Journal of Jilin University(Engineering and Technology Edition) ›› 2021, Vol. 51 ›› Issue (3): 1121-1130.doi: 10.13229/j.cnki.jdxbgxb20200199

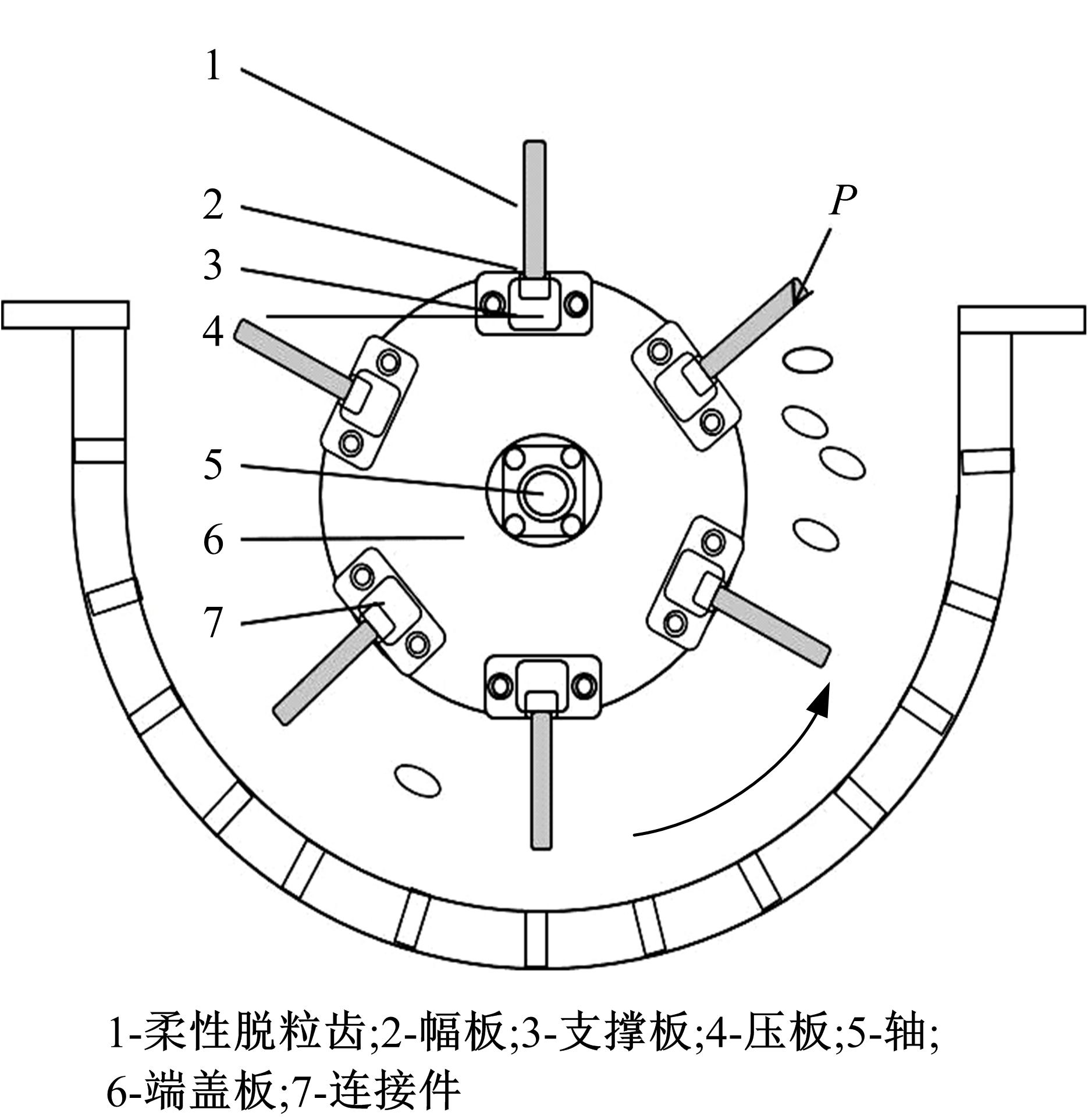

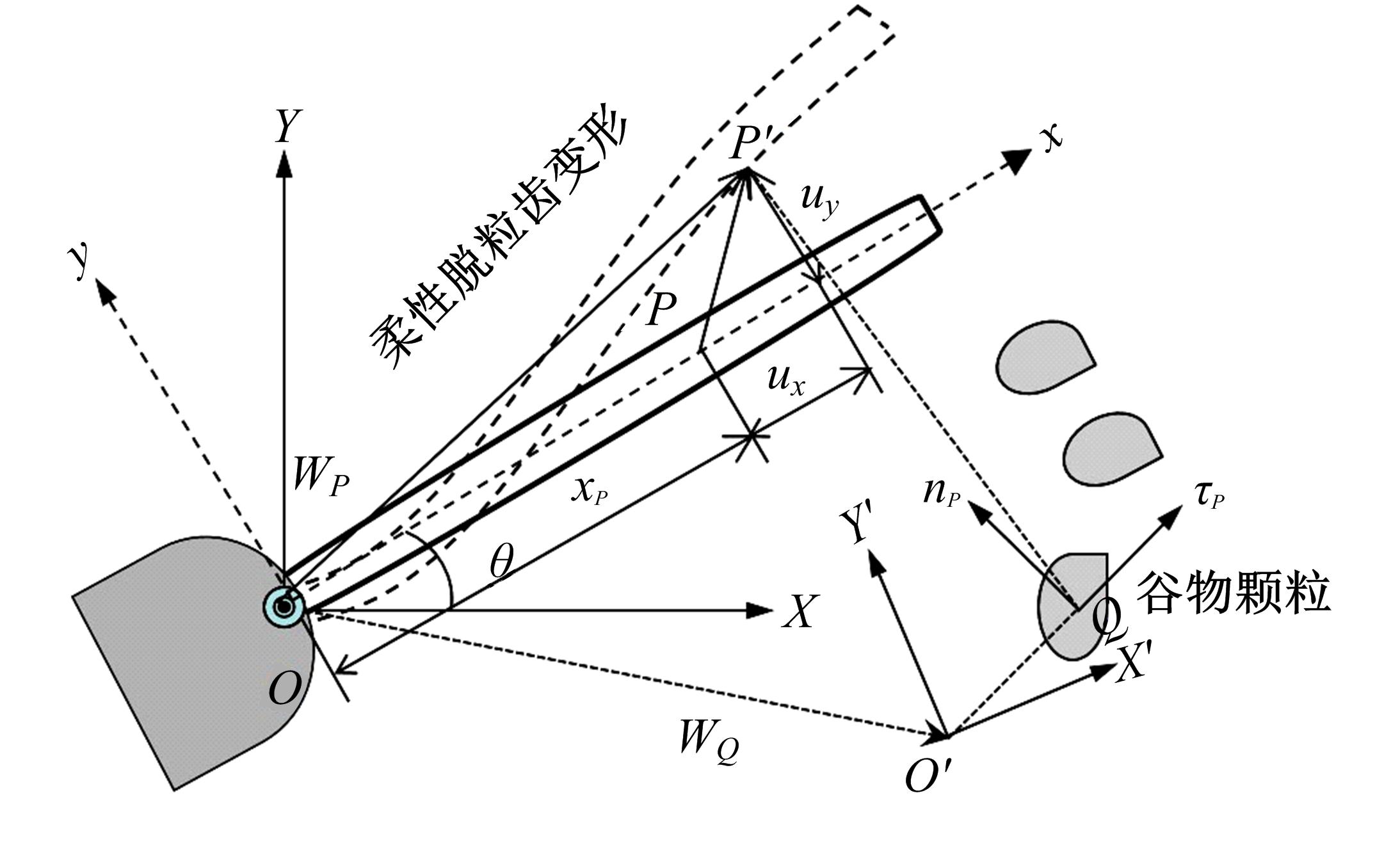

Frictional impact dynamics model of threshing process between flexible teeth and grains

Zhen-jie QIAN( ),Cheng-qian JIN(

),Cheng-qian JIN( ),Wen-sheng YUAN,You-liang NI,Guang-yue ZHANG

),Wen-sheng YUAN,You-liang NI,Guang-yue ZHANG

- Nanjing Institute of Agricultural Mechanization,Ministry of Agriculture and Rural Affairs,Nanjing 210014,China

CLC Number:

- S225.3

| 1 | Mesquita C M, Hanna M A. Soya bean threshing mechanics 1: frictional rubbing by flat belts[J]. Transactions of the ASAE, 1993, 36(2):275-279. |

| 2 | Ukatu A C. A modified threshing unit for soya beans[J]. Biosystems Engineering, 2006, 95(3):371-377. |

| 3 | 师清翔, 刘师多, 姬江涛, 等. 水稻的控速喂入柔性脱粒试验研究[J]. 农业机械学报, 1996, 27(1):41-46. |

| Shi Qing-xiang, Liu Shi-duo, Ji Jiang-tao, et a1. Research on speed-controlled feed and soft threshing for rice[J]. Transactions of the Chinese Society of Agricultural Engineering, 1996, 27(1):41-46. | |

