Journal of Jilin University(Engineering and Technology Edition) ›› 2024, Vol. 54 ›› Issue (1): 105-113.doi: 10.13229/j.cnki.jdxbgxb.20220188

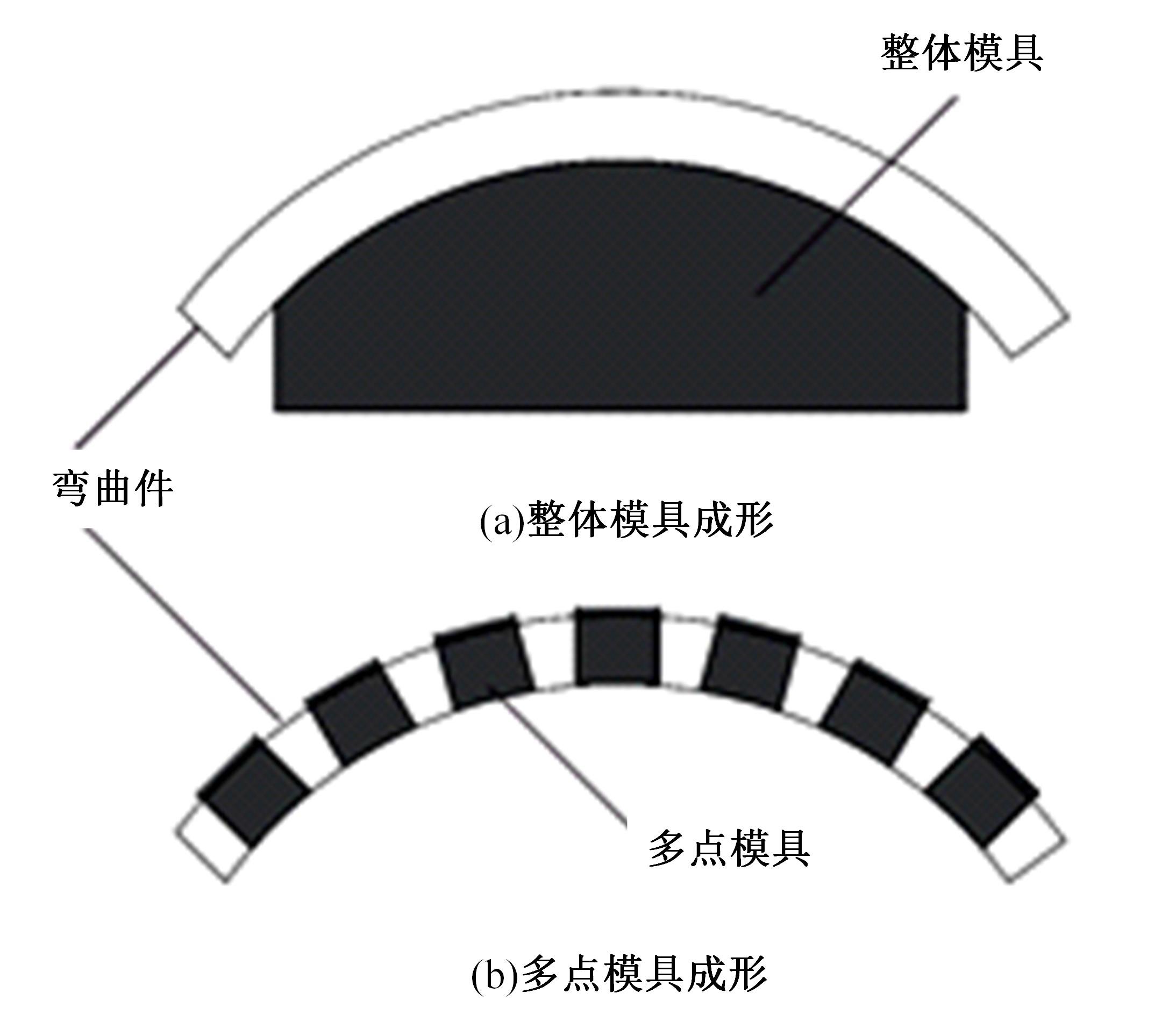

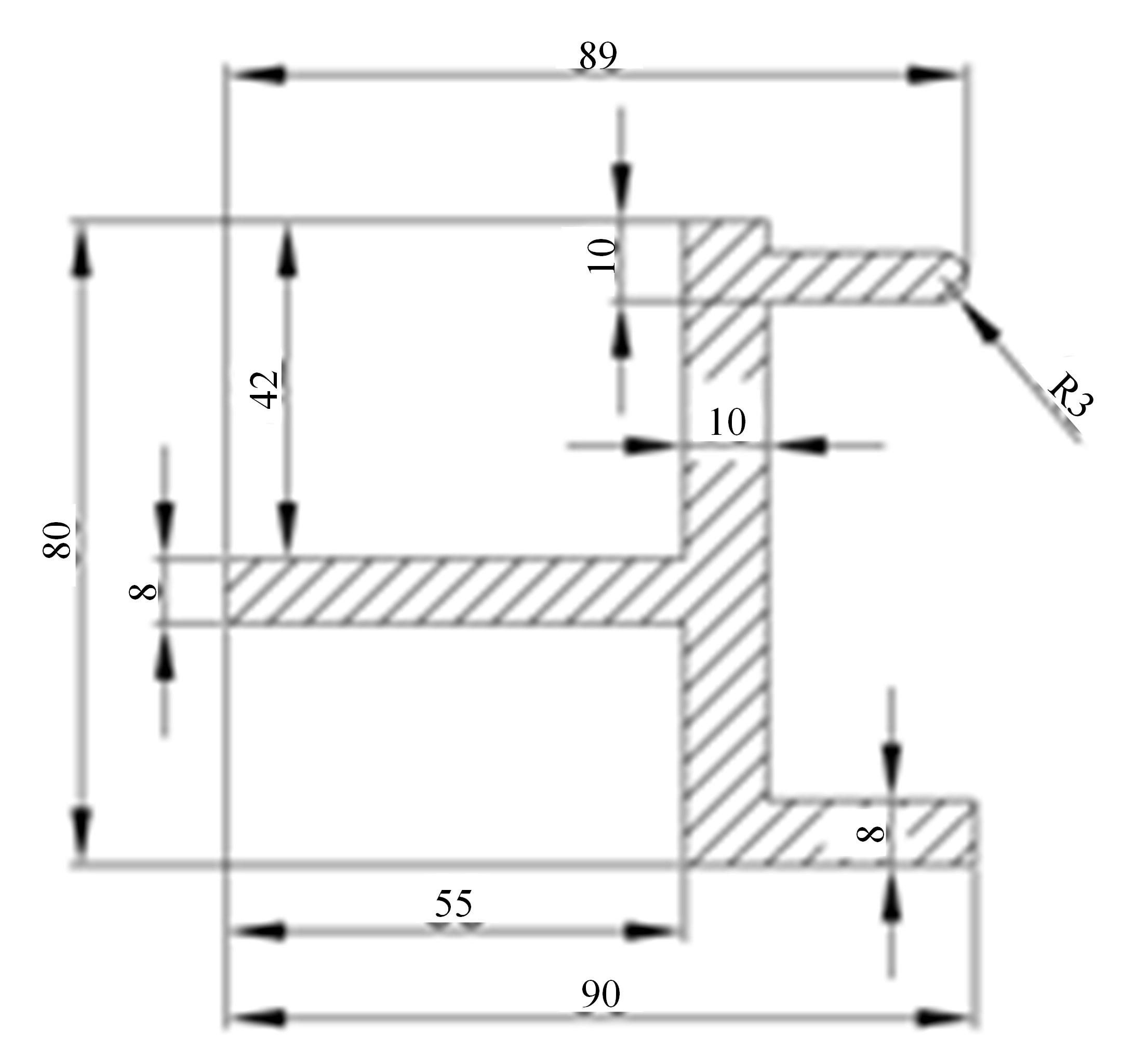

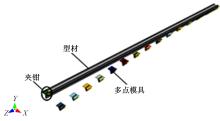

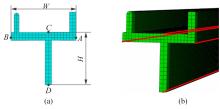

