Journal of Jilin University(Engineering and Technology Edition) ›› 2018, Vol. 48 ›› Issue (6): 1770-1776.doi: 10.13229/j.cnki.jdxbgxb20170772

Previous Articles Next Articles

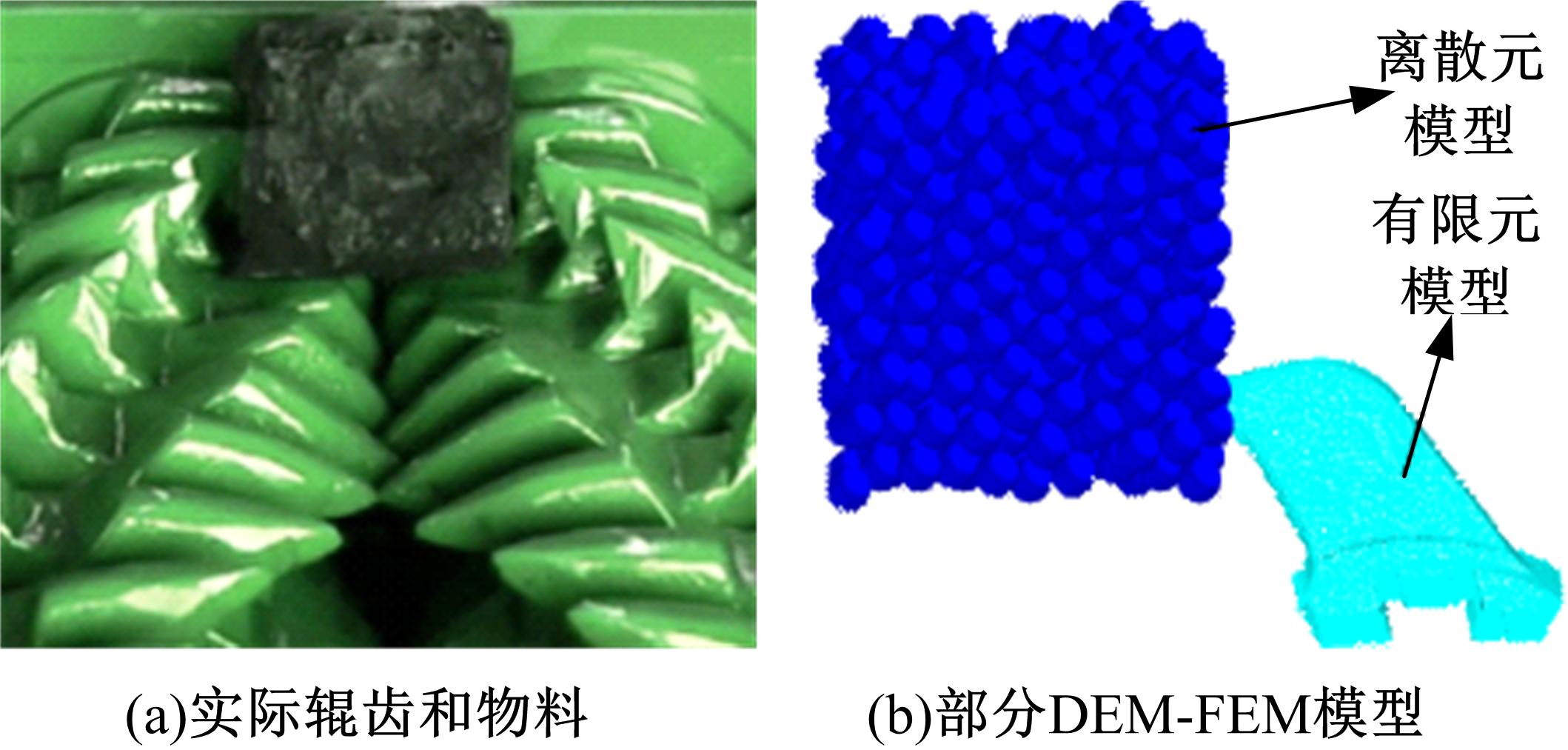