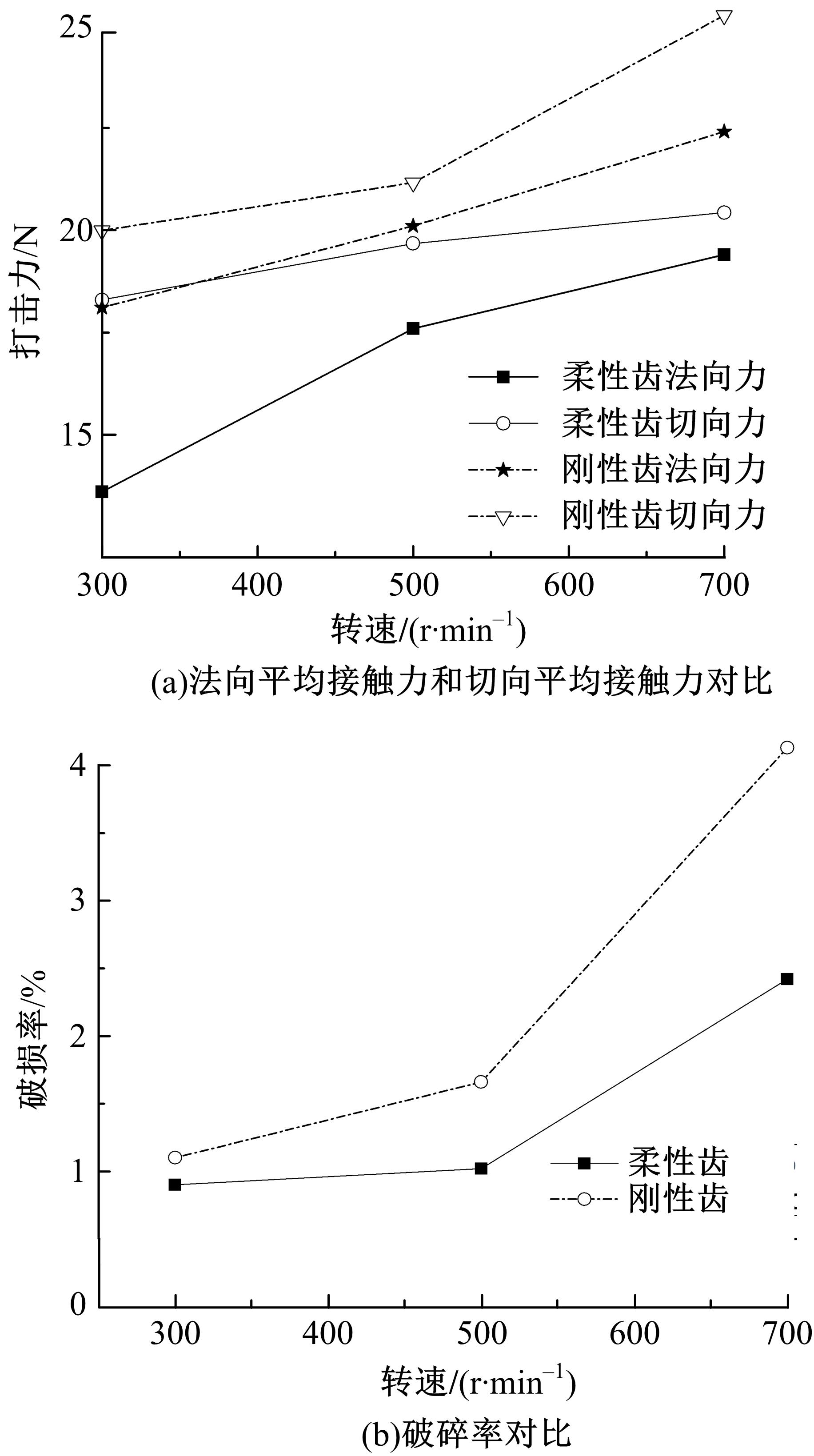

| 4 | 任述光, 谢方平, 罗锡文, 等. 柔性齿与刚性齿脱粒水稻功耗比较分析与试验[J]. 农业工程学报, 2013,29(5):12-18. |

| Ren Shu-guang, Xie Fang-ping, Luo Xi-wen, et a1. Analysis and test of power consumption in paddy threshing using flexible and rigid teeth[J]. Transactions of the Chinese Society of Agricultural Engineering, 2013,29(5):12-18. | |

