Journal of Jilin University(Engineering and Technology Edition) ›› 2022, Vol. 52 ›› Issue (3): 604-614.doi: 10.13229/j.cnki.jdxbgxb20200825

Experiment on mechanical properties of detachable prefabricated composite beams subjected to negative bending moment

Jun CHEN1( ),Shao-xian WANG1,Hui XU1,Duan-quan MO2,Jing-si HUO3,Xu-hua DENG1(

),Shao-xian WANG1,Hui XU1,Duan-quan MO2,Jing-si HUO3,Xu-hua DENG1( )

)

- 1.College of Civil Engineering and Mechanics,Xiangtan University,Xiangtan 411105,China

2.Hunan Hengyun Construction Technology Development Co. ,Ltd. ,Xiangtan 411101,China

3.College of Civil Engineering,Huaqiao University,Xiamen 361021,China

CLC Number:

- TU398.9

| 1 | 钟琼. 预制装配式钢-混凝土组合梁的试验研究[D]. 长沙:湖南大学建筑安全与节能教育部重点实验室, 2017. |

| Zhong Qiong. The experimental study on composite steel-prefabricated precast concrete slab beam[D]. Changsha: Key Laboratory of the Ministry of Building Safety and Energy Conservation, Hunan University, 2017. | |

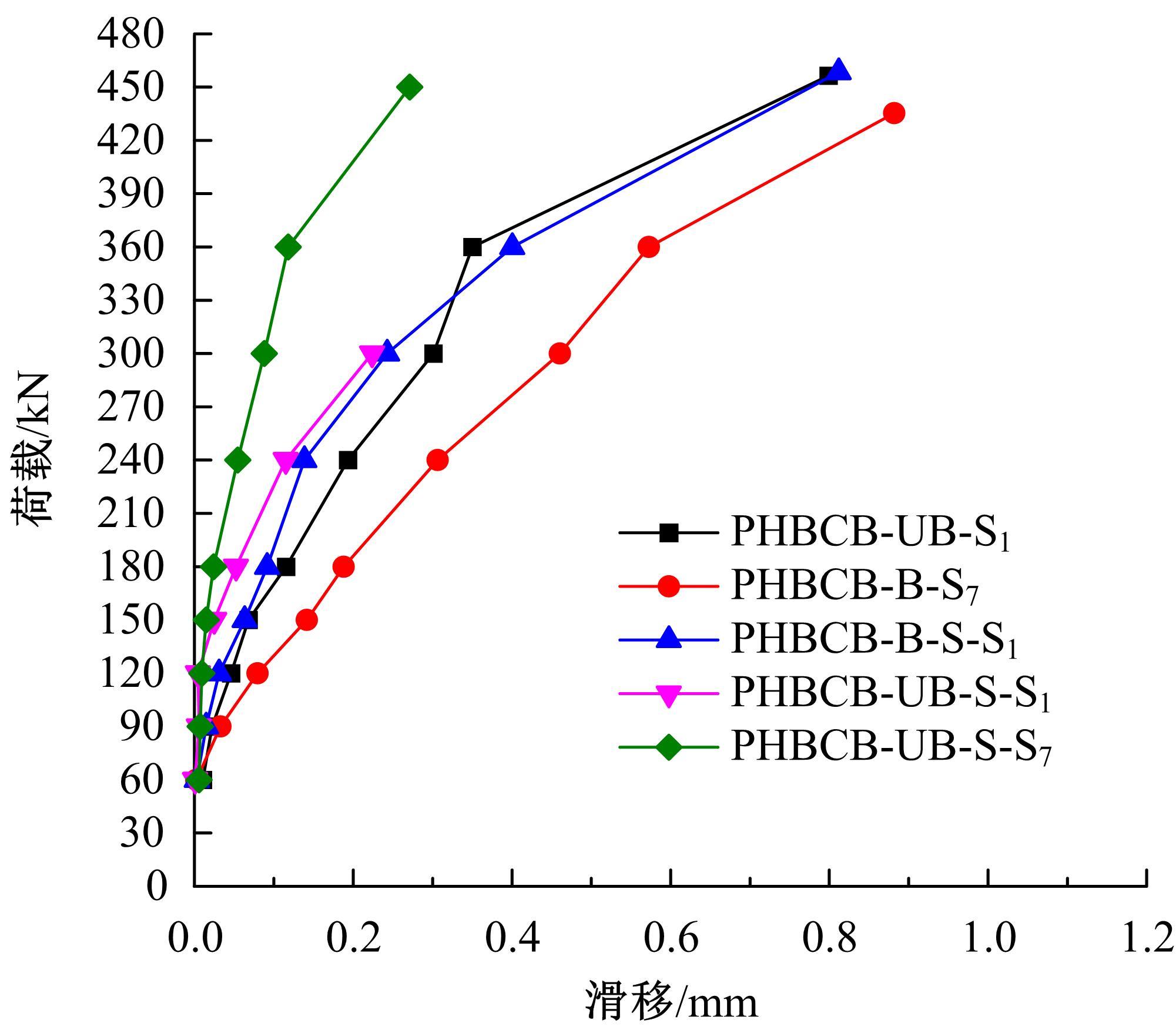

| 2 | 钟琼, 霍静思, 王海涛, 等. 预制装配式组合梁栓钉连接件抗剪性能试验研究[J]. 建筑钢结构进展, 2018, 20(2): 13-19, 27. |

| Zhong Qiong, Huo Jing-si, Wang Hai-tao, et al. Experimental study on the shear bearing capacity of stud connectors in prefabricated compositebeams[J]. Progress in Steel Building Structures, 2018, 20(2): 13-19, 27. | |

| 3 | 刘中良. 装配式组合梁高强螺栓连接件抗剪性能试验研究[D]. 湘潭:湘潭大学土木工程与力学学院, 2017. |

| Liu Zhong-liang. Experimental study on the shear behavior of the prefabricated composite beam high strength bolt connector[D]. Xiangtan: College of Civil Engineering and Mechanics, Xiangtan University, 2017. | |

| 4 | 刘中良, 陈俊, 霍静思. 装配式组合梁高强螺栓连接件抗剪性能试验研究[J]. 建筑结构, 2017, 47(10): 65-70, 64. |

