Journal of Jilin University(Engineering and Technology Edition) ›› 2019, Vol. 49 ›› Issue (3): 865-871.doi: 10.13229/j.cnki.jdxbgxb20180309

Previous Articles Next Articles

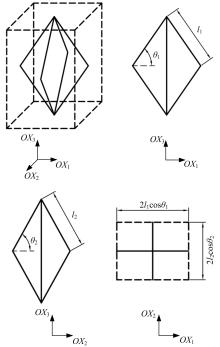

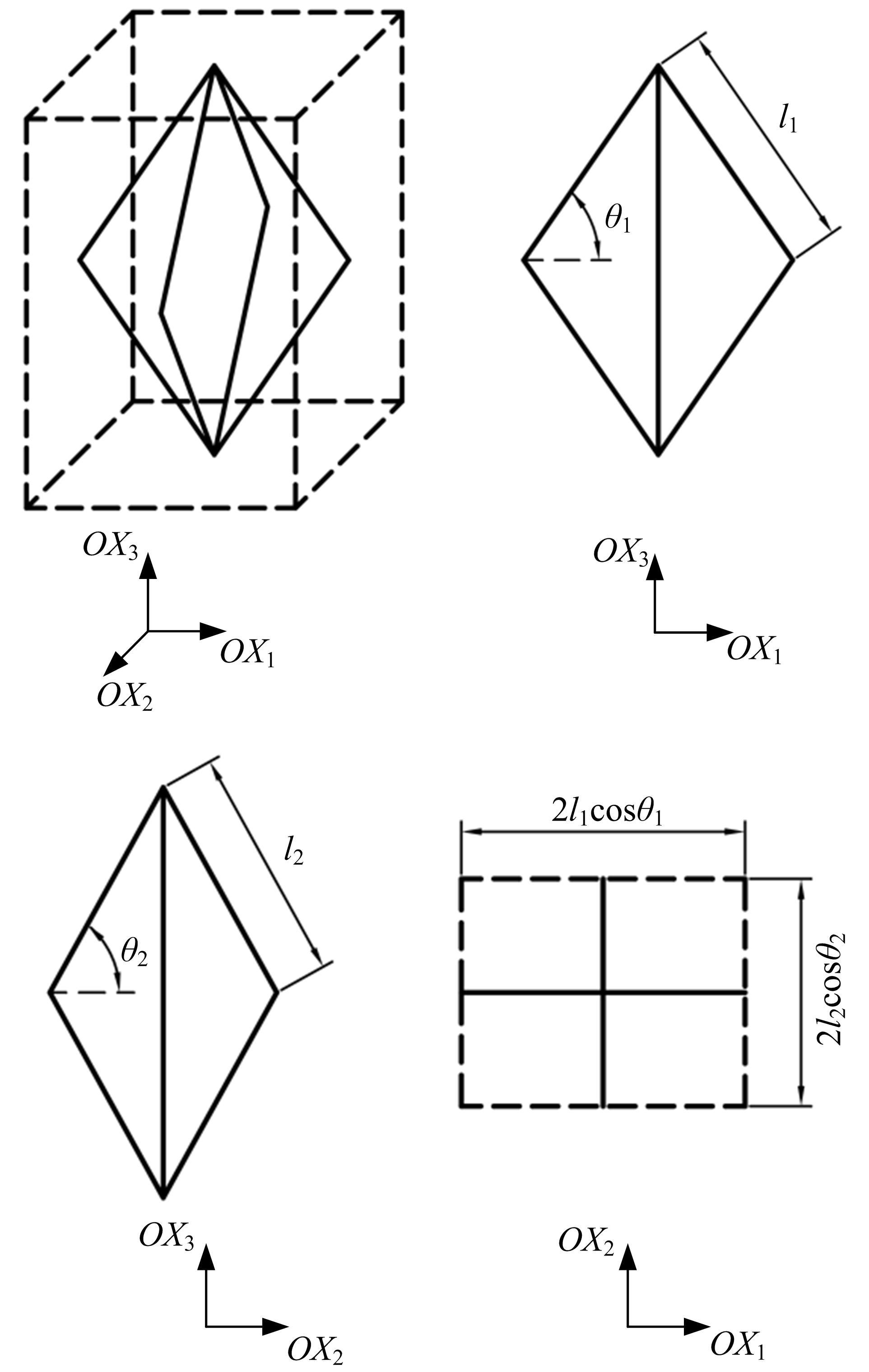

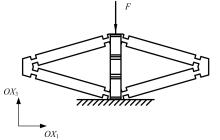

