Journal of Jilin University(Engineering and Technology Edition) ›› 2021, Vol. 51 ›› Issue (2): 478-485.doi: 10.13229/j.cnki.jdxbgxb20200053

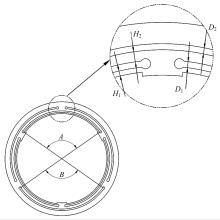

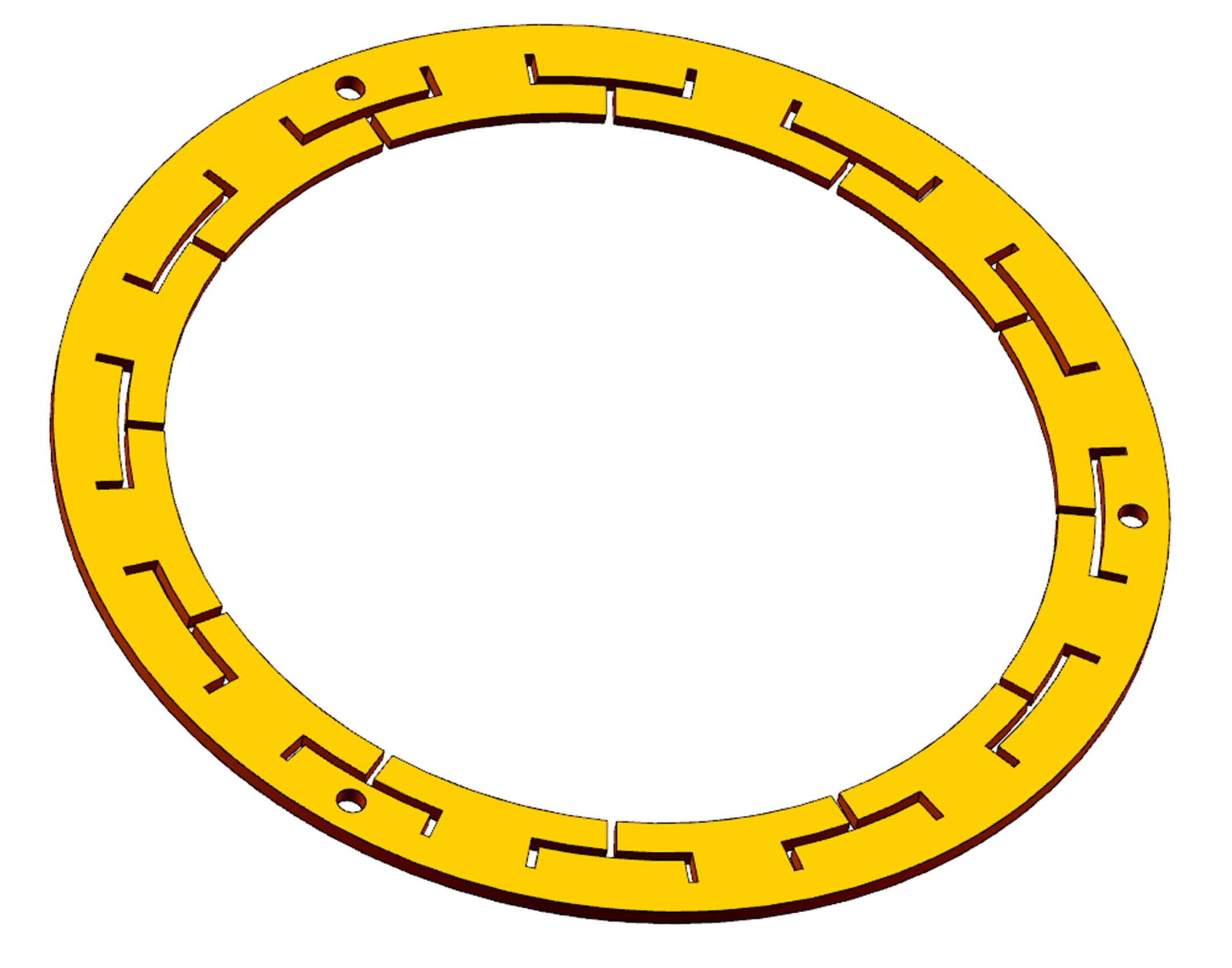

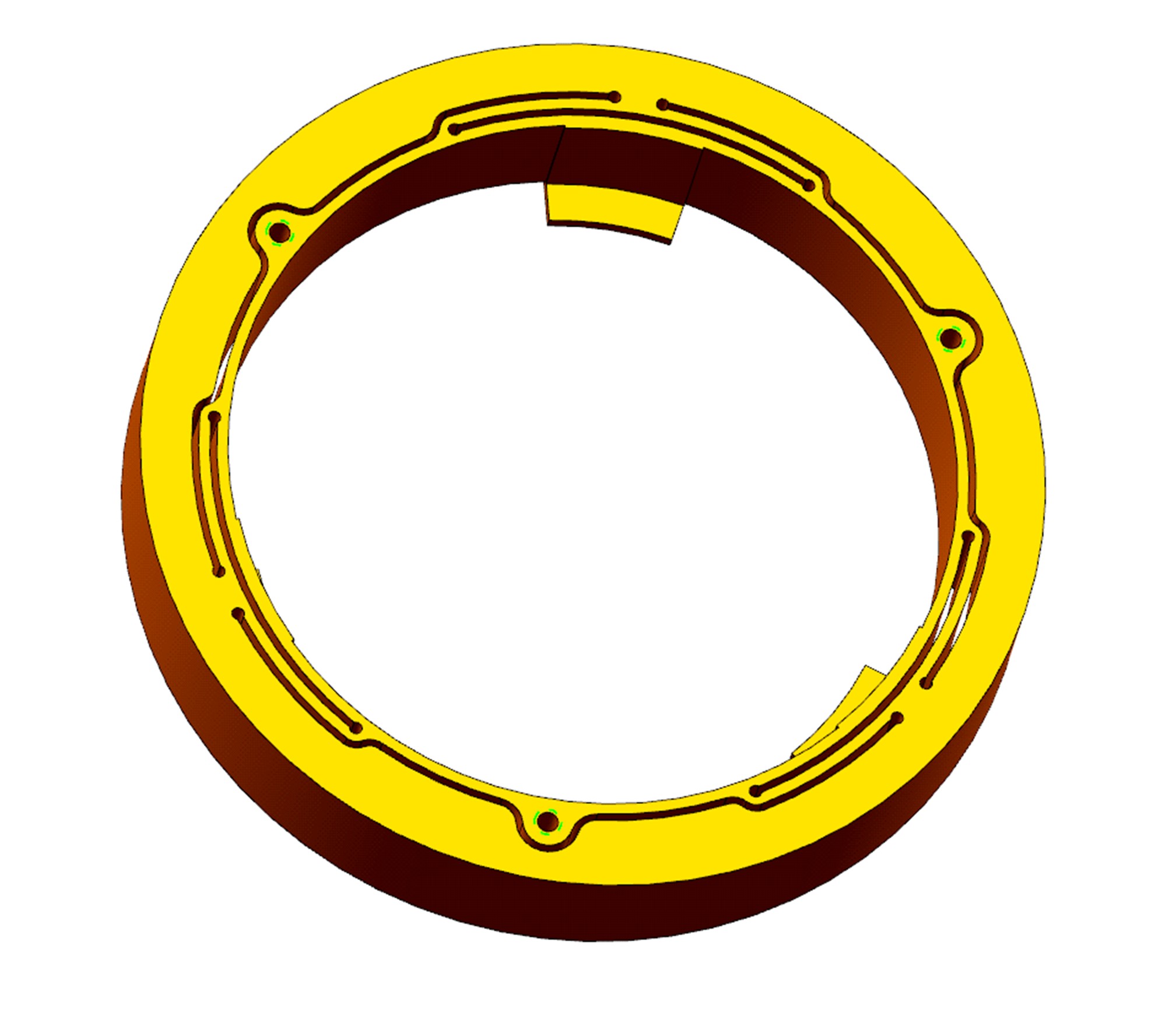

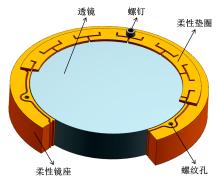

