Journal of Jilin University(Engineering and Technology Edition) ›› 2026, Vol. 56 ›› Issue (1): 131-139.doi: 10.13229/j.cnki.jdxbgxb.20240662

Previous Articles Next Articles

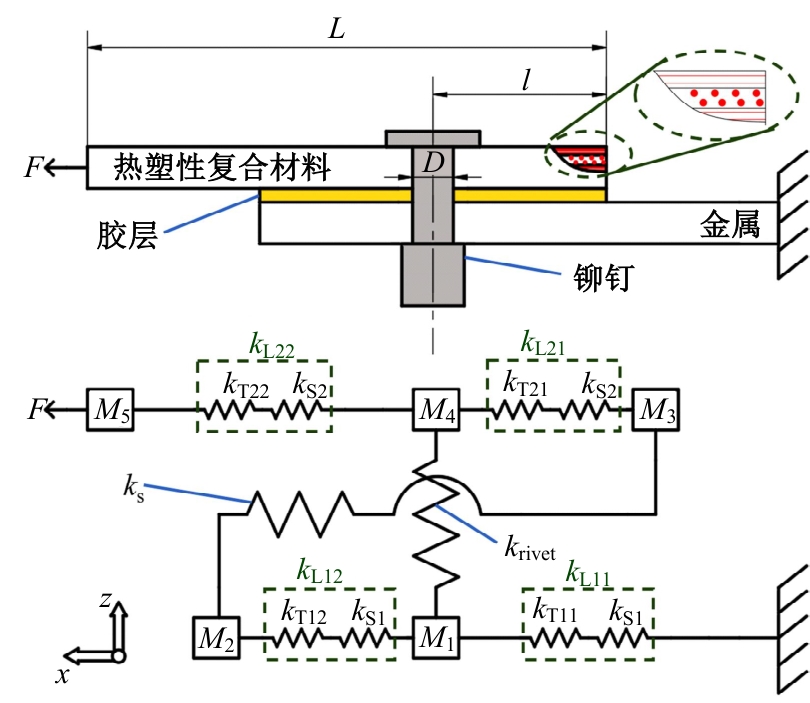

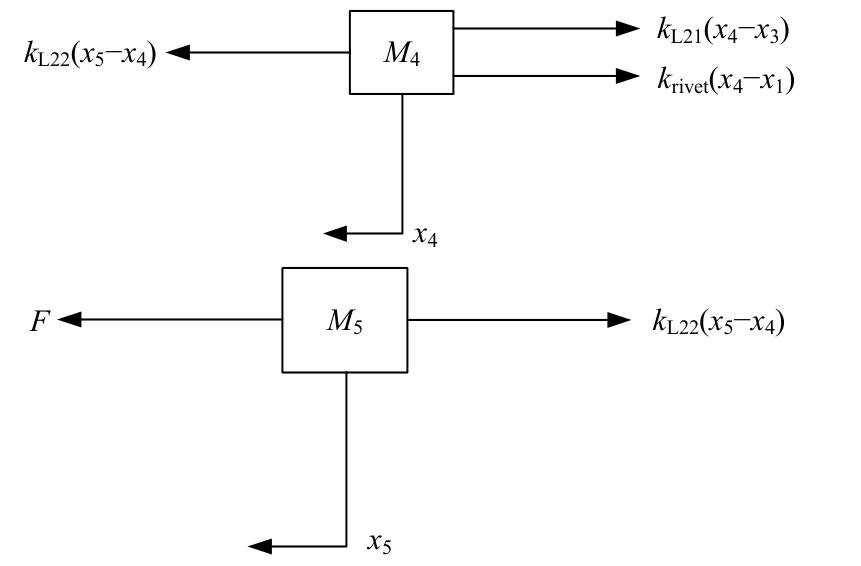

Stiffness prediction model of thermoplastic composites-metal bonded-riveted hybrid joints

Hong-zhe ZHANG1( ),Yu-xin JIA1,Yong-jie BAO2,Yu-xing YANG2(

),Yu-xin JIA1,Yong-jie BAO2,Yu-xing YANG2( )

)

- 1.Engineering Training Center,Dalian University of Technology,Dalian 116024,China

2.College of Marine Engineering,Dalian Maritime University,Dalian 116026,China

CLC Number:

- TG498

| [1] | 邓海, 王超, 杨京浩, 等. 碳纤维增强热塑性复合材料研究进展[J]. 吉林大学学报: 工学版, 2023, 53(1): 18-30. |

| Deng Hai, Wang Chao, Yang Jing-hao, et al. Research progress of carbon fiber reinforced thermoplastic composites[J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(1): 18-30. | |

| [2] | Feng Z W, Zhao H Y, Tan C W, et al. Nanosecond laser ablation for improving the strength of CFRTP and aluminum alloy adhesively bonded joints[J]. Composite Structures, 2021, 274: No.114369. |

| [3] | Li Y Y, Meng S, Gong Q M, et al. Experimental and theoretical investigation of laser pretreatment on strengthening the heterojunction between carbon fiber-reinforced plastic and aluminum alloy[J]. ACS Applied Materials and Interfaces, 2019, 11(24): 22005-22014. |

| [4] | Di Franco G, Fratini L, Pasta A. Analysis of the mechanical performance of hybrid(SPR/bonded) single-lap joints between CFRP panels and aluminum blanks[J]. International Journal of Adhesion and Adhesives, 2013, 41: 24-32. |

| [5] | 周利, 秦志伟, 刘杉, 等. 热塑性树脂基复合材料连接技术的研究进展[J]. 材料导报, 2019, 33(19): 3177-3183. |

| Zhou Li, Qin Zhi-wei, Liu Shan, et al. Progress on joining technology of thermoplastic resin matrix composites[J]. Materials Reports, 2019, 33(19): 3177-3183. | |

