Journal of Jilin University(Engineering and Technology Edition) ›› 2020, Vol. 50 ›› Issue (5): 1923-1933.doi: 10.13229/j.cnki.jdxbgxb20190467

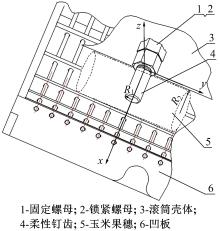

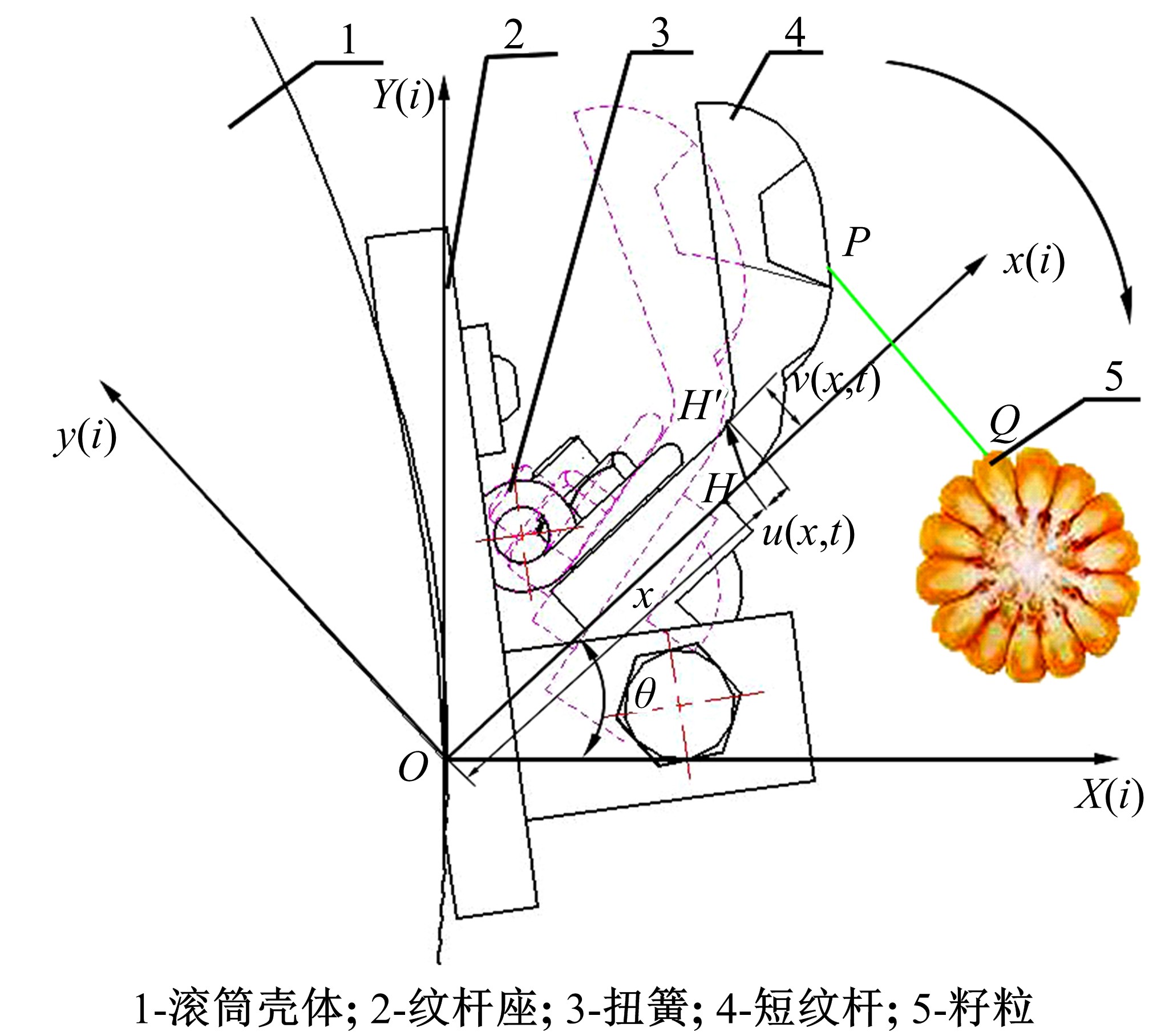

Design and test of corn flexible threshing cylinder element

Duan-yang GENG1( ),De-lei TAN1,Xing-rui YU1,Guo-liang SU1,Qian WANG1,Xiu-feng LU2,Cheng-qian JIN1

),De-lei TAN1,Xing-rui YU1,Guo-liang SU1,Qian WANG1,Xiu-feng LU2,Cheng-qian JIN1

- 1.School of Agricultural Engineering and Food Science, Shandong University of Technology, Zibo 255000, China

