Journal of Jilin University(Engineering and Technology Edition) ›› 2019, Vol. 49 ›› Issue (3): 822-828.doi: 10.13229/j.cnki.jdxbgxb20180210

Previous Articles Next Articles

Effect of hygrothermal environment on vehicle adhesive tensile strength

Jing⁃xin NA1( ),Hao⁃lei LIU1,Yi⁃sa FAN2(

),Hao⁃lei LIU1,Yi⁃sa FAN2( ),Guo⁃feng QIN1,Lei⁃xin PU1

),Guo⁃feng QIN1,Lei⁃xin PU1

- 1. State Key Laboratory of Vehicle Simulation and Control,Jilin University,Changchun 130022,China

2. School of Mechanical Engineering, North China University of Water Resources and Electric Power, Zhengzhou 450045,China

CLC Number:

- TG14

| 1 | 曲凌夫. 汽车与环境污染[J]. 生态经济:中文版,2010(7):146⁃149. |

| QuLing⁃fu. Automobile and environmental pollution[J]. Ecological Economy,2010(7):146⁃149. | |

| 2 | KorichoE G, BelingardiG. An experimental and finite element study of the transverse bending behaviour of CFRP composite T⁃joints in vehicle structures[J]. Composites Part B,2015,79(1):430⁃443. |

| 3 | 冯美斌. 汽车轻量化技术中新材料的发展及应用[J]. 汽车工程,2006,28(3):213⁃220. |

| FengMei⁃bin. Development and applications of new materials in automotive lightweighting technologies[J]. Automotive Engineering,2006,28(3):213⁃220. | |

| 4 | 李永兵,李亚庭,楼铭,等. 轿车车身轻量化及其对连接技术的挑战[J]. 机械工程学报,2012,48(18):44⁃54. |

| LiYong⁃bing, LiYa⁃ting, LouMing, et al. Lightweighting of car body and its challenges to joining technologies[J]. Journal of Mechanical Engineering,2012,48(18):44⁃54. | |

| 5 | 曾俊伟. 结构胶在车身安全与轻量化设计中的应用研究[D].长沙:湖南大学机械与运载工程学院,2015. |

| ZengJun⁃wei. Research of structural adhesive’s application in vehicle body safety and lightweight design[D]. Changsha: College of Mechanical and Vehicle Engineering,Hunan University,2015. | |

| 6 | 那景新,贺午阳,张师源,等. 客车粘接式车窗玻璃参数化串联刚度模型[J]. 吉林大学学报:工学版,2017,47(4):1017⁃1023. |

| Najing⁃xin,hewu⁃yang,zhangshi⁃yuan,et al. Parameterization series⁃stiffness model of adhesive bonded bus window[J]. Journal of Jilin University(Engineering and Technology Edition), 2017,47(4):1017⁃1023. | |

| 7 | 那景新,杨丹瑒,郭新宇,等. 粘接式客车侧窗玻璃对客车侧翻性能的影响[J]. 吉林大学学报:工学版,2016,46(4):1052⁃1056. |

| NaJing⁃xin,YangDan⁃yang,GuoXin⁃yu,et al. Effect of side window bounding system on the performance of bus rollover process[J]. Journal of Jilin University(Engineering and Technology Edition), 2017,47(4):1017⁃1023. | |

| 8 | ZhangQ, MclellanB C, TezukaT, et al. A methodology for economic and environmental analysis of electric vehicles withdifferent operational conditions[J]. Energy,2013,61(6):118⁃127. |

| 9 | TianGuang⁃dong, QiangTian⁃gang, ChuJiang⁃wei, et al. Condensation dripping water detection and its control method from exhaust pipe of gasohol vehicle under low environmental temperature conditions: a case study in harbin, China[J]. Advances in Mechanical Engineering,2012(2012):79⁃88. |

