Journal of Jilin University(Engineering and Technology Edition) ›› 2024, Vol. 54 ›› Issue (8): 2174-2180.doi: 10.13229/j.cnki.jdxbgxb.20221303

Previous Articles Next Articles

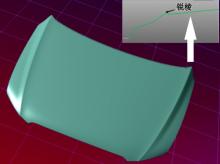

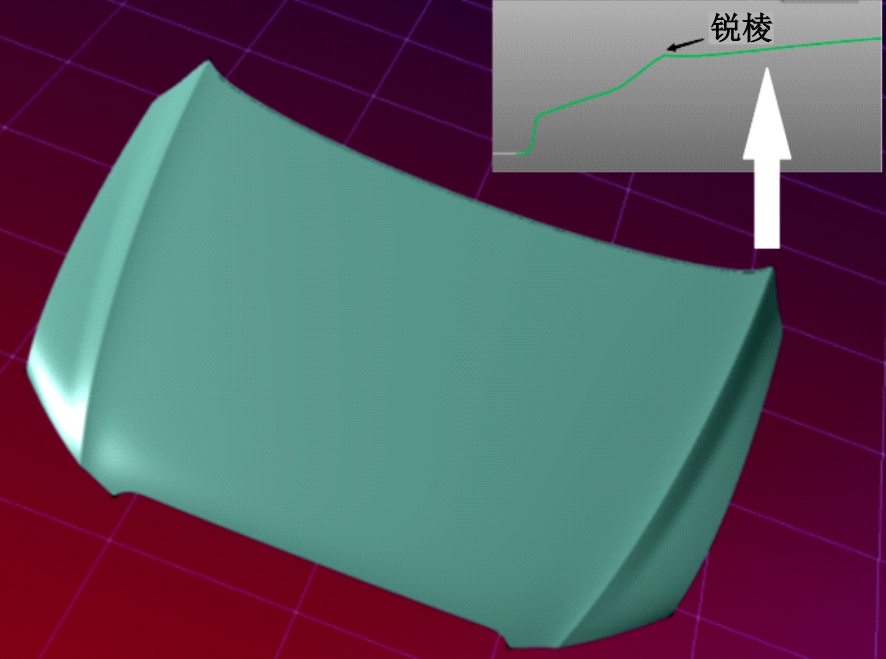

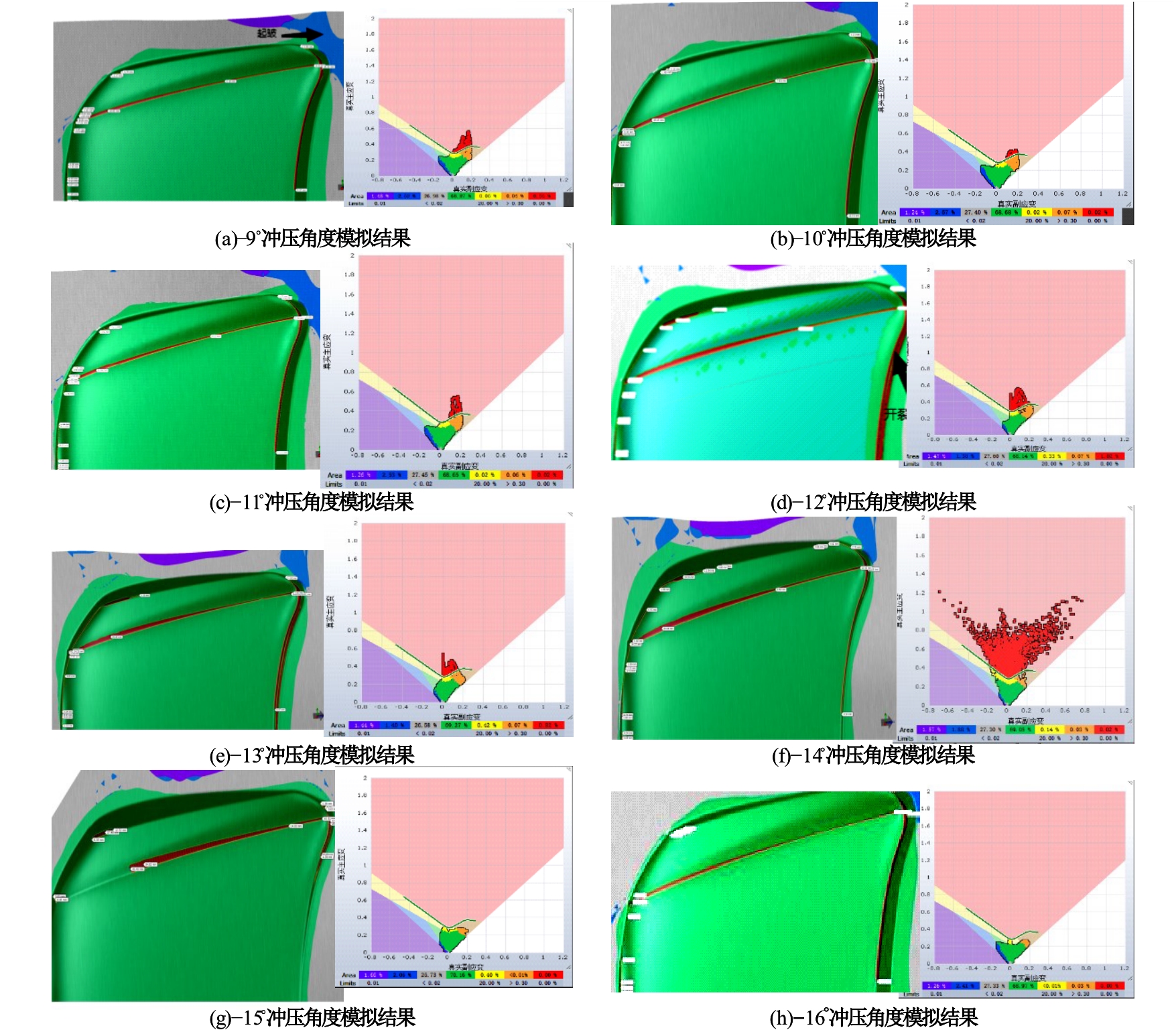

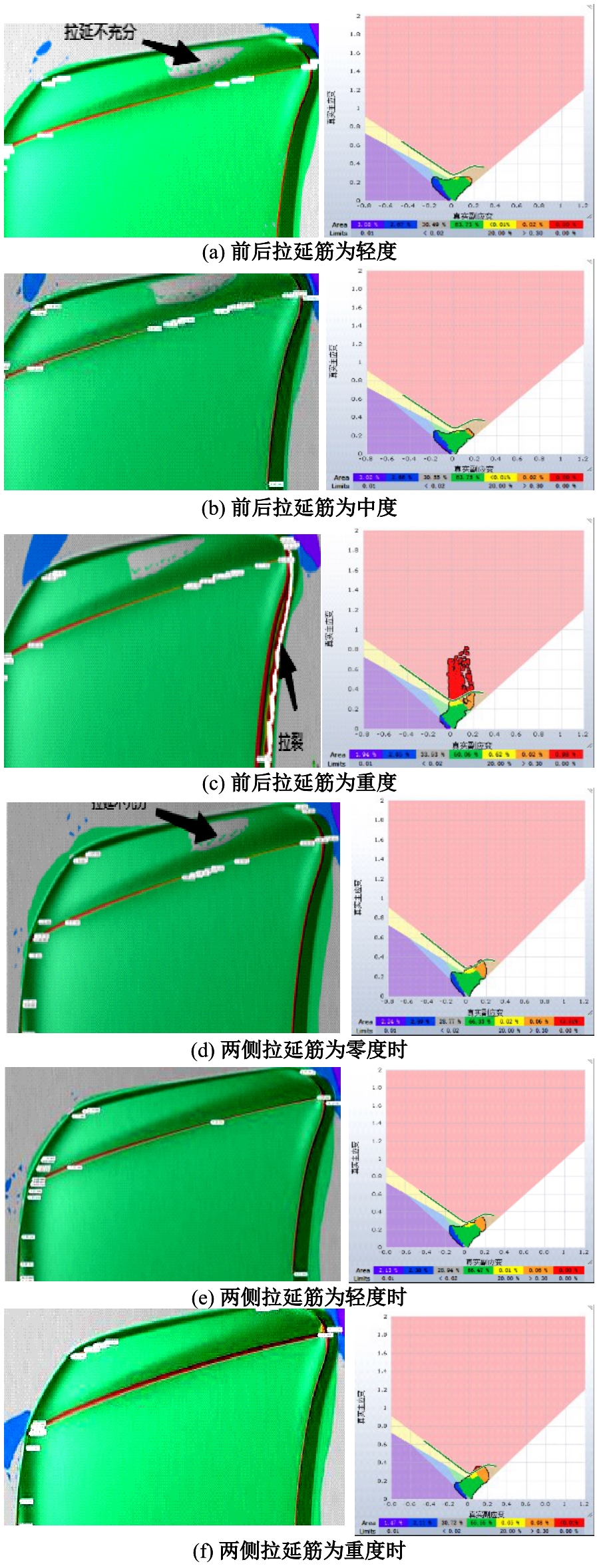

Process optimization for slip-line defects in automobile hood edge drawing

Ji-cai LIANG( ),Qing-yu ZHANG,Ce LIANG(

),Qing-yu ZHANG,Ce LIANG( )

)

- College of Materials Science and Engineering,Jilin University,Changchun 130022,China

CLC Number:

- TG385

| 1 | 柴武倩, 杨建, 刘艳兵, 等. 前门外板锐利化棱线工艺设计方法[J]. 锻压技术, 2019, 44(4): 78-82. |