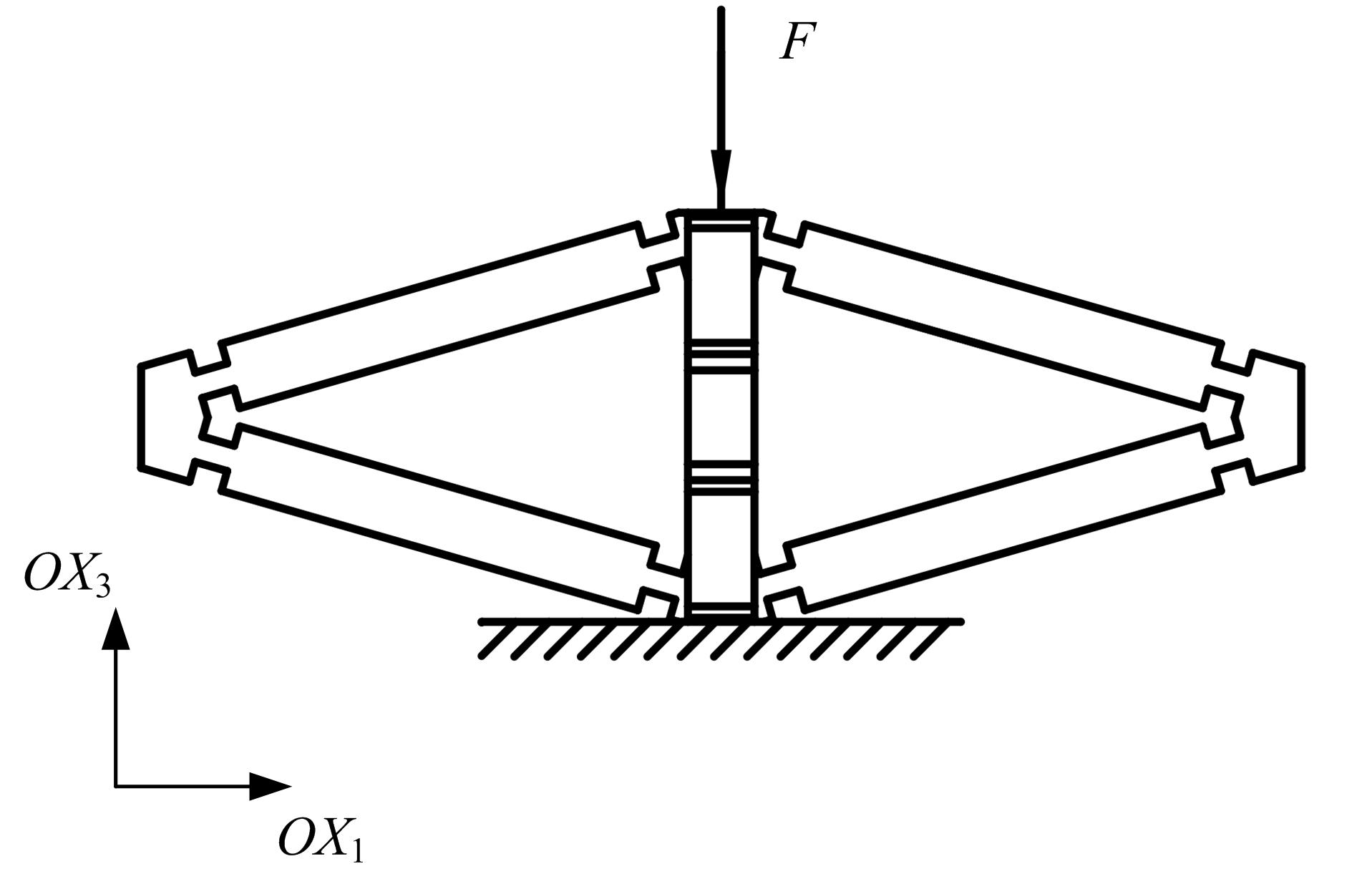

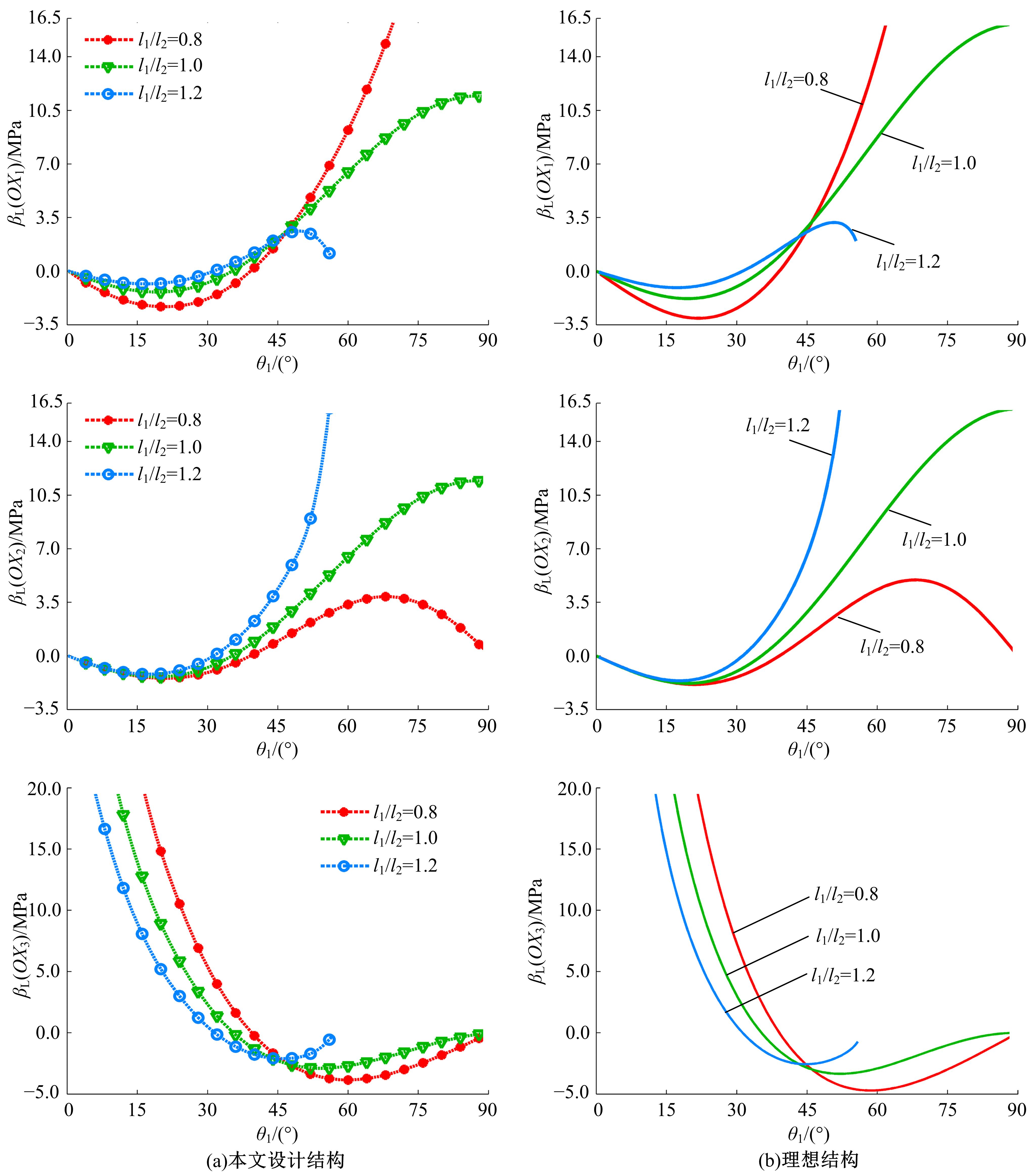

Finite element analysis of hinging octahedron structure withnegative compressibility

