Journal of Jilin University(Engineering and Technology Edition) ›› 2023, Vol. 53 ›› Issue (11): 3069-3077.doi: 10.13229/j.cnki.jdxbgxb.20211429

Previous Articles Next Articles

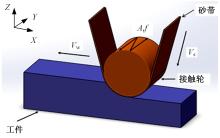

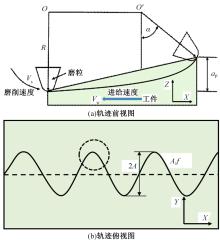

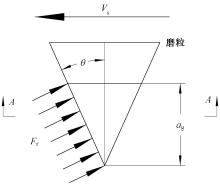

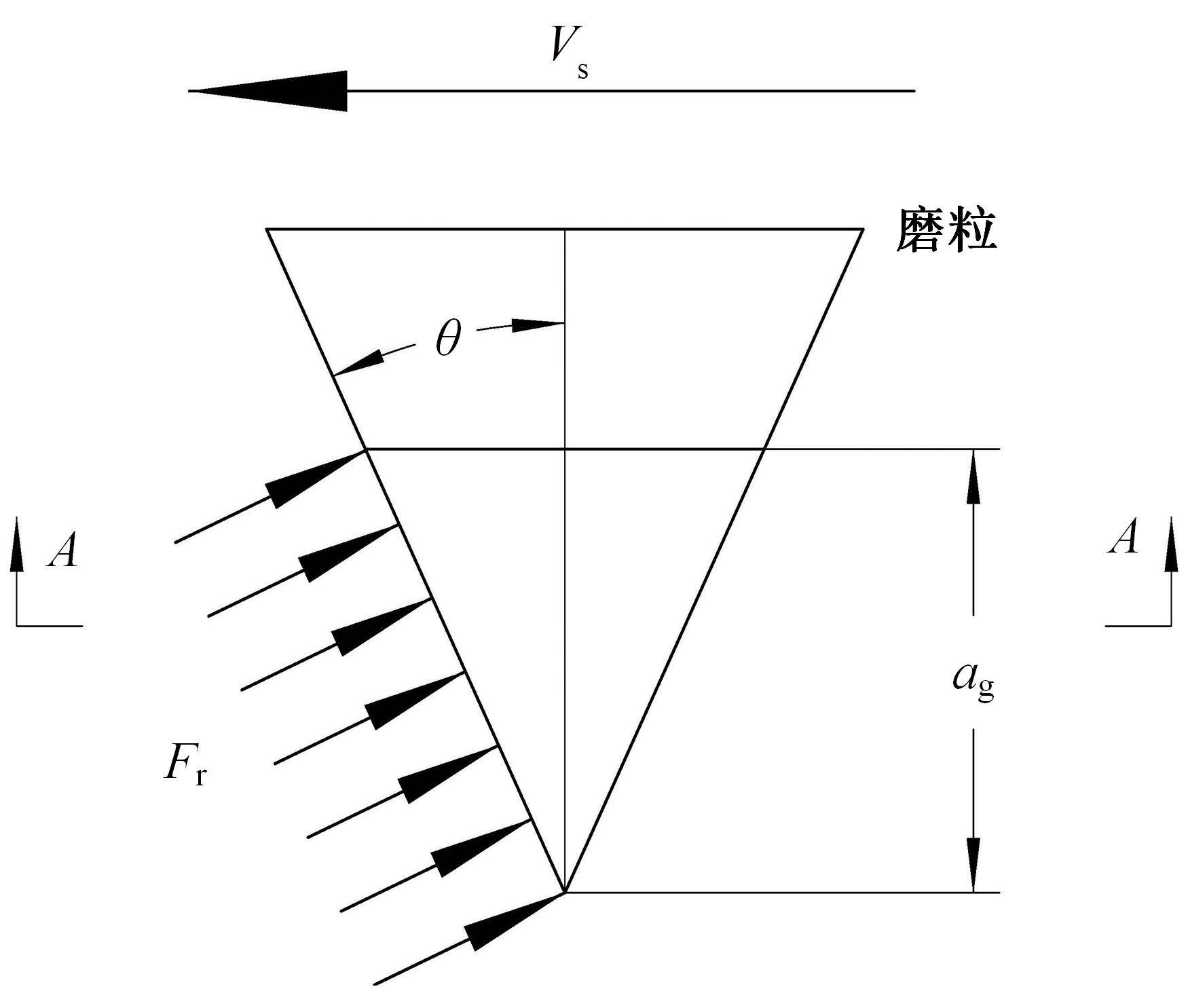

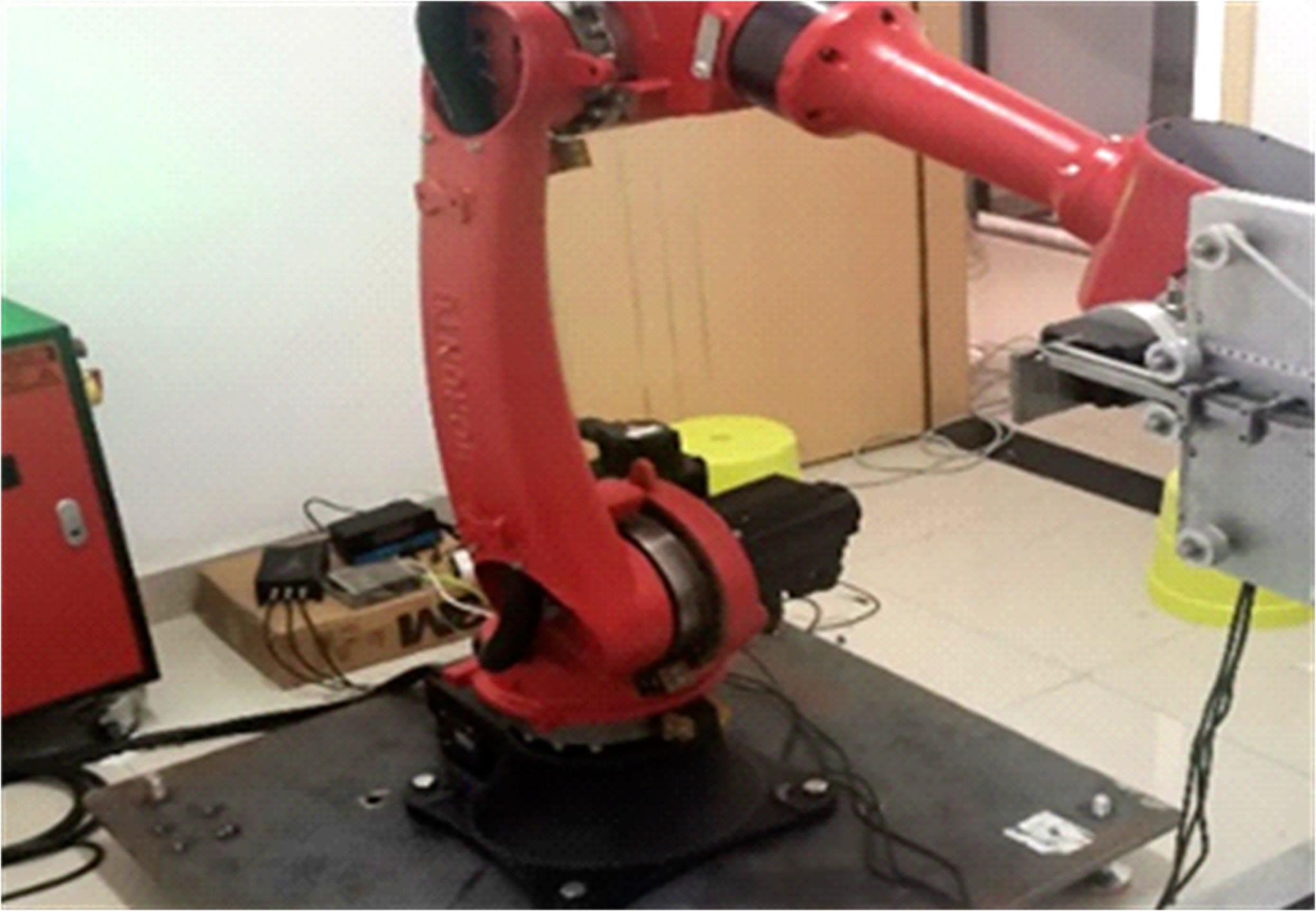

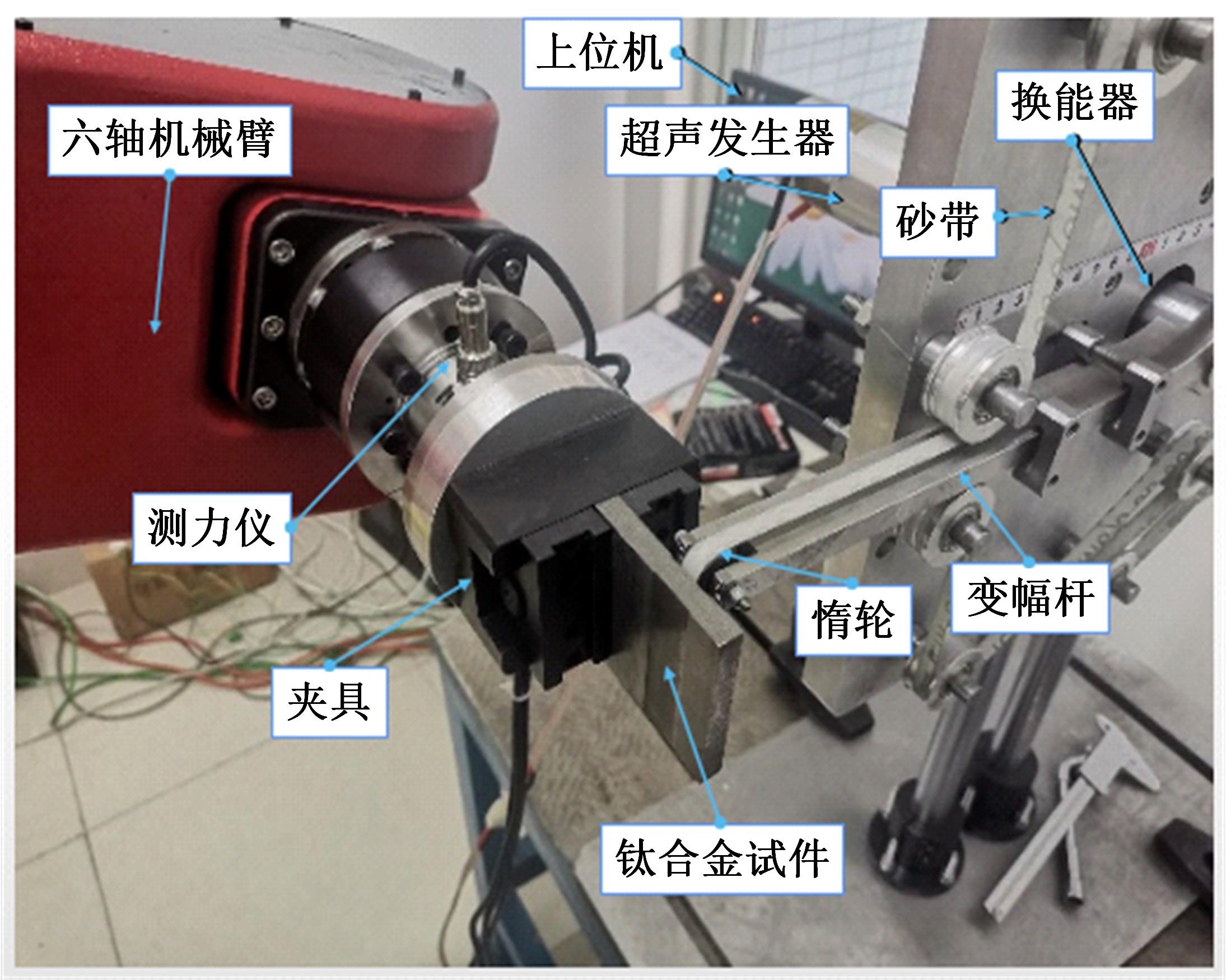

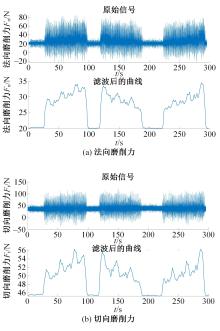

Modeling and analysis of grinding force for grinding titanium alloy with abrasive belt assisted by ultrasonic vibration

Zhi HUANG1( ),Jie MIN1,Tao ZHOU1,Jian YANG2,Li-xing XIAO2,Lin-ze LI2

),Jie MIN1,Tao ZHOU1,Jian YANG2,Li-xing XIAO2,Lin-ze LI2

- 1.School of Mechanical and Electrical Engineering,University of Electronic Science and Technology,Chengdu 611731,China

2.Sichuan Chengfei Integration Technology Corp. ,Chengdu 610091,China

CLC Number:

- V216.3

| 1 | Xu X, Zhu D, Wang J, et al. Calibration and accuracy analysis of robotic belt grinding system using the ruby probe and criteria sphere[J]. Robotics and Computer-Integrated Manufacturing, 2018, 51: 189-201. |

| 2 | Yu T B, Yang X Z, An J H, et al. Material removal mechanism of two-dimensional ultrasonic vibration assisted polishing Inconel718 nickel-based alloy[J]. Int J Adv Manuf Technol, 2018, 96: 657-667. |

| 3 | Jiao F, Zhao B, Liu C S, et al. Material removal rate characteristics in ultrasonic aided lapping of engineering ceramics based on single-point scratch[J]. Key Engineering Materials, 2008, 375/376: 263-267. |

| 4 | Wu Y, Sun A G, Zhao B, et al. Modeling of high efficiency removal in the grinding of aluminal/ZrO2 nanocomposites with the aid of two-dimensional ultrasonic vibration[J]. Key Engineering Materials, 2007, 329: 451-458. |

| 5 | Kuo K L, Tsao C C. Rotary ultrasonic-assisted milling of brittle materials[J]. Transactions of Nonferrous Metals Society of China, 2012, 22: 793-800. |

| 6 | Yan Y Y, Zhao B, Wu Y, et al. Study on material removal mechanism of fine-crystalline ZrO2 ceramics under two dimensional ultrasonic grinding[J]. Materials Science Forum, 2006, 532/533: 532-535. |

| 7 | Yan W, Bo Z, Xun S Z. Modeling of material removal in workpiece lateral ultrasonic vibration grinding of fine-crystalline zirconia ceramics[J]. Key Engineering Materials, 2006, 315/316(4): 304-308. |

| 8 | 赵波, 陈凡, 童景琳. 超声磨削材料去除率的理论分析与试验研究[J]. 河南理工大学学报: 自然科学版, 2013, 32(3): 302-307. |

| Zhao Bo, Chen Fan, Tong Jing-lin. Theoretical and experimental research on material removal rate under ultrasonic grinding[J]. Journal of Henan Polytechnic University (Natural Science Edition), 2013, 32(3): 302-307. | |

| 9 | Suzuki K, Uematsu T, Makizaki T, et al. Ultrasonic grinding utilizing a stator of an ultrasonic motor[J]. The Proceedings of The Manufacturing & Machine Tool Conference, 2000, 2: 183-184. |

| 10 | Shen J Y, Dai B, Wu X, et al. Study on the material removal mechanism of glass in single diamond grain grinding with ultrasonic vibration assisted[J]. Int J of Abrasive Technology, 2019, 9(1): 60-72. |

| 11 | Tanaka Y, Yano A, Shinke N. Study on ultrasonic grinding (1st report): on the relations between the vibrational direction and stock removal[J]. Journal of the Japan Society for Precision Engineering, 1968, 34: 687-692. |

| 12 | Qin N, Pei Z J, Treadwell C, et al. Physics-based predictive cutting force model in ultrasonic-vibration-assisted grinding for titanium drilling[J]. Journal of Manufacturing Science and Engineering, 2009, 131(4): 481-498. |

| 13 | Das S, Pandivelan C. Grinding characteristics during ultrasonic vibration assisted grinding of alumina ceramic in selected dry and MQL conditions[J]. Materials Research Express, 2020, 7(8): 085404. |

| 14 | Xiao X, Zheng K, Liao W, et al. Study on cutting force model in ultrasonic vibration assisted side grinding of zirconia ceramics[J]. International Journal of Machine Tools & Manufacture, 2016(5): 58-67. |

| 15 | Sheng X M, Tang K, Yu J W, et al. Experimental research of grinding force and specific grinding energy of TC4 titanium alloy in high speed deep grinding[J]. Advanced Materials Research, 2009, 76/78: 55-60. |

| 16 | 黄智, 董华章, 周振武, 等. 砂带磨削TC4磨削力数字建模及其预测[J]. 表面技术, 2018, 47(9): 250-258. |

| Huang Zhi, Dong Hua-zhang, Zhou Zhen-wu, et al. Modeling and prediction of grinding force on belt grinding TC4[J]. Surface Technology, 2018, 47(9): 250-258. | |

| 17 | Leng Y F, Zhang N. Experiment research on abrasive belt vibration grinding terminal surface of work piece[J]. Advanced Materials Research,2010, 154/155: 1240-1243. |