| Chai Wu-qian, Yang Jian, Liu Yan-bing, et al. Process design method for sharpening edge of front door outer panel[J]. Forging Technology, 2019, 44(4): 78-82. | |

| 2 | 王忠华, 王强, 杨德军, 等. 提高翼子板棱线清晰效果的锐棱处理[J]. 模具制造, 2014, 6: 29-33. |

| Wang Zhong-hua, Wang Qiang, Yang De-jun, et al. Sharp edge treatment to improve the clear edge effect of fender[J]. Die Making, 2014, 6: 29-33. | |

| 3 | 蒋磊, 龚剑, 王龙, 等. 侧围外板浅拉延成形工艺数值模拟[J]. 塑性工程学报, 2020, 29(9): 73-81. |

| Jiang Lei, Gong Jian, Wang Long, et al. Numerical simulation of shallow drawing process for side outer panel[J]. Journal of Plastic Engineering, 2020, 29(9): 73-81. | |

| 4 | Wanintradul C, Gurumurthy G T, Smith L M, et al. An experimental analysis device for obtaining skid line limit diagrams[J]. AIP Conference Proceedings, 2011, 1383: 557-564. |

| 5 | Moon Y H, Kim D W, Tyne C J. Analytical model for prediction of sidewall curl during stretch-bend sheet metal forming[J]. International Journal of Mechanical Sciences, 2008, 50(4): 666-675. |

| 6 | Smith L M C W, Gurumurthy Gopinath T. Design of skid line simulation machine for sheet metal surface quality analysis[C]∥Final Report to USAMP and A/SP, 2009. |

| 7 | 魏春谊, 孙胜伟, 李惠龙, 等. 汽车冲压车身锐棱技术发展浅谈[J]. 汽车工艺与材料, 2020, 377(5): 30-33. |

| Wei Chun-yi, Sun Sheng-wei, Li Hui-long, et al. A brief talk on the development of sharp edge technology for automobile body stamping[J]. Automotive Technology and Materials, 2020, 377(5): 30-33. | |

| 8 | 李春光, 胡平, 郭威. 汽车覆盖件深拉延有限元仿真过程中的材料塑性与失效模型[J]. 吉林大学学报: 工学版, 2005, 35(3): 277-281. |