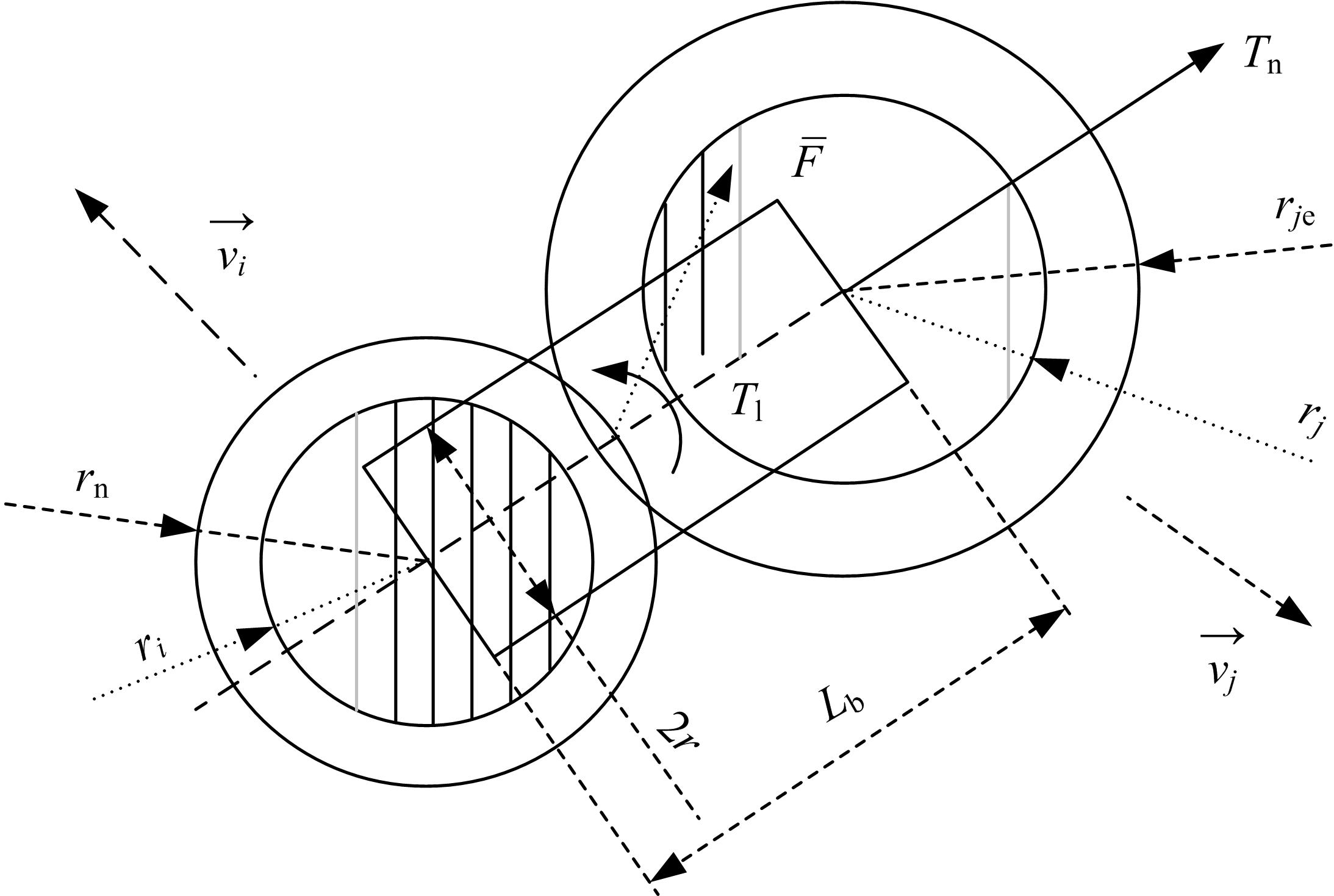

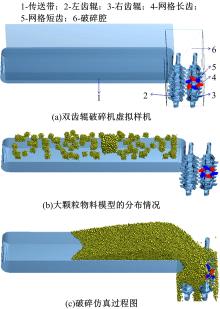

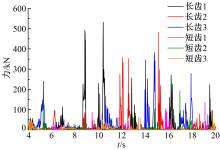

Tooth strength analysis of mineral sizer by coupling discrete element method and finite element method