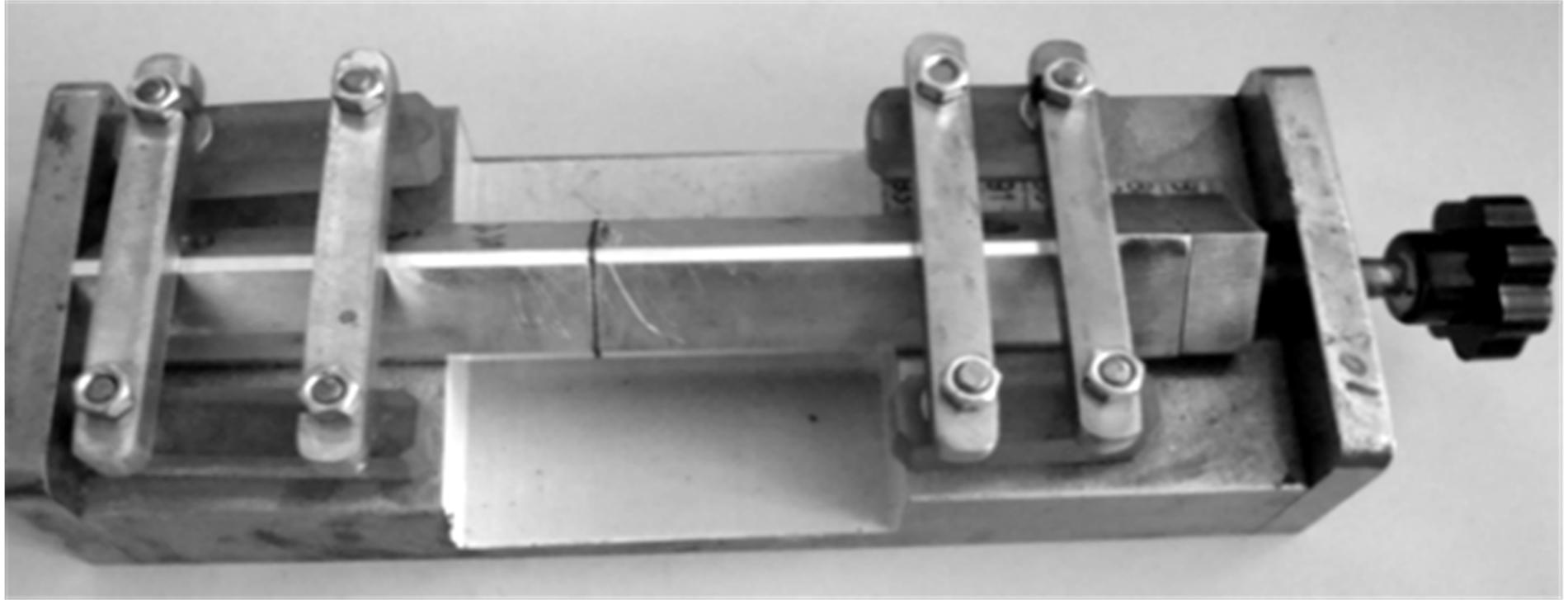

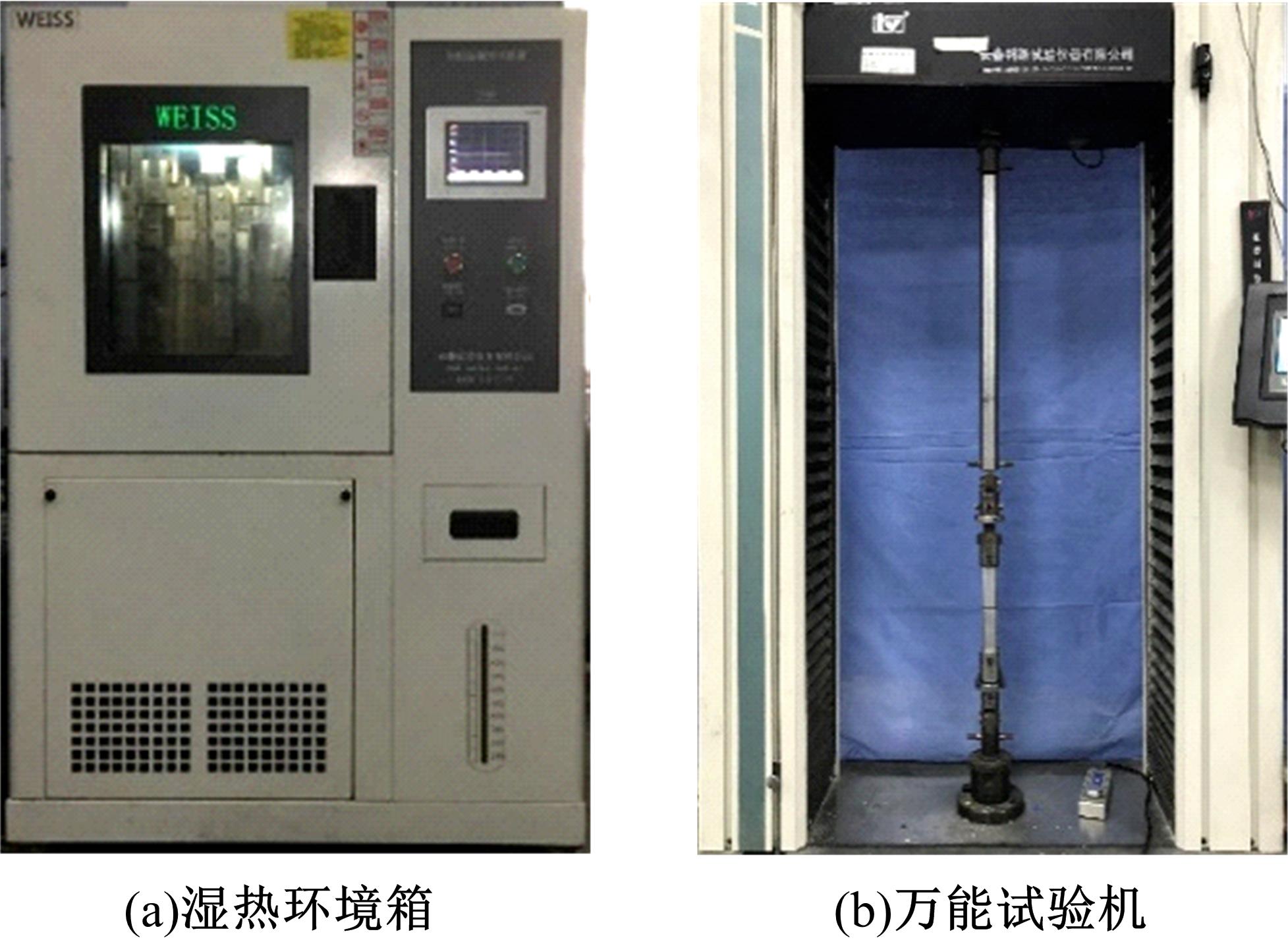

| 10 | TomitaY, ShohjiI, KoyamaS, et al. Effect of high temperature and humidity treatment on adhesion properties and bulk properties of structural adhesive[C]∥International Conference on Electronics Packaging, Yamagata,2017:559⁃562. |

| 11 | HanX, CrocombeA D, AnwarS N R, et al. The effect of a hot wet environment on adhesively bonded joints under a sustained load[J]. Journal of Adhesion,2014,90(5/6):420⁃436. |

| 12 | 姚力,夏勇,周青.车用胶粘接头机械性能的湿热老化与恢复[J]. 汽车安全与节能学报,2017,8(1):46⁃52. |

| YaoLi, XiaYong, ZhouQing. Hygrothermal degradation and recoverability of mechanical properties of epoxy adhesive joints for automotive[J]. Journal of Automotive Safety and Energy,2017,8(1):46⁃52. | |

| 13 | 严志云. 湿热环境对胶粘剂吸水性及其胶接性能的影响研究[D]. 上海:同济大学机械与能源工程学院,2009. |

| YanZhi⁃yun. Study on influence of moisture condition on water absorption of adhesive and adhesive property[D]. Shanghai: School of Mechanical Engineering,Tongji University,2009. | |

| 14 | BaneaM D, SousaF S M D, SilvaL F M D, et al. Effects of temperature and loading rate on the mechanical properties of a high temperature epoxy adhesive[J]. Journal of Adhesion Science & Technology,2011,25(18):2461⁃2474. |