| Li Chun-guang, Hu Ping, Guo Wei. Material plasticity and invalidation model in FEM simulation of automobile panels deep drawing[J]. Journal of Jilin University (Engineering and Technology Edition), 2005, 35(3): 277-281. | |

| 9 | 那景新, 闫亚坤, 庄蔚敏. 用厚度阈值法改善深拉延冲压件坯料形状预测精度[J]. 吉林大学学报: 工学版, 2006, 36(2): 20-23. |

| Na Jing-xin, Yan Ya-kun, Zhuang Wei-min. Improvement of blank shape prediction precision of deep drawing stamping part by thickness threshold value method[J]. Journal of Jilin University (Engineering and Technology Edition), 2006, 36(2): 20-23. |

| [1] | Yi LI,Ya-sai BAI,Ji-cai LIANG,Wei-guo YAO,Ce LIANG. Simulation on influence of temperature field on composite glued structure of car interior [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(7): 1887-1893. |

| [2] | Cong-zhen LIU,Gao CHEN,Hong-zhu LIU,Qiang MA,Cheng-wei XU,Hui MENG,Guo-lin WANG. Tire grounding mechanical model on wet roads [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(6): 1501-1511. |

| [3] | Liang-liang GUAN,Guo-hong TIAN. Fault detection algorithm for indicator diagram of automobile shock absorber based on dynamic analysis [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(5): 1221-1226. |

| [4] | Peng GUO,Wen-chao ZHAO,Kun LEI. Dual⁃resource constrained flexible job shop optimal scheduling based on an improved Jaya algorithm [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(2): 480-487. |

| [5] | Fu-heng QU,Tian-yu DING,Yang LU,Yong YANG,Ya-ting HU. Fast image codeword search algorithm based on neighborhood similarity [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(8): 1865-1871. |

| [6] | Na LI,Shao-sheng TAN. Image segmentation of fencing continuous action based on spatial neighborhood information [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(7): 1639-1644. |

| [7] | Wei ZHENG,Jian-jun SUN,Chen-bo MA,Qiu-ping YU,Yu-yan ZHANG,Tao NIU. Research status and prospect of automobile wheel hub machining fixture [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(1): 25-36. |

| [8] | En-hui ZHANG,Ren HE,Wei-dong SU. Numerical analysis of oil liquid sloshing characteristics in fuel tank with different baffle structures [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(1): 83-95. |

| [9] | Hui YE,Chang LIU,Kang-kang YAN. Application of fiber reinforced composite in auto⁃body panel [J]. Journal of Jilin University(Engineering and Technology Edition), 2020, 50(2): 417-425. |

| [10] | Xin LI,Yan-peng SUN,Dan WANG,Jun-xu CHEN,Zheng-wei GU,Hong XU. Finite element numerical simulation for automobile front floor forming [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(5): 1608-1614. |

| [11] | DAI Cun-jie,LI Yin-zhen,MA Chang-xi,CHAI Huo,MU Hai-bo. Multi-criteria optimization for hazardous materials distribution routes under uncertain conditions [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(6): 1694-1702. |

| [12] | LIU Yun, KANG Bing, HOU Tao, WANG Ke, LIU Fu. Optimal initialization-based C-means method [J]. 吉林大学学报(工学版), 2018, 48(1): 306-311. |

| [13] | XING Hai-yan, GE Hua, LI Si-qi, YANG Wen-guang, SUN Xiao-jun. Hidden defect metal magnetic memory identification for welded joints based on fuzzy membership and maximum likelihood estimation [J]. 吉林大学学报(工学版), 2017, 47(6): 1854-1860. |

| [14] | WANG Chun-sheng, ZOU Li, YANG Xin-hua. Analysis of fatigue life factors of aluminum alloy welded joints based on neighborhood rough set theory [J]. 吉林大学学报(工学版), 2017, 47(6): 1848-1853. |

| [15] | WANG Sheng-sheng, WANG Chuang-feng, GU Fang-ming. Spatio-temporal reasoning for OPRA direction relation network [J]. 吉林大学学报(工学版), 2017, 47(4): 1238-1243. |

|