Journal of Jilin University(Engineering and Technology Edition) ›› 2021, Vol. 51 ›› Issue (3): 855-865.doi: 10.13229/j.cnki.jdxbgxb20190607

Previous Articles Next Articles

Effect of carbon equivalent elements on fluidity of hypoeutectic ductile iron by cellular automata finite element method

Jin-guo WANG1,2( ),Kai HUANG1,2,Rui-fang YAN1,2,Shuai REN1,2,Zhi-qiang WANG1,2,Jin GUO1,2

),Kai HUANG1,2,Rui-fang YAN1,2,Shuai REN1,2,Zhi-qiang WANG1,2,Jin GUO1,2

- 1.Key Laboratory of Automotive Materials,Ministry of Education,Jilin University,Changchun 130022,China

2.College of Materials Science and Engineering,Jilin University,Changchun 130022,China

CLC Number:

- TG143.5

| 1 | 王金国, 任帅, 闫瑞芳, 等. TiC颗粒对铸态球墨铸铁组织和力学性能的影响[J]. 吉林大学学报:工学版, 2019, 49(6): 2010-2018. |

| Wang Jin-guo, Ren Shuai, Yan Rui-fang, et al. Effect of TiC particles on microstructure and mechanical properties of as cast ductile iron[J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(6): 2010-2018. | |

| 2 | 何东野, 杨慎华, 寇淑清. 发动机曲轴箱轴承座裂解加工数值分析[J]. 吉林大学学报:工学版, 2009, 39(1): 78-82. |

| He Dong-Ye, Yang Shen-hua, Kou Shu-qing. Numerical analysis on fracture splitting technology of main bearing block of engine[J]. Journal of Jilin University(Engineering and Technology Edition), 2009, 39(1): 78-82. | |

| 3 | Pathak N, Kumar A, Yadav A, et al. Effects of mould filling on evolution of the solid-liquid interface during solidification[J]. Applied Thermal Engineering, 2009, 29(17-18): 3669-3678. |

| 4 | Vijayaram T R, Sulaiman S, Hamouda A M S, et al. Numerical simulation of casting solidification in permanent metallic molds[J]. Journal of Materials Processing Technology, 2006, 178(1-3): 29-33. |

| 5 | 张振波, 盛文斌, 孙策. 大型球墨铸铁下箱体铸造过程数值模拟及工艺优化[J]. 热加工工艺, 2019, 48(7): 113-116, 120. |

| Zhang Zhen-bo, Sheng Wen-bin, Sun Ce. Numerical simulation and process optimization of large spheroidal graphite cast iron lower box[J]. Hot Working Technology, 2019, 48(7): 113-116, 120. | |

| 6 | 陈映东, 丁旭, 沈刚, 等. 大型球墨铸铁蜗壳件砂型铸造模拟分析与工艺优化[J]. 铸造技术, 2018, 39(10): 2249-2252, 2264. |

| Chen Ying-dong, Ding Xu, Shen Gang, et al. Large nodular cast iron volute parts sand ca-sting simulation analysis and process optimization[J]. Foundry Technology, 2018, 39(10): 2249-2252, 2264. | |

| 7 | 魏胜辉, 张帆, 卢景秀, 等. 球墨铸铁轴封体铸造工艺设计及数值模拟[J]. 铸造技术, 2017, 38(6): 1493-1496. |

| Wei Sheng-hui, Zhang Fan, Lu Jing-xiu, et al. Casting process design and numerical simulation of ductile iron shaft seal[J]. Foundry Technology, 2017, 38(6): 1493-1496. | |

| 8 | 赵二梅, 鲁晨光, 杨刚. 球墨铸铁壳体件制备过程的数值模拟研究[J]. 铸造技术, 2015, 36(3): 809-812. |

| Zhao Er-mei, Lu Chen-guang, Yang Gang. Numerical simulation on manufacturing process of ductile cast iron shell parts[J]. Foundry Technology, 2015, 36(3): 809-812. | |

| 9 | 张晓敏. 高韧性球墨铸铁冷却壁的组织性能研究及凝固模拟试验[D]. 郑州:郑州大学材料科学与工程学院, 2010. |

| Zhang Xiao-min. Study on the microstructure and properties of high-ductility ductile iron cooling stave and its experiment of solidified simulation[D]. Zhengzhou:School of Materials Science and Engineering, Zhengzhou University, 2010. | |

