Journal of Jilin University(Engineering and Technology Edition) ›› 2021, Vol. 51 ›› Issue (5): 1887-1896.doi: 10.13229/j.cnki.jdxbgxb20200568

Design of 4QJ⁃3 type pickup header of silage oat

Rong-qing LIANG1,2( ),Bo ZHONG2,He-wei MENG1,3,Zhi-min SUN2,Za KAN1,3(

),Bo ZHONG2,He-wei MENG1,3,Zhi-min SUN2,Za KAN1,3( )

)

- 1.College of Mechanical and Electronic Engineering,Shihezi University,Shihezi 832000,China

2.Shandong Academy of Agricultural Machinery Sciences,Jinan 250100,China

3.Key Laboratory of Northwest Agricultural Equipment,Ministry of Agriculture and Rural Affairs,Shihezi 832000,China

CLC Number:

- S225.8

| 1 | 张越, 王小芬, 代佳丽, 等. 低温燕麦青贮乳酸菌复合菌系的构建及其青贮效果[J]. 农业工程学报, 2019, 35(14): 308-314. |

| Zhang Yue, Wang Xiao-fen, Dai Jia-li, et al. Construction and effect of lactic acid bacteria in oat silage and mechanism at low temperature[J]. Transactions of the Chinese Society of Agricultural Engineering, 2019, 35(14): 308-314. | |

| 2 | Brinton M M, Hansen B H, Ulmer K M, et al. Forage production and calf gains when grazing oats following corn harvest[J]. Translational Animal Science, 2019, 3: 1641-1645. |

| 3 | 李志强, 冯富. 燕麦青贮研究进展[J]. 西南民族大学学报: 自然科学版, 2018, 44(1): 1-5. |

| Li Zhi-qiang, Feng Fu. Research progress of oat silage[J]. Journal of Southwest Minzu University(Natural Science Edition), 2018, 44(1): 1-5. | |

| 4 | Rezende A, Freitas G P, Costa M, et al. Nutritional Composition of White Oat(Avena Sativa L.) with Different Levels of Dry Matter for Use in the Diet of Horses[M].Wageningen: Wageningen Academic Publishers, 2012. |

| 5 | Andrés B M V, Felipe L G, Gertrudis E, et al. Oat silage for grazing dairy cows in small-scale dairy systems in the highlands of central Mexico[J]. African Journal of Range and Forage Science, 2018, 35(1): 63-70. |

| 6 | Shinners K J, Boettcher G C, Muck R E, et al. Harvest and storage of two perennial grasses as biomass feedstocks[J]. Transactions of the Asabe, 2010, 53(2): 359-370. |

| 7 | Odogherty M J. A review of research on forage chopping[J]. Journal of Agricultural Engineering Research, 1982, 27(4): 267-289. |

| 8 | Siahsar B, Taleei A, Peyghambari A, et al. QTL analysis of forage quantity and quality-related traits of barley[J]. Journal of Crop Production and Processing Isfahan University of Technology, 2009, 13(47): 195-208. |

| 9 | Blevins F Z, Hansen H J. Analysis of forage harvester design[J]. Agricultural Engineering, 1956, 37: 21-27, 29. |

| 10 | Johnson L M, Harrison J H, Hunt C W, et al. Nutritive value of corn silage as affected by maturity and mechanical processing: a contemporary review[J]. Journal of Dairy Science, 1999, 82(12): 2813-2825. |

| 11 | Zhang M, Sword M L, Buckmaster D R, et al. Design and evaluation of a corn silage harvester using shredding and flail cutting[J]. Transactions of the Asabe, 2003, 46(6): 1503-1511. |

| 12 | Amiama C, Bueno J, Alvarez C J, et al. Design and field test of an automatic data acquisition system in a self-propelled forage harvester[J]. Computers and Electronics in Agriculture, 2008, 61(2): 192-200. |