Xiao⁃qin ZHOU1( ),Lu YANG1,Lei ZHANG1,Li⁃jun CHEN2(

),Lu YANG1,Lei ZHANG1,Li⁃jun CHEN2( )

)

- 1. College of Mechanical Science and Aerospace Engineering, Jinlin University, Changchun 130022, China

2. Big Data and Network Management Center, Jilin University, Changchun 130022, China

CLC Number:

- O342

| 1 | MorosinB, SchirberJ E. Linear compressibilities and the pressure dependence of the atomic positional parameter of As[J]. Solid State Communications, 1972, 10(3): 249⁃251. |

| 2 | SkeltonE F, FeldmanJ L, LiuC Y, et al. Study of the pressure⁃induced phase transition in paratellurite (TeO2)[J]. Physical Review B, 1976, 13(6): 2605⁃2613. |

| 3 | MariathasanJ W E, FingerL W, HazenR M. High⁃pressure behavior of LaNbO4[J]. Acta Crystallographica Section B: Structural Science, 1985, 41(3): 179⁃184. |

| 4 | FortesA D, SuardE, KnightK S. Negative linear compressibility and massive anisotropic thermal expansion in methanol monohydrate[J]. Science, 2011, 331(6018): 742⁃746. |

| 5 | BaughmanR H, StafstromS, CuiC, et al. Materials with negative compressibility in one or more dimensions[J]. Science, 1998, 279(5356): 1522⁃1524. |

| 6 | GrimaJ N, AttardD, Caruana⁃GauciR, et al. Negative linear compressibility of hexagonal honeycombs and related systems[J]. Scripta Materialia, 2011, 65(7): 565⁃568. |

