Journal of Jilin University(Engineering and Technology Edition) ›› 2019, Vol. 49 ›› Issue (5): 1608-1614.doi: 10.13229/j.cnki.jdxbgxb20180764

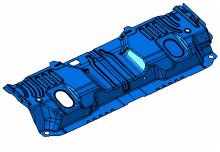

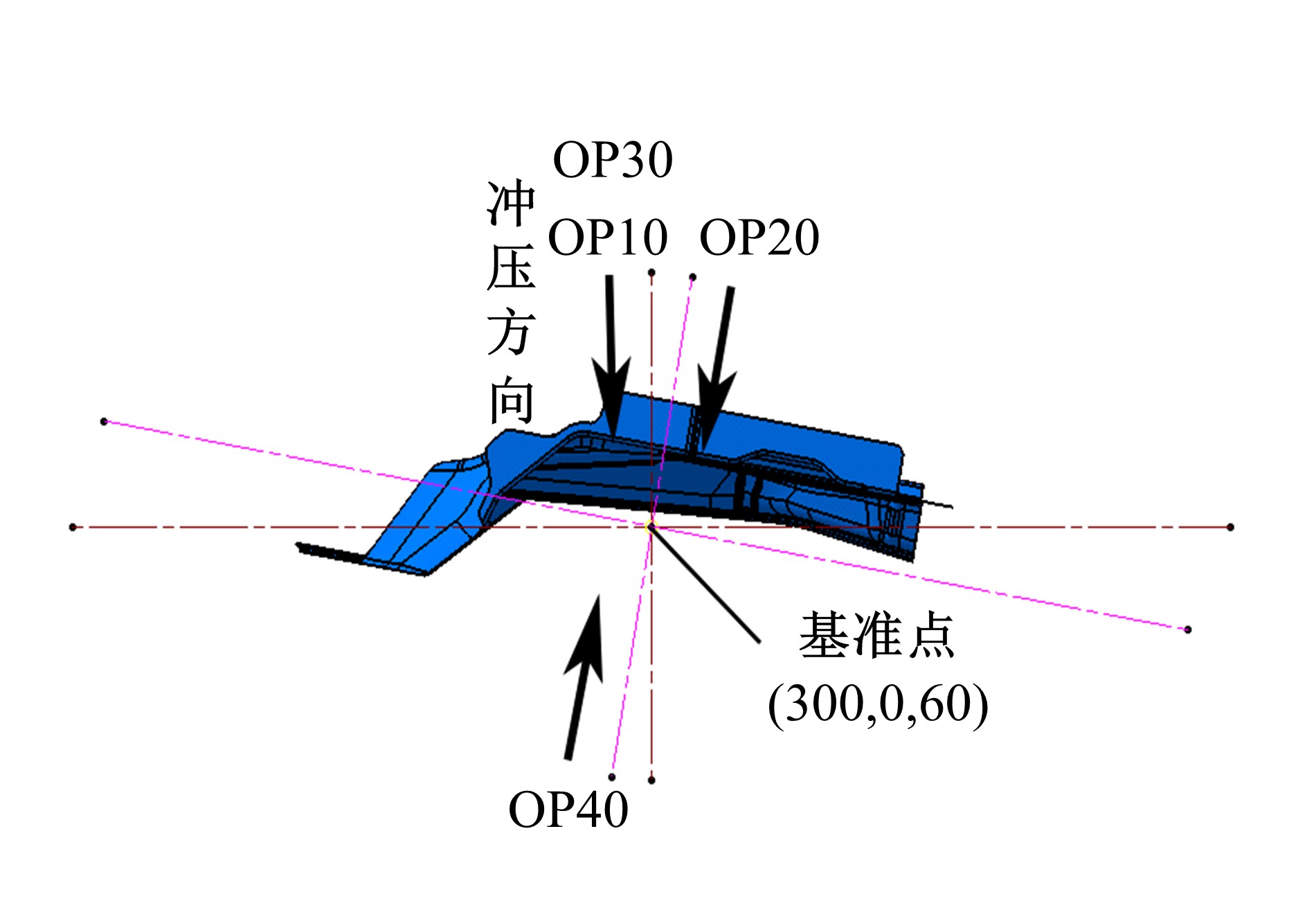

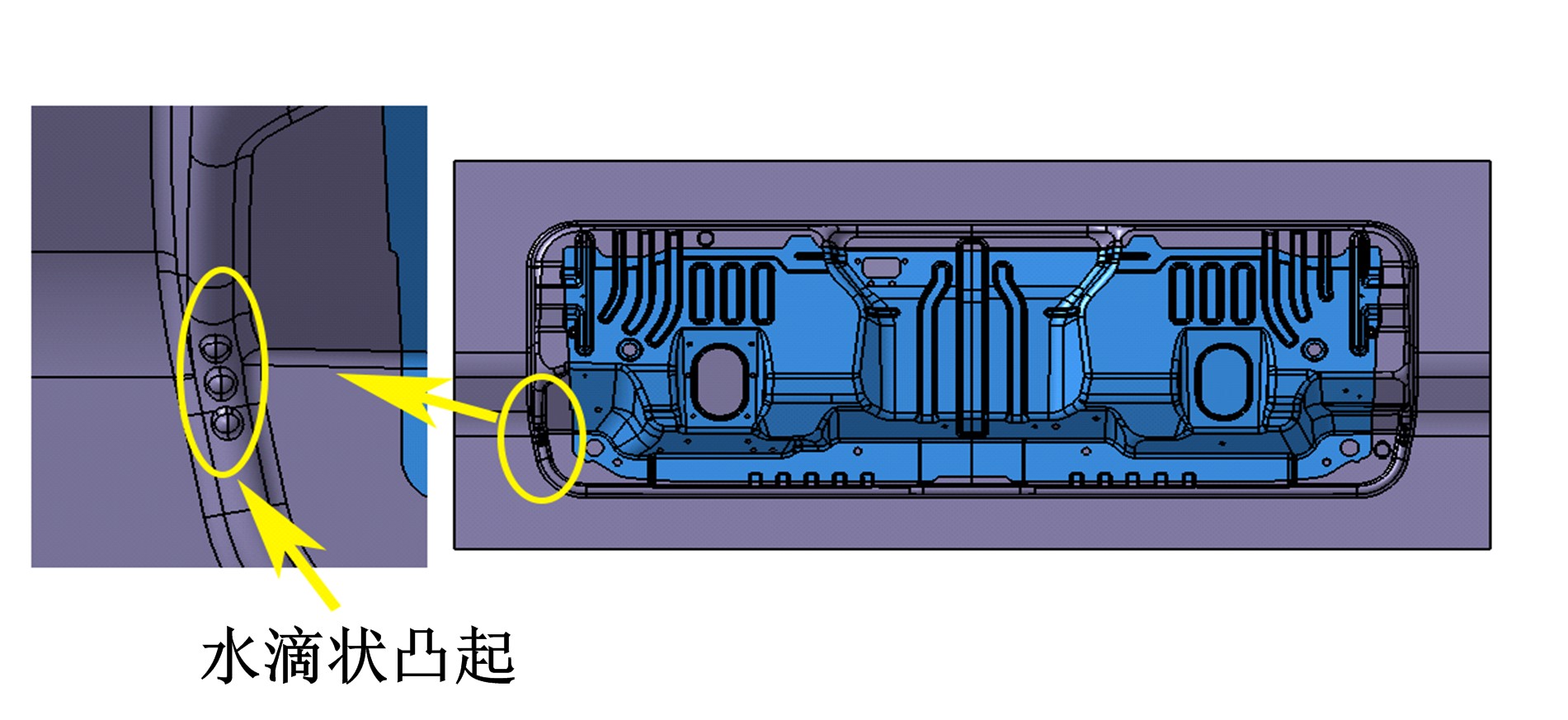

Finite element numerical simulation for automobile front floor forming

Xin LI1( ),Yan-peng SUN1,Dan WANG1,Jun-xu CHEN2,Zheng-wei GU1,Hong XU1

),Yan-peng SUN1,Dan WANG1,Jun-xu CHEN2,Zheng-wei GU1,Hong XU1

- 1. College of Materials Science and Engineering, Jilin University, Changchun 130022, China