| Liu Zhong-liang, Chen Jun, Huo Jing-si. Experimental study on shear behavior of high strength bolt connection for prefabricated composite beam[J]. Building Structure, 2017, 47(10): 65-70, 64. | |

| 5 | 汪威. 装配式组合梁高强螺栓连接件力学性能研究[D]. 湘潭:湘潭大学土木工程与力学学院, 2019. |

| Wang Wei. Mechanical performance study on high-strength bolt connectors in prefabricated steel-concrete composite beams[D]. Xiangtan: College of Civil Engineering and Mechanics, Xiangtan University, 2019. | |

| 6 | 陈俊,汪威,丁发兴,等. 钢-混凝土组合梁高强螺栓抗剪连接件受剪性能[J]. 铁道科学与工程学报, 2019, 16(10): 2553-2561. |

| Chen Jun, Wang Wei, Ding Fa-xing, et al. Shear bearing capacity of high-strength bolt connectors in steel-concrete composite beams[J]. Journal of Railway Science and Engineering, 2019, 16(10): 2553-2561. | |

| 7 | 聂建国. 钢-混凝土组合梁结构[M]. 北京:科学出版社, 2005. |

| 8 | 樊健生,聂建国,贾维,等. 钢-混凝土连续组合梁的设计方法[J]. 建筑结构, 2003, 33(1): 41-44. |

| Fan Jian-sheng, Nie Jian-guo, Jia Wei, et al. Design method of steel-concrete continuous composite beam[J]. Building Structure, 2003, 33(1): 41-44. | |

| 9 | 戴益民. 钢-混凝土预制板组合梁的试验研究[D].长沙:湖南大学土木工程学院, 2005. |

| Dai Yi-min. The experimental studies on composite steel-FDPCP beam[D]. Changsha: College of Civil Engineering, Hunan University, 2005. | |

| 10 | 刘寒冰,时成林,谭国金.考虑剪切滑移效应的叠合梁有限元解[J].吉林大学学报: 工学版, 2016, 46(3): 792-797. |

| Liu Han-bing, Shi Cheng-lin, Tan Guo-jin. Finite element solution of composite beams considering shear slip effect[J]. Journal of Jilin University (Engineering and Technology Edition), 2016, 46(3): 792-797. | |

| 11 | 刘寒冰, 刘天明, 张云龙. 钢-混凝土组合连续梁抗弯性能[J]. 吉林大学学报: 工学版, 2009, 39(6): 1486-1491. |

| Liu Han-bing, Liu Tian-ming, Zhang Yun-long. Flexural behavior of steel-concrete composite continuous beams[J]. Journal of Jilin University (Engineering and Technology Edition), 2009, 39(6): 1486-1491. | |