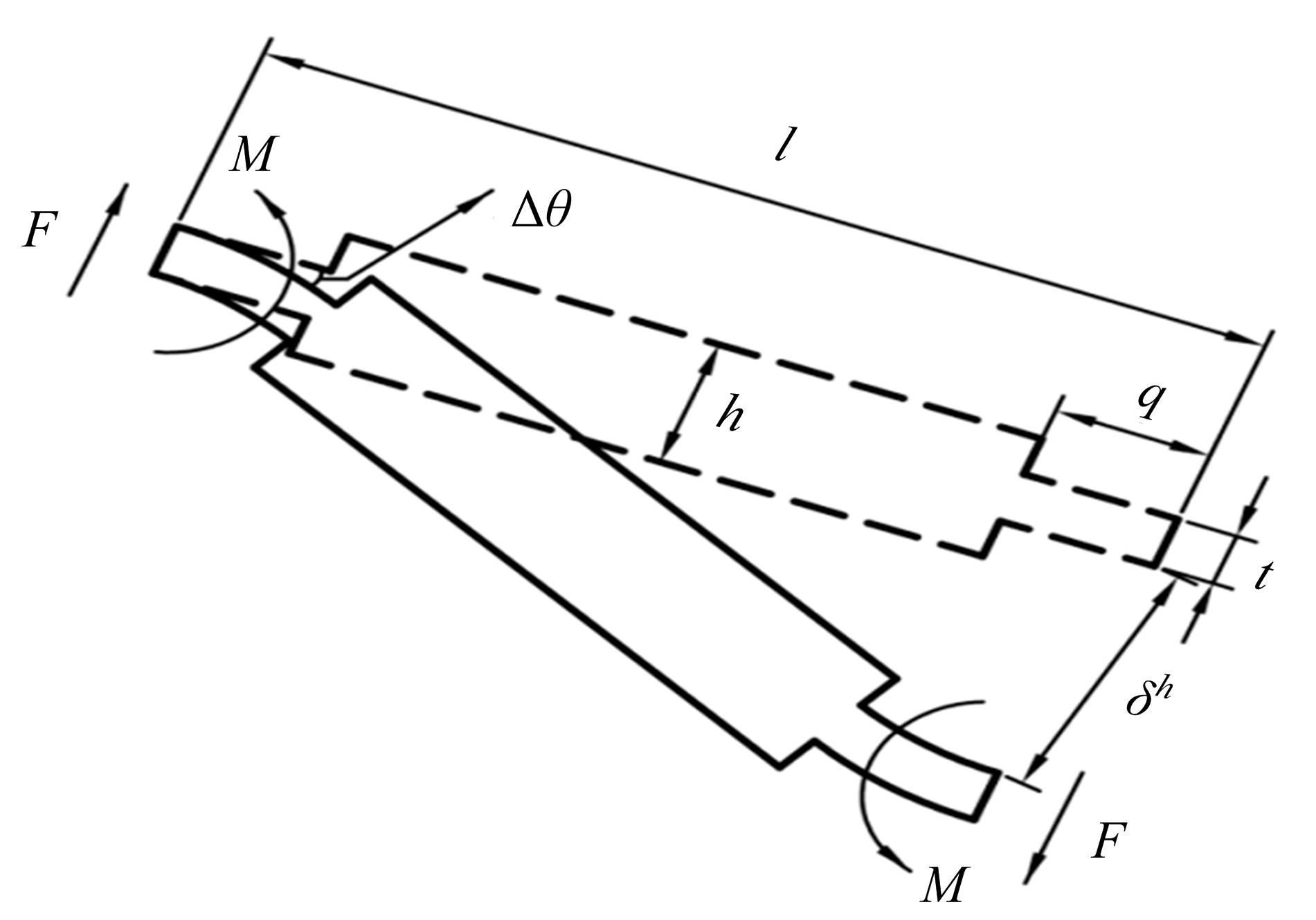

| 7 | BarnesD L, MillerW, EvansK E, et al. Modelling negative linear compressibility in tetragonal beam structures[J]. Mechanics of Materialia, 2012, 46: 123⁃128. |

| 8 | GrimaJ N, Caruana⁃GauciR, WojciechowskiK W, et al. Smart hexagonal truss systems exhibiting negative compressibility through constrained angle stretching[J]. Smart Materials and Structures, 2013, 22(8): 84015. |

| 9 | GrimaJ N, AttardD, GattR. Truss⁃type systems exhibiting negative compressibility[J]. Physical Status Solidi, 2008, 245(11): 2405⁃2414. |

| 10 | ChoiJ B, LakesR S. Analysis of elastic modulus of conventional foams and of re⁃entrant foam materials with a negative Poisson's ratio[J]. International Journal of Mechanical Science, 1995, 37(1): 51⁃59. |

| 11 | ChoiJ B, LakesR S. Nonlinear analysis of the Poisson's ratio of negative Poisson's ratio foams[J]. Journal of Composite Materials, 1995, 29(1): 113⁃128. |

| 12 | LuZ X, LiuQ, YangZ Y. Predictions of Young's modulus and negative Poisson's atio of auxetic foams[J]. Physica Status Solidi B, 2011, 248: 167⁃174. |

| 13 | LiK, GaoX L, RoyA K. Micromechanics model for three⁃dimensional open⁃cell foams using a tetrakaidecahedral unit cell and Castigliano's second theorem[J]. Composites Science and Technology, 2003, 63(12): 1769⁃1781. |

| 14 | GrimaJ N, Caruana⁃GauciR, AttardD,et al. Three⁃dimensional cellular structures with negative Poisson's ratio and negative compressibility properties[J]. Proceedings of the Royal Society A: Mathematical Physical and Engineering Sciences, 2012, 468(2146): 3121⁃3138. |

| 15 | XieY M, YangX Y, ShenJ H et. al. Designing orthotropic materials for negative or zero compressibility[J]. International Journal of Solids and Structures, 2014, 51(23/24): 4038⁃4051. |

| 16 | ZhouX Q, ZhangL, ZhangH, et al. 3D cellular models with negative compressibility through the wine⁃rack⁃type mechanism: 3D cellular models with negative compressibility[J]. Physica Status Solidi, 2016, 253(10): 1977⁃1993. |

