Journal of Jilin University(Engineering and Technology Edition) ›› 2019, Vol. 49 ›› Issue (3): 829-835.doi: 10.13229/j.cnki.jdxbgxb20180419

Previous Articles Next Articles

Scratch resistance of aluminum automotive coatings based on continuum damage mechanics

Wei⁃min ZHUANG1( ),Peng⁃yue WANG1,Dong⁃xuan XIE2,Yan⁃hong CHEN3

),Peng⁃yue WANG1,Dong⁃xuan XIE2,Yan⁃hong CHEN3

- 1. State Key Laboratory of Automotive Simulation and Control, Jilin University, Changchun 130022, China

2. FAW?Volkswagen Automotive Co. , Ltd. , Changchun 130011, China

3. Department of Aeronautics,Imperial College,London SW7 2AZ 1, England

CLC Number:

- TQ630.7

| 1 | ChristopherS, NieteringK, NicholsM. An overview of the scratch resistance of automotive coatings: exterior clearcoats and polycarbonate hardcoats[J]. Coatings,2012,2(4):221⁃234. |

| 2 | BrowningR, SueH J, MinkwitzR, et al. Effects of acrylonitrile content and molecular weight on the scratch behavior of styrene⁃acrylonitrile random copolymers[J]. Polymer Engineering & Science,2011,51(11):2282⁃2294. |

| 3 | HainsworthS, KilgallonP. Temperature variant scratch deformation response of automotive paint systems[J]. Progress in Organic Coatings,2008,62(9): |

| 21⁃27. | |

| 4 | InabaH. Applications of numerical analysis to the evaluation of scratch resistance for automotive clear coatings[J]. Pigments Paints & Printing Inks,2010,83(11):449⁃457. |

| 5 | FelderE, BucailleJ L, HochstetterG. Influence of the rheology of polymers on their scratch resistance: Experimental and numerical simulation studies[J]. Annales de Chimie Science des Matériaux,2011,28(3):15⁃28. |

| 6 | 庄蔚敏,陈延红. 基于连续损伤力学的表面涂层损伤模拟[J]. 吉林大学学报:工学版,2012,42(4):857⁃862. |

| ZhuangWei⁃min,ChenYan⁃hong. Research on the failure of surface coatings based on continuum damage mechanics[J]. Journal of Jilin University(Engineering and Technology Edition),2012,42(4):857⁃862. | |

| 7 | LemaitreJ. Engineering Damage Mechanics[M]. Berlin: Springer Berlin Heidelberg,2010. |

| 8 | LinJ, HavhurstD, DysonB. A new design of uniaxial testpiece with slit extensometer ridges for improved accuracy of strain measurement[J]. International Journal of Mechnical Sciences,1993,35(1):63⁃78. |

| 9 | LinJ, LiuY, FarrugiaD, et al. Development of dislocation based⁃unified material model for simulating microstructure evolution in multipass hot rolling[J]. Philosophical Magazine A,2005,85(18):1967⁃1987. |

| 10 | LiB, LinJ, YaoX. A novel evolutionary algorithm for determining unified creep damage constitutive equations[J]. International Journal of Mechanical Sciences,2002,44(2): 987⁃1002. |

| 11 | CaoJ, LinJ. A study on formulation of objective functions for determining material models[J]. International Journal of Mechanical Sciences,2008,50(7):193⁃204. |