2.College of Mechanical and Electrical Engineering, Shandong Career Development College, Jining 272000, China

CLC Number:

- S225.5

| 1 | 中国国家统计局. 中国统计年鉴2018[EB/OL]. [2018-10-24]. |

| 2 | 邸志峰, 崔中凯, 张华, 等. 纹杆块与钉齿组合式轴流玉米脱粒滚筒的设计与试验[J]. 农业工程学报, 2018, 34(1): 28-34. |

| Di Zhi-feng, Cui Zhong-kai, Zhang Hua, et al. Design and experiment of rasp bar and nail tooth combined axial flow corn threshing cylinder[J]. Transactions of the CSAE, 2018, 34(1): 28-34. | |

| 3 | 相茂国. 玉米籽粒直收机械适应性研究[D]. 淄博: 山东理工大学农业工程与食品科学学院, 2014. |

| Xiang Mao-guo. Study on the adaptability of corn grain harvesting device[D]. Zibo: College of Agricultural Engineering and Food Science, Shandong University of Technology, 2014. | |

| 4 | 雷晓鹏. 黄淮海地区玉米机械收获籽粒可行性研究[D]. 保定: 河北农业大学农学院, 2015. |

| Lei Xiao-peng. Studies on the feasibility of maize mechanically harvesting grain in huanghuaihai regions[D]. Baoding: College of Agronomy, Hebei Agricultural University, 2015. | |

| 5 | 赵武云. 组合式螺旋板齿种子玉米脱粒装置研究[D]. 杨凌: 西北农林科技大学机械与电子工程学院, 2012. |

| Zhao Wu-yun. Research on combined type of spiral bar tooth threshing mechanism for seed corn[D]. Yangling: College of Mechanical and Electronic Engineering, Northwest A&F University,2012. | |

| 6 | 徐立章, 李耀明, 王成红, 等. 切纵流双滚筒联合收获机脱粒分离装置[J]. 农业机械学报, 2014, 45(2): 105-108, 135. |

| Xu Li-zhang, Li Yao-ming, Wang Cheng-hong, et al. A combinational threshing and separating unit of combine harvesterwith with a transverse tangential cylinder and an axial rotor[J]. Transactions of the Chinese Society for Agricultural Machinery, 2014, 45(2): 105-108, 135. | |

| 7 | 杨立权, 王万章, 张红梅, 等. 切流-横轴流玉米脱粒系统改进设计及台架试验[J]. 农业工程学报, 2018, 34(1): 35-43. |

| Yang Li-quan, Wang Wan-zhang, Zhang Hong-mei, et al. Improved design and bench test based on tangential flow-transverse axial flow threshing system[J]. Transactions of the Chinese Society of Agricultural Engineering, 2018, 34(1): 35-43. | |

| 8 | Burkhardt T H, Stout B A. Laboratory investigations of corn shelling utilizing high-velocity impact loading[J]. Trans Asae Gen Ed Am Soc Agric Eng, 1974, 17(1): 11-14. |

| 9 | Miu P I, Kutzbach H D. Mathematical model of material kinematics in an axial threshing unit[J]. Computers & Electronics in Agriculture, 2007, 58(2): 93-99. |

| 10 | Miu P I, Kutzbach H D. Modeling and simulation of grain threshing and separation in threshing units—part I[J]. Computers & Electronics in Agriculture, 2008, 60(1): 96-104. |

| 11 | Petkevichius S, Shpokas L, Kutzbach H D. Investigation of the maize ear threshing process[J]. Biosystems Engineering, 2008, 99(4): 532-539. |

| 12 | Srison W, Chuan-Udom S, Saengprachatanarug K. Design factors affecting losses and power consumptionof an axial flow corn shelling unit[J]. Songklanakarin Journal of Science & Technology, 2016, 38(5): 591-598. |

| 13 | 何晓鹏, 蔡学斌, 师建芳,等. 挤搓式玉米脱粒机的研制[J]. 农业工程学报, 2003, 19(2): 105-108. |

| He Xiao-peng, Cai Xue-bin, Shi Jian-fang. Research and design on corn sheller by extruding and rubbing method[J]. Transactions of the Chinese Society of Agricultural Engineering, 2003, 19(2): 105-108. | |

| 14 | 李心平, 李玉柱, 高吭, 等. 种子玉米籽粒仿生脱粒机理分析[J]. 农业机械学报, 2011, 42(2): 99-103. |

| Li Xin-ping, Li Yu-zhu, Gao Hang, et al. Bionic threshing progress analysis ofseed corn kernel[J]. Transactions of the Chinese Society for Agricultural Machinery, 2011, 42(2): 99-103. | |