| 17 | MastersI G, EvansK E. Models for the elastic deformation of honeycombs[J]. Composite Structures, 1996, 35: 403⁃422. |

| [1] | BI Qiu-shi,WANG Guo-qiang,HUANG Ting-ting,MAO Rui,LU Yan-peng. Tooth strength analysis of mineral sizer by coupling discrete element method and finite element method [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(6): 1770-1776. |

| [2] | WANG Jing-yu, YU Xu-tao, HU Xing-jun, GUO Peng, XIN Li, GUO Feng, ZHANG Yang-hui. Fluid-induced vibration and flow mechanism of automotive external rearview mirror [J]. 吉林大学学报(工学版), 2017, 47(6): 1669-1676. |

| [3] | SUN Rong-jun, GU Shuan-cheng, JU Pei, GAO Ke. Optimal design of new arc angle PDC drill bit for coal mining based on finite element method [J]. 吉林大学学报(工学版), 2017, 47(6): 1991-1998. |

| [4] | ZHANG Yun-long, LIU Zhan-ying, WU Chun-li, WANG Jing. Static and dynamic responses of steel-concrete composite beams [J]. 吉林大学学报(工学版), 2017, 47(3): 789-795. |

| [5] | LIU Yu, LI Peng-fei, ZHANG Yi-min. Analysis and prediction of micro milling deformation of copper thin-wall parts [J]. 吉林大学学报(工学版), 2017, 47(3): 844-849. |

| [6] | LIU Cheng, SHI Wen-ku, CHEN Zhi-yong, HE Wei, RONG Ru-song, SONG Huai-lan. Experiment on tooth root bending stress of driving axle hypoid gear of automobile [J]. 吉林大学学报(工学版), 2017, 47(2): 344-352. |

| [7] | YAN Guang, ZHUANG Wei, LIU Feng, ZHU Lian-qing. Preload package and characteristics of a sensitizing effect sensor based Fiber Bragg Grating (FBG) [J]. 吉林大学学报(工学版), 2016, 46(5): 1739-1745. |

| [8] | ZHUANG Ye, CHEN Yu-hang, YANG Ye-hai, XU Shu-fang. Twin-tube hydraulic shock absorber F-V modeling based on structure parameters [J]. 吉林大学学报(工学版), 2016, 46(3): 732-736. |

| [9] | LIU Han-bing, SHI Cheng-lin, TAN Guo-jin. Finite element solution of composite beam with effect of shear slip [J]. 吉林大学学报(工学版), 2016, 46(3): 792-797. |

| [10] | XIAO Xiang, HUANG En-hou, NI Ying-sheng. Theoretical analysis and experiment of the effect of flange width on beam-plates system of prestressed concrete [J]. 吉林大学学报(工学版), 2015, 45(6): 1784-1790. |

| [11] | MENG Guang-wei,LI Xiao-lin,LI Feng,ZHOU Li-ming,WANG Hui. Smoothed multiscale finite element method for flow in fractured media [J]. 吉林大学学报(工学版), 2015, 45(2): 481-486. |

| [12] | FU Zhi-qiang,AN Zi-jun,DU Feng-shan,DUAN Li-ying,YU Hui,YANG Fan. Elongation of rectangular tube in continuous roll forming [J]. 吉林大学学报(工学版), 2015, 45(2): 487-493. |

| [13] | MA Yao, DONG Xiao-long, LI Ze-jun, SHEN Lin, ZHAO Hong-wei. Finite element simulation of the effect of different initial contact on nano-indentation [J]. 吉林大学学报(工学版), 2014, 44(5): 1366-1370. |

| [14] | MA Biao, ZHAO Jia-xin, LI He-yan, NING Ke-yan, HE Chun-ping. Effect of clutches' structural parameters on thermalelastic instability [J]. 吉林大学学报(工学版), 2014, 44(4): 933-938. |

| [15] | LI Xiao-jun,LIANG Lu-lu,XIE Cheng-wei,YANG Shuo. Auto-generation and application of virtual mechanical simulation model of asphalt concrete [J]. 吉林大学学报(工学版), 2014, 44(3): 655-660. |

|

||