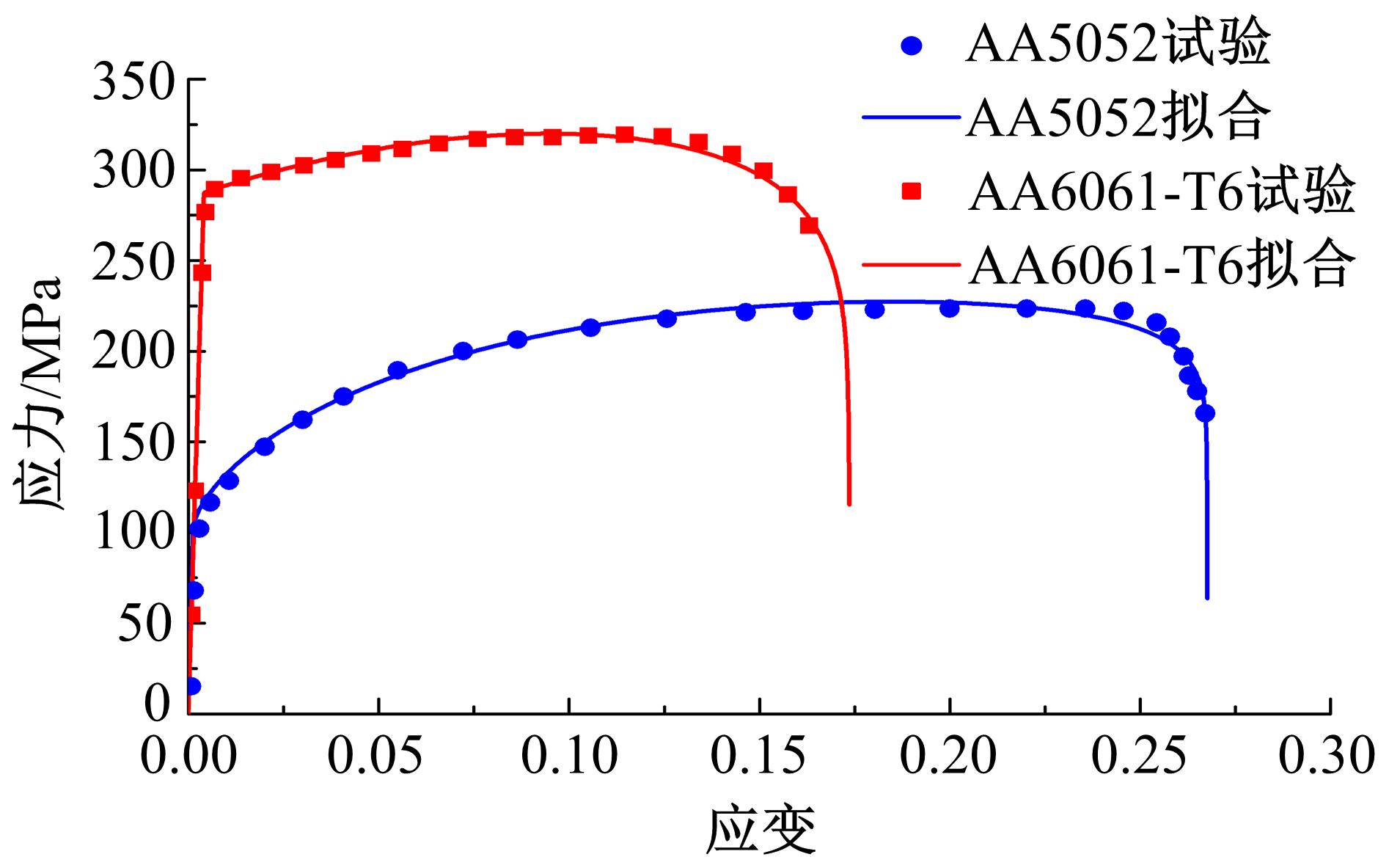

| 12 | 刘大海,于海平,李春峰,等. AA5052板材准静态/动态平面应变成形极限实验研究[J]. 材料科学与工艺,2009,17(5):593⁃596. |

| LiuDa⁃hai, YuHai⁃ping, LiChun⁃feng, et al. Experimental investigation on forming limits of AA5052 sheet in hybrid quasi⁃static/dynamic plane⁃strain tensile process[J]. Materials Science and Technology,2009,17(5):593⁃596. | |

| 13 | AminiK, AltenhofW, YuenS C K, et al. Experimental and numerical investigation on the deformation and energy dissipation of AA6061⁃T6 circular extrusion subjected to blast loading[J]. International Journal of Impact Engineering,2017,110:228⁃241. |

| 14 | 罗正怡. 汽车涂层力学性能测试及分析[D]. 成都:西南交通大学力学与工程学院,2009. |

| LuoZheng⁃yi. Testing and analysis of mechanical properties for automotive coatings[D]. Chengdu:School of Mechanics and Engineering,Southwest Jiaotong University,2009. |

| No related articles found! |

|