2. FAW Jiefang Automobile Company Limited, Qingdao 266000, China

CLC Number:

- TG386

| 1 | 谢晖, 成艾国, 杨旭静, 等. CAE技术在汽车翼子板拉延模具设计中的应用[J]. 汽车工程, 2003, 25(6): 630-633. |

| XieHui, ChengAi-guo, YangXu-jing, et al. A study on the application of CAE to the design of drawing die for front fender[J]. Automotive Engineering, 2003, 25(6): 630-633. | |

| 2 | 徐金波, 董湘怀. 基于有限元分析的汽车覆盖件模具设计及优化[J]. 锻压技术, 2004, 29(1): 63-67. |

| XuJin-bo, DongXiang-huai. Design and optimization of the process and dies for the antomobile body panel based on finite element analysis[J]. Forging & Stamping Technology, 2004, 29(1): 63-67. | |

| 3 | KawkaM, OlejnikL, RosochowskiA, et al. Simulation of wrinkling in sheet metal forming[J]. Journal of Materials Processing Technology, 2001, 109(3): 283-289. |

| 4 | 刘志卫, 李明哲, 韩奇钢. 具有防皱功能的多点成形工艺数值模拟[J]. 吉林大学学报: 工学版, 2012, 42(5): 1208-1213. |

| LiuZhi-wei, LiMing-zhe, HanQi-gang. Numerical simulation on multi-point sheet metal forming with wrinkle resistance function[J]. Journal of Jinlin University (Engineering and Technology Edition), 2012, 42(5): 1208-1213. | |

| 5 | 关来德. 汽车侧围外板A柱拐角起皱的分析及解决方案[J]. 锻压技术, 2017, 42(4): 50-54. |

| GuanLai-de. Analysis and solution on corner wrinkling of side panel A column for automobile[J]. Forging & Stamping Technology, 2017, 42(4): 50-54. | |

| 6 | 廖代辉, 成艾国, 钟志华, 等. 驾驶室车门内板拉延成形分析及其工程应用[J]. 湖南大学学报: 自然科学版, 2006, 33(3): 63-66. |

| LiaoDai-hui, ChengAi-guo, ZhongZhi-hua, et al. The drawing formality analysis of cab inside door and its application[J]. Journal of Hunan University (Natural Sciences), 2006, 33(3): 63-66. | |

| 7 | 胡丽, 李欣, 程万军, 等. 基于Autoform的轿车左B柱内上板冲压成形模拟研究[J]. 模具工业, 2015, 41(11): 19-22, 26. |

| HuLi, LiXin, ChengWan-jun, et al. Autoform-based stamping simulation study on the upper inner plate of automotive left column B[J]. Die & Mould Industry, 2015, 41(11): 19-22, 26. | |

| 8 | 谷诤巍, 吕萌萌, 张文学, 等. 中国标准动车组前端三维蒙皮件冲压成形[J]. 吉林大学学报: 工学版, 2017, 47(3): 869-875. |

| GuZheng-wei, Meng-mengLyu , ZhangWen-xue, et al. Stamping of front-end three-dimensional skin of China electric multiple units[J]. Journal of Jinlin University (Engineering and Technology Edition), 2017, 47(3): 869-875. | |

| 9 | 邱晓刚, 黄跃东. 汽车顶盖零件冲压成形的数值模拟研究[J]. 锻压技术, 2009, 34(4): 148-152. |

| QiuXiao-gang, HuangYue-dong. Study on numerical simulation of automobile covering part stamping process[J]. Forging & Stamping Technology, 2009, 34(4): 148-152. | |