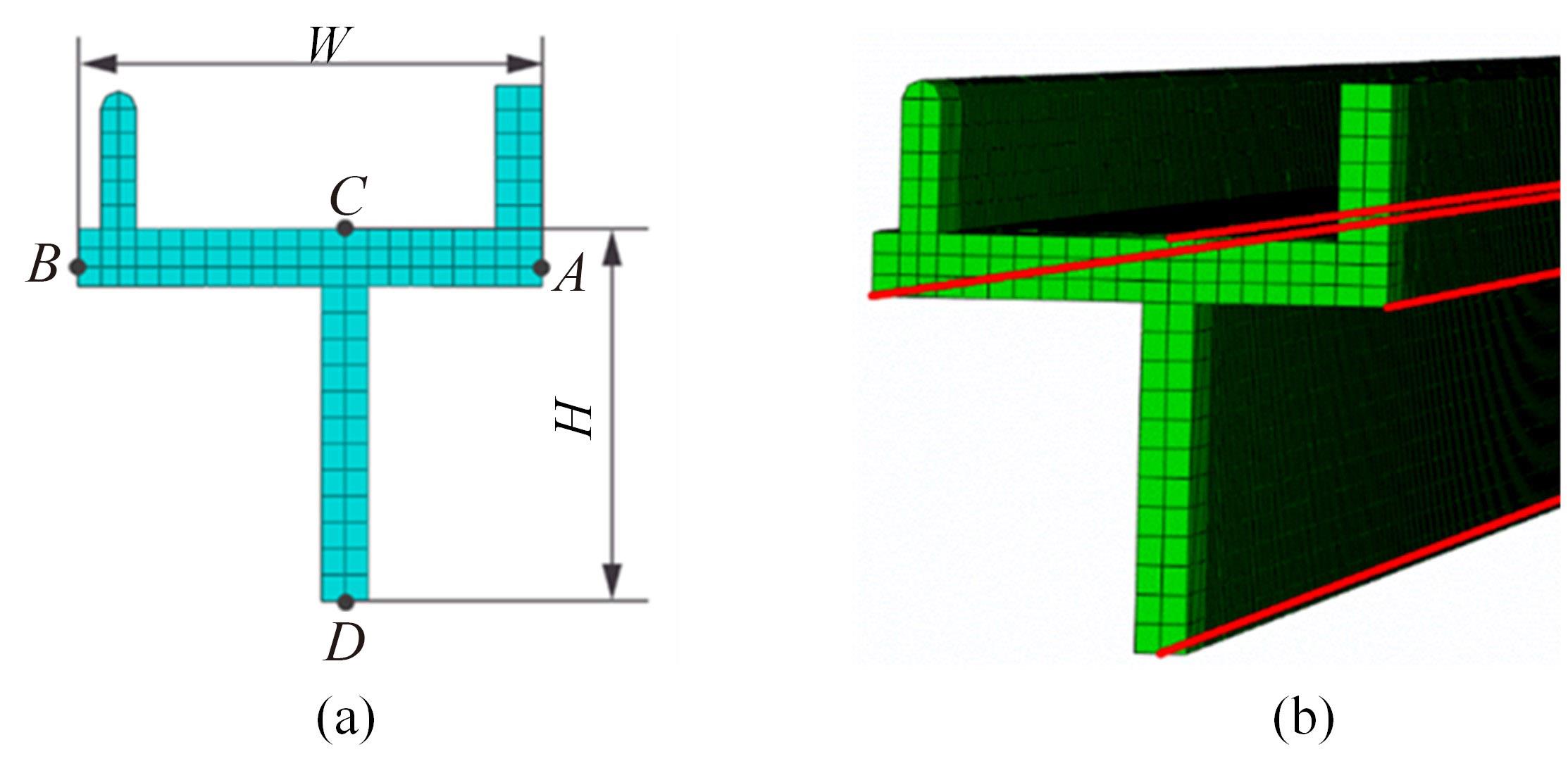

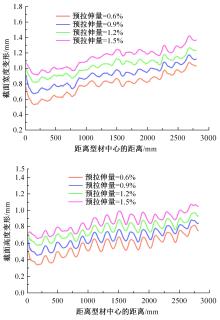

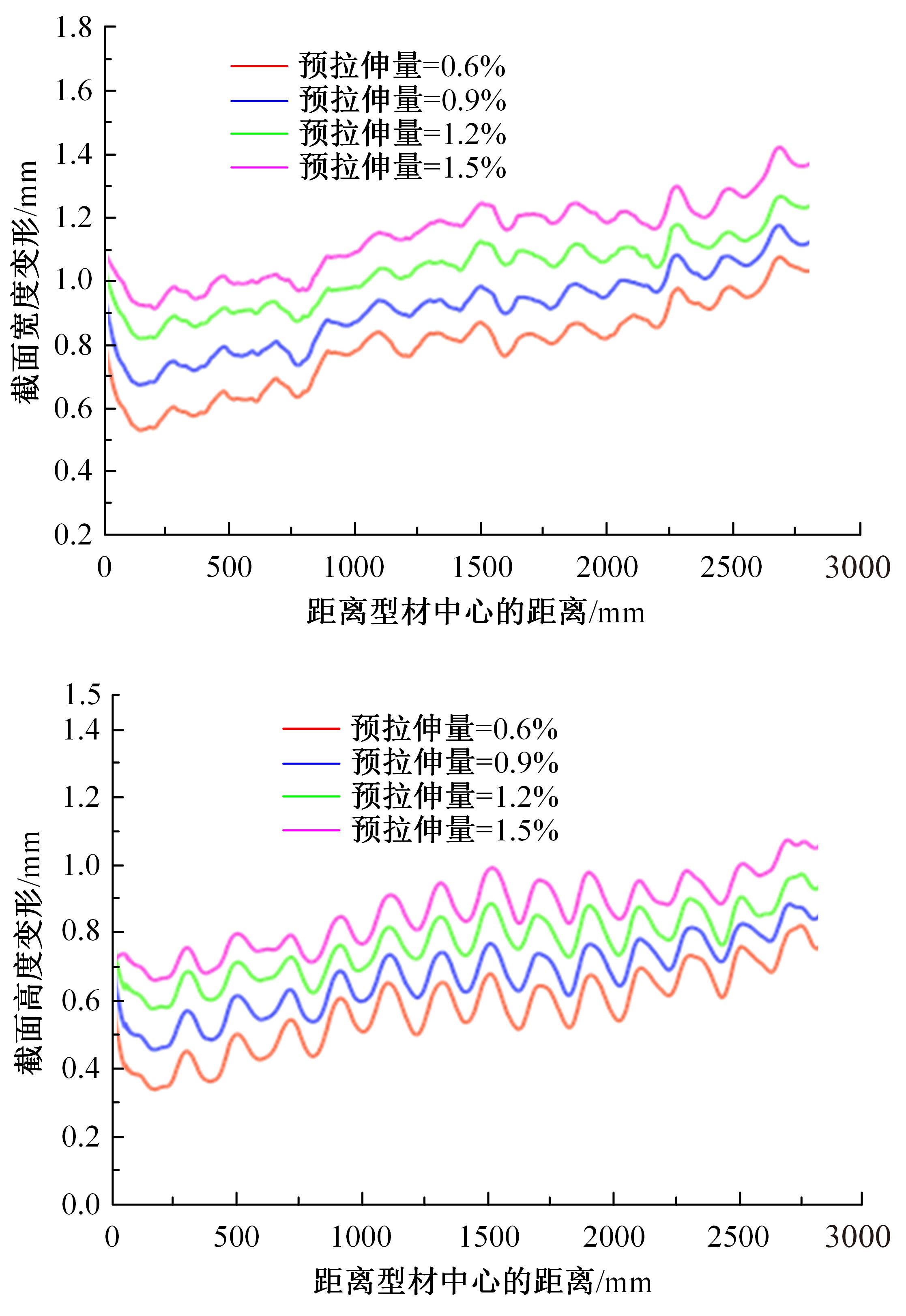

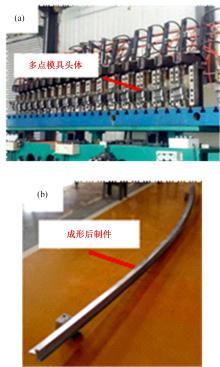

