Journal of Jilin University(Engineering and Technology Edition) ›› 2021, Vol. 51 ›› Issue (1): 386-396.doi: 10.13229/j.cnki.jdxbgxb20190848

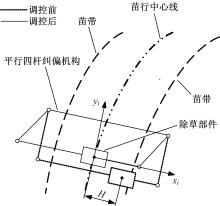

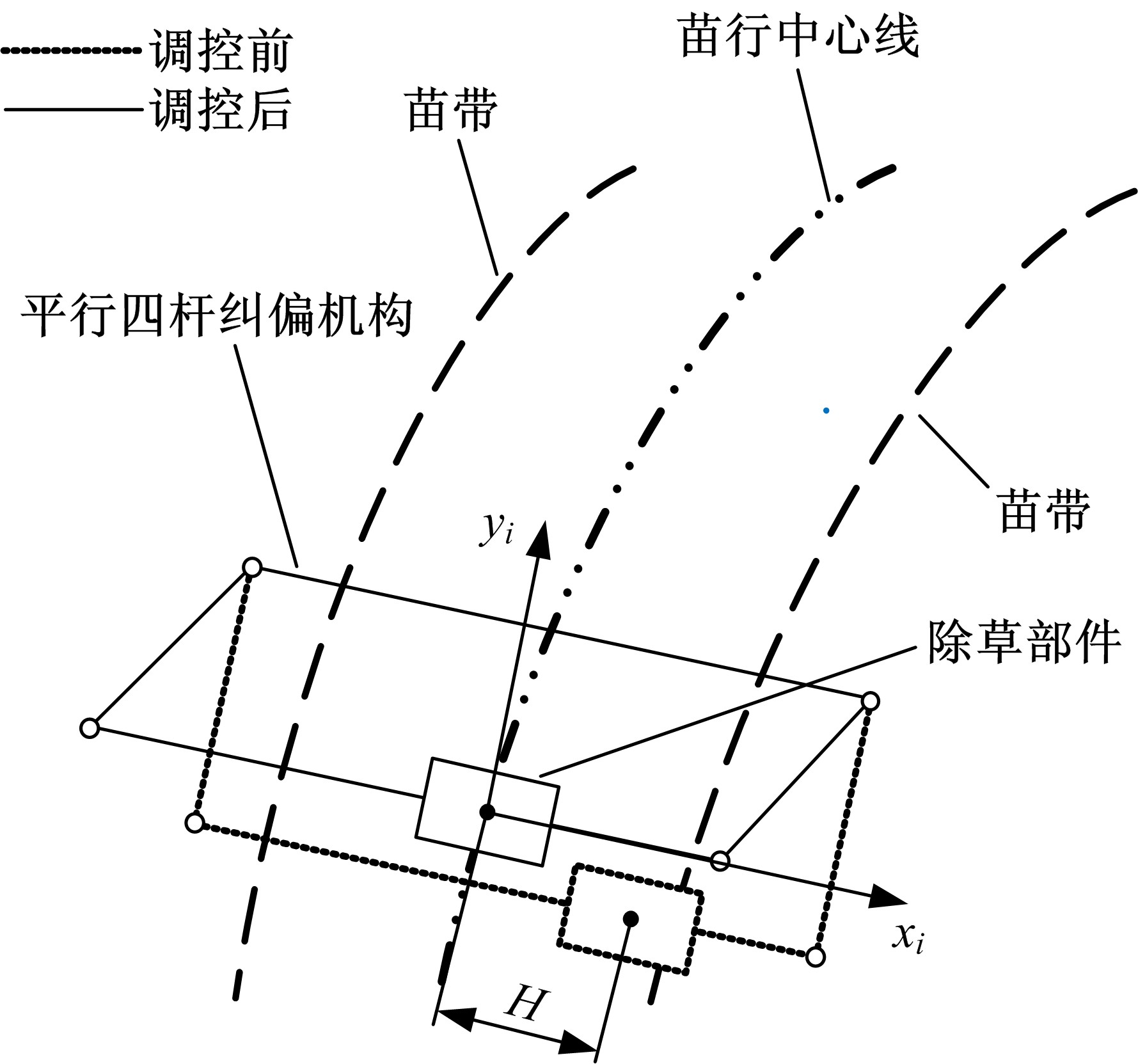

Design and test of control system for rice mechanical weeding and seedling-avoiding control