| 13 | Cerdeira-Pena A, Carpente L, Amiama C. Optimised forage harvester routes as solutions to a traveling salesman problem with clusters and time windows[J]. Biosystems Engineering, 2017, 164: 110-123. |

| 14 | Reyns P, Missotten B, Ramon H, et al. A review of combine sensors for precision farming[J]. Precision Agriculture, 2002, 3(2): 169-182. |

| 15 | Mathanker S K, Hansen A C. Harvesting system design and performance[J]. Engineering and Science of Biomass Feedstock Production and Provision, 2014(1): 85-139. |

| 16 | Bortolini M, Cascini A, Gamberi M, et al. Sustainable design and life cycle assessment of an innovative multi-functional haymaking agricultural machinery[J]. Journal of Cleaner Production, 2014, 82(1): 23-36. |

| 17 | 万霖, 车刚, 汪春, 等. 4QZR-30型青贮饲料收获机设计与试验[J]. 农业机械学报, 2008, 39(3): 187-190. |

| Wan Lin, Che Gang, Wang Chun, et al. Design and test of 4QZR-30 silage harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2008, 39(3): 187-190. | |

| 18 | 丛宏斌, 李明利, 李汝莘, 等. 4YQK-2型茎秆青贮打捆玉米收获机的设计[J]. 农业工程学报, 2009, 25(10): 96-100. |

| Cong Hong-bin, Li Ming-li, Li Ru-xin, et al. Design of 4YQK-2 combine harvester for corn and straw ensilage[J]. Transactions of the Chinese Society of Agricultural Engineering, 2009, 25(10): 96-100. | |

| 19 | 赵满全, 黄炎. 黄贮饲料收获机关键部件设计与性能试验[J]. 农业机械学报, 2013, 44(): 91-95. |

| Zhao Man-quan, Huang Yan. Structure simulation and performance experiment of yellow corn forage harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2013, 44(Sup.2): 91-95. | |