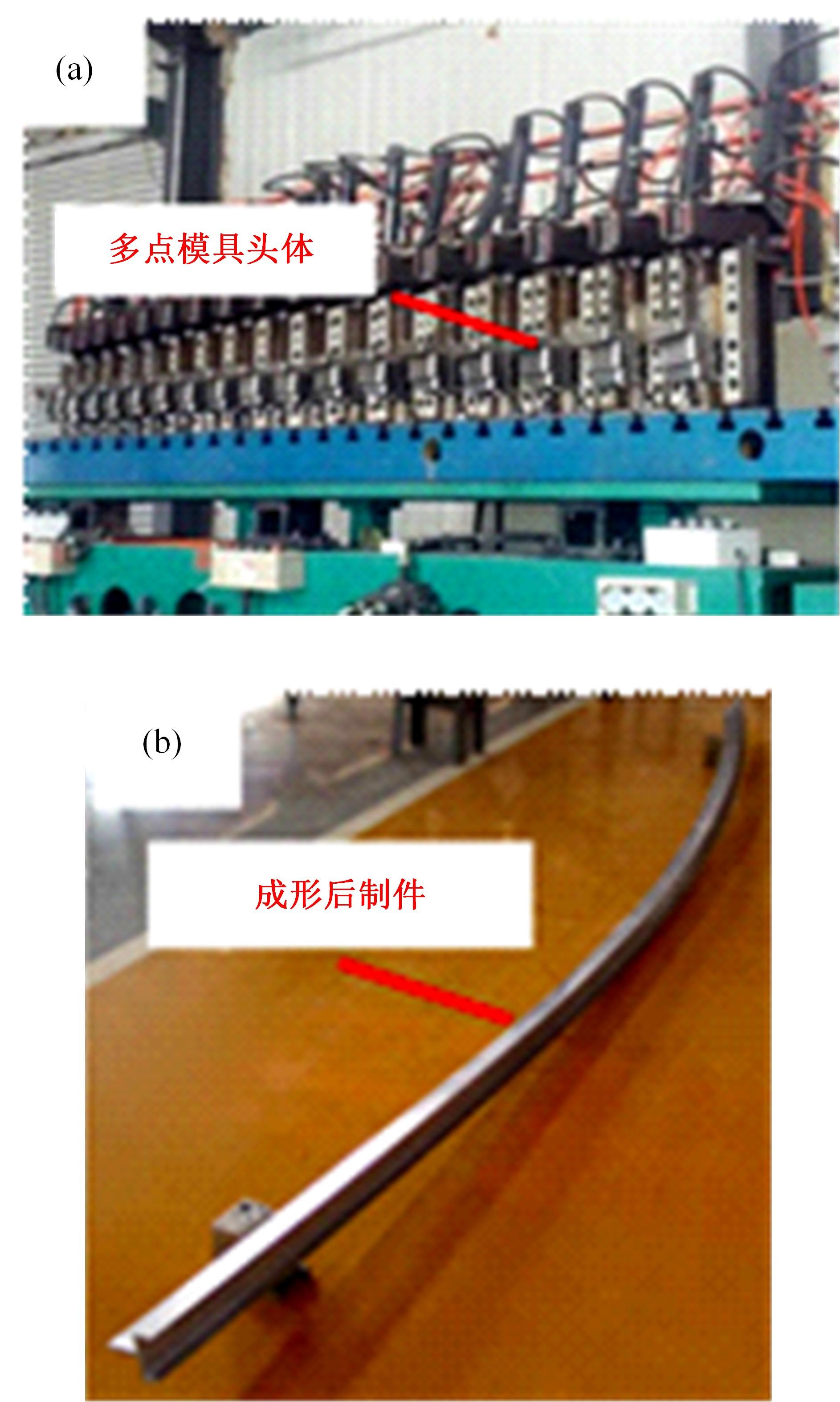

Section deformation analysis of irregular Y-shaped aluminum profile of multi-point stretch-bending process

