| 1 | IIW:Recommendations for fatigue design of welding joints and components[S].International Institute of Welding, XIII-2151-07/XV-1254 -07, 2008. |

| 2 | Packer JA . Concrete-filled rectangular hollow section X and T connections[S]. Delft University Press (Netherlands), 1991382-91. |

| 3 | van Wingerde A M . The fatigue behaviour of T-and X-joints made of square hollow sections[D]. Netherlands: Dlft University of Technology, 1992: 1-180. |

| 4 | van Wingerde A M , Packer J A , Wardenier J . Criteria for the fatigue assessment of hollow structural section connections[J]. Journal of Constructional Steel Research, 1995, 35(1): 71-115. |

| 5 | Zhao Xiao-lin , Herion S , Packer J A , et al . Design Guide for Circular and Rectangular Hollow Section Welded Joints under Fatigue Loading[M]. Germany: TüV-Verlag, 2001. |

| 6 | 曹珊珊, 雷俊卿 . 考虑区间不确定性的钢结构疲劳寿命分析[J]. 吉林大学学报:工学版, 2016, 46(3): 804-810. |

| 6 | Cao Shan-shan , Lei Jun-qing . Fatigue life prediction of steel structure considering interval uncertainty[J] Journal of Jilin University(Engineering and Technology Edition), 2016, 46(3): 804-810. |

| 7 | Sakai Y , Hosaka T , Isoe A , et al . Experiments on concrete filled and reinforced tubular K-joints of truss girder[J]. Journal of Constructional Steel Research, 2004, 60(3-5):683-699. |