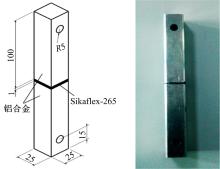

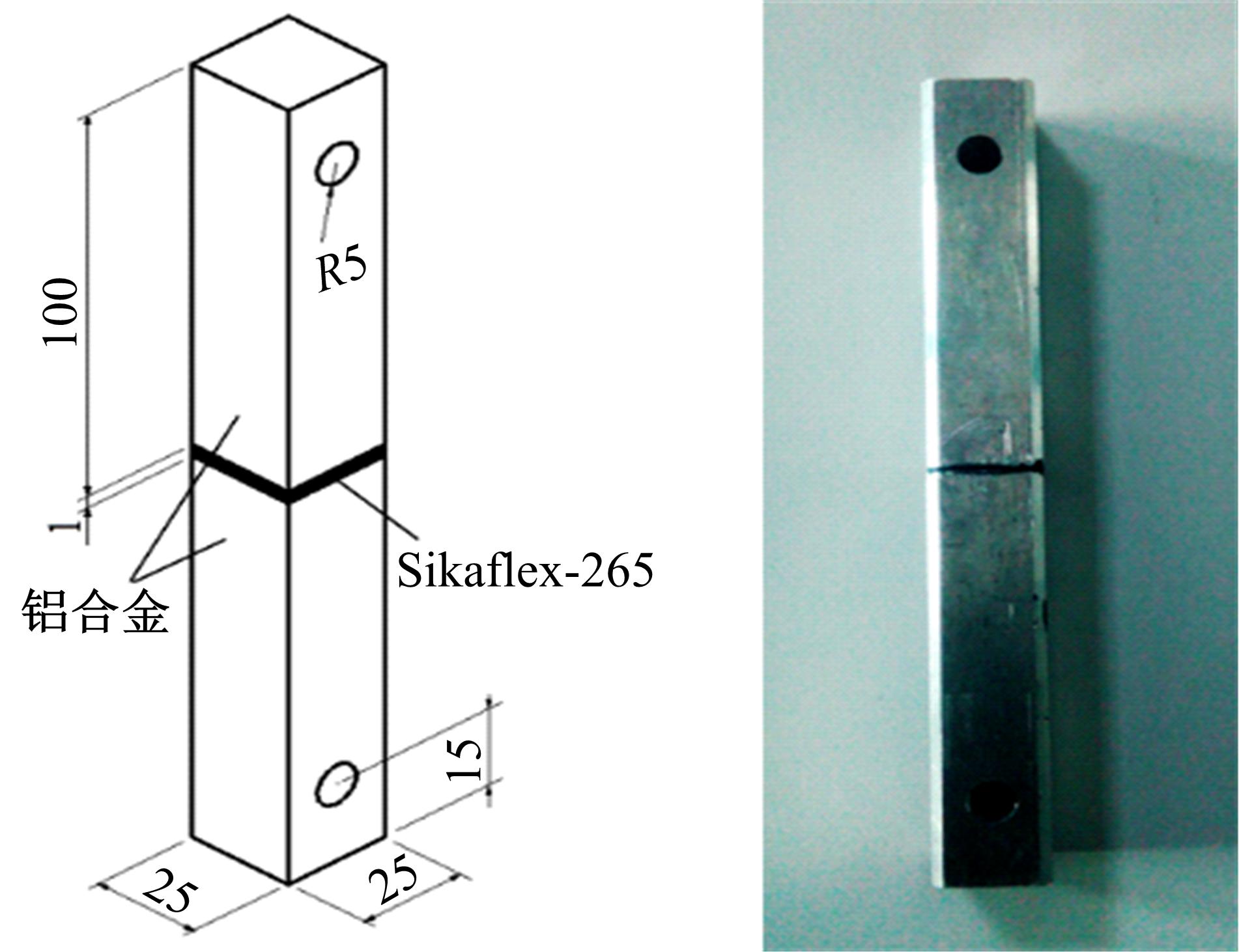

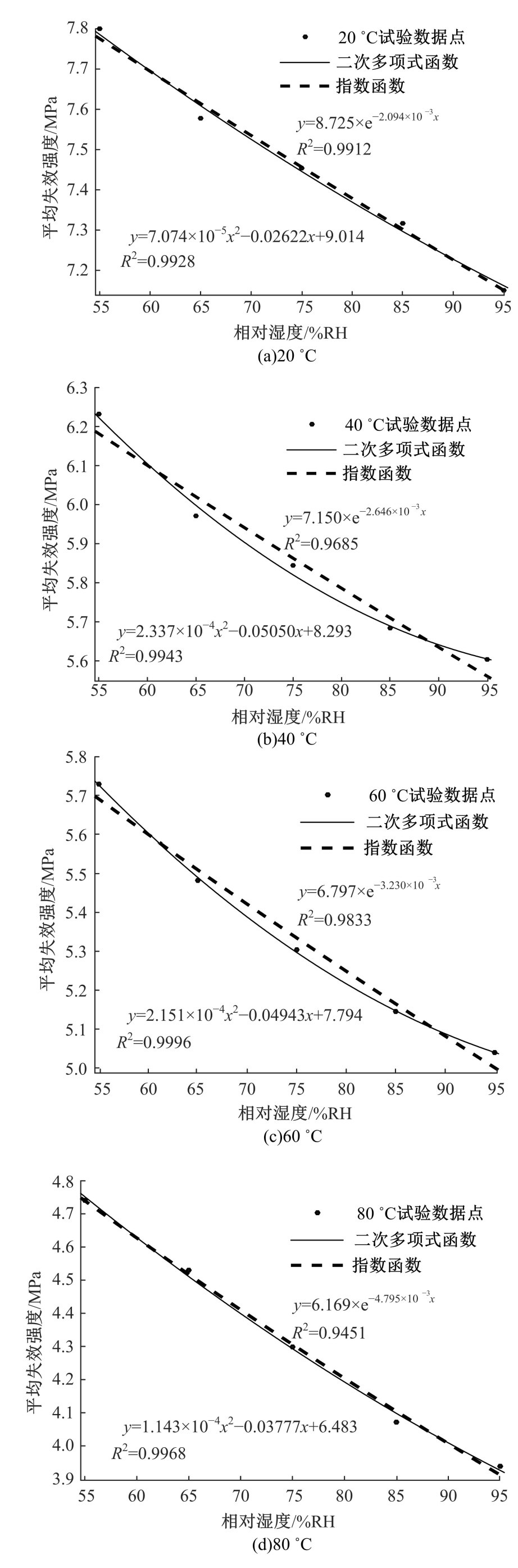

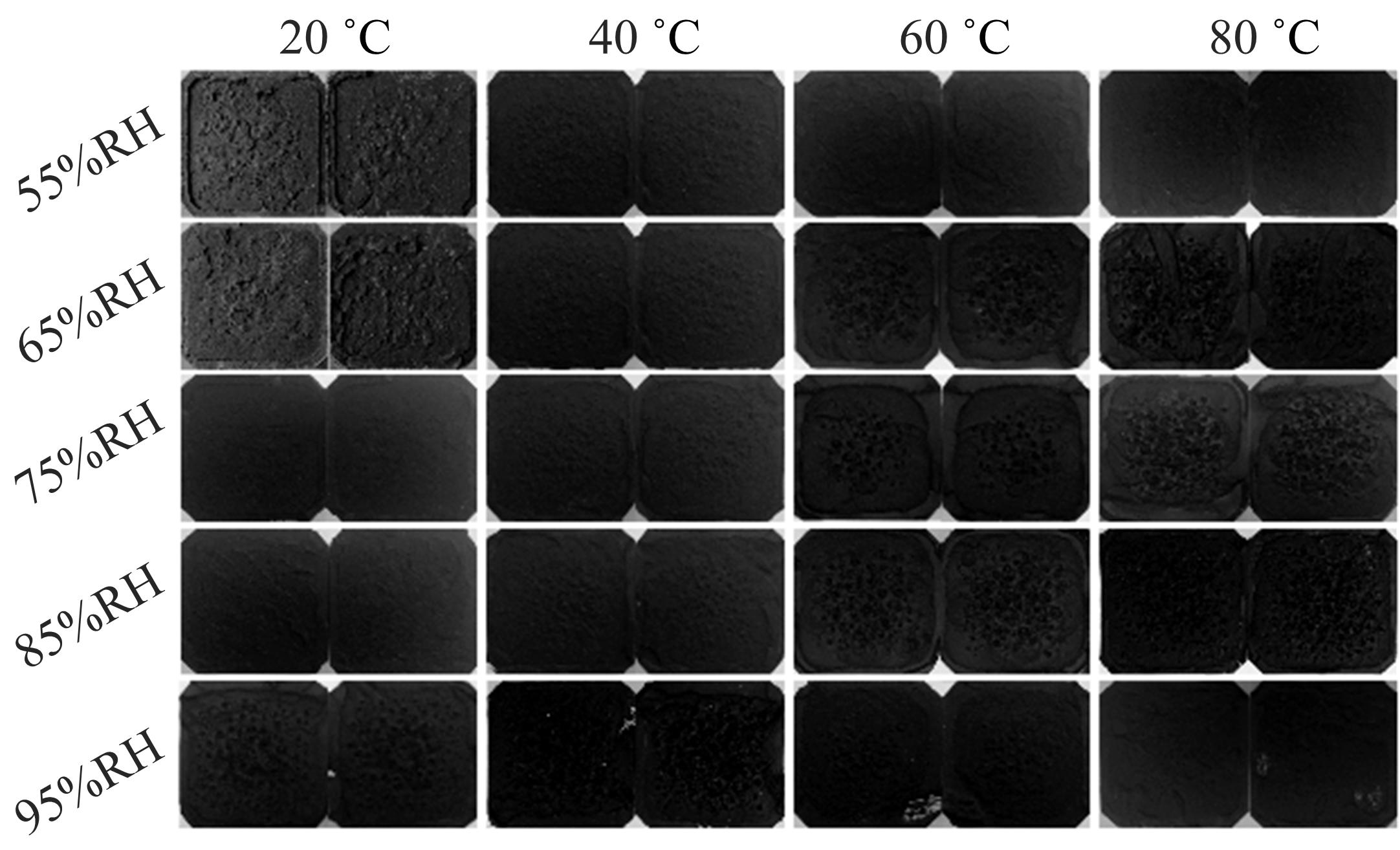

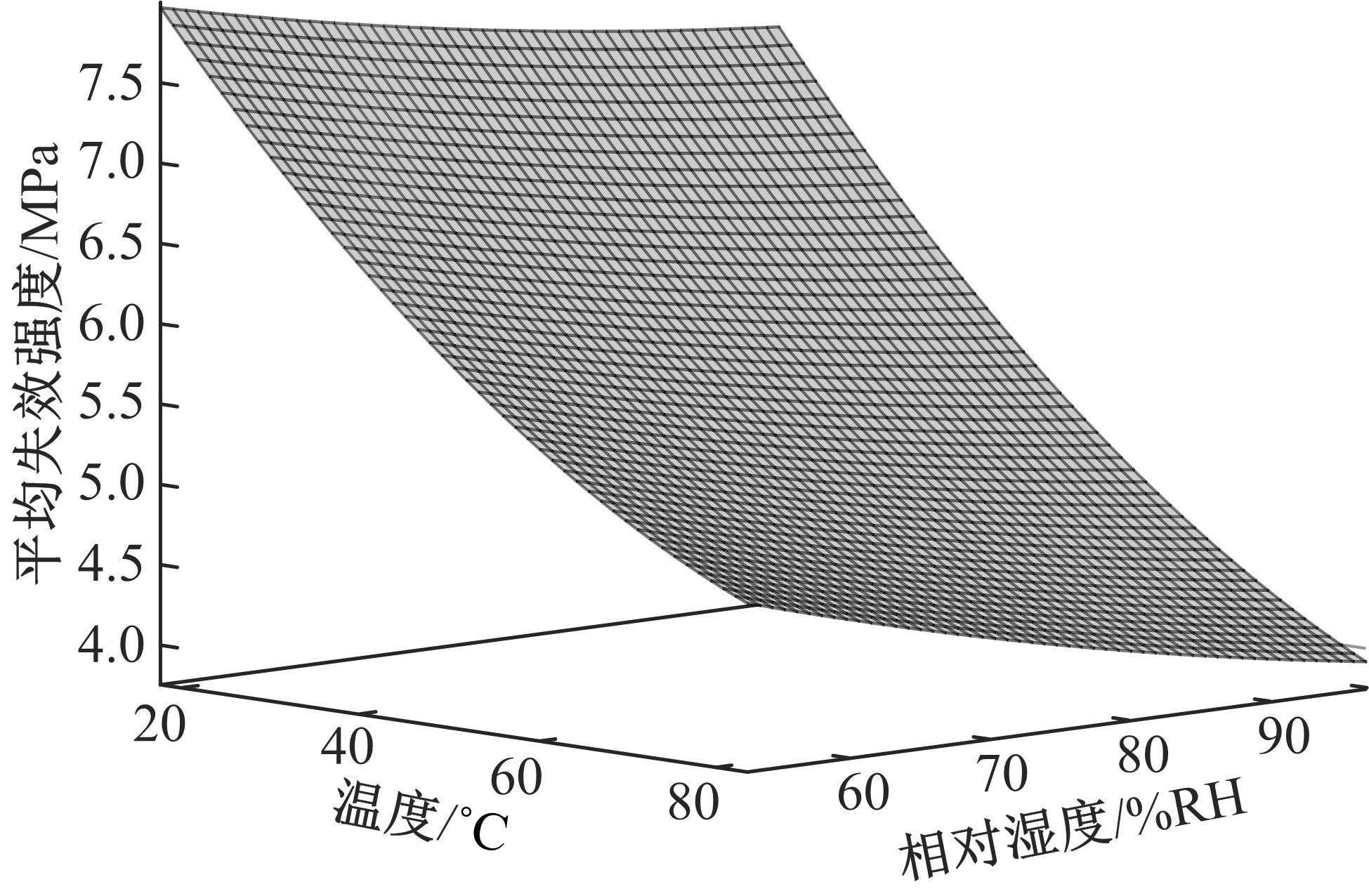