Yi LI1,2( ),Chen-yang LYU1,2,Ji-cai LIANG1,3,Ce LIANG1,2(

),Chen-yang LYU1,2,Ji-cai LIANG1,3,Ce LIANG1,2( )

)

- 1.College of Materials Science and Engineering,Jilin University,Changchun 130022,China

2.Key Laboratory of Automobile Materials,Ministry of Education,Jilin University,Changchun 130022,China

3.Chongqing Research Institute,Jilin University,Chongqing 401123,China

CLC Number:

- TG356

| 1 | 李军,周佳,王利刚,等. 中国乘用车轻量化水平发展趋势研究[J]. 汽车工程学报, 2021, 11(5): 313-319, 362. |

| Li Jun, Zhou Jia, Wang Li-gang, et al. Research on the development trend of lightweight level of passenger cars in China[J]. Journal of Automotive Engineering, 2021, 11(5): 313-319, 362. | |

| 2 | 郑雪芹. 汽车新材料的应用及发展趋势[J]. 汽车纵横, 2021(11): 73-76. |

| Zheng Xue-qin. Application and development trend of new automotive materials[J]. Automotive Vertical and Horizontal, 2021(11): 73-76. | |

| 3 | 陈文博,屈闯,丁介然,等. 简述汽车用铝合金防护方式[J]. 汽车实用技术, 2021, 46(13): 202-204. |

| Chen Wen-bo, Qu Chuang, Ding Jie-ran,et al. Brief description of aluminum alloy protection methods for automobile[J]. Automobile Practical Technology, 2021, 46(13): 202-204. | |

| 4 | Li M Z, Cai Z Y, Sui Z, et al. Principle and applications of multi-point matched-die forming for sheet metal[J]. Journal of Engineering Manufacture, 2008, 222(5): 581-589. |

| 5 | Cai Z Y, Li M Z. Principle and theoretical analysis of continuous roll forming for three-dimensional surface parts[J]. Science China Technological Sciences, 2013, 56(2): 351-358. |

| 6 | 彭赫力,于亚平,李明哲,等. 大尺寸三维曲面件多点分段成形技术[J]. 锻压技术, 2018, 43(2): 29-33. |

| Peng He-li, Yu Ya-ping, Li Ming-zhe, et al. Multi-point segmented forming technology for large-size 3D curved parts[J]. Forging Technology, 2018, 43(2): 29-33. | |

| 7 | Li Y, Li R, Liang C, et al. Influence of the curvature of the multipoint die for flexible multipoint stretch bending on the quality of aluminum profile[J]. Mathematical Problems in Engineering, 2020(1):1-9. |

| 8 | 郝涛涛. 非对称截面型材拉弯成形数值模拟研究[J]. 机械制造, 2014, 52(6): 40-42. |

| Hao Tao-tao. Numerical simulation of stretch bending of asymmetric section profiles[J]. Mechanical Manufacturing, 2014, 52(6): 40-42. | |

| 9 | Gu Z W, Lv M M, Li X, et al. Stretch bending defects control of L-section aluminum components with variable curvatures[J]. The International Journal of Advanced Manufacturing Technology, 2016, 85(5-8): 1053-1061. |

| 10 | Gu Z W, Lv M M, Li X, et al. Stretch bending of Z-section stainless steel profile[J]. Journal of Iron and Steel Research International, 2016, 23(6): 525-530. |

| 11 | Gu Z W, Lv M M, Li X, et al. Stretch bending defect control of L-section SUS301L stainless-steel components with variable contour curvatures[J]. Journal of Iron and Steel Research International, 2019, 26(12): 1376-1384. |

| 12 | Liang K F, Chen Z Z, Wang S M, et al. Finite element simulation and respond surface optimization on stretch bending of square tube aluminum profile[J]. Advanced Materials Research, 2012, 365: 28-32. |

| 13 | 高嵩,梁继才,滕菲,等. 柔性三维拉弯成形零件的形状控制[J]. 华南理工大学学报:自然科学版, 2014, 42(9): 53-58. |

| Gao Song, Liang Ji-cai, Teng Fei,et al. Shape control of flexible 3D stretch bending parts[J]. Journal of South China University of Technology(Natural Science Edition), 2014, 42(9): 53-58. | |