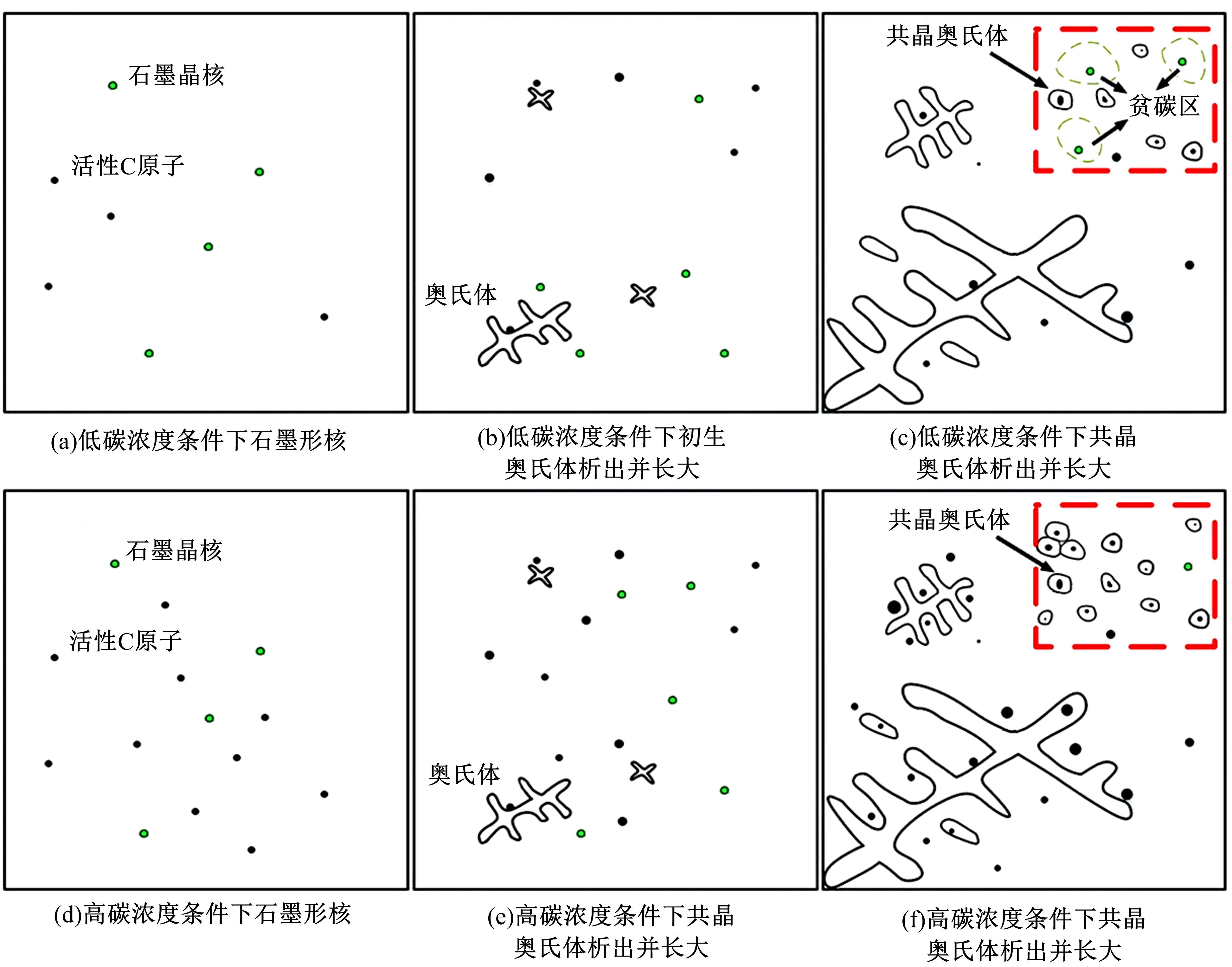

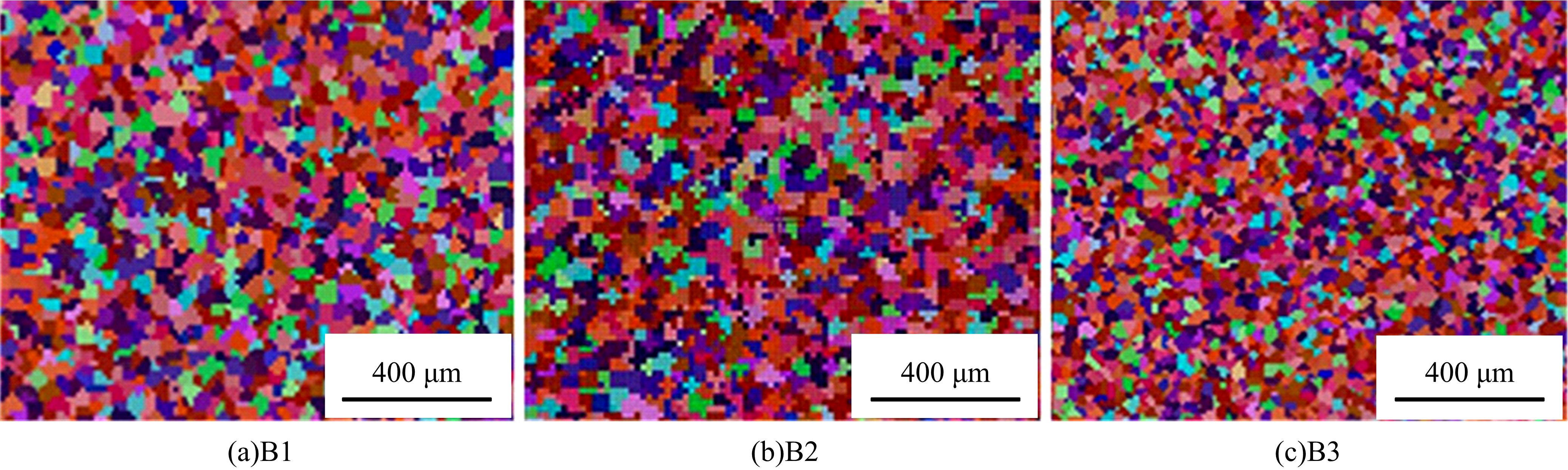

| 10 | Burbelko A A, Gurgul D, Kapturkiewicz W, et al. Cellular automaton modelling of ductile iron microstructure in the thin wall casting[J]. IOP Conference Series Materials Science and Engineering, 2012, 33(1): 012083. |

| 11 | Burbelko A A, Fraś E, Kapturkiewicz W. Modelling of dendritic growth during unidirectional solidification by the method of cellular automata[J].Materials Science Forum, 2010, 649: 217-222. |