BI Qiu-shi1( ),WANG Guo-qiang1,HUANG Ting-ting1,MAO Rui2,LU Yan-peng1

),WANG Guo-qiang1,HUANG Ting-ting1,MAO Rui2,LU Yan-peng1

- 1. College of Mechanical Science and Engineering, Jilin University, Changchun 130022,China

2. Technical Center, Taiyuan Heavy Industry Co., Ltd., Taiyuan 030024, China

CLC Number:

- TD451

| [1] |

Legendre D, Zevenhoven R . Assessing the energy efficiency of a jaw crusher[J]. Energy, 2014,74:119-130.

doi: 10.1016/j.energy.2014.04.036 |

| [2] |

Cleary P W, Sinnott M D, Morrison R D , et al. Analysis of cone crusher performance with changes in material properties and operating conditions using DEM[J]. Minerals Engineering, 2017,100:49-70.

doi: 10.1016/j.mineng.2016.10.005 |

| [3] | 贡凯军, 诸文农 . 新型双齿辊破碎机辊齿受力工况及其有限元[J]. 吉林工业大学学报, 1994,24(4):16-20. |

| Gong Kai-jun, Zhu Wen-nong . Study on load case and static analysis of crush teeth for advanced sizing machine and its FEM[J]. Journal of Jilin University of Technology, 1994,24(4):16-20. | |

| [4] | 王国强, 赫万军, 王继新 . 离散单元法及其在EDEM上的实践[M]. 西安: 西北工业大学出版社, 2010. |

| [5] | 杨圣奇 . 裂隙岩石力学特性研究及时间效应分析[M]. 北京: 科学出版社, 2011. |

| [6] | 托鲁基安Y S . 岩石与矿物的物理性质[M]. 北京: 石油工业出版社, 1990. |

| [7] | Brown J N . Discrete element modelling of cementitious materials[D]. Scotland: Institute for Infrastructure and Environment, University of Edinburgh, 2013. |

| [8] |

Tatone B S A, Grasselli G . A calibration procedure for two-dimensional laboratory-scale hybrid finite-discrete element simulations[J]. International Journal of Rock Mechanics & Mining Sciences, 2015,75:56-72.

doi: 10.1016/j.ijrmms.2015.01.011 |

| [9] |

Dai Y, Chen L S, Zhu X . Modelling and simulation of a mining machine excavating seabed massive sulfide deposits[J]. International Journal of Simulation Modelling, 2016,15(2):377-387.

doi: 10.2507/IJSIMM |

| [10] |

Yang B, Jiao Y, Lei S . A study on the effects of microparameters on macroproperties for specimens created by bonded particles[J]. Engineering Computations, 2006,23(6):607-631.

doi: 10.1108/02644400610680333 |

| [11] | 王运敏 . 现代采矿手册[M]. 北京: 冶金工业出版社, 2011. |

| [12] | 刘胜新, 范云华, 苗晋琦 , 等. 新编钢铁材料手册:钢铁材料手册[M]. 北京: 机械工业出版社, 2010. |

| [13] | 刘鸿文 . 材料力学[M]. 5版. 北京: 高等教育出版社, 2011. |

| [1] | Kun LIU,Shuo JI,Zhen⁃yuan SUN,Hong⁃wei XU,Yong LIU,Jing⁃xia ZHAO. Mechanical structure design and optimization of multifunctional auxiliary toilet wheelchair [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(3): 872-880. |

| [2] | Xing⁃ye WANG,Jin⁃qiu ZHANG,Guo⁃qiang LI,Zhi⁃zhao PENG. Influence of inertial mass on rack and pinion actuator′s damping characteristic [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(3): 881-887. |