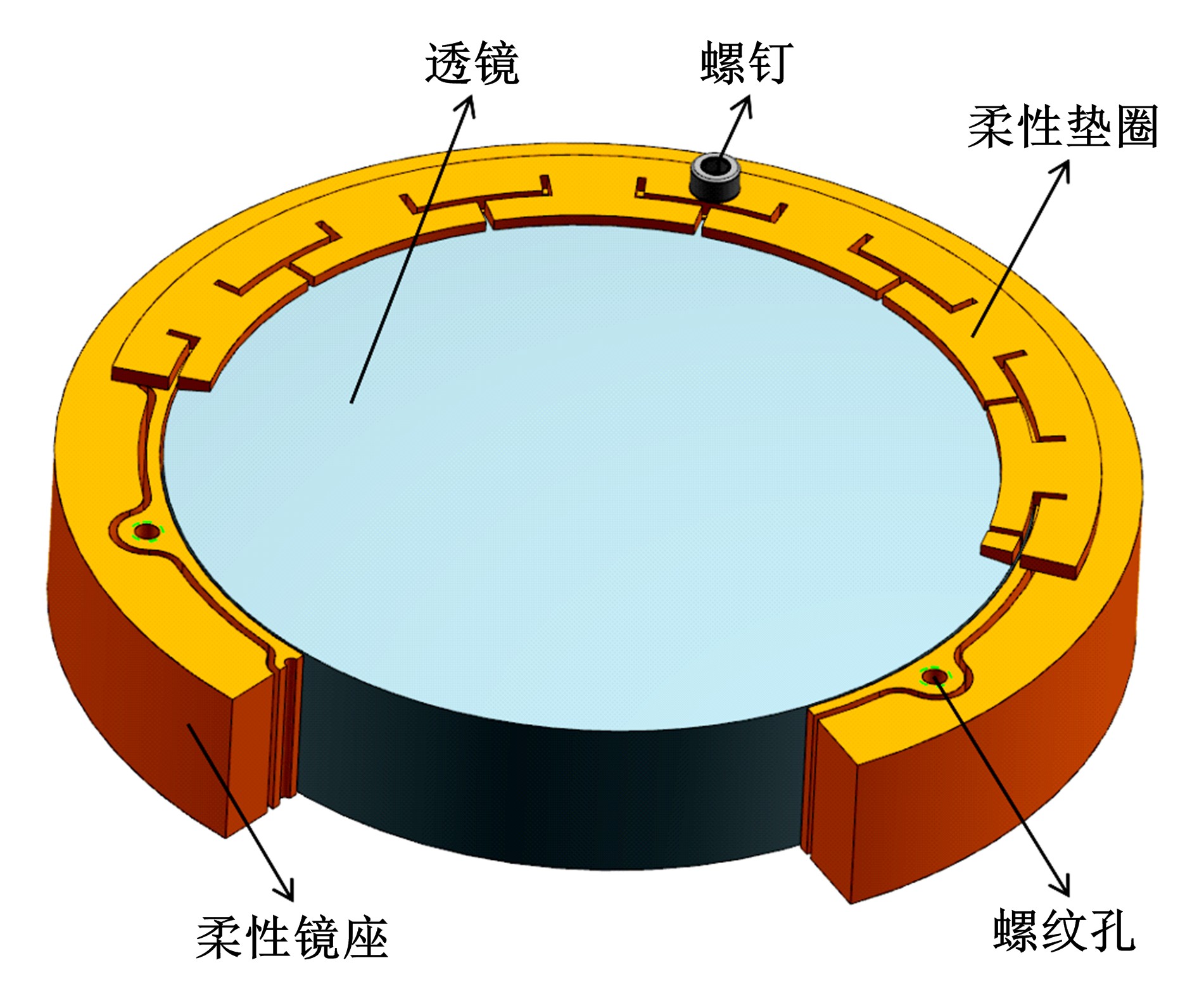

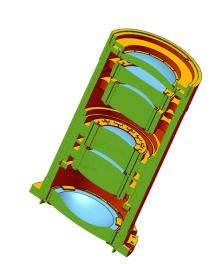

Structural optimization design of large tolerance and multi⁃flexibility lens subassembly