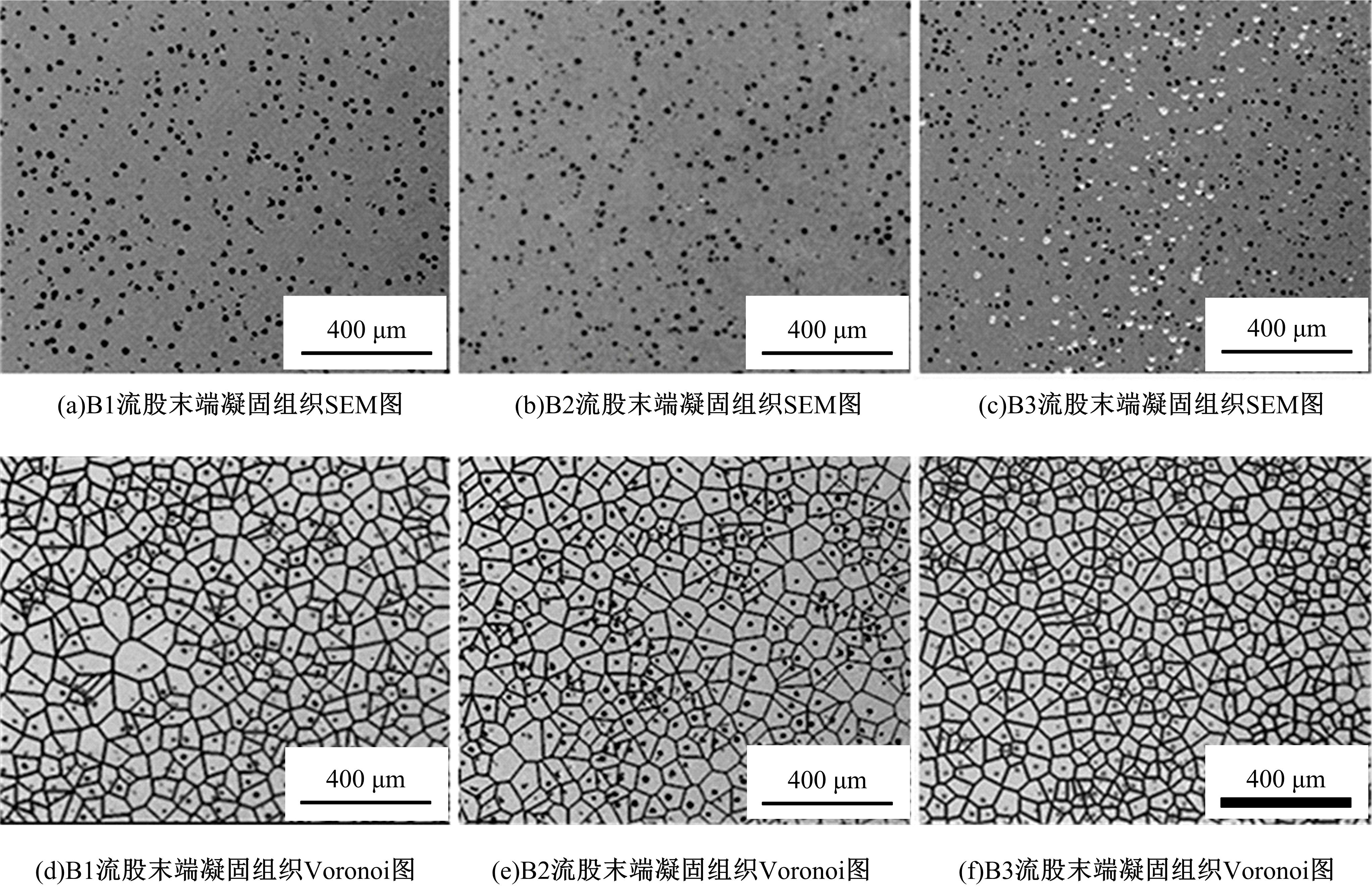

| 12 | Zhang Lei, Zhao Hong-lei, Zhu Ming-fang. Simulation of solidification microstructure of spheroidal graphite cast iron using a cellular automaton method[J]. Acta Metallurgica Sinica Chinese Edition, 2015, 51(2): 148-158. |

| 13 | 王雪涛. 风电球墨铸铁件铸造工艺及组织数值模拟的优化[D]. 济南:山东大学材料科学与工程学院, 2017. |

| Wang Xue-tao. Numerical simulation optimization of casting processes and structure of ductile iron casting for wind power[D]. Jinan:School of Materials Science and Engineering, Shandong University, 2017. | |

| 14 | Rappaz M. Modeling and characterization of grain structures and defects in solidification[J]. Current Opinion in Solid State & Materials Science, 2016, 20(1): 37-45. |