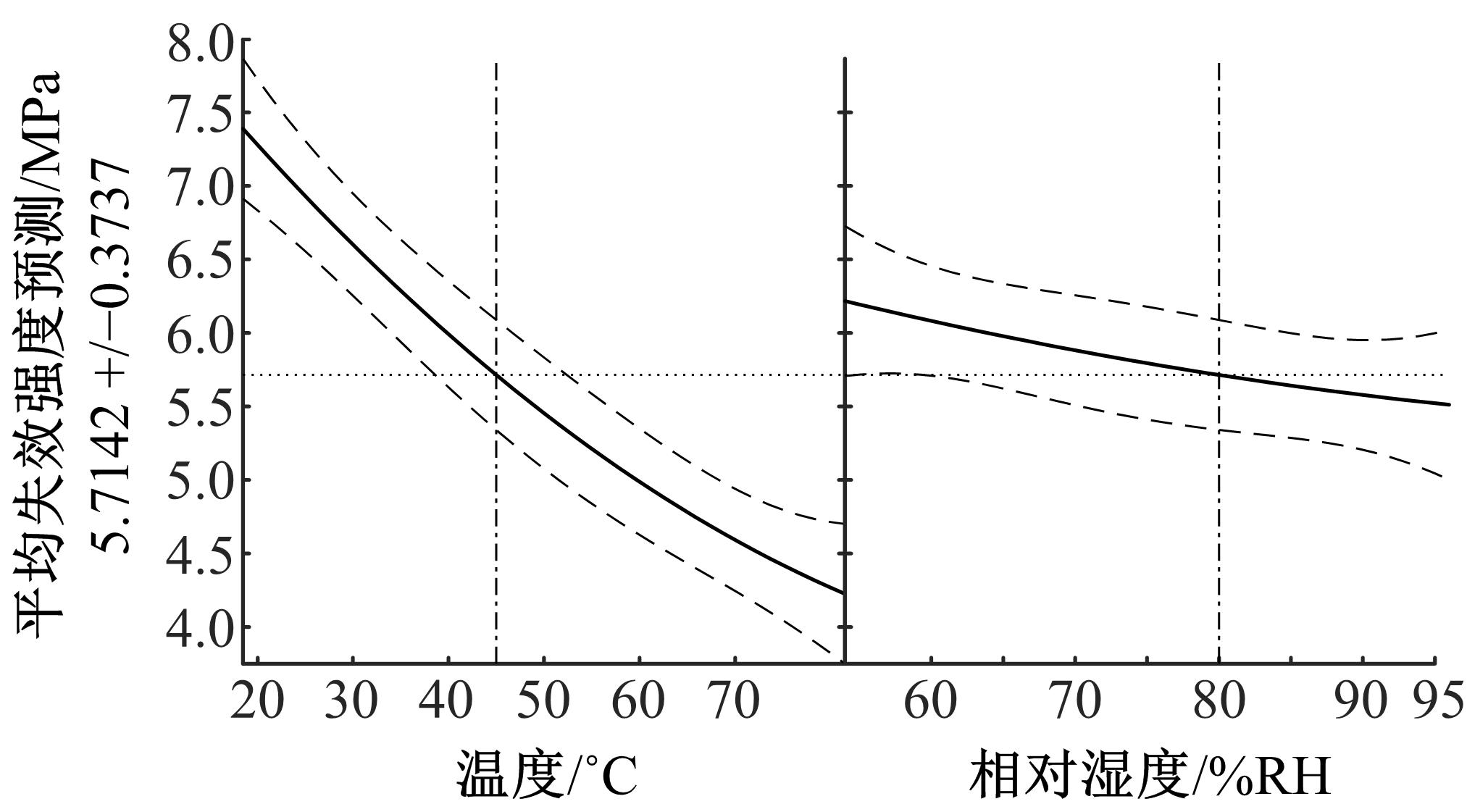

| 15 | 那景新,浦磊鑫,范以撒,等. 湿热环境对Sikaflex⁃265铝合金粘接接头失效强度影响的研究[J]. 吉林大学学报:工学版,2018,48(5):1331⁃1338. |

| NaJing⁃xin, PuLei⁃xin, FanYi⁃sa,et al. Effect of temperature and humidity on the failure strength of Sikaflex⁃265 aluminum adhesive joints[J]. Journal of Jilin University(Engineering and Technology Edition),2018,48(5):1331⁃1338. | |

| 16 | 那景新,慕文龙,范以撒,等. 车身钢⁃铝粘接接头湿热老化性能[J]. 吉林大学学报:工学版,2018,48(6):1653⁃1660. |

| Na Jing⁃xin Mu Wen⁃long Fan Yi⁃sa,et al. Effect of hygrothermal aging on steel⁃aluminum adhesive joints for automotive applications[J]. Journal of Jilin University(Engineering and Technology Edition), 2017,47(4):1017⁃1023. | |