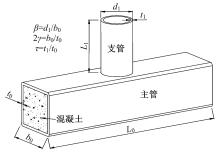

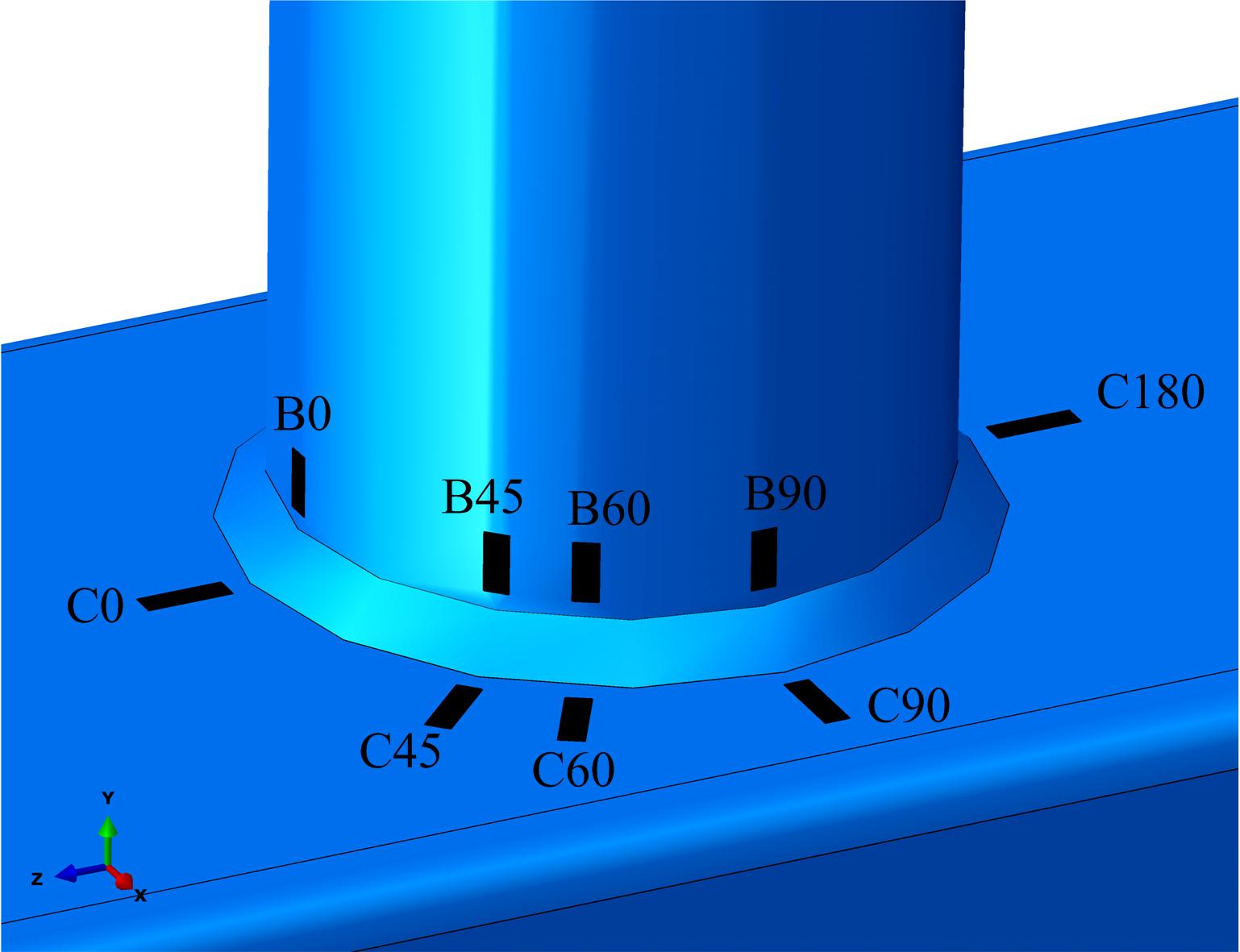

| 8 | Tong Le-wei , Wang Ke . Experimental study on stress concentration factors of concrete-filled circular hollow section T-joints under axial loading[C]∥China:Pacific Structural Steel Conference2007, in New Zealand, Vol.2. |

| 9 | Tong Le-wei , Sun Chuan-qi , Chen Yi-yi , et al . Experimental comparison in hot spot stress between CFCHS and CHS K-joints with gap[C]∥Proceedings of 12th International Symposium on Tubular Structures, Shanghai, China, 2008: 389-395. |

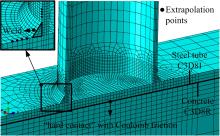

| 10 | Gu M , Tong L W , Zhao X L , et al . Stress intensity factors of surface cracks in welded T-joints between CHS brace and concrete-filled CHS chord[C]∥Tubular Structures XII: Proceedings of Tubular Structures XII, Shanghai, China, 2008: 359. |

| 11 | Chen J , Chen J , Jin W L . Experiment investigation of stress concentration factor of concrete-filled tubular T joints[J]. Journal of Constructional Steel Research, 2010, 66(12): 1510-1515. |

| 12 | Han Lin-hai , Li Wei , Bjorhovde R . Developments and advanced applications of concrete-filled steel tubular (CFST) structures: members[J]. Journal of Constructional Steel Research, 2014, 100: 211-228. |

| 13 | Kim I G , Chung C H , Shim C S , et al . Stress concentration factors of N-joints of concrete-filled tubes subjected to axial loads[J]. International Journal of Steel Structures, 2014, 14(1): 1-11. |

| 14 | Qian Xu-dong , Jitpairod K , Marshall P , et al . Fatigue and residual strength of concrete-filled tubular X-joints with full capacity welds[J]. Journal of Constructional Steel Research, 2014, 100: 21-35. |

| 15 | Xu Fei , Chen Ju , Jin Wei-liang . Experimental investigation of SCF distribution for thin-walled concrete-filled CHS joints under axial tension loading[J]. Thin-Walled Structures, 2015, 93: 149-157. |

| 16 | SIMULIA . Abaqus 6.12.Analysis User’s Manual[Z]. USA, Dassault Systems Simulia Corp., 2013. |

| 17 | Machiri F R , Zhao X L , Grundy P . Stress concentration factors and fatigue behaviour of welded thin-walled CHS-SHS T-joints under in-plane bending[J]. Engineering Structures, 2004, 26(13): 1861-1875. |

| 18 | 童乐为, 杨德磊, Zhao X L .圆管-方管混凝土T型节点疲劳性能试验研究[J]. 振动与冲击, 2013(2): 99-105. |

| 18 | Tong Le-wei , Yang De-lei , Zhao X L . Experimental study on fatigue behaviour of welded CHS-to-Concrete filled SHS T-joints [J]. Journal of Vibration and Shock, 2013(2): 99-105. |

| 19 | 王柯 . 圆管-圆管混凝土T型焊接节点热点应力和疲劳强度研究[D]. 上海:同济大学土木工程学院, 2008. |

| 19 | Wang Ke . Fatigue behaviour of welded CHS-to-Concrete filled CHS T-joints[D]. Shanghai: School of Civil Engineering, Tongji University, 2008. |