| 5 | 李耀明, 王显仁, 徐立章, 等. 水稻谷粒的挤压力学性能研究[J]. 农业机械学报, 2007, 38(11):56-59. |

| Li Yao-ming, Wang Xian-ren, Xu Li-zhang, et a1. Study on compression properties of rice grains[J]. Transactions of the Chinese Society of Agricultural Engineering, 2007, 38(11):56-59. | |

| 6 | Xu L Z, Li Y M, Ma Z, et al. Theoretical analysis and finite element simulation of a rice kernel obliquely impacted by a threshing tooth[J]. Biosystems Engineering, 2013, 114(2):146-156. |

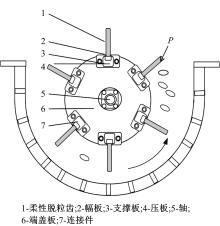

| 7 | 耿端阳,谭德蕾,于兴瑞,等.玉米柔性脱粒滚筒脱粒元件设计与试验[J].吉林大学学报:工学版,2020,50(5):1923-1933. |

| Geng Duan-yang, Tan De-lei, Yu Xing-rui, et al. Design and test of corn flexible threshing cylinder element[J]. Journal of Jilin University (Engineering and Technology Edition), 2020,50(5):1923-1933. | |

| 8 | 付君,张屹晨,程超,等. 刚柔耦合式小麦脱粒弓齿设计及试验[J]. 吉林大学学报:工学版,2020,50(2):730-738. |

| Fu Jun, Zhang Yi-chen, Cheng Chao, et al. Design and experiment of bow tooth of rigid flexible coupling for wheat threshing[J]. Journal of Jilin University (Engineering and Technology Edition), 2020,50(2):730-738. | |

| 9 | 付宏,吕游,李艳双,等. 基于离散元法的玉米脱粒过程分析[J]. 吉林大学学报:工学版,2012, 42(4):997-1002. |

| Fu Hong, Lyu You, Li Yan-shuang, et a1. Analysis for corn threshing process based DEM[J]. Journal of Jilin University (Engineering and Technology Edition), 2012, 42(4):997-1002. | |

| 10 | 段玥晨,章定国,洪嘉振. 作大范围运动柔性梁的一种碰撞动力学求解方法[J]. 机械工程学报, 2012, 48(19):95-102. |

| Duan Yue-chen, Zhang Ding-guo, Hong Jia-zhen. Method for solving the impact problem of a flexible beam with large overall motion[J]. Journal of Mechanical Engineering, 2012, 48(19):95-102. | |

| 11 | Pfister J, Eberhard P. Frictional contact of flexible and rigid bodies[J]. Granular Matter, 2002, 4(1):25-36. |

| 12 | 任祖方,许乔沼,吴杰,等. 稻谷的机械力学特性试验[J]. 湖北农业科学,2012,51(21):4880-4883. |

| Ren Zu-fang, Xu Qiao-ming, Wu Jie, et al. Research on the mechanical properties of rice kernel [J]. Hubei Agricultural Sciences, 2012,51(21):4880-4883. | |

| 13 | 李耀明,周金芝,徐立章,等. 水稻复脱分离系统脱粒分离性能的试验[J]. 江苏大学学报:自然科学版,2005,26(1):1-4. |

| Li Yao-ming, Zhou Jin-zhi, Xu Li-zhang, et al. Experimental test of grain threshing and separating unit[J]. Journal of Jiangsu University (Natural Science Edition), 2005,26(1):1-4. | |

| 14 | 李耀明,孙夕龙,徐立章. 水稻穗头连接力的试验与分析[J]. 江苏大学学报:自然科学版,2008,29(2):97-100, 105. |

| Li Yao-ming, Sun Xi-long, Xu Li-zhang. Test and analysis on connection force of rice spike[J]. Journal of Jiangsu University (Natural Science Edition), 2008,29(2):97-100, 105. | |

| 15 | 李杰,阎楚良,杨方飞. 纵向轴流脱粒装置的理论模型与仿真[J]. 江苏大学学报:自然科学版,2006,27(4):299-302. |

| Li Jie, Yan Chu-liang, Yang Fang-fei. Theoretical model and simulation of threshing of axial unit with axial feeding[J]. Journal of Jiangsu University (Natural Science Edition), 2006,27(4):299-302. | |