| 12 | 刘寒冰, 代艳杰, 韩硕, 等. 预应力钢-轻骨料混凝土组合梁抗弯承载力[J]. 吉林大学学报: 工学版, 2009, 39(): 138-140. |

| Liu Han-bing, Dai Yan-jie, Han Shuo. Flexural capacity of prestressed steel lightweight aggregate concrete composite beams [J]. Journal of Jilin University (Engineering and Technology Edition), 2009, 39(Sup.1): 138-140. | |

| 13 | 樊健生, 聂建国, 张彦玲. 钢-混凝土组合梁抗裂性能的试验研究[J]. 土木工程学报, 2011, 44(2): 1-7. |

| Fan Jian-sheng, Nie Jian-guo, Zhang Yan-ling. Experimental study of crack resistance of steel-concrete beams[J]. China Civil Engineering Journal, 2011, 44(2): 1-7. | |

| 14 | 樊健生,聂建国. 钢-混凝土组合桥梁研究及应用新进展[J]. 建筑钢结构进展, 2006, 8(5): 35-39. |

| Fan Jian-sheng, Nie Jian-guo. Progress in research and application of composite steel-concrete bridges[J]. Progress in Steel Building Structures, 2006, 8(5): 35-39. | |

| 15 | 聂建国, 樊健生. 组合梁在负弯矩作用下的刚度分析[J]. 工程力学, 2002, 19(4): 33-36, 28. |

| Nie Jian-guo, Fan Jian-sheng. Analysis of composite beam stiffness under negative bending[J]. Engineering Mechanics, 2002, 19(4): 33-36, 28. | |

| 16 | 胡少伟, 叶祥飞. 预应力连续组合梁负弯矩区抗弯承载力分析[J]. 工程力学, 2013, 30(11): 160-165. |

| Hu Shao-wei, Ye Xiang-fei. Analysis on the bending capacity of the negative-moment region in prestressed continuous composite beam[J]. Engineering Mechanics, 2013, 30(11): 160-165. | |

| 17 | 聂建国, 陶慕轩, 聂鑫, 等. 抗拔不抗剪连接新技术及其应用[J]. 土木工程学报, 2015, 48(4): 7-14, 58. |

| Nie Jian-guo, Tao Mu-xuan, Nie Xin, et al. New technique and application of uplift-restricted and slip-permitted connection[J]. China Civil Engineering Journal, 2015, 48(4): 7-14, 58. | |

| 18 | 聂建国, 李一昕, 陶慕轩. 新型抗拔不抗剪连接件的滑移性能及其滞回模型[J]. 工程力学, 2014, 31(11): 46-52. |

| Nie Jian-guo, Li Yi-xin, Tao Mu-xuan. Slip performance and hysteresis model of a new type of uplift restricted-slipfree connectors[J]. Engineering Mechanics, 2014, 31(11): 46-52. | |

| 19 | 庄亮东, 陈伟, 聂鑫, 等. 抗拔不抗剪连接件在钢-混凝土组合框架结构中的应用[J]. 建筑结构学报, 2020, 41(1): 104-112. |

| Zhuang Liang-dong, Chen Wei, Nie Xin, et al. Application of uplift-restricted and slip-permitted connectorsin steel-concrete composite frame structures[J]. Journal of Building Structures, 2020, 41(1): 104-112. | |

| 20 | John O D, George S. Composite beams with limited-slip-capacity shear connectors[J]. Journal of Structural Engineering, 1995, 121(6): 932-938. |

| 21 | Nie J G, Li Y X, Tao M X, et al. Uplift-restricted and slip-permitted t-shape connectors[J]. Journal of Bridge Engineering, 2015, 20(4): No.04014073. |

| 22 | Duan Lin-li. Research on application of uplift-restricted slip-permitted (URSP) connectors in steel-concrete composite frames[J]. Applied Science, 2019, 9(11): 2235. |

| 23 | . 混凝土结构设计规范 [S]. |

| 24 | . 钢结构设计设计标准 [S]. |

| 25 | . 金属材料拉伸试验第1部分:室温试验方法 [S]. |

| 26 | 陈超. 预制装配式组合梁及可拆卸预制装配式组合梁性能研究[D]. 湘潭:湘潭大学土木工程与力学学院, 2020. |

| Chen Chao. Study on the performance of prefabricated composite beams and detchable prefabricated composite beams[D]. Xiangtan: College of Civil Engineering and Mechanics,Xiangtan University, 2020. | |