| [6] | Kumar S A, Rajesh R, Pugazhendhi S. A review of stress concentration studies on fibre composite panels with holes/cutouts[J]. Journal of Materials: Design and Applications, 2020, 234(11): 1461-1472. |

| [7] | Othman A R, Jadee K J, Ismadi M. Mitigating stress concentration through defense hole system for improvement in bearing strength of composite bolted joint, part 1: numerical analysis[J]. Journal of Composite Materials, 2017, 51(26): 3685-3699. |

| [8] | Soykok I F. End geometry and pin-hole effects on axially loaded adhesively bonded composite joints[J]. Composites Part B: Engineering, 2015, 77: 129-138. |

| [9] | Sun G Y, Xia X G, Liu X L, et al. On quasi-static behaviors of different joint methods for connecting carbon fiber reinforce plastic(CFRP) laminate and aluminum alloy[J]. Thin-walled Structures, 2021, 164: No.107657. |

| [10] | Han S L, Guang X J, Li Z Y, et al. Joining processes of CFRP-Al sheets in automobile lightweighting technologies: a review[J]. Polymer Composites, 2022, 43(12): 8622-8633. |

| [11] | Chen Y W, Yang X J, Li M J, et al. Mechanical behavior and progressive failure analysis of riveted, bonded and hybrid joints with CFRP-aluminum dissimilar materials[J]. Thin-walled Structures, 2019, 139: 271-280. |

| [12] | Zhang H, Zhang L, Liu Z, et al. Research in failure behaviors of hybrid single lap aluminum-CFRP(plain woven) joints[J]. Thin-walled Structures, 2021, 161: No.107488. |

| [13] | Bodjona K, Lessard L. Hybrid bonded-fastened joints and their application in composite structures: a general review[J]. Journal of Reinforced Plastics and Composites, 2016, 35(9): 764-781. |

| [14] | Mccarthy M A, Mccarthy C T, Padhi G S. A simple method for determining the effects of bolt-hole clearance on load distribution in single-column multi-bolt composite joints[J]. Composite Structures, 2006, 73(1): 78-87. |

| [15] | Olmedo A, Santiuste C, Barbero E. An analytical model for the secondary bending prediction in single-lap composite bolted-joints[J]. Composite Structures, 2014, 111: 354-361. |

| [16] | Yang Y, Liu X, Wang Y, et al. An enhanced spring-mass model for stiffness prediction in single-lap composite joints with considering assembly gap and gap shimming[J]. Composite Structures, 2018, 187: 18-26. |

| [17] | Goland M, Reissner E. The stresses in cemented joints[J]. Journal of Applied Mechanics, 1944, 11(1): 17-27. |

| [18] | De Bruyne N A. The strength of glued joints[J]. Aircraft Engineering and Aerospace Technology, 1944, 16(4): 115-118. |

| [19] | Xiao X, Foss P H, Schroeder J A. Stiffness prediction of the double lap shear joint, part 1: analytical solution[J]. International Journal of Adhesion and Adhesives, 2004, 24(3): 229-237. |

| [20] | Tsai M Y, Oplinger D W, Morton J. Improved theoretical solutions for adhesive lap joints[J]. International Journal of Solids and Structures, 1998, 35(12): 1163-1185. |

| [21] | Xu P F, Zhou Z G, Liu T Z, et al. A novel double-spring analytical model for hybrid GLARE joints: model development, validation, parameter study and global sensitivity analysis[J]. International Journal of Mechanical Sciences, 2020, 177: No.105606. |

| [22] | 赵波. 混元胶接单搭接头的应力与刚度分析[J]. 机械强度, 2009, 31(1): 95-103. |

| Zhao Bo. Stress and stiffness analysis of bi-adhesive bonded single-lap joints[J]. Journal of Mechanical Strength, 2009, 31(1): 95-103. | |

| [23] | Tate M B, Rosenfeld S J. Preliminary investigation of the loads carried by individual bolts in bolted joints[R]. Washington: U.S. Langley Memorial Aeronautical Laboratory, 1946. |

| [24] | Nelson W D, Bunin B L, Hart-Smith L J. Critical joints in large composite aircraft structure[R]. Long Beach: Douglas Aircraft Company, 1983. |

| [25] | 黄河源, 赵美英, 万小朋, 等. 一种复合材料螺栓连接结构非线性刚度模型及应用[J]. 西北工业大学学报, 2018, 36(1): 66-73. |

| Huang He-yuan, Zhao Mei-ying, Wan Xiao-peng, et al. A composite bolted joints non-linear stiffness model and its application[J]. Journal of Northwestern Polytechnical University, 2018, 36(1): 66-73. | |

| [26] | Owens J F P, Lee-Sullivan P. Stiffness behaviour due to fracture in adhesively bonded composite-to-aluminum joints II. experimental[J]. International Journal of Adhesion and Adhesives, 2000, 20(1): 47-58. |

| [27] | 侯文彬, 刘璟琳, 陈广义, 等. 胶层缺陷对胶接-拉铆搭接剪切接头力学性能影响研究[J]. 机械工程学报, 2019, 55(24): 37-44. |

| Hou Wen-bin, Liu Jing-lin, Chen Guang-yi, et al. Effect of defects in adhesive layer on the mechanical property of hybrid bond-riveted lap shear joint[J]. Journal of Mechanical Engineering, 2019, 55(24): 37-44. | |

| [28] | Campilho R D S G, Banea M D, Neto J A B P, et al. Modelling adhesive joints with cohesive zone models: effect of the cohesive law shape of the adhesive layer[J]. International Journal of Adhesion and Adhesives, 2013, 44: 48-56. |

| No related articles found! |

|

||