| 18 | 唐进元, 周伟华, 黄于林. 轴向超声振动辅助磨削的磨削力建模[J]. 机械工程学报, 2016, 52(15): 184-191. |

| Tang Jin-yuan, Zhou Wei-hua, Huang Yu-lin. Modeling on grinding force assisted with aial ultrasonic vibration[J]. Journal of Mechanical Engineering, 2016, 52(15): 184-191. | |

| 19 | 任庆磊, 魏昕, 谢小柱, 等. 硅片自旋转磨削中基于力的微接触机理[J]. 吉林大学学报: 工学版, 2018, 48(3): 796-802. |

| Ren Qing-lei, Wei Xin, Xie Xiao-zhu, et al. Micro contact mechanism based on force in self rotation grinding of silicon wafer[J]. Journal of Jilin University (Engineering and Technology Edition), 2018, 48(3): 796-802. | |

| 20 | Zhou H, Ding W F, Li Z, et al. Predicting the grinding force of titanium matrix composites using the genetic algorithm optimizing back-propagation neural network model[J]. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 2019, 233(4): 1157-1167. |

| 21 | 王家忠, 王龙山, 李国发, 等. 外圆纵向磨削表面粗糙度的模糊预测与控制[J]. 吉林大学学报: 工学版, 2005,35(4): 386-390. |

| Wang Jia-zhong, Wang Long-shan, Li Guo-fa, et al. Surface roughness prediction and control of cylinder traverse grinding based on fuzzy logic[J]. Journal of Jilin University (Engineering and Technology Edition), 2005, 35(4): 386-390. | |

| 22 | 任敬心, 华定安. 磨削原理[M]. 西安: 西北工业大学出版社, 1988. |

| Ren Jing-xin, Hua Ding-an. Grinding Principles[M]. Xi'an: Northwestern Polytechnic University Press, 1988. | |

| 23 | Agarwal S, Venkateswara R P. Predictive modeling of force and power based on a new analytical undeformed chip thickness model in ceramic grinding[J]. International Journal of Machine Tools and Manufacture, 2013, 65: 68-78. |

| [1] | Li HUI,Jia-chen LU,Song ZHOU,Jin-lan AN,Guan-yan ZHOU,Xiao-peng LIU. Effect of heat treatment on fatigue properties of TC4 titanium alloy by laser double beam welded joint [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(1): 105-110. |

| [2] | Qing-feng GUAN,Xin-wen YAO,Yang YANG,Ling-yan ZHANG,Di LIU,Chen LI,Peng LYU. Preparation and property of Cr alloying layer on TC4 after surface alloying induced by high current pulsed electron beam [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 2002-2009. |

| [3] | ZHANG Lei, GENG Wei-qiang, BAO Yong-ji, ZHAO Ji. Ultrosonic powder feeding system in hydroxyapatite cold spraying equipment [J]. , 2012, (06): 1402-1408. |

| [4] | Peng Tai-jiang,Yang shu-chen,Yang Zhi-gang,Cheng Guang-ming,Zeng Ping, Zhang De-jun . Experimental study on ultrasonic antifriction behavior [J]. 吉林大学学报(工学版), 2006, 36(增刊2): 88-90. |

| [5] |

Tan Fu-xing;Li Ming-zhe;Qian Zhi-rui;Yuan Yuan.

Numerical simulation on process of multipoint forming for titanium alloy cranial prosthesis [J]. 吉林大学学报(工学版), 2006, 36(06): 851-0855. |

| [6] | Guo Wei, Zhao Xi-hua, Song Min-xia,Feng Ji-cai,Yang Biao1. Pattern analysis on diffusion bonding of TC4 and QAL1031.5 [J]. 吉林大学学报(工学版), 2006, 36(03): 285-0288. |

| [7] | Song Minxia,Zhao Xihua,Guo Wei,Feng Jicai. Diffusion Bonding of Ti-6Al-4V to ZQSn10-10 with Nickel Interlayer [J]. 吉林大学学报(工学版), 2006, 36(01): 42-0045. |

| [8] | CHANG Ying, WU Bo-da, YANG Zhi-gang, CHENG Guang-ming, TIAN Feng-jun. Bearing capacity and anti-friction behavior of ultrasonic vibration bearing [J]. 吉林大学学报(工学版), 2004, (2): 222-225. |

|