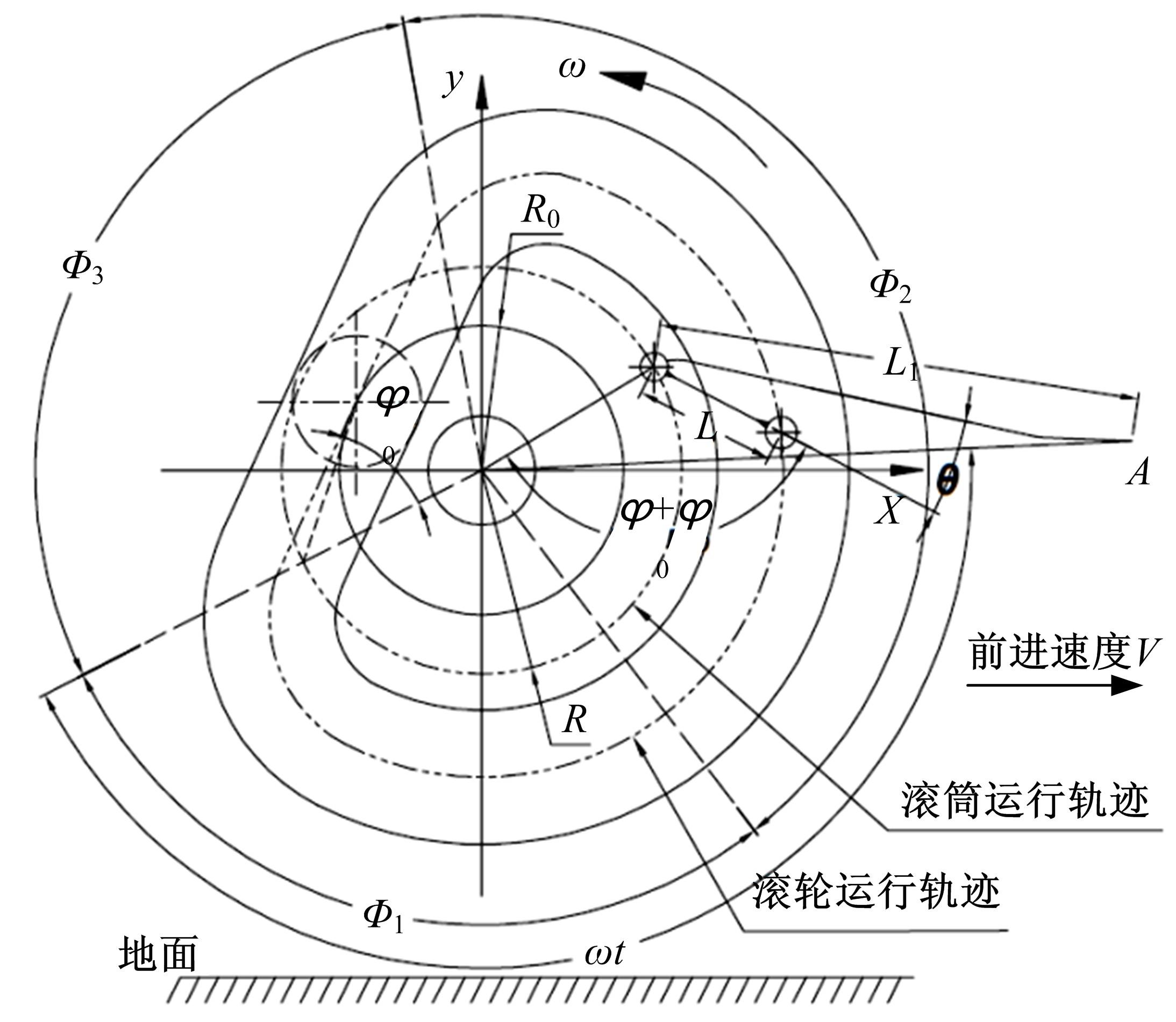

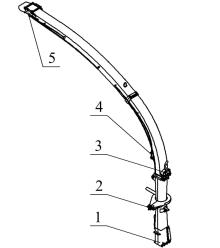

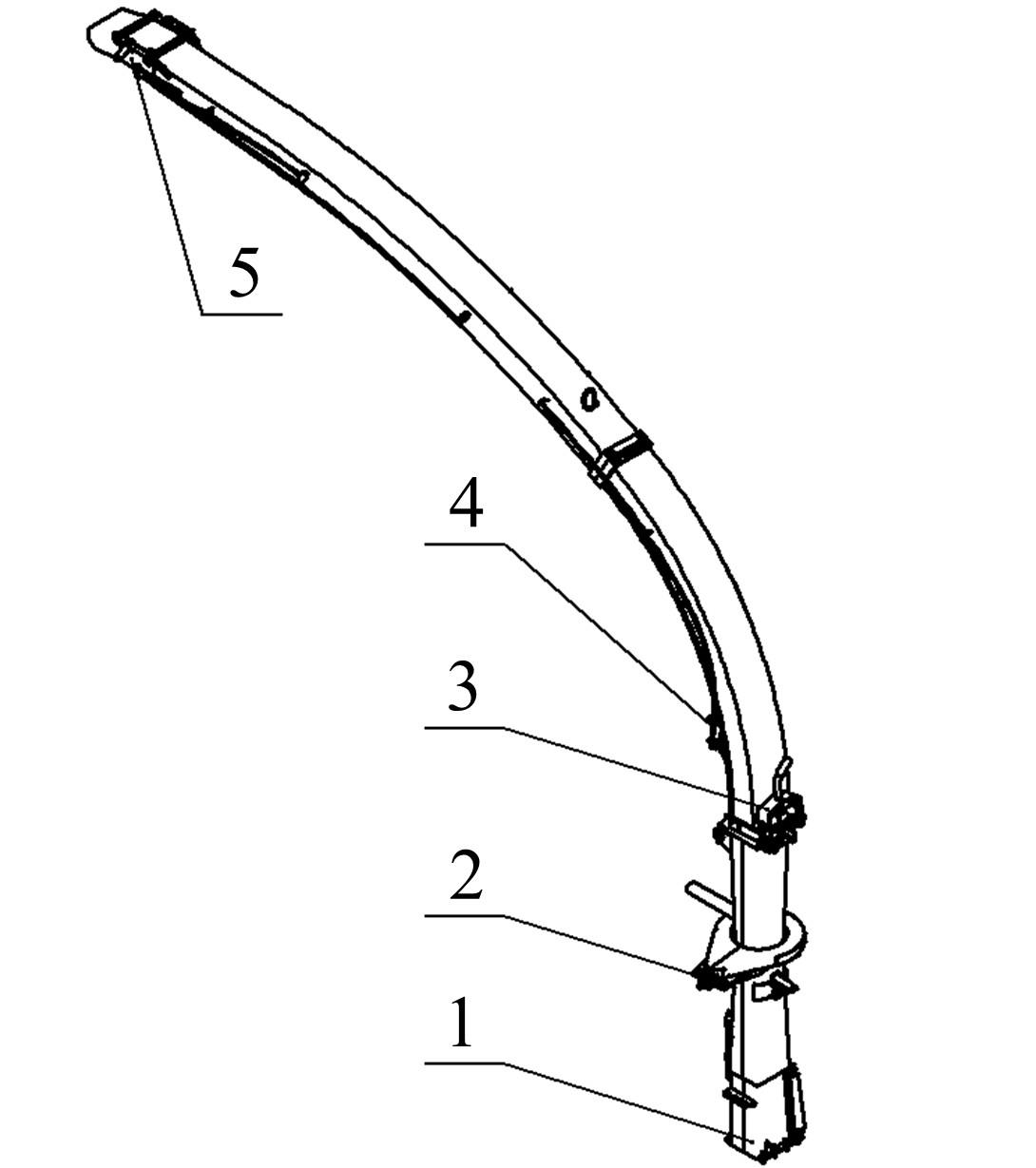

| 20 | 王进华, 王泽群, 贾晶霞, 等. 饲料收获机矮秆割台拨禾轮导轨运动轨迹研究[J]. 农业机械学报, 2011, 42(): 152-155. |

| Wang Jin-hua, Wang Ze-qun, Jia Jing-xia, et al. Guide rail trajectory of mower table reel device for silage harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2011, 42(Sup.1): 152-155. | |

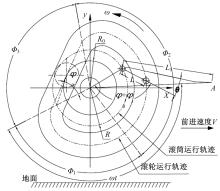

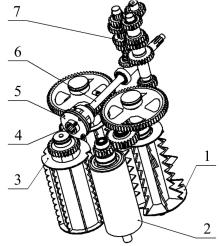

| 21 | 郁志宏, 王文明, 莫日根毕力格, 等. 弹齿滚筒式捡拾器捡拾性能试验[J]. 农业机械学报, 2017, 48(3): 106-112. |

| Yu Zhi-hong, Wang Wen-ming, Morigenbilige, et al. Experiment on performance of spring-finger cylinder pickup collector[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(3): 106-112. | |

| 22 | 王文明, 王春光. 弹齿滚筒式捡拾装置参数分析与仿真[J]. 农业机械学报, 2012, 43(10): 82-88. |

| Wang Wen-ming, Wang Chun-guang. Parameter analysis and simulation of spring-finger cylinder pickup collector[J]. Transactions of the Chinese Society for Agricultural Machinery, 2012, 43(10): 82-88. | |

| 23 | 王国权, 余群, 卜云龙, 等. 秸秆捡拾打捆机设计及捡拾器的动力学仿真[J]. 农业机械学报, 2001, 32(5): 59-61, 68. |

| Wang Guo-quan, Yu Qun, Bu Yun-Long, et al. Design of pickup baler and dynamic simulation of pickup roller[J]. Transactions of the Chinese Society for Agricultural Machinery, 2001, 32(5): 59-61, 68. | |