| 15 | 李心平, 马义东, 金鑫, 等. 玉米种子仿生脱粒机设计与试验[J]. 农业机械学报, 2015, 46(7): 97-101. |

| Li Xin-ping, Ma Yi-dong, Jin Xin, et al. Design and test of corn seed bionic threshing[J]. Transactions of the Chinese Society for Agricultural Machinery, 2015, 46(7): 97-101. | |

| 16 | 李心平, 熊师, 杜哲, 等. 浮动式玉米单穗脱粒装置设计与试验[J]. 农业机械学报, 2017, 48(7): 104-111. |

| Li Xin-ping, Xiong Shi, Du Zhe, et al. Design and experiment on floating corn single panicle threshing device[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(7): 104-111. | |

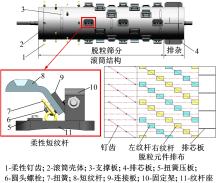

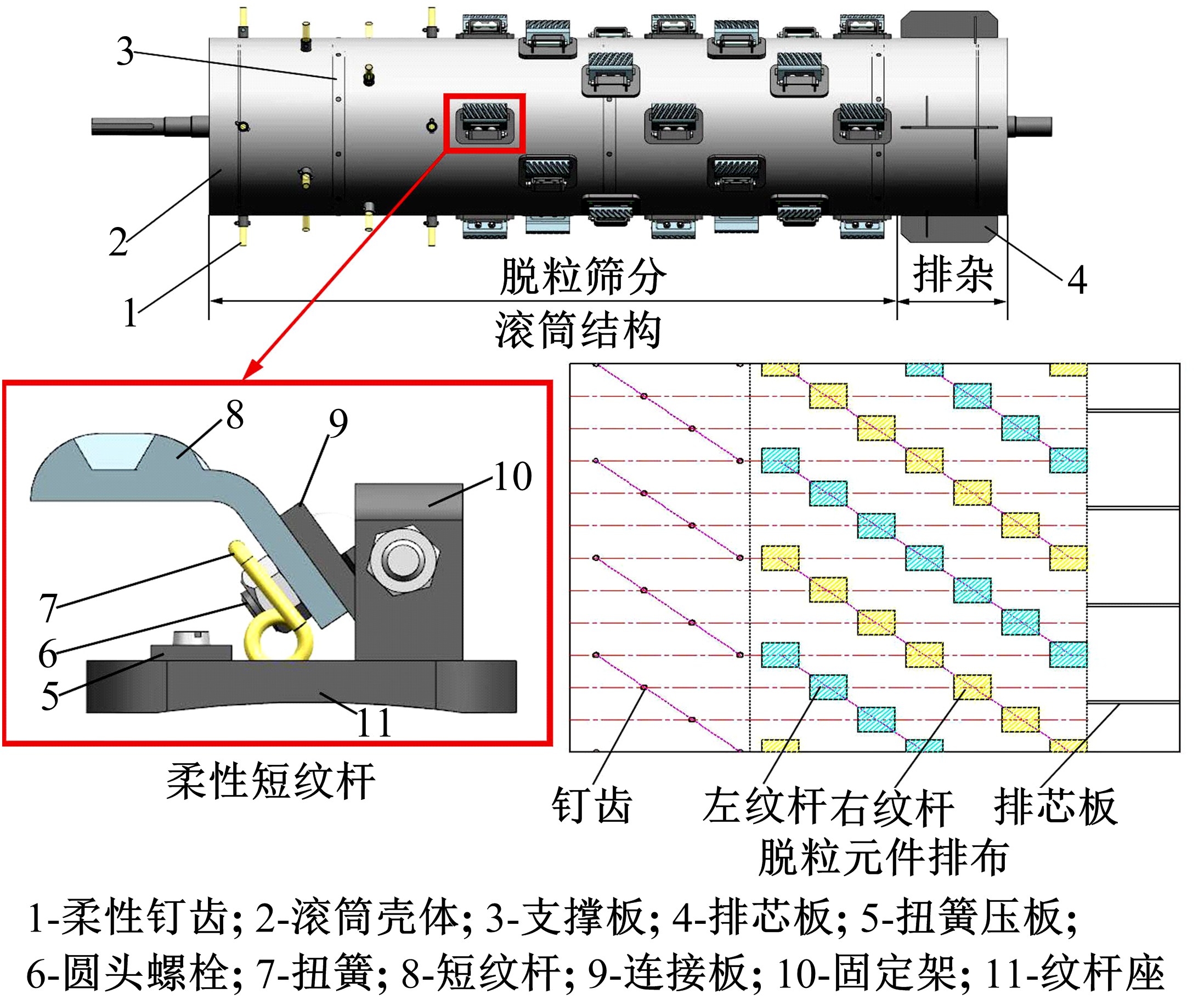

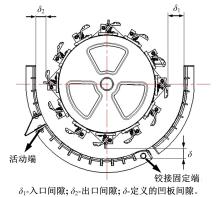

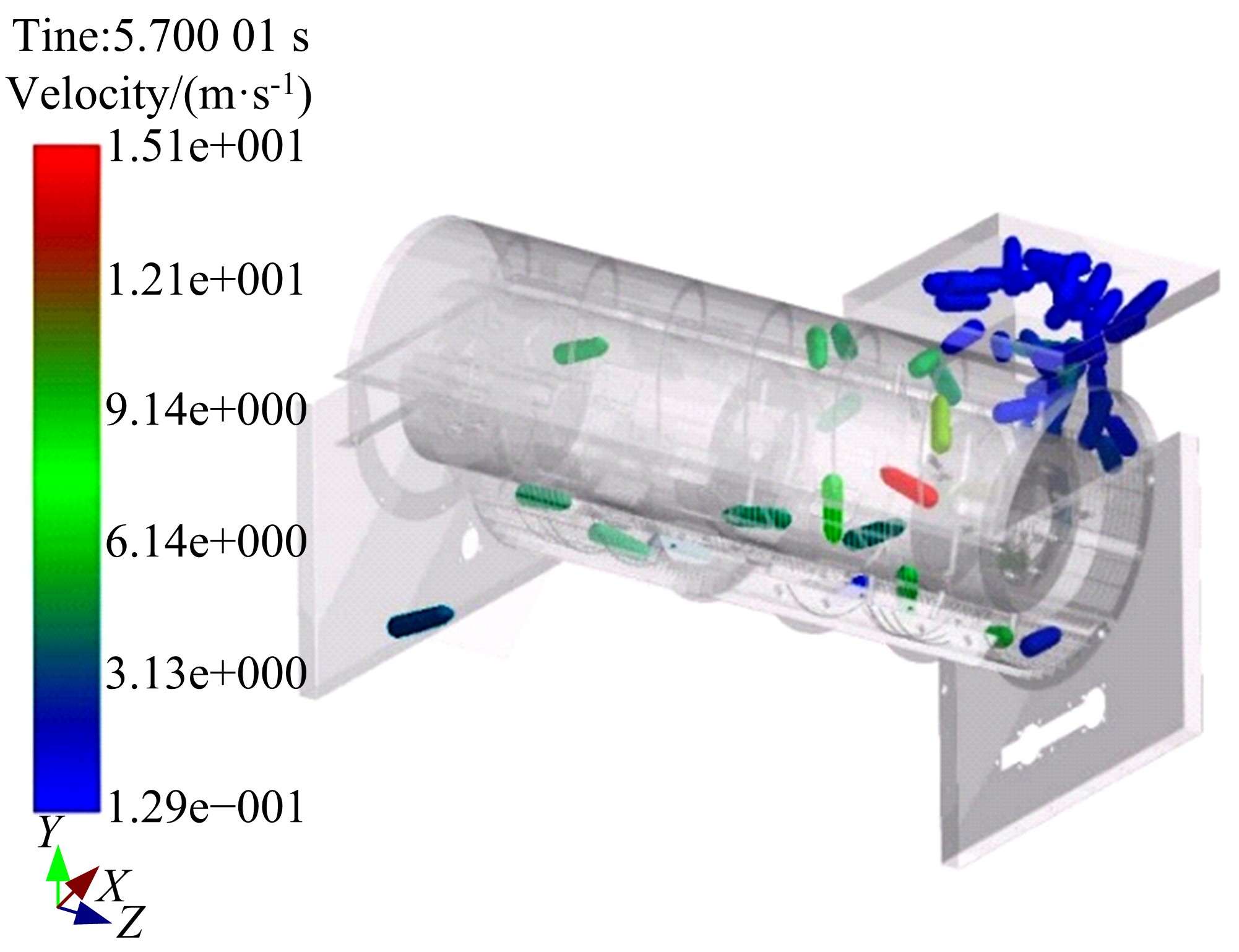

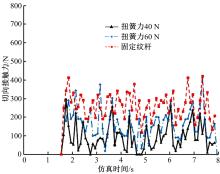

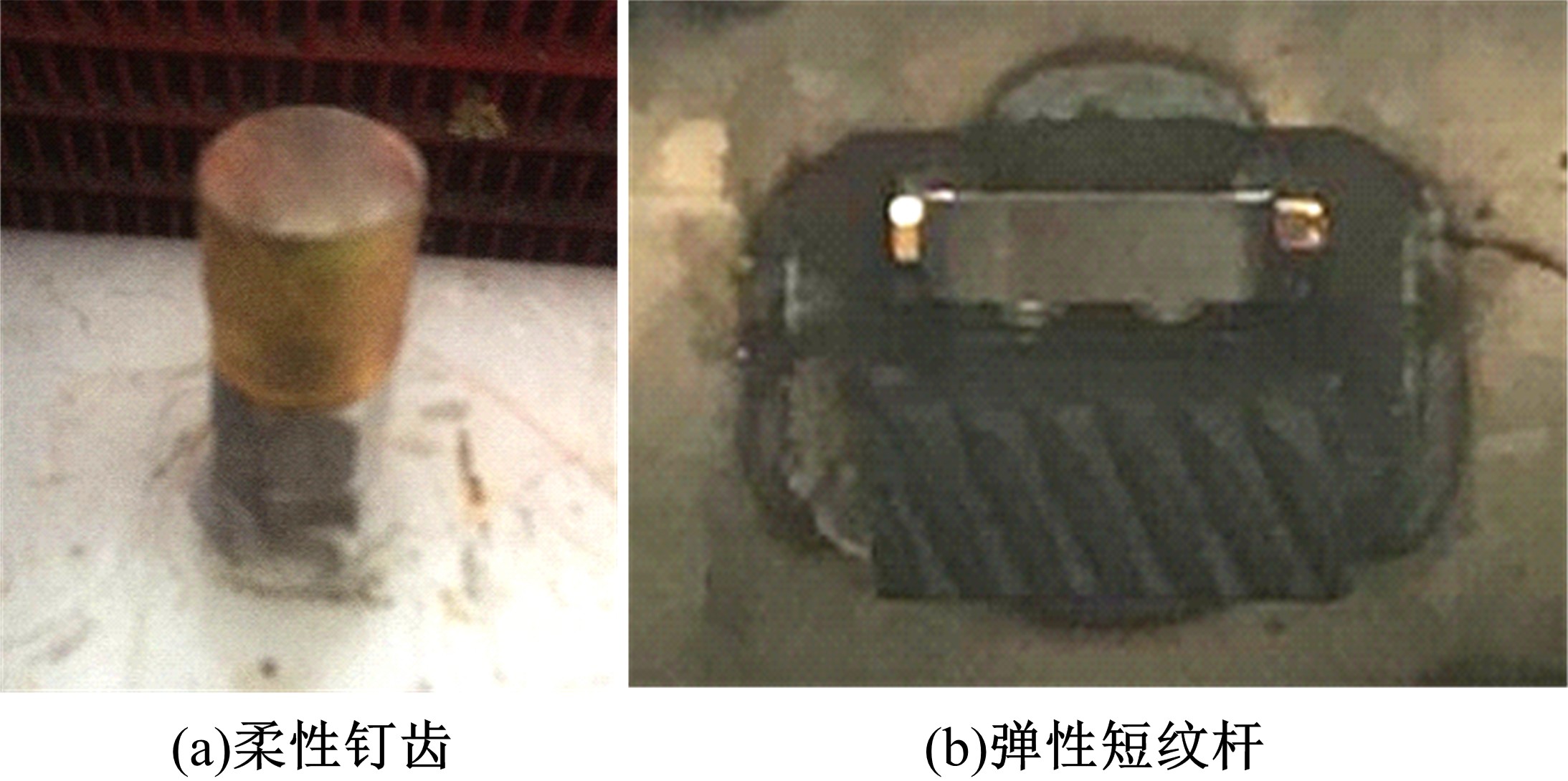

| 17 | 耿端阳, 何珂, 王骞, 等. 横轴流式玉米柔性脱粒装置设计与试验[J]. 农业机械学报, 2019, 50(3): 101-108. |

| Geng Duan-yang, He Ke, Wang Qian, et al. Design and experiment on transverse axial flow flexible threshing device for corn[J]. Transactions of the Chinese Society for Agricultural Machinery, 2019, 50(3): 101-108. | |

| 18 | 屈哲, 张东兴, 杨丽, 等. 纵轴流玉米脱粒分离装置喂入量与滚筒转速试验[J]. 农业机械学报, 2018, 49(2): 58-65. |

| Qu Zhe, Zhang Dong-xing, Yang Li, et al. Experiment on feed rate and cylinder speed of longitudinal axial flow threshing and separating device for maize[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(2): 58-65. | |

| 19 | Qian Z J, Jin C Q, Zhang D G. Multiple frictional impact dynamics of threshing process between flexible tooth and grain kernel[J]. Computers & Electronics in Agriculture, 2017, 141: 276-285. |