Xue-shen CHEN( ),Zhu-jian HUANG,Xu MA(

),Zhu-jian HUANG,Xu MA( ),Long QI,Gui-jin FANG

),Long QI,Gui-jin FANG

- College of Engineering,South China Agricultural University,Guangzhou 510642,China

CLC Number:

- S237

| 1 | 徐文蓉, 赵灿, 强胜, 等. 杂草稻灌浆期剑叶的叶绿素荧光特性[J]. 植物生理学报, 2017, 53(9):1742-1752. |

| Xu Wen-rong, Zhao Can, Qiang Sheng, et al. The chlorophyll fluorescence characteristics of flag leaf of weedy rice during grain filling[J]. Plant Physiology Communications, 2017, 53(9): 1742-1752. | |

| 2 | 张家源, 孙卓, 王志涛, 等. 水稻田间机械除草装备与技术现状及发展研究[J]. 内燃机与配件, 2018(15): 256-257. |

| Zhang Jia-yuan, Sun Zhuo, Wang Zhi-tao,et al. Present status and prospects of mechanical weeding equipment and technology in paddy field[J]. Internal Combustion Engine & Parts, 2018(15): 256-257. | |

| 3 | 王哲, 戎俊, 卢宝荣. 杂草稻的发生、危害与我国水稻生产面临的挑战[J]. 杂草科学, 2015, 33(1): 1-9. |

| Wang Zhe, Rong Jun, Lu Bao-rong. Occurrence and damage of weedy rice and its threats to rice production in China[J]. Weed Science, 2015, 33(1): 1-9. | |

| 4 | 马钢, 侯宪东, 张阳阳. 农田生态系统杂草生态控制策略研究[J]. 安徽农业科学, 2018, 46(17): 37-40, 43. |

| Ma Gang, Hou Xian-dong, Zhang Yang-yang. Ecological control strategy research of farmland ecosystem weeds[J]. Journal of Anhui Agricultural Sciences,2018,46(17):37-40, 43. | |

| 5 | 齐月, 李俊生, 闫冰, 等. 化学除草剂对农田生态系统野生植物多样性的影响[J]. 生物多样性, 2016, 24(2): 228-236. |

| Qi Yue, Li Jun-sheng, Yan Bing, et al. Impact of herbicides on wild plant diversity in agro-ecosystems[J]. Biodiversity Science,2016, 24(2): 228-236. | |

| 6 | 王金峰, 王金武, 闫东伟, 等. 3SCJ-2型水田行间除草机设计与试验[J]. 农业机械学报, 2017, 48(6): 71-78, 202. |

| Wang Jin-feng,Wang Jin-wu,Yan Dong-wei, et al. Design and experiment of 3SCJ-2 type row weeding machine for paddy field[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(6): 71-78, 202. | |

| 7 | 金凤. 化学除草剂对环境的污染及防治对策[J]. 绿色科技, 2018(8): 139-140. |

| Jin Feng. Chemical Herbicide of pesticides on envi ronment and countermeasures for prevention and control[J]. Journal of Green Science and Technology, 2018(8): 139-140. | |

| 8 | 李杨, 马智宏, 李冰茹, 等. 我国主要作物中除草剂登记情况及存在问题[J]. 食品安全质量检测学报, 2018, 9(17): 4483-4488. |

| Li Yang, Ma Zhi-hong, Li Bing-ru, et al. Registration status and existing problems of herbicides in the major crops in China[J]. Journal of Food Safety & Quality, 2018, 9(17): 4483-4488. | |

| 9 | 娄帅帅, 曹成茂, 丁冉, 等. 自走式前胡除草机的设计与试验[J]. 农机化研究, 2017, 39(9): 91-97, 106. |

| Lou Shuai-shuai, Cao Cheng-mao, Ding Ran, et al. Design and experiment on self-propelled peucedanum weeder [J]. Journal of Agricultural Mechanization Research, 2017, 39(9): 91-97, 106. | |

| 10 | 陶桂香, 王金武, 周文琪, 等. 水田株间除草机械除草机理研究与关键部件设计[J]. 农业机械学报, 2015, 46(11): 57-63. |

| Tao Gui-xiang, Wang Jin-wu, Zhou Wen-qi, et al. Herbicidal mechanism and key components design for paddy weeding device[J]. Transactions of the Chinese Society for Agricultural Machinery, 2015, 46(11): 57-63. | |