| [3] | Jia⁃xu WANG,Xiao⁃kang NI,Yan⁃feng HAN,Guo XIANG,Ke XIAO. Numerical model of mixed lubrication for microgroove bearing considering axial reciprocating motion [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(3): 888-896. |

| [4] | ZHU Wei,WANG Chuan-wei,GU Kai-rong,SHEN Hui-ping,XU Ke,WANG Yuan. Stiffness and dynamics analysis of a new type of tensegrity parallel mechanism [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(6): 1777-1786. |

| [5] | LIU Jian-fang, WANG Ji-bo, LIU Guo-jun, LI Xin-bo, LIANG Shi-hai, YANG Zhi-gang. PMMA micromixer embedded with 3D channel based on piezoelectric actuation [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(5): 1500-1507. |

| [6] | SUN Xiu-rong, DONG Shi-min, WANG Hong-bo, LI Wei-cheng, SUN Liang. Comparison of multistage simulation models of entire sucker rod with spatial buckling in tubing [J]. 吉林大学学报(工学版), 2018, 48(4): 1124-1132. |

| [7] | WANG Tao, SAN Xiao-gang, GAO Shi-jie, WANG Hui-xian, WANG Jing, NI Ying-xue. Dynamic characteristics of vertical shaft system of photoelectric turntable [J]. 吉林大学学报(工学版), 2018, 48(4): 1099-1105. |

| [8] | LIU Kun, LIU Yong, YAN Jian-chao, JI Shuo, SUN Zhen-yuan, XU Hong-wei. Dynamic analysis of sit-to-stand human motion based on in vitro-sensor detection [J]. 吉林大学学报(工学版), 2018, 48(4): 1140-1146. |

| [9] | YOSHINO Tatsuo, FAN Lu-lu, YAN Lei, XU Tao, LIN Ye, GUO Gui-kai. Multiobjective optimization design for dummy chest structure based on MBNWS algorithm [J]. 吉林大学学报(工学版), 2018, 48(4): 1133-1139. |

| [10] | HE Ji-lin, CHEN Yi-long, WU Kang, ZHAO Yu-ming, WANG Zhi-jie, CHEN Zhi-wei. Energy flow analysis of crane hoisting system and experiment of potential energy recovery system [J]. 吉林大学学报(工学版), 2018, 48(4): 1106-1113. |

| [11] | XIE Chuan-liu, TANG Fang-ping, SUN Dan-dan, ZHANG Wen-peng, XIA Ye, DUAN Xiao-hui. Model experimental analysis of pressure pulsation in vertical mixed-flow pump system [J]. 吉林大学学报(工学版), 2018, 48(4): 1114-1123. |

| [12] | LIU Zhi-feng, ZHAO Dai-hong, WANG Yu-mo, HUN Lian-ming, ZHAO Yong-sheng, DONG Xiang-min. Relationship between bearing capacity of heavy machine hydrostatic rotary table and temperature field distribution of oil pad [J]. 吉林大学学报(工学版), 2018, 48(3): 773-780. |

| [13] | CAO Jing-hua, KONG Fan-sen, RAN Yan-zhong, SONG Rui-chen. Back pressure controller design of air compressor based on fuzzy self-adaptive PID control [J]. 吉林大学学报(工学版), 2018, 48(3): 781-786. |

| [14] | LI Rui, ZHANG Lu-yang, LIU Lin, WU Yue-yuan, CHEN Shi-wei. Magneto-rheological vibration isolation for three-span bridge based on similarity theory [J]. 吉林大学学报(工学版), 2018, 48(3): 787-795. |

| [15] | CHEN Zhong-min, HOU Li, DUAN Yang, ZHANG Qi, YANG Zhong-xue, JIANG Yi-qiang. Vibration analysis of a new pin-cycloid speed reducer [J]. 吉林大学学报(工学版), 2018, 48(1): 174-185. |

|