shui, Ma Guo-hong, Chen Shan-ben. Autonomous decision-making of welding position during multipass GMAW with T-Joints: a Bayesian network approach[J]. IEEE Transactions on Industrial Electronics, 2021, 69(4): 3909-3917. |

| [1] | 王春生, 邹丽, 杨鑫华. 基于邻域粗糙集的铝合金焊接接头疲劳寿命影响因素分析[J]. 吉林大学学报(工学版), 2017, 47(6): 1848-1853. |

| [2] | 段,孙同景,李振华, 黄长伟, 张光先. 全数字逆变电源IIR Butterworth数字滤波[J]. 吉林大学学报(工学版), 2009, 39(增刊2): 311-0314. |

|

||