| 20 | 蔡超杰, 陈志, 韩增德, 等. 种子玉米生物力学特性与脱粒性能的关系研究[J]. 农机化研究, 2017, 39(4): 192-196. |

| Cai Chao-jie, Chen Zhi, Han Zeng-de, et al. Stduy on relationship of biomechanical characteristics of corn seed and threshing perforcane[J]. Journal of Agricultural Mechanization Research, 2017, 39(4): 192-196. | |

| 21 | 许大兴, 杨健明. 卧式轴流脱粒分离装置研究[J]. 农业机械学报, 1984, 15(3): 57-66. |

| Xu Da-xing, Yang Jian-ming. Study of horizontal axial-flow threshing-separating unit characteristics[J]. Transactions of the Chinese Society for Agricultural Machinery, 1984, 15(3): 57-66. | |

| 22 | 徐立章, 李耀明, 丁林峰. 水稻谷粒与脱粒元件碰撞过程的接触力学分析[J]. 农业工程学报, 2008, 24(6): 146-149. |

| Xu Li-zhang, Li Yao-ming, Ding Lin-feng. Contacting mechanics analysis during impact process between rice and threshing component[J]. Transactions of the Chinese Society of Agricultural Engineering, 2008, 24(6): 146-149. | |

| 23 | 邵志威, 陈智, 侯占峰, 等. BYW-400型冰草种子振动丸粒化包衣机种子丸化运动特性[J]. 农业工程学报, 2018, 34(3): 57-64. |

| Shao Zhi-wei, Chen Zhi, Hou Zhan-feng, et al. Analysis of pelleting movement characteristics of BYW-400 type vibrating seed coating machine for wheatgrass[J]. Transactions of the Chinese Society of Agricultural Engineering, 2018, 34(3): 57-64. | |

| 24 | 丁林峰, 李耀明, 徐立章. 稻谷压缩试验的接触力学分析[J]. 农机化研究, 2007(12): 112-115. |

| Ding Lin-feng, Li Yao-ming, Xu Li-zhang. Research and analysis in the compressing experimentation about corn with contact mechanicals[J]. Journal of Agricultural Mechanization Research, 2007(12): 112-115. | |

| 25 | 段玥晨, 章定国, 洪嘉振. 作大范围运动柔性梁的一种碰撞动力学求解方法[J]. 机械工程学报, 2012, 48(19): 95-102. |

| Duan Yue-chen, Zhang Ding-guo, Hong Jia-zhen. Method for solving the impact problem of a flexible beam with large overall motion[J]. Journal of Mechanical Engineering, 2012, 48(19): 95-102. | |

| 26 | 方建士, 李宝玉, 章定国. 大范围运动柔性梁的连续力法撞击动力学分析[J]. 南京理工大学学报: 自然科学版, 2008, 32(6): 661-665. |

| Fang Jian-shi, Li Bao-yu, Zhang Ding-guo. Continus force approach for impact dynamics of flexible beam in large overall motion[J]. Journal of Nanjing University of Science and Technology(Natural Science), 2008, 32(6): 661-665. | |

| 27 | 刘锦阳, 洪嘉振. 刚-柔耦合动力学系统的建模理论研究[J]. 力学学报, 2002, 34(3): 408-415. |

| Liu Jin-yang, Hong Jia-zhen. Study on dynamic modeling theory of rigid-flexible coupling system[J]. Theoretical and Applied Mechanics, 2002, 34(3): 408-415. | |