Liu ZHANG1( ),Xiao-yi ZHENG1,Fan ZHANG1(

),Xiao-yi ZHENG1,Fan ZHANG1( ),Yu ZHAO2,Shu-yang ZHAO3

),Yu ZHAO2,Shu-yang ZHAO3

- 1.College of Instrument and Electrical Engineering,Jilin University,Changchun 130061,China

2.College of Mechanical Engineering,Changchun University of Science and Technology,Changchun 130022,China

3.Research Institute of Telemetry,Beijing 100094,China

CLC Number:

- TF303

| 1 | 薛向尧, 高云国. 卫星激光测距中主镜柔性支撑结构设及分析[J]. 电子测量与仪器学报, 2013, 27(8): 696-702. |

| Xue Xiang-yao, Gao Yun-guo. Design and analysis of a flexible support structure for the primary mirror of SLR[J]. Journal of Electronic Measurement and Instrment, 2013, 27(8): 696-702. | |

| 2 | 卢晓明. 空间大口径望远镜光机结构优化设计[D]. 北京: 中国科学院大学中国科学院上海技术物理研究所, 2018. |

| Lu Xiao-ming. Optimization design of space large aperture telescope optical machine structure[D]. Beijing: Shanghai Institute of Technical Physics, Chinese Academy of Sciences, University of Chinese Academy of Sciences, 2018. | |

| 3 | 黎代维. 基于响应面方法的反射镜背部支撑结构优化[D]. 北京: 中国工程物理研究院, 2019. |

| Li Dai-wei. Optimization design of space large aperture telescope optical machine structure[D]. Beijing: China Academy of Engineering Physics, 2019. | |

| 4 | 柯瑞. 空间反射镜镜片及其支撑结构分析与设计[D]. 哈尔滨: 哈尔滨工业大学航天学院, 2010. |

| Ke Rui. Analysis and design of space mirror and support structure[D]. Harbin: School of Astronautics, Harbin Institute of Technology, 2010. | |

| 5 | 汪奎, 辛宏伟, 曹乃亮, 等. 空间相机快速反射镜的两轴柔性支撑结构设计[J]. 红外与激光工程, 2019, 48(12): 233-240. |

| Wang Kui, Xin Hong-wei, Cao Nai-liang, et al. Design of two-axis flexible support structure for fast steering mirror in space cameras[J]. Infrared and Laser Engineering, 2019, 48(12): 233-240. | |

| 6 | 孙宝玉. 光学反射镜柔性支撑结构尺寸稳定性分析[J]. 光电工程, 2009, 36(9): 142-145. |

| Sun Bao-yu. Stability analysis on the dimension of flexible supporting structure of the optical reflector[J]. Opto-Electronic Engineering, 2009, 36(9): 142-145. | |