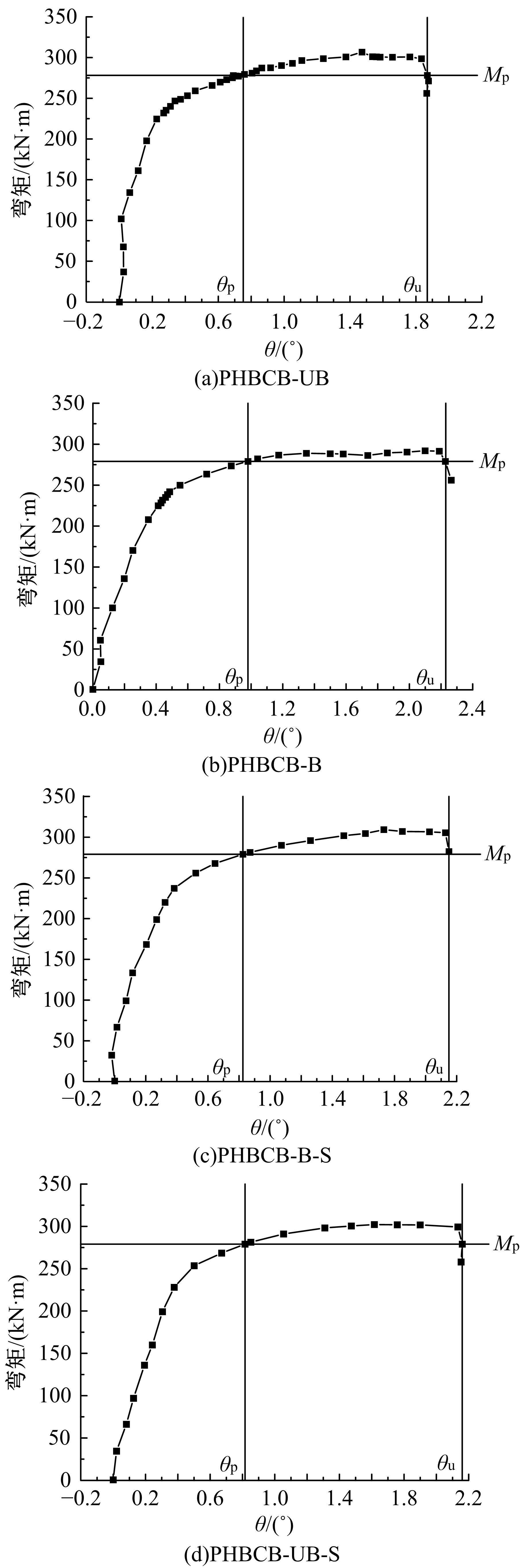

| 27 | 贾远林,陈世鸣. 预应力组合梁负弯矩作用下梁端转动能力研究[J]. 河北工程大学学报: 自然科学版, 2009, 26(1): 14-20. |

| Jia Yuan-lin, Chen Shi-ming. Buckling coefficient of steel-concrete composite beams in negative bending[J]. Journal of Hebei University of Engineering(Natural Science Edition), 2009, 26(1): 14-20. |

| [1] | Shi⁃cheng WAN,Qiao HUANG,Jian GUAN,Zhao⁃yuan GUO. Strengthening of continuous steel⁃concrete composite beams in negative moment region using prestressed carbon fiber⁃reinforced polymer plates [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1114-1123. |

| [2] | SUN Wei, LI Jian, JIA Shi. Identification of nonlinear stiffness and damping for hard-coating composite structure [J]. 吉林大学学报(工学版), 2016, 46(4): 1156-1162. |

| [3] | WU Jian-ying1,2, CAI Jian1,2, HE Jun1, CHEN Qing-jun1,2 . Load capacity and stiffness of beamcolumn joint strengthened by plate rings with irregularly arranged double level beams [J]. 吉林大学学报(工学版), 2008, 38(04): 829-834. |

| [4] | Shi Qi-yin,Lu Ming,Zhang Qing-zong,Li Ai-qun,Hui Zhuo . Bending fatigue behavior of RC crane beam strengthened with carbon fiber reinforced plastic [J]. 吉林大学学报(工学版), 2008, 38(01): 99-104. |

| [5] | JIN Zhai-nan, JU Yan-zhong, QIN Li, YANG Xiang-jiang, CHEN Jian-hua. Experimental Investigations on Dynamic Modification of Multistory Shear Wall Structure [J]. 吉林大学学报(工学版), 2000, (3): 83-86. |

|

||