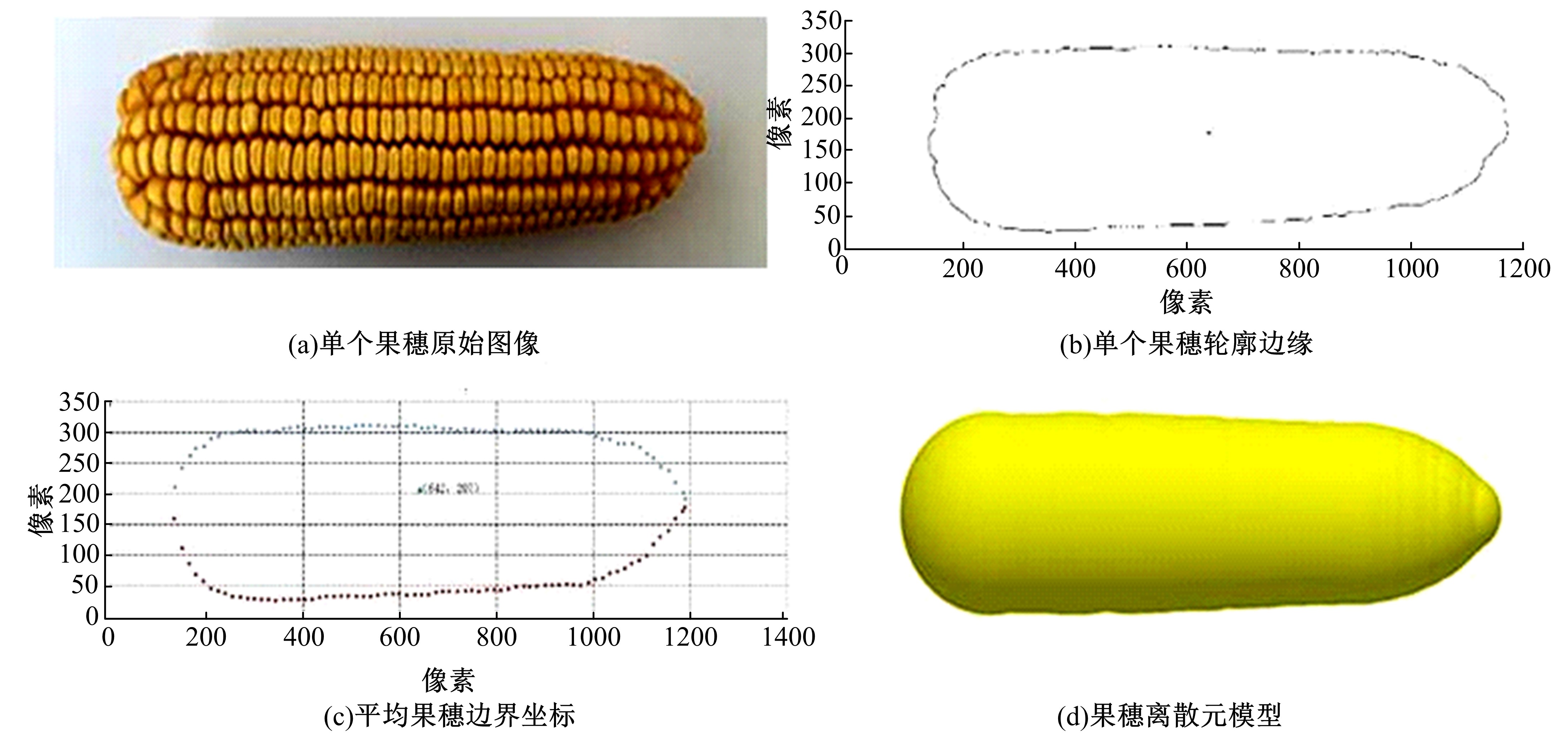

| 28 | 于亚军, 周海玲, 付宏, 等. 基于颗粒聚合体的玉米果穗建模方法[J]. 农业工程学报, 2012, 28(8): 167-174. |

| Yu Ya-jun, Zhou Hai-ling, Fu Hong, et al. Modeling method of corn ears based on particles agglomerate[J]. Transactions of the Chinese Society of Agricultural Engineering, 2012, 28(8): 167-174. | |

| 29 | 于亚军, 于建群, 陈仲, 等. 三维离散元法边界建模软件设计[J]. 农业机械学报, 2011, 42(8): 98-103. |

| Yu Ya-jun, Yu Jian-qun, Chen Zhong, et al. Design of 3-D DEM boundary modeling software[J]. Transactions of the Chinese Society for Agricultural Machinery, 2011, 42(8): 98-103. | |

| 30 | Kovacs A, Kerenyi G. Modeling of corn ears by discrete element method(DEM)[C]∥Conference on Modelling and Simulation, Cambridge, 2017: 355-361. |

| 31 | 刘长青, 陈兵旗. 基于机器视觉的玉米果穗参数的图像测量方法[J]. 农业工程学报, 2014, 30(6): 131-138. |

| Liu Chang-qing, Chen Bing-qi. Method of image detection for ear of corn based on computer vision[J]. Transactions of the Chinese Society of Agricultural Engineering, 2014, 30(6): 131-138. | |

| 32 | 王立军, 彭博, 宋慧强. 玉米收获机聚氨酯橡胶筛筛分性能仿真与试验[J]. 农业机械学报, 2018, 49(7): 90-96. |

| Wang Li-jun, Peng Bo, Song Hui-qiang. Cleaning of maize mixture based on polyurethane rubber sieve[J] Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(7): 90-96. | |

| 33 | 王云霞, 梁志杰, 张东兴, 等. 基于离散元的玉米种子颗粒模型种间接触参数标定[J]. 农业工程学报, 2016, 32(22): 36-42. |

| Wang Yun-xia, Liang Zhi-jie, Zhang Dong-xing, et al. Calibration method of contact characteristic parameters for corn seeds based on EDEM[J]. Transactions of the Chinese Society of Agricultural Engineering, 2016, 32(22): 36-42. | |