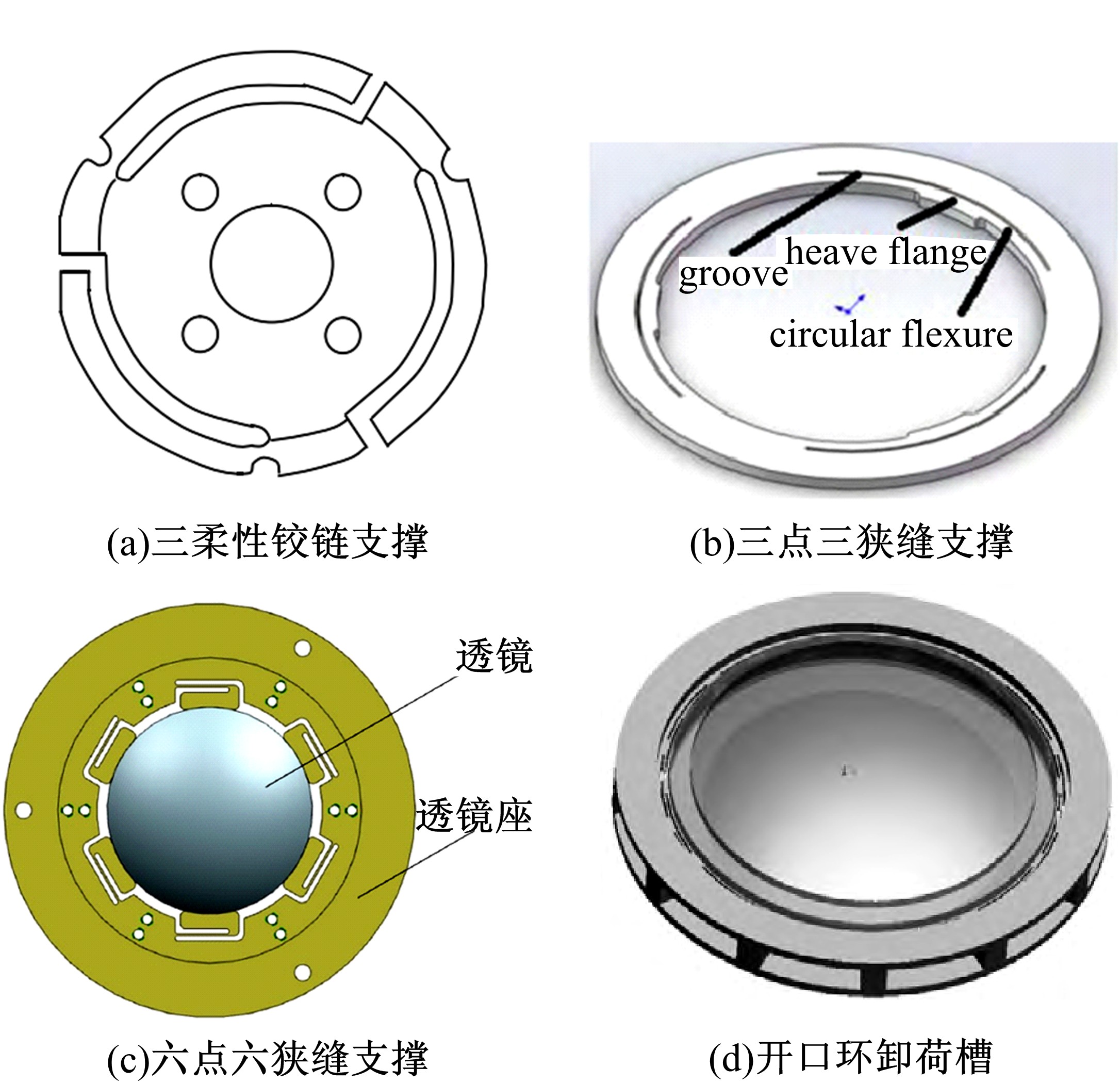

| 7 | 马磊, 曹佃生, 刘承志. 大口径透镜多点柔性支撑结构设计与分析[J]. 光电工程, 2015, 42(5): 88-94. |

| Ma Lei, Cao Dian-sheng, Liu Cheng-zhi. Design and analysis on multi-points flexible supporting structure of large-aperture lens[J]. Opto-Electronic Engineering, 2015, 42(5): 88-94. | |

| 8 | 郄永军, 徐勇, 王方鹏.基于多岛遗传-模拟退火算法的气动外形优化[J].飞行力学, 2017, 35(5): 26-30. |

| Yong-jun Qie, Xu Yong, Wang Fang-peng. Aerodynamic shape optimization based on the hybrid MIGA-SA method[J]. Glight Dynamics, 2017, 35(5): 26-30. | |

| 9 | 王建国, 任建刚. 大口径精密光学元件柔性支撑结构设计和分析[J]. 煤炭技术, 2018, 37(7): 314-316. |

| Wang Jian-guo, Ren Jian-gang. Design and analysis of large diameter precision optics flexible supporting structure[J]. Coal Technology, 2018, 37(7): 314-316. | |

| 10 | 赵勇志, 曹玉岩, 韩西达, 等. 大口径透镜柔性支撑结构设计与分析[J]. 长春理工大学学报: 自然科学版, 2018, 41(5): 1-7. |