| 15 | Lee S Y, Lee S M, Hong C P. Numerical modeling of deflected columnar dendritic grains solidified in a flowing melt and its experimenttal verification[J]. ISIJ International, 2000, 40(1): 48-57. |

| 16 | 殷竞存, 朱晓临, 郭清伟. 基于分子间作用力改进的液体表面张力处理算法[J]. 合肥工业大学学报:自然科学版, 2018, 41(11): 1574-1578. |

| Yin Jing-cun, Zhu Xiao-lin, Guo Qing-wei. An improved liquid surface tension processing algorithm based on inter-molecular forces[J]. Journal of Hefei University of Technology(Natural Science), 2018, 41(11): 1574-1578. | |

| 17 | 黄锋. 薄带双辊铸轧凝固过程组织演变的数值模拟[D]. 沈阳:东北大学材料与冶金学院, 2015. |

| Huang Feng. Numerical simulation of microst-ructure evolution during solidification of twin roll casting process[D]. Shenyang:School of Materials and Metallurgy, Northeastern University, 2015. | |

| 18 | Rivera G, Boeri R, Sikora J. Revealing and characterising solidification structure of ductile cast iron[J]. Materials Science and Technology, 2002, 18(6): 691-697. |

| 19 | Ghahremaninezhad A, Ravi-Chandar K. Deformation and failure in nodular cast iron[J]. Acta Materialia, 2012, 60(5): 2359-2368. |