| 11 | 齐龙, 梁仲维, 蒋郁, 等. 轻型水田除草机的设计及试验[J]. 吉林大学学报:工学版, 2016, 46(3): 1004-1012. |

| Qi Long, Liang Zhong-wei, Jiang Yu, et al. Design and field test of lightweight paddy weeder[J]. Journal of Jilin University(Engineering and Technology Edition), 2016, 46(3): 1004-1012. | |

| 12 | 齐龙, 赵柳霖, 马旭, 等. 3GY-1920型宽幅水田中耕除草机的设计与试验[J]. 农业工程学报, 2017, 33(8): 47-55. |

| Qi Long, Zhao Liu-lin,Ma Xu, et al. Design and test of 3GY-1920 wide-swath type weeding-cultivating machine for paddy[J]. Transactions of the Chinese Society of Agricultural Engineering, 2017, 33(8): 47-55. | |

| 13 | 张勤, 黄小刚, 李彬, 等. 基于彩色模型和近邻法聚类的水田秧苗列中心线检测方法[J]. 农业工程学报, 2012, 28(17): 163-171, 295-296. |

| Zhang Qin, Huang Xiao-gang, Li Bin, et al. Detection of rice seedlings rows' centerlines based on color model and nearest neighbor clustering algorithm[J]. Transactions of the Chinese Society of Agricultural Engineering, 2012, 28(17): 163-171, 295-296. | |

| 14 | Choi K H, Han S K, Han S H, et al. Morphology-based guidance line extraction for an autonomous weeding robot in paddy fields[J]. Computers and Electronics in Agriculture, 2015, 113: 266-274. |