| 24 | Langer T H, Ebbesen M K, Kordestani A. Experimental analysis of occupational whole-body vibration exposure of agricultural tractor with large square baler[J]. International Journal of Industrial Ergonomics, 2015, 47: 79-83. |

| 25 | Cundiff J S, Marsh L S. Harvest and storage costs for bales of switchgrass in the southeastern United States[J]. Bioresource Technology, 1996, 56(1): 95-101. |

| 26 | 盛凯, 曾南宏. 弹齿滚筒捡拾器的机构特性及其运动数学模型[J]. 农业机械学报, 1991, 22(1): 51-57. |

| Sheng Kai, Zeng Nan-hong. Mechanism characteristics and movement mathematical model of the spring-toothed roller picker[J]. Transactions of the Chinese Society for Agricultural Machinery, 1991, 22(1): 51-57. | |

| 27 | 卡那沃依斯基. 收获机械[M]. 北京: 中国农业机械出版社, 1983. |

| 28 | 车刚, 万霖, 张伟, 等. 青贮饲料收获机实体设计与试验[J]. 农业机械学报, 2010, 41(2): 82-86. |

| Che Gang, Wan Lin, Zhang Wei, et al. Solid design and experiment of forage harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2010, 41(2): 82-86. | |

| 29 | 周德义, 王子佳, 张丹丹, 等. 新型玉米收获机的秸秆处理装置[J]. 吉林大学学报: 工学版, 2012, 42(): 113-116. |

| Zhou De-yi, Wang Zi-jia, Zhang Dan-dan, et al. The new device of stalk cutting with in corn narvester[J]. Journal of Jilin University(Engineering and Technology Edition), 2012, 42(Sup.1): 113-116. | |

| 30 | Weiss W P, Wyatt D J. Effect of oil content and kernel processing of corn silage on digestibility and milk production by dairy cows[J]. Journal of Dairy Science, 2000, 83(2): 351-358. |

| 31 | Bhandari S K, Li S, Ominski K H, et al. Effects of the chop lengths of alfalfa silage and oat silage on feed intake, milk production, feeding behavior, and rumen fermentation of dairy cows[J]. Journal of Dairy Science, 2008, 91(5): 1942-1958. |

| 32 | 薛钊, 付君, 陈志, 等. 青饲玉米收获机械切碎装置参数优化试验[J]. 吉林大学学报: 工学版, 2020, 50(2): 739-748. |

| Xue Zhao, Fu Jun, Chen Zhi, et al. Optimization experiment on parameters of chopping device of forage maize harvester[J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 739-748. | |

| 33 | 邱进, 吴明亮, 官春云, 等. 动定刀同轴水稻秸秆切碎还田装置结构设计与试验[J]. 农业工程学报, 2015(10): 10-19. |

| Qiu Jin, Wu Ming-liang, Guan Chun-yun, et al. Design and experiment of chopping device with dynamic fixed knife coaxial for rice straw[J]. Transactions of the Chinese Society of Agricultural Engineering, 2015(10): 10-19. | |

| 34 | Siemens M C, Wilkins D E, Correa R F. Development and evaluation of a residue management wheel for hoe-type no-till drills[J].Transactions of the American Society of Agricultural Engineers, 2004, 47(2): 397-404. |

| 35 | Kroes S, Harris H D. A kinematic model of the dual basecutter of a sugar cane harvester[J]. Journal of Agricultural Engineering Research, 1995, 62(3): 163-172. |

| 36 | 梁荣庆, 张翠英, 李青江, 等. 4QG-2型青贮收获机切碎揉搓装置的设计[J]. 农机化研究, 2018, 40(11): 99-104. |

| Liang Rong-qing, Zhang Cui-ying, Li Qing-jiang, et al. Design of chopping and rubbing device of 4QG-2 silage harvester[J]. Journal of Agricultural Mechanization Research, 2018, 40(11): 99-104. | |