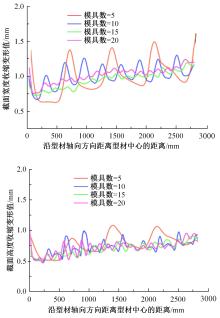

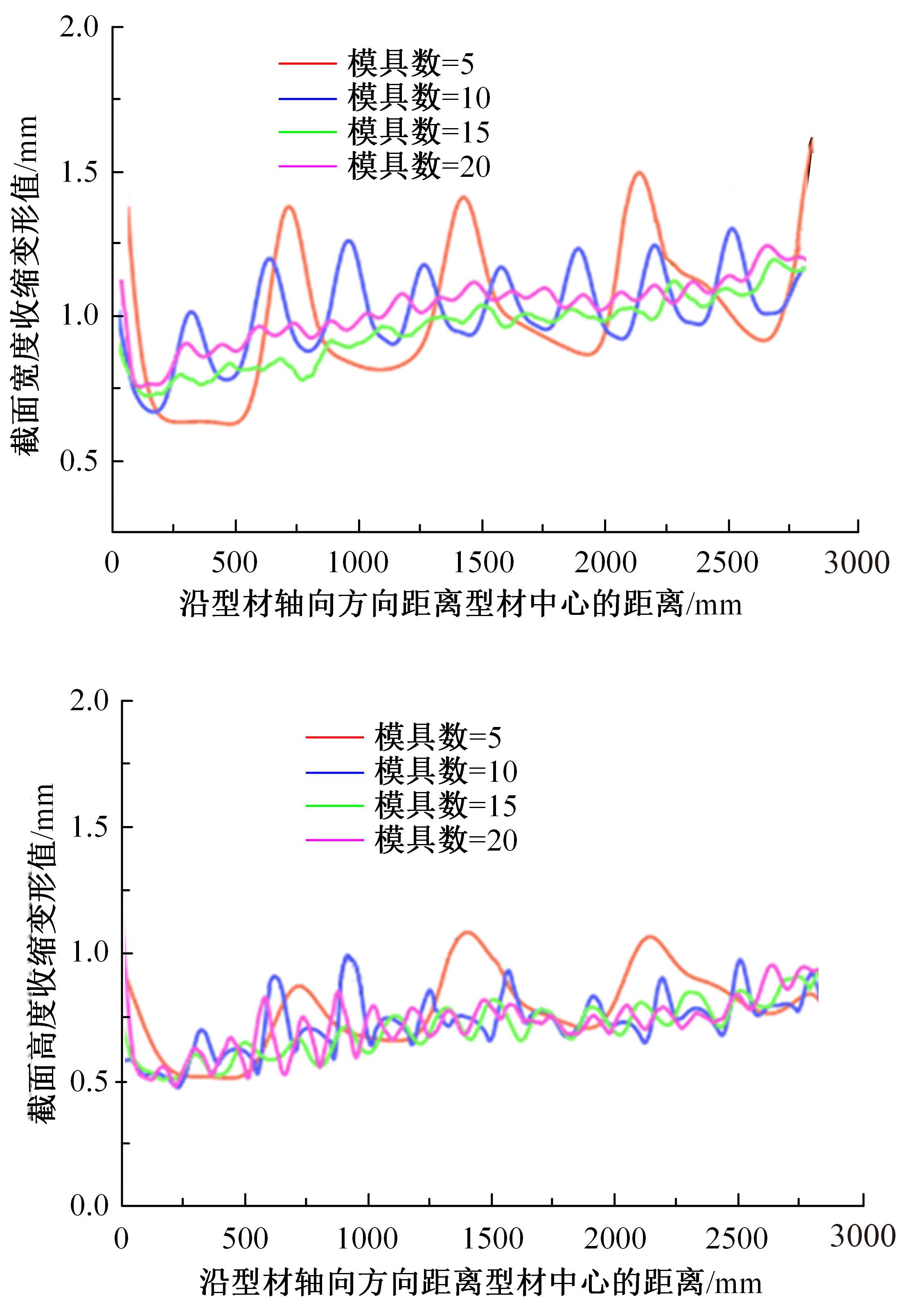

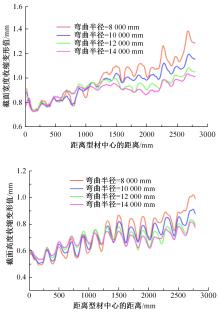

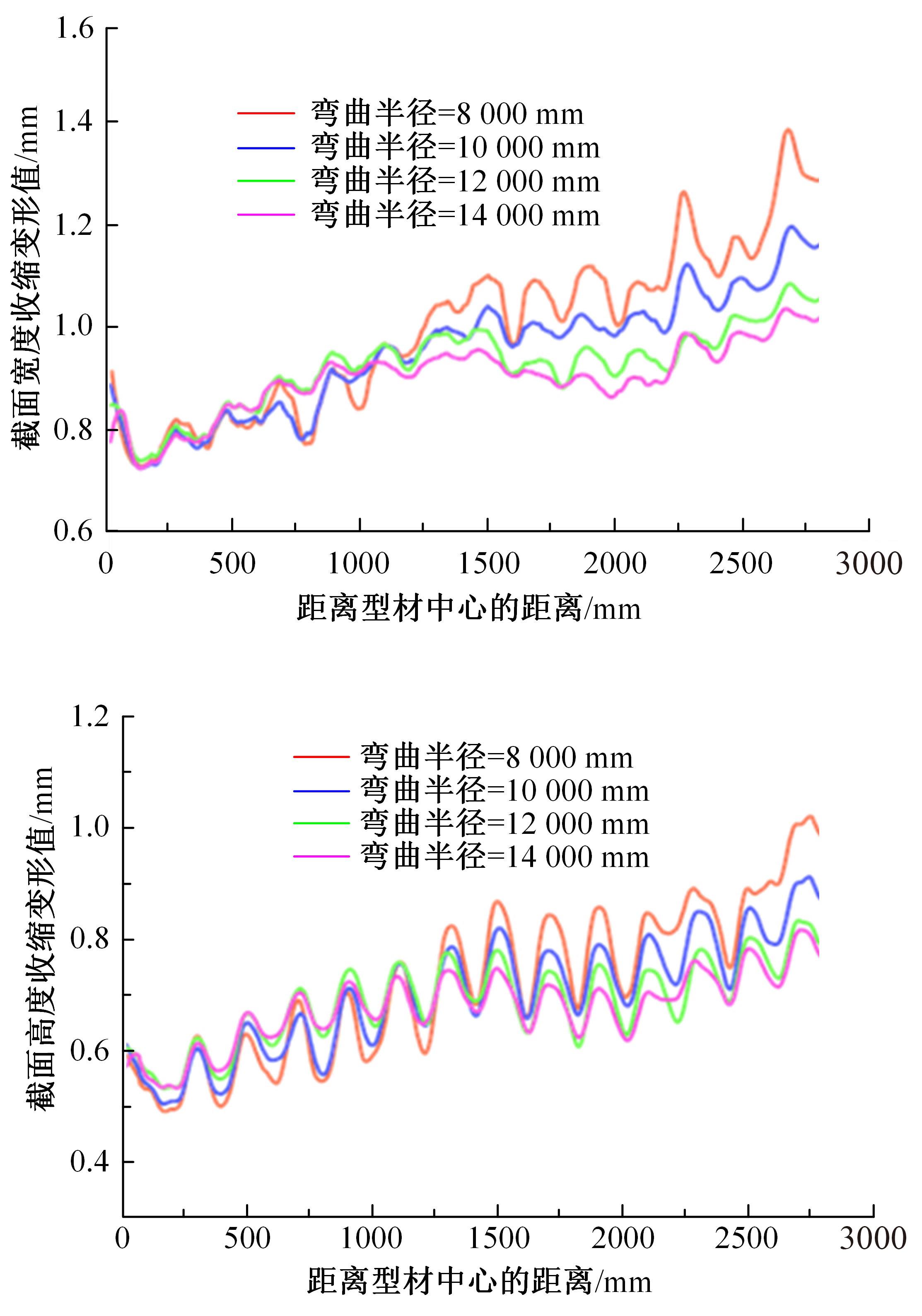

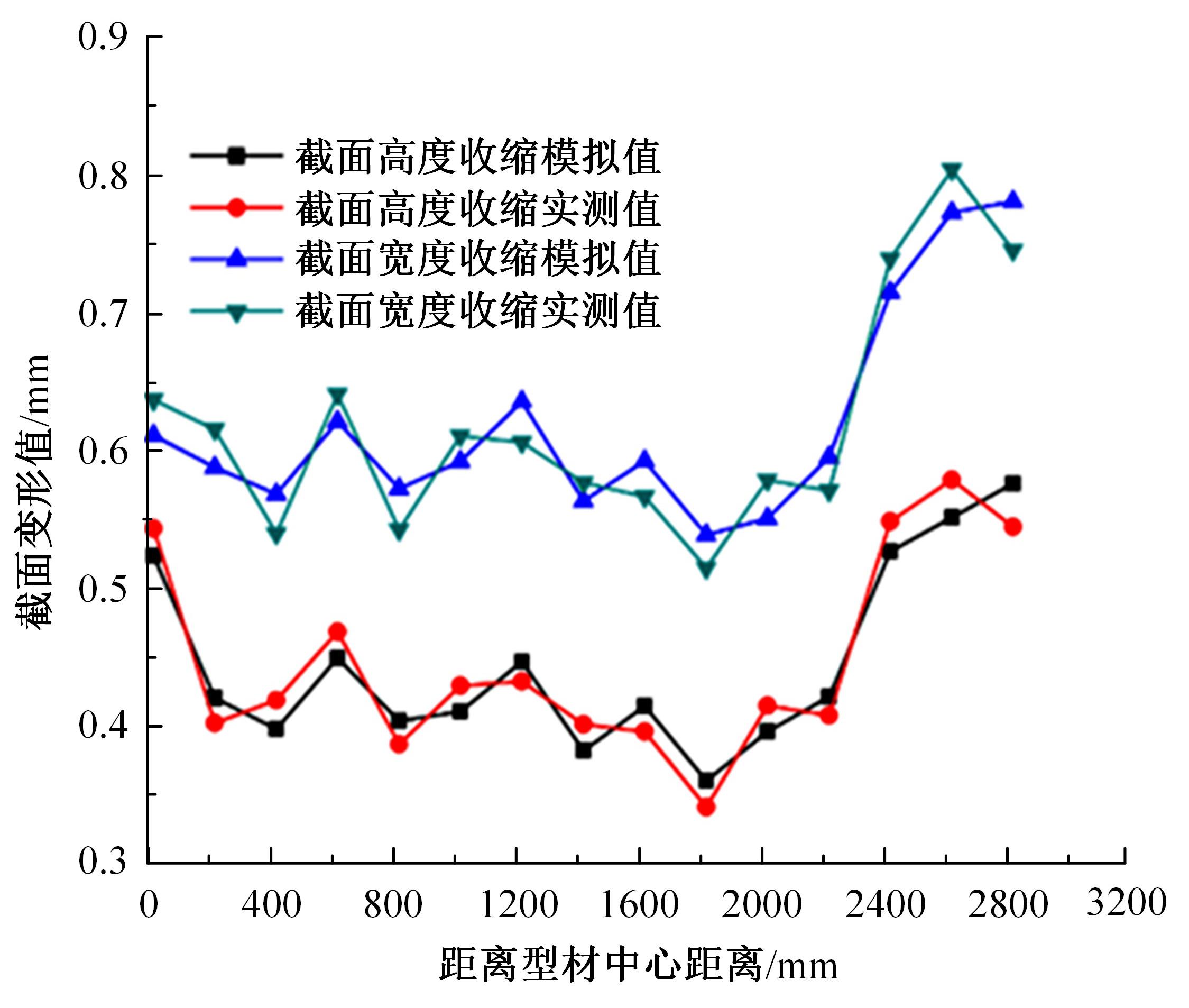

| 14 | Liang J C, Liao Y F, Li Y, et al. Study on the influence of bending angle of multipoint stretch-bending of profiles on section distortion of parts[J]. Mathematical Problems in Engineering, 2020(1):1-11. |

| 15 | Chen C D, Liang J C, Li Y, et al. Effect of discrete roller dies on the contour accuracy of profiles in multi-point flexible stretch-bending forming[J]. The International Journal of Advanced Manufacturing Technology, 2021, 113(7): 1959-1971. |

| 16 | 李义,梁继才,滕菲,等. 型材多点拉弯成形模具型面的分段补偿迭代方法[J]. 吉林大学学报:工学版, 2016,46(6): 1961-1966. |

| Li Yi, Liang Ji-cai, Teng Fei,et al. Sectional compensation iterative method for die surface of profile multi-point stretch bending[J]. Journal of Jilin University(Engineering and Technology Edition), 2016,46(6): 1961-1966. |