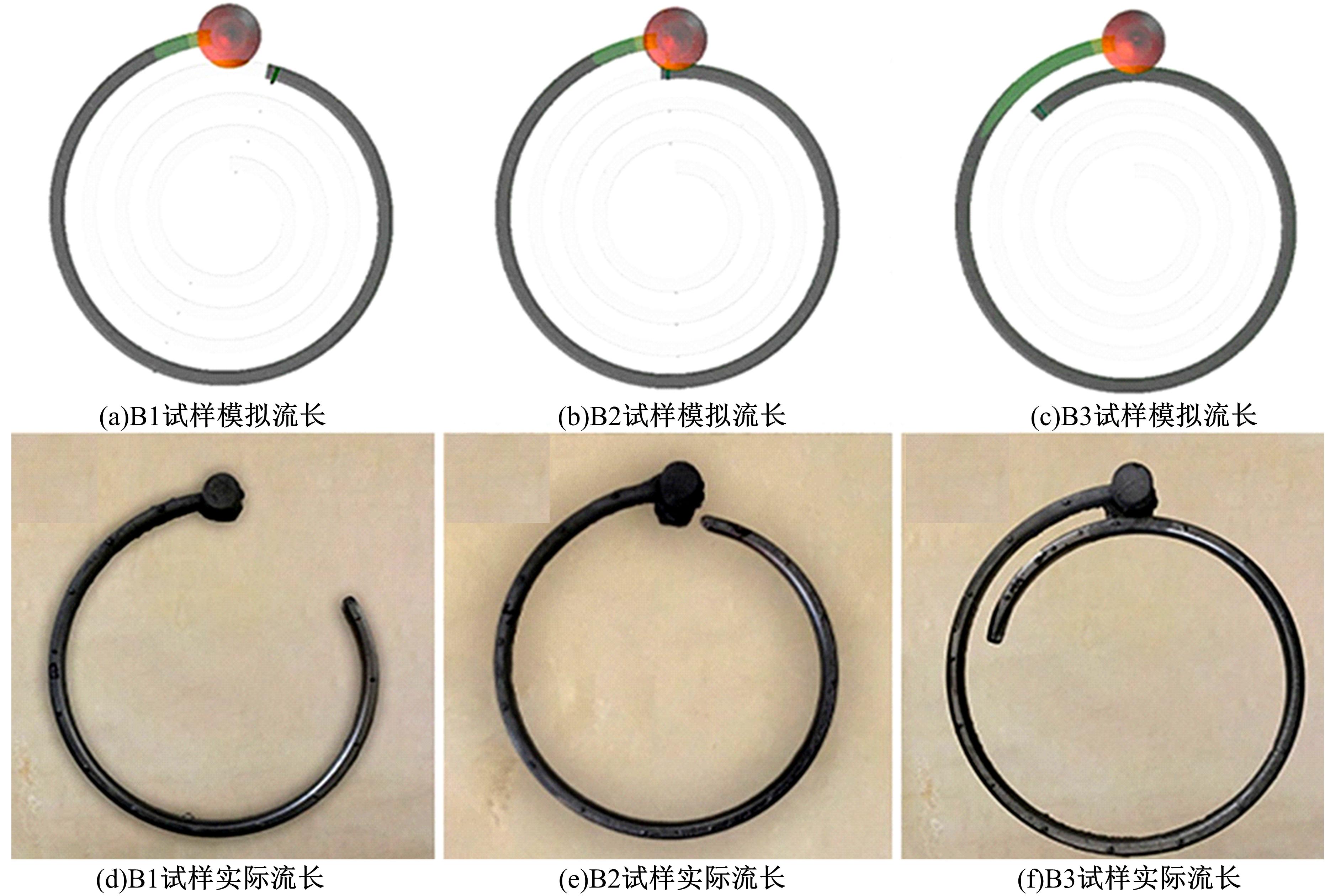

| 20 | Górny M. Fluidity and temperature profile of ductile iron in thin sections[J]. Journal of Iron and Steel Research(International), 2012, 19(8): 52-59. |

| 21 | 高升. 球墨铸铁碳当量的研究及生产实践[D]. 武汉:华中科技大学材料科学与工程学院, 2005. |

| Gao Sheng. Research and production practice of carbon equivalent of nodular cast iron[D]. Wuhan:School of Materials Science and Engineering, Huazhong University of Science and Technology, 2005. | |

| 22 | 张湛, 周尧和. 液态金属停止流动机理的实验研究[J]. 西北工业大学学报, 1965(1): 29-39. |

| Zhang Zhan, Zhou Yao-he. Experimental study on the mechanism of liquid metal stopping flow[J]. Journal of Northwestern Polytechnical University, 1965(1): 29-39. | |

| 23 | 吴德海. 球墨铸铁[M]. 北京:中国水利水电出版社, 2006. |

| 24 | Carazo F D, Dardati P M, Celentano D J, et al. Nucleation and growth of graphite in eutectic spheroidal cast iron: modeling and testing[J].Metallurgical and Materials Transactions A, 2016, 47(6): 2625-2641. |

| 25 | Stefanescu D M, Alonso G, Larrañaga P, et al. On the stable eutectic solidification of iron carb-on silicon alloys[J]. Acta Materialia, 2016, 103: 103-114. |

| 26 | Ghassemali E, Hernando Jua C, Stefanescu D M, et al. Revisiting the graphite nodule in ductile iron[J]. Scripta Materialia, 2019, 161: 66-69. |

| 27 | 李桐桐. 球墨铸铁中碳元素扩散系数的计算及分析[D]. 济南:山东大学材料科学与工程学院, 2013. |

| Li Tong-tong. The calculation and analysis of carbon diffusion coefficient in ductile iron[D]. Jinan:School of Materials Science and Engineering, Shandong University, 2013. | |

| 28 | Stefanescu D. Science and Engineering of Casting Solidification[M]. Second Edition.New York: Springer, 2009. |

| 29 | Fredriksson H, Stjerndah J, Tinoco J. On the solidification of nodular cast iron and its relation to the expansion and contraction[J]. Materials Science & Engineering:A, 2005, 413/414: 363-372. |

| 30 | 张蕾, 赵红蕾, 朱鸣芳. 球墨铸铁凝固显微组织的元胞自动机模拟[J]. 金属学报, 2015, 51(2): 148-158. |

| Zhang Lei, Zhao Hong-lei, Zhu Ming-fang. Simulation of solidification microstruc-ture of spheroidal graphite cast iron using a cellular automaton method[J]. Acta Metallurgica Sinica, 2015, 51(2): 148-158. | |