| 37 | . 玉米青贮收获机作业质量[S]. |

| 38 | . 牧草捡拾器[S]. |

| [1] | Ji-hai JIANG,Cun-ran ZHAO,Guan-long ZHANG,Ming-yang CHE. Tribological properties of coating materials of tribopairs for aviation kerosene piston pump [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(1): 147-153. |

| [2] | Zhi-gang YANG,Ya-jun FAN,Chao XIA,Shi-jun CHU,Xi-zhuang SHAN. Drag reduction of a square⁃back Ahmed model based on bi⁃stable wake [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(5): 1635-1644. |

| [3] | Zhao XUE,Jun FU,Zhi CHEN,Feng-de WANG,Shao-ping HAN,Lu-quan REN. Optimization experiment on parameters of chopping device of forage maize harvester [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 739-748. |

| [4] | Jun FU,Yi-chen ZHANG,Chao CHENG,Zhi CHEN,Xin-long TANG,Lu-quan REN. Design and experiment of bow tooth of rigid flexible coupling for wheat threshing [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 730-738. |

| [5] | Chao CHENG,Jun FU,Fu-ping HAO,Zhi CHEN,De-yi ZHOU,Lu-quan REN. Effect of motion parameters of cleaning screen on corn cob blocking law [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(1): 351-360. |

| [6] | Chao CHENG,Jun FU,Xin⁃long TANG,Zhi CHEN,Lu⁃quan REN. Effects of vibration mode on interface adhesion law of rice threshed mixtures [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1228-1235. |

| [7] | Wei⁃min ZHUANG,Peng⁃yue WANG,Dong⁃xuan XIE,Yan⁃hong CHEN. Scratch resistance of aluminum automotive coatings based on continuum damage mechanics [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(3): 829-835. |

| [8] | JIN Jing-fu, LI Yang, CHEN Ting-kun, CONG Qian, QI Ying-chun. Effect of elastic modulus of coating on ice-adhesion strength on substrate [J]. 吉林大学学报(工学版), 2017, 47(5): 1548-1553. |

| [9] | SUN Wei, LI Jian, JIA Shi. Identification of nonlinear stiffness and damping for hard-coating composite structure [J]. 吉林大学学报(工学版), 2016, 46(4): 1156-1162. |

| [10] | WANG Chun-yue, WANG Li-xue, ZHANG Jun-ru, SHI Wen-xiao. Simulating floating inductance based on MDDCC [J]. 吉林大学学报(工学版), 2016, 46(2): 652-657. |

| [11] | FU Jun,QIAN Zhi-hui,YIN Wei,WANG Jia-jia,REN Lu-quan. Experimental study of friction and tensile properties of wheat [J]. 吉林大学学报(工学版), 2015, 45(2): 501-507. |

| [12] | DAI Sheng, ZUO Dun-wen, LI Xiang-feng, CHENG Hu, FANG Zhi-gang, WANG Min, MIAO Hong. Friction and wear behavior of Ni-based WC composite coating on mould steel 2738 prepared by laser cladding [J]. , 2012, 42(04): 924-929. |

| [13] | ZHUANG Wei-min, CHEN Yan-hong. Simulation of surface coating failure based on continuum damage mechanics [J]. , 2012, 42(04): 857-862. |

| [14] | GUO Yun-wen, REN Lu-quan, LIU Xian-li, ZHANG Guang-cheng, ZHANG Zhi-hui. Abrasion properties of coupling surface of bionic concave pits and nano-sized SiC/Ni composite coatings [J]. 吉林大学学报(工学版), 2012, 42(01): 74-78. |

| [15] | JIANG Gui-Yan, CHANG An-De, CONG Yu-Liang. Link average travel time of traffic flow estimation based on floating car data [J]. 吉林大学学报(工学版), 2010, 40(增刊): 158-0162. |

|

||