| Zhao Yong-zhi, Cao Yu-yan, Han Xi-da, et al. Design and mechanical analysis of the flexible mounting structure for the large aperture lens[J]. Journal of Changchun University of Science and Technology (Natural Science Edition), 2018, 41(5): 1-7. | |

| 11 | 王乃祥, 惠守文. 航空双波段相机胶粘主次镜柔性支撑结构设计[J]. 仪器仪表学报, 2014, 35():77-81. |

| Wang Nai-xiang, Hui Shou-wen. The flexible support structure design of the glued primary-secondary mirror of the aviation dual-band camera[J]. Chinese Journal of Scientific Instrument, 2014, 35(Sup.1): 77-81. | |

| 12 | 邵梦旗, 张雷, 李林, 等. 超轻反射镜柔性支撑结构设计与试验[J]. 光子学报, 2019, 48(12): 201-209. |

| Shao Meng-qi, Zhang Lei, Li Lin, et al. Designand test of flexible supporting structure for ultra-lilght mirror[J]. Acta Photonica Sinica, 2019, 48(12): 201-209. | |

| 13 | 汪纯鹏, 刘波. 大型空间相机柔性支撑结构的设计[J]. 长春理工大学学报: 自然科学版, 2019, 42(5): 1-4. |

| Wang Chun-peng, Liu Bo. Design of flexure support structure of large-scale space camera[J].Journal of Changchun University of Science and Technology (Natural Science Edition), 2019, 42(5): 1-4. | |

| 14 | 王辰忠, 胡中文, 陈忆, 等. 空间引力波望远镜主反射镜系统的结构设计优化[J/OL]. [2020-01-14]. |

| 15 | 吴欣宇. 基于ANSYS的柔性支撑结构随机振动分析[J]. 机械工程师, 2019(12): 40-42, 44. |

| Wu Xin-yu. Random vibration analysis of flexible support structure based on ANSYS[J]. Mechanical Engineer, 2019(12): 40-42, 44. | |

| 16 | 丁泉惠, 王森, 黄修长, 等. 基于有限元法和多岛遗传算法的飞轮结构参数优化设计[J]. 噪声与振动控制, 2016, 36(2): 56-60. |

| Ding Quan-hui, Wang Sen, Huang Xiu-chang, et al. Optimization design of flywheel structural parameters based on finite element analysis and MIGA method[J]. Noise and Vibration Control, 2016, 36(2): 56-60. |

| [1] | Yin-ping LI,Tian-xu JIN,Li LIU. Design and dynamic characteristic simulation of pantograph⁃catenary continuous energy system for pure electric LHD [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 454-463. |

| [2] | Wei-min ZHUANG,Hong-da SHI,Dong-xuan XIE,Guan-nan YANG. Thickness distribution of adhesive layer in dissimilar clinch⁃adhesive hybrid joint with steel and aluminum alloy [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(1): 100-106. |

| [3] | MAO Yu-ze, WANG Li-qin. Influence of squirrel-cage flexible support on the dynamic performance of ball bearing [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(5): 1508-1514. |

| [4] | ZHOU Jie, LUO Yan, WANG Xun, WANG Hui, LI Yang, TAO Ya-ping. Multi-objective optimization of stamping forming process of head based on response surface model [J]. 吉林大学学报(工学版), 2016, 46(1): 205-212. |

| [5] | CHENG Qiang, ZHANG Zhen-dong, GUO Hui, XIE Nai-liu. Electro-magnetic-thermal coupling of GDI injector [J]. 吉林大学学报(工学版), 2015, 45(3): 806-813. |

| [6] | LI Guo-fa, HAN Ming-zuo, SHAN Cui-yun, LIU Jia. Finite element simulation and experiment of magneto-rheological torque servo device [J]. 吉林大学学报(工学版), 2013, 43(05): 1284-1289. |

| [7] | YAN Qing-dong, ZOU Bo, WEI Wei. 3-D integrated optimization of blade forward-curved angle of hydraulic retarder [J]. , 2012, 42(05): 1135-1139. |

|

||