| [1] | Ce LIANG,Fu-lei HUANG,Ji-cai LIANG,Yi LI. Numerical simulation on deformation of protective beam with “日”-shaped section during rotary draw bending [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(12): 3397-3403. |

| [2] | Jian-ping LI,Yong-liang BIAN,Xin YANG,Peng-fei WANG,Xin-hao LI,Chun-lin XUE. Operational parameter optimization and testing of an air-assisted multi-fan orchard sprayer [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(10): 2474-2485. |

| [3] | QIAN Zhi-hui, ZHOU Liang, REN Lei, REN Lu-quan. Completely passive walking machine with bionic subtalar joint and matatarsal phalangeal joint [J]. 吉林大学学报(工学版), 2018, 48(1): 205-211. |

| [4] | SUN Bo-hua, DENG Wei-wen, ZHU Bing, WU Jian, WANG Shan-shan. Identification of vehicle motion intention based on reaction behavior model [J]. 吉林大学学报(工学版), 2018, 48(1): 36-43. |

| [5] | GU Zheng-wei, LYU Meng-meng, ZHANG Wen-xue, LEI Jiao-jiao, XU Hong. Stamping of front-end three-dimensional skin of China electric multiple units [J]. 吉林大学学报(工学版), 2017, 47(3): 869-875. |