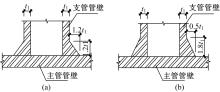

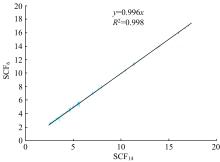

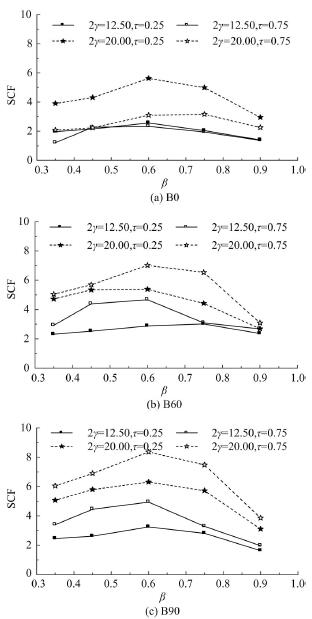

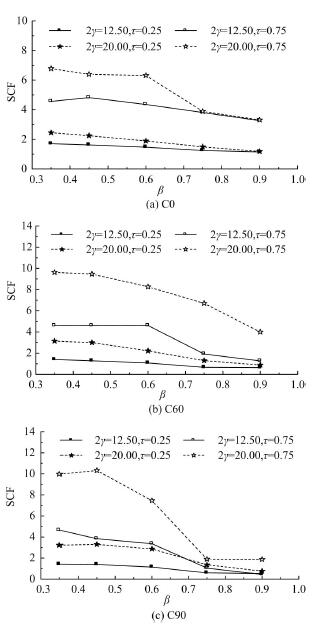

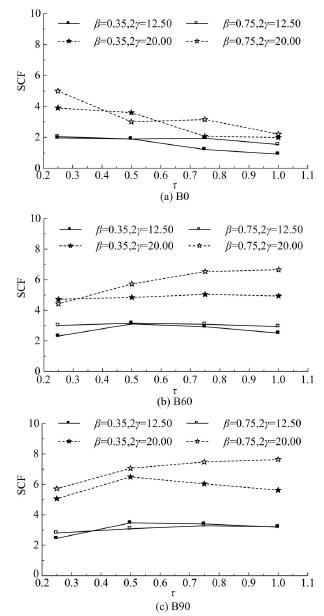

| 20 | Tong Le-wei , Zheng Hong-Zhi , Mashiri F R , et al . Stress-concentration factors in circular hollow section and square hollow section T-connections: experiments, finite-element analysis, and formulas[J]. Journal of Structural Engineering, 2013, 139(11): 66-81. |

| 21 | Yang De-lei , Tong Le-wei . Research on hot spot stress calculation method of CHS-CFSHS joints [J]. Jordan Journal of Civil Engineering, 2018, 12(2): 323-332. |

| 22 | 中国工程建设标准化协会 .CECS280. 钢管结构技术规程[S]. 北京:中国建筑工业出版社, 2010. |

| 23 | 中国工程建设标准化协会 .GB 50017—2003. 钢结构设计规范[S]. 北京:中国建筑工业出版社, 2003. |

| 24 | 中华人民共和国建设部 .JGJ 81—2002.建筑钢结构焊接技术规程[S]. 北京:中国建筑工业出版社, 2002. |

| 25 | van Wingerde A M , Packer J A , Wardenier J . Criteria for the fatigue assessment of hollow structural section connections[J]. Journal of Constructional Steel Research, 1995, 35(1): 71-115. |

| 26 | Yang Dei-lei , Tong Le-wei , Zhao Xiao-lin . Experimental study on SNCF of welded CHS-CFSHS T-Joints under Axial loading[J]. Advanced Materials Research, 2011, 163-167: 127-131. |