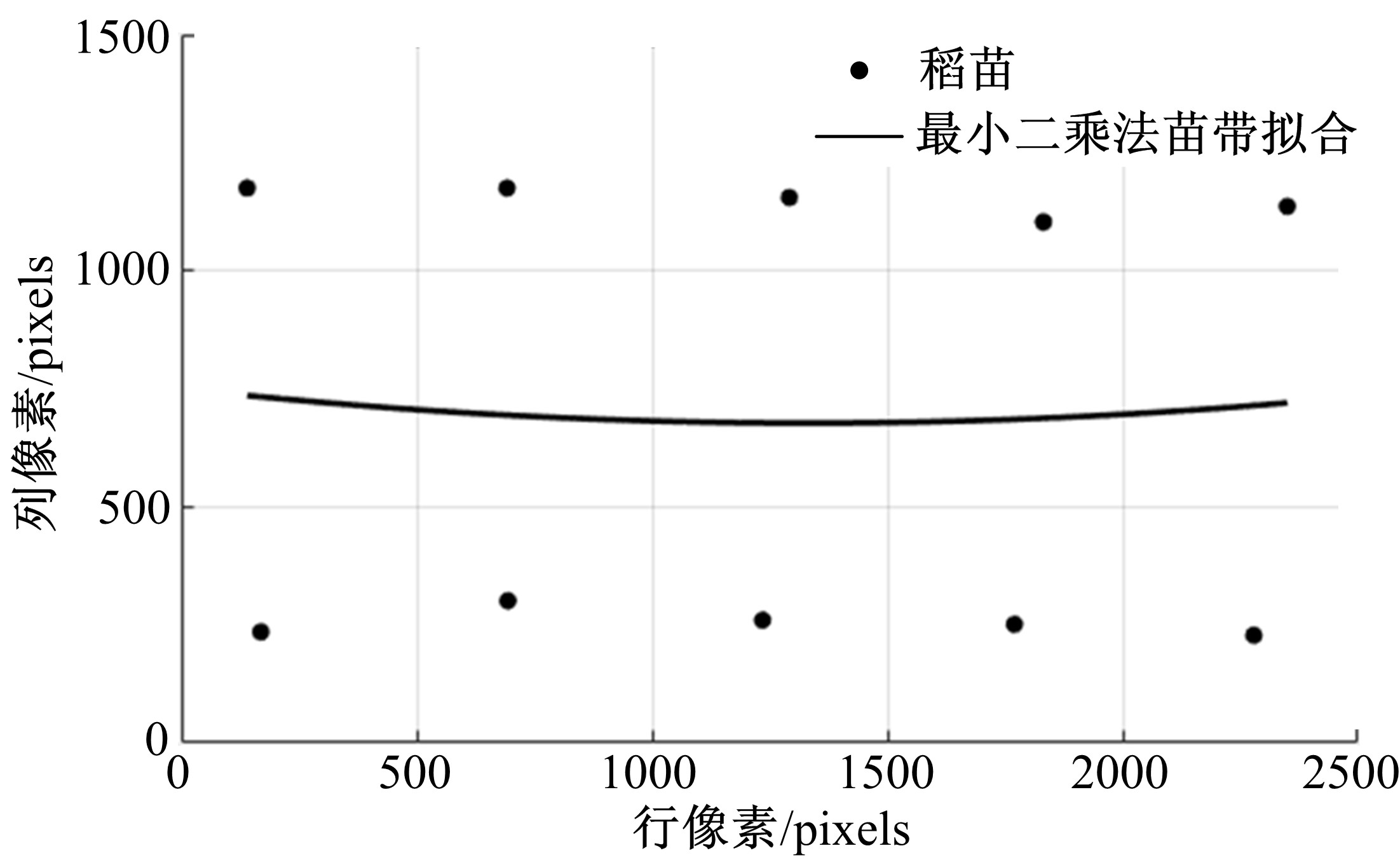

| 15 | 蒋郁, 崔宏伟, 区颖刚, 等. 基于茎基部分区边缘拟合的稻株定位方法研究[J]. 农业机械学报, 2017, 48(6): 23-31, 49. |

| Jiang Yu, Cui Hong-wei, Ying-gang Ou, et al. Positioning method of rice seedlings based on edge fitting in separated region of stem base[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(6): 23-31, 49. | |

| 16 | 陈勇, 田磊, 郑加强. 基于直接施药方法的除草机器人[J]. 农业机械学报, 2005, 36(10): 91-93, 129. |

| Chen Yong, Tian Lei, Zheng Jia-qiang. Development of weeding robot based on direct herbicide application method[J]. Transactions of the Chinese Society for Agricultural Machinery, 2005, 36(10): 91-93, 129. | |

| 17 | 郭伟斌, 陈勇, 侯学贵, 等. 除草机器人机械臂的逆向求解与控制[J]. 农业工程学报, 2009, 25(4): 108-112. |

| Guo Wei-bin, Chen Yong, Hou Xue-gui, et al. Inverse kinematics solving and motion control for a weeding robotic arm[J]. Transactions of the Chinese Society of Agricultural Engineering, 2009, 25(4): 108-112. | |

| 18 | Wisserodt E, Grimm J, Kemper M, et al. Gesteuerte Hacke zur Beikrautregulierung innerhalb der Reihe von Pflanzenkulturen. (Controlled hoe for weeding within crop rows)[C]∥Proceedings of the VDI-Tagung Landtechnik, Braunschweig, Germany, 1999: 155-160. |

| 19 | 胡炼, 罗锡文, 严乙桉, 等. 基于爪齿余摆运动的株间机械除草装置研制与试验[J]. 农业工程学报, 2012, 28(14): 10-16. |

| Hu Lian, Luo Xi-wen, Yan Yi-an, et al. Development and experiment of intra-row mechanical weeding device based on trochoid motion of claw tooth[J]. Transactions of the Chinese Society of Agricultural Engineering, 2012, 28(14): 10-16. | |

| 20 | 张春龙, 黄小龙, 耿长兴, 等. 智能锄草机器人系统设计与仿真[J]. 农业机械学报, 2011, 42(7): 196-199, 185. |

| Zhang Chun-long, Huang Xiao-long, Geng Chang-xing, et al. Design and simulation of intelligent weeding robot system[J]. Transactions of the Chinese Society for Agricultural Machinery, 2011, 42(7): 196-199, 185. | |

| 21 | Hague T, Tillett N D. A bandpass filter-based approach to crop row location and tracking[J]. Mechatronics, 2001, 11(1): 1-12. |

| 22 | 齐龙, 廖文强, 马旭, 等. 水田小型除草机器人平台控制系统设计与测试[J]. 吉林大学学报:工学版, 2013, 43(4): 991-996. |

| Qi Long, Liao Wen-qiang, Ma Xu, et al. Design and testing of control system of mini-weeding-robot platform in rice paddy field[J]. Journal of Jilin University (Engineering and Technology Edition), 2013, 43(4): 991-996. | |