| 10 | 陈军绪, 兰明, 邹飞. 深U形覆盖件冲压工艺设计及CAE技术的应用[J]. 金属加工: 热加工, 2017(13): 32-35. |

| ChenJun-xu, LanMing, ZouFei. Stamping process design of deep U-shaped cover and application of CAE technology[J]. Metal Forming (Stamping Edition), 2017(13): 32-35. |

| [1] | Zhuo YI,Wen-zhi FU,Ming-zhe LI. Numerical simulation and experiment on double⁃layered split ultrahigh pressure die [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(5): 1593-1599. |

| [2] | Hua ZHOU,Zhi⁃gang YANG,Hui ZHU. Aerodynamic calculation of MIRA model correlated with wind tunnel test [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1043-1053. |

| [3] | Zhao⁃wei QU,Zhao⁃tian PAN,Yong⁃heng CHEN,Peng⁃fei TAO,Di SUN. Car⁃following model with improving safety distance based on optimal velocity model [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1092-1099. |

| [4] | Xin LI,Dan WANG,Jun⁃xu CHEN,Yan⁃peng SUN,Zheng⁃wei GU,Hong XU. Numerical simulation for handbrake fixed plate forming [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1258-1265. |

| [5] | Wen⁃quan LIU,Liang YING,Hai RONG,Ping HU. Forming limit prediction of high strength steel based on damage modified M⁃K model [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1266-1271. |

| [6] | Xue⁃guang ZHANG,Ming⁃meng JIA,Chun⁃guo LIU,Guang⁃zhong HE. Trajectory design and FE simulation for profile stretch bending based on incremental control method [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(4): 1272-1279. |

| [7] | Xiao⁃qin ZHOU,Lu YANG,Lei ZHANG,Li⁃jun CHEN. Finite element analysis of hinging octahedron structure withnegative compressibility [J]. Journal of Jilin University(Engineering and Technology Edition), 2019, 49(3): 865-871. |

| [8] | BI Qiu-shi,WANG Guo-qiang,HUANG Ting-ting,MAO Rui,LU Yan-peng. Tooth strength analysis of mineral sizer by coupling discrete element method and finite element method [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(6): 1770-1776. |

| [9] | GUO Hao-tian,XU Tao,LIANG Xiao,YU Zheng-lei,LIU Huan,MA Long. Optimization on thermal surface with rib turbulator inspired by turbulence of alopias' gill in simplified gas turbine transition piece [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(6): 1793-1798. |

| [10] | JIANG Qiu-yue,YANG Hai-feng,TAN Cai-wang. Strengthening properties of welded joints of 22MnB5 super high strength steel [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(6): 1806-1810. |

| [11] | GONG Ya-feng, WANG Bo, WEI Hai-bin, HE Zi-heng, HE Yu-long, SHEN Yang-fan. Surface subsidence law of double-line shield tunnel based on Peck formula [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(5): 1411-1417. |

| [12] | HU Zhi-qing, YAN Ting-xu, LI Hong-jie, LYU Zhen-hua, LIAO Wei, LIU Geng. Effect of cryogenic treatment on punch-shearing performance of aluminum alloy sheet [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(5): 1524-1530. |

| [13] | QIU Yan-kai, LI Bao-ren, YANG Gang, CAO Bo, LIU Zhen. Characteristics and mechanism reducing pressure ripple of hydraulic system with novel hydraulic muffler [J]. 吉林大学学报(工学版), 2018, 48(4): 1085-1091. |

| [14] | QIU Xiao-ming, WANG Yin-xue, YAO Han-wei, FANG Xue-qing, XING Fei. Multi-objective optimization of resistance spot welding parameters for DP1180/DP590 using grey relational analysis based Taguchi [J]. 吉林大学学报(工学版), 2018, 48(4): 1147-1152. |

| [15] | CHEN Jun-fu, GUAN Zhi-ping, YANG Chang-hai, NIU Xiao-ling, JIANG Zhen-tao, Song Yu-quan. Comparison of strain ranges and mechanical properties of metal rods under tension and torsion tests [J]. 吉林大学学报(工学版), 2018, 48(4): 1153-1160. |

|

||