| 31 | 井ノ山哉, 山本悟, 川野豊. 反应论铸铁学[M].庞建路,杨丽萍译. 北京:机械工业出版社, 2012. |

| 32 | 周学源. 合金元素对渗碳体长大动力学及热稳定性影响[D]. 南京:东南大学材料科学与工程学院, 2014. |

| Zhou Xue-yuan. The effect of alloy elements on the coarsening kinetics and thermal stability of cementite[D]. Nanjing:School of Materials Science and Engineering, Southeast University, 2014. |

| [1] | Wen-cui XIU,Hua WU,Ying HAN,Yun-xu LIU. Effect of isothermal heat treatment temperature on microstructure and mechanical properties of super bainite [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 520-525. |

| [2] | Wu⁃jiao XU,Cheng⁃shang LIU,Xin⁃yao LU. Simulation and prediction of surface roughness of 6061 aluminum alloy workpiece after shot peening [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1280-1287. |

| [3] | ZHANG Jia-tao, ZHAO Yu-guang, TAN Juan. Effect of starting microstructure on refining potency of electro-pulsing on reverse austenite grain [J]. 吉林大学学报(工学版), 2016, 46(1): 193-198. |

| [4] | ZHANG Zhi-qiang, JIA Xiao-fei, YUAN Qiu-ju. Springback analysis of trip high strength steel based on Yoshida-Uemori model [J]. 吉林大学学报(工学版), 2015, 45(6): 1852-1856. |

| [5] | ZHANG Zhi-qiang, JIA Xiao-fei, ZHAO Yong, LI Xiang-ji. Experiment and simulation on quenching interface heat transfer coefficient of high-strength boron steel [J]. 吉林大学学报(工学版), 2015, 45(4): 1195-1199. |

| [6] | YING Liang, DAI Ming-hua, HU Ping, FAN Zheng-shuai, SHEN Guo-zhe, SHI Dong-yong. Strength and hardness prediction based on cooling rate for hot forming high strength steel [J]. 吉林大学学报(工学版), 2014, 44(6): 1716-1722. |

| [7] | LI Zhi-jie, PENG Yan, LIU Hong-min, WANG Su-fen, XIAO Li-zi. Flow stress of medium carbon steel under warm compression deformation [J]. 吉林大学学报(工学版), 2013, 43(05): 1320-1324. |

| [8] | CHENG Yong-chun, JIANG Ping, TAN Guo-jin, SUN Yan-yi, JIAO Yu-bo. Real-time evaluation of soil slope stability based on the information of displacement monitor [J]. , 2012, (06): 1487-1490. |

| [9] | GAO Sheng-yuan,WANG Tong-hui,LE Qi-chi,ZHANG Zhi-qiang,JIA Zheng,CUI Jian-zhong. Refinement effect of MgCO3 in AZ31 magnesium alloy [J]. 吉林大学学报(工学版), 2011, 41(6): 1625-1629. |

| [10] | GUAN Qing-feng,QIU Dong-hua,LI Yan,CHEN Kang-min,AN Chun-xiang,LONG He-sun. The formation behavior of aging precipitates on 17-4PH stainless steel [J]. 吉林大学学报(工学版), 2011, 41(03): 654-658. |

| [11] | Du Zhongze, Huang Junxia, Fu Hanguang, Wang Jingtao, Zhao Xicheng. Microstructure and mechanical property of 65Mn steel after severe plastic deformation [J]. 吉林大学学报(工学版), 2006, 36(02): 143-0147. |

| [12] | Song Minxia,Zhao Xihua,Guo Wei,Feng Jicai. Diffusion Bonding of Ti-6Al-4V to ZQSn10-10 with Nickel Interlayer [J]. 吉林大学学报(工学版), 2006, 36(01): 42-0045. |

| [13] | HE Shu, MA Yu-kuan, YANG Jian-bo. Acoustic emission characteristics of various defects in metallic materials [J]. 吉林大学学报(工学版), 2003, (4): 21-25. |

|

||