| 16 | Leine R I, Campen D H V, Glocker C H. Nonlinear dynamics and modeling of various wooden toys with impact and friction[J]. Journal of Vibration and Control, 2003, 9(1/2):25-78. |

| 17 | Qian Zhen-jie, Zhang Ding-guo, Jin Cheng-qian. A regularized approach for frictional impact dynamics of flexible multi-link manipulator arms considering the dynamic stiffening effect[J]. Multibody System Dynamics, 2017, 17(4):229-255. |

| 18 | 张烨, 李长友, 李建民,等. 稻谷摩擦特性研究[J]. 广东农业科学, 2011, 38(13):15-17. |

| Zhang Ye, Li Chang-you, Li Jian-min, et al. Experimental study on frictional characteristic of grain[J]. Guangdong Agricultural Sciences, 2011, 38(13):15-17. | |

| 19 | 冯家畅, 程绪铎, 严晓婕. 大豆与仓壁材料摩擦因数的研究[J]. 大豆科学, 2014, 33(5): 787-794. |

| Feng Jia-chang, Cheng Xu-duo, Yan Xiao-jie. Research on the coefficient of friction between soybean and silo wall material[J]. Soybean Science, 2014, 33(5):787-794. | |

| 20 | 杨明芳. 基于离散元法的玉米排种器的数字化设计方法研究[D]. 长春: 吉林大学生物与农业工程学院, 2009. |

| Yang Ming-fang. Study on digital design method of corn seed-metering device based on DEM[D]. Changchun:College of Biological and Agricultural Engineering, Jilin University, 2009. | |

| 21 | 崔涛,刘佳,杨丽, 等. 基于高速摄像的玉米种子滚动摩擦特性试验与仿真[J]. 农业工程学报,2013, 29(15):34-41. |

| Cui Tao, Liu Jia, Yang Li, et al. Experiment and simulation of rolling friction characteristic of corn seed based on high-speed photography[J]. Transactions of the Chinese Society of Agricultural Engineering, 2013, 29(15):34-41. | |

| 22 | Yu Y, Fu H, Yu J. Dem-based simulation of the corn threshing process[J]. Advanced Powder Technology, 2015, 26(5):1400-1409. |

| 23 | 陈艳普,康艳,王廷恩,等.大豆收获机纵轴流柔性脱粒装置脱出物分布规律[J]. 中国农业大学学报, 2020,25(9):104-111. |

| Chen Yan-pu, Kang Yan, Wang Ting-en, et al. Distribution regularities of the threshed mixtures in longitudinal axial flow flexible thresher of soybean harvester[J]. Journal of China Agricultural University, 2020, 25(9):104-111. |

| [1] | Duan-yang GENG,De-lei TAN,Xing-rui YU,Guo-liang SU,Qian WANG,Xiu-feng LU,Cheng-qian JIN. Design and test of corn flexible threshing cylinder element [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(5): 1923-1933. |

| [2] | Rui-tao GAO,Jian SHAN,Zhou YANG,Sheng WEN,Yu-bin LAN,Quan-yong ZHANG,Yang WANG. Real⁃time interpretation system of variable spray prescription map based on plant protection UAV [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(1): 361-374. |

| [3] | JIA Hong-lei, WANG Wan-peng, CHEN Zhi, ZHUANG Jian, WANG Wen-jun, LIU Hui-li. Real-time pressure measurement of profiling elastic press roller based on soil cone index [J]. 吉林大学学报(工学版), 2018, 48(4): 1169-1175. |

| [4] | ZHANG Qiang, YU Lu-lu, JIA Hong-lei. Design and experiment of handling mechanism for tractors [J]. 吉林大学学报(工学版), 2012, 42(增刊1): 108-112. |

| [5] | WANG Zeng-hui, HUANG Dong-yan, LI Zhuo-shi, JIA Hong-lei, WAN Bao-cheng. Universal the blade the broken stubble power consumption influence of the working parameters of the rotary tiller broken stubble [J]. 吉林大学学报(工学版), 2012, 42(增刊1): 122-125. |

| [6] | Liu Hui;Wang Mao-hua;Wang Yue-xuan;Ma Dao-kun;Li Hai-xia. Development of farmland soil moisture and temperature monitoring system based on wireless sensor network [J]. 吉林大学学报(工学版), 2008, 38(03): 604-0608. |

|

||