| 34 | 付宏, 吕游, 李艳双, 等. 基于离散元法的玉米脱粒过程分析[J]. 吉林大学学报: 工学版, 2012, 42(4): 997-1002. |

| Fu Hong, Lyu You, Li Yan-shuang, et al. Analysis for corn threshing process based DEM[J]. Journal of Jilin University(Engineering and Technology Edition), 2012, 42(4): 997-1002. | |

| 35 | 王扬, 王晓梅, 陈泽仁, 等. 基于离散元法的玉米籽粒建模[J]. 吉林大学学报: 工学版, 2018, 48(5): 1537-1547. |

| Wang Yang, Wang Xiao-mei, Chen Ze-ren, et al. Modeling method of maize kernels based on discrete element method[J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(5): 1537-1547. |

| [1] | Chao CHENG,Jun FU,Fu-ping HAO,Zhi CHEN,De-yi ZHOU,Lu-quan REN. Effect of motion parameters of cleaning screen on corn cob blocking law [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(1): 351-360. |

| [2] | Rui-tao GAO,Jian SHAN,Zhou YANG,Sheng WEN,Yu-bin LAN,Quan-yong ZHANG,Yang WANG. Real⁃time interpretation system of variable spray prescription map based on plant protection UAV [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(1): 361-374. |

| [3] | JIA Hong-lei, WANG Wan-peng, CHEN Zhi, ZHUANG Jian, WANG Wen-jun, LIU Hui-li. Real-time pressure measurement of profiling elastic press roller based on soil cone index [J]. 吉林大学学报(工学版), 2018, 48(4): 1169-1175. |

| [4] | TIAN Yan-tao, ZHANG Yu, WANG Xiao-yu, CHEN Hua. Estimation of side-slip angle of electric vehicle based on square-root unscented Kalman filter algorithm [J]. 吉林大学学报(工学版), 2018, 48(3): 845-852. |

| [5] | CHEN Dong-hui, LIU Wei, LYU Jian-hua, CHANG Zhi-yong, WU Ting, MU Hai-feng. Bionic design of corn stubble collector based on surface structure of Patinopecten yessoensis [J]. 吉林大学学报(工学版), 2017, 47(4): 1185-1193. |

| [6] | NA Jing-xin, BAI Shuang, LIU Hai-peng, YAN Ya-kun. Effects of drawbead corner radius and metal flow direction on drawbead restraining force [J]. 吉林大学学报(工学版), 2015, 45(5): 1402-1407. |

| [7] | WANG Jing-yu, WANG Ze-wei, GU Qing-tong, HU Xing-jun, WANG Bao-yu. Numerical simulation of transient aerodynamic characteristics of turning vehicle [J]. 吉林大学学报(工学版), 2015, 45(1): 44-48. |

| [8] | LIU Li-wei, MA Song-quan, MA Li-rong. Design and implementation of stereo measure system based on double digital signal processor [J]. 吉林大学学报(工学版), 2013, 43(增刊1): 335-339. |

| [9] | WANG Tong-jian, CHEN Jin-shi, ZHAO Feng, ZHAO Qing-bo, LIU Xin-hui, YUAN Hua-shan. Mechanical-hydraulic co-simulation and experiment of full hydraulic steering systems [J]. 吉林大学学报(工学版), 2013, 43(03): 607-612. |

| [10] | LIU Jing-jing, SUN Yong-hai, DING Jian-feng, SUN Zhong-lei. Optimization of sensor array for identification of corn juice [J]. 吉林大学学报(工学版), 2013, 43(02): 538-543. |

| [11] | JIANG Wei, LU Zhao-yang, LI Jing, LIU Xiao-pei. Text localization algorithm in complex scene based on corner-type feature and histogram of oriented gradients of edge magnitude statistical feature [J]. 吉林大学学报(工学版), 2013, 43(01): 250-255. |

| [12] | ZHANG Qiang, YU Lu-lu, JIA Hong-lei. Design and experiment of handling mechanism for tractors [J]. 吉林大学学报(工学版), 2012, 42(增刊1): 108-112. |

| [13] | WANG Zeng-hui, HUANG Dong-yan, LI Zhuo-shi, JIA Hong-lei, WAN Bao-cheng. Universal the blade the broken stubble power consumption influence of the working parameters of the rotary tiller broken stubble [J]. 吉林大学学报(工学版), 2012, 42(增刊1): 122-125. |

| [14] | ZHOU De-yi, WANG Zi-jia, ZHANG Dan-dan, WU Guan-jun, ZHOU Han-yu. The new device of stalk cutting within corn narvester [J]. 吉林大学学报(工学版), 2012, 42(增刊1): 113-116. |

| [15] | FU Hong, LV You, LI Yan-shuang, YU Jian-qun. Analysis for corn threshing process based DEM [J]. , 2012, 42(04): 997-1002. |

|

||