| [6] | ZHANG Ze-xing, CHEN Guo-ying, ZONG Chang-fu. Objective evaluation indices of steering performance for EPS based on sensitivity analysis [J]. 吉林大学学报(工学版), 2015, 45(4): 1043-1048. |

| [7] | QI Long, TAN Zu-ting, MA Xu, CHEN Guo-rui, XIE Jun-feng, KUANG Jian-xia. Optimization and test of operational parameters of pneumatic vibration uniform-seeds device [J]. 吉林大学学报(工学版), 2014, 44(6): 1684-1691. |

| [8] | REN Li-Li, ZHOU Jiang, TONG Jin. Factors influencing degree of substitution of hydroxyl groups of surfacemodified starch films with alkenyl succinic anhydrides [J]. 吉林大学学报(工学版), 2010, 40(06): 1624-1628. |

| [9] |

Wang Jing-chun,Chen Li-li,Ren Lu-quan,Gu Song-tao,Cong Qian .

Experimental research on drag reduction of bionic injector needles [J]. 吉林大学学报(工学版), 2008, 38(02): 379-0382. |

| [10] | REN Luquan, ZHANG Chengchun, TIAN Limei. Experimental Study on Drag Reduction for Bodies of Revolution Using Bionic NonSmoothness [J]. 吉林大学学报(工学版), 2005, 35(04): 431-436. |

|

||