| 23 | 吕金庆, 刘志峰, 王鹏榕, 等. 驱动式碎土除草多功能马铃薯中耕机设计与试验[J]. 农业工程学报, 2019, 35(10): 1-8. |

| Jin-qing Lyu, Liu Zhi-feng, Wang Peng-rong, et al. Design and experiment of driving-type crushing-weeding multi-functional potato cultivator[J]. Transactions of the Chinese Society of Agricultural Engineering, 2019, 35(10): 1-8. |

| [1] | Chao CHENG,Jun FU,Xin⁃long TANG,Zhi CHEN,Lu⁃quan REN. Effects of vibration mode on interface adhesion law of rice threshed mixtures [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1228-1235. |

| [2] | WANG Yang, WANG Xiao-mei, CHEN Ze-ren, YU Jian-qun. Modeling method of maize kernels based on discrete element method [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(5): 1537-1547. |

| [3] | WANG Yang, LYU Feng-yan, XU Tian-yue, YU Jian-qun. Shape and size analysis of soybean kernel and modeling [J]. 吉林大学学报(工学版), 2018, 48(2): 507-517. |

| [4] | LI Jun-ye, QIAO Ze-min, YANG Zhao-jun, ZHANG Xin-ming. Influence of abrasive concentration on processing quality of abrasive flow in mesoscopic scale [J]. 吉林大学学报(工学版), 2017, 47(3): 837-843. |

| [5] | QI Long, TAN Zu-ting, MA Xu, CHEN Guo-rui, XIE Jun-feng, KUANG Jian-xia. Optimization and test of operational parameters of pneumatic vibration uniform-seeds device [J]. 吉林大学学报(工学版), 2014, 44(6): 1684-1691. |

| [6] | QI Long, LIAO Wen-qiang, MA Xu, LIN Jian-heng, OU Zhi-xing, ZHAN Zhi-xun. Design and testing of control system of mini-weeding-robot platform in rice paddy field [J]. 吉林大学学报(工学版), 2013, 43(04): 991-996. |

| [7] | WANG Li-min, XIAO Zhi-gang, LIU Yu-xin, LI Jie, SUN Xu, SHEN Xun-ye, LI Jia-dong. Optimization of extrusion process parameters of nutritious rice rich in chestnut by response surface method [J]. 吉林大学学报(工学版), 2013, 43(02): 550-556. |

| [8] | YAO Liang, CHU Liang, ZHOU Fei-kun, LIU Ming-hui, ZHANG Yong-sheng, WEI Wen-ruo. Simulation and analysis of potential of energy-saving from braking energy recovery of electric vehicle [J]. 吉林大学学报(工学版), 2013, 43(01): 6-11. |

| [9] | WANG Deng-feng, JI Feng, CHEN Shu-ming, SU Li-li, HAO He. Simulation analysis and experiment of pneumatic ABS performance for multi-axles heavy-duty truck [J]. 吉林大学学报(工学版), 2012, 42(增刊1): 7-12. |

| [10] | CHEN Jin-shi, YUAN Wan-rong, YUAN Hua-shan, LIU Xin-hui, WANG Zhan. Self-level system of skid-steer loader based on AMESim [J]. , 2012, (06): 1390-1395. |

| [11] | LI Qing-hua, YUAN Zhi, WANG Chang-hong, WEN Fan. On the robust H∞ control of discrete networked control systems [J]. 吉林大学学报(工学版), 2011, 41(05): 1426-1432. |

| [12] | LIU Ying-ting, LIU Xin, LI Zan, ZHANG Hai-lin. Collusion-resistant dynamic spectrum resource renting and offering mechanism [J]. 吉林大学学报(工学版), 2011, 41(05): 1497-1502. |

| [13] | LIU Jie, HE Shi-wei, SONG Rui. Optimization of railway transit ticket price based on maximization of social-economic benefit [J]. 吉林大学学报(工学版), 2011, 41(05): 1268-1272. |

| [14] | HAN Bao,WU Wen-fu,QUAN Long-zhe. Multi-objective optimization design and simulation on horizontal disk type weeding unit between seedlings [J]. 吉林大学学报(工学版), 2011, 41(03): 692-696. |

| [15] | SHI Feng,LUO Duan-gao,WANG Ying-zi,TAN Gui-jun. Optimization of operating frequency and ticket price of intercity bus with elastic demand [J]. 吉林大学学报(工学版), 2009, 39(06): 1475-1479. |

|

||