| 17 | 那景新,浦磊鑫,范以撒,等. 湿热环境对Sikaflex⁃265铝合金粘接接头失效强度的影响[J]. 吉林大学学报:工学版,2018,48(5):1331⁃1338. |

| Na Jing⁃xin Pu Lei⁃xin Fan Yi⁃sa,et al. Effect of temperature and humidity on the failure strength of Sikaflex⁃265 aluminum adhesive joints[J]. Journal of Jilin University(Engineering and Technology Edition), 2017,47(4):1017⁃1023. | |

| 18 | 李云雁,胡传荣.试验设计与数据处理[M]. 北京:化学工业出版社,2005. |

| 19 | 任露泉. 试验优化设计与分析[M]. 北京:高等教育出版社,2003. |

| 20 | 司守奎,孙兆亮. 数学建模算法与应用[M]. 2版. 北京:国防工业出版社,2015. |

| 21 | 毛李帆,江岳春,龙瑞华,等. 基于偏最小二乘回归分析的中长期电力负荷预测[J]. 电网技术,2008,32(19):71⁃77. |

| MaoLi⁃fan, JiangYue⁃chun, LongRui⁃hua. Medium⁃ and long⁃term load forecasting based on partial least squares regression analysis[J]. Power System Technology,2008,32(19):71⁃77. |

| [1] | NA Jing-xin,MU Wen-long,FAN Yi-sa,TAN Wei,YANG Jia-zhou. Effect of hygrothermal aging on steel-aluminum adhesive joints for automotive applications [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(6): 1653-1660. |

| [2] | NA Jing-xin, PU Lei-xin, FAN Yi-sa, SHEN Chuan-liang. Effect of temperature and humidity on the failure strength of Sikaflex-265 aluminum adhesive joints [J]. Journal of Jilin University(Engineering and Technology Edition), 2018, 48(5): 1331-1338. |

| [3] | HU Zhi-qing, ZHENG Hui-hui, XU Ya-nan, ZHANG Chun-ling, DANG Ting-ting. Effect of Al surface with micro/macro grooves on Al/CFRP adhesive-bonded joints [J]. 吉林大学学报(工学版), 2018, 48(1): 229-235. |

| [4] | NA Jing-xin, HE Wu-yang, ZHANG Shi-yuan, YUAN Zheng, CHEN Li-jun. Parameterization series-stiffness model of adhesive bonded bus window [J]. 吉林大学学报(工学版), 2017, 47(4): 1017-1023. |

| [5] | LI Chun-liang, WANG Fang-yan, ZHANG Li-hui, WANG Jing. Stress analysis of adhesively bonded single lap joint under eccentric load [J]. 吉林大学学报(工学版), 2016, 46(6): 1874-1880. |

| [6] | LAN Feng-chong, LI Zhong-chao, ZHOU Yun-jiao, CHEN Ji-qing. Stress distribution and strength prediction of aluminum-magnesium alloy adhesive-bonded single-lap joints [J]. 吉林大学学报(工学版), 2015, 45(3): 726-732. |

| [7] | MENG Song-He, GAO Hui-Ting, SUN Li-An, SHI Hong-Jun. Effect of silica fumeslag on performance of polypropylene fiber concrete [J]. 吉林大学学报(工学版), 2010, 40(增刊): 214-0217. |

| [8] | ZHENG Wen-Zhong, WAN Fu-Xiong, LI Shi-Guang. Mechanical performance of reinforced concrete slabs strengthened with CFRP sheets bonded with an inorganic adhesive after fire [J]. 吉林大学学报(工学版), 2010, 40(05): 1244-1249. |

| [9] | YANG Xiao-hong1, ZHANG Kui2,ZHANG Mei-juan1,LUO Ke-shuai1,LIU Yong-bing1 . Microstructure and friction and wear properties of Mg-Y4-Nd3 alloy [J]. 吉林大学学报(工学版), 2008, 38(04): 835-839. |

| [10] | JIN Jing-fu, CONG Qian, YANG Xiao-dong. Freezing Adhesive Characteristics of Engineering Materials and [J]. 吉林大学学报(工学版), 2005, 35(05): 486-0489. |

| [11] | MA Jian-hua . Study on Sealing Adhesive of PVC-Pipes [J]. 吉林大学学报(工学版), 2002, (2): 91-93. |

| [12] | YANG Xiao-dong, CAI Xiong-liang, CONG Qian, REN Lu-quan . Experimental Research on Freezing Adhesive between Mine Car Model and Coal Particles [J]. 吉林大学学报(工学版), 2002, (2): 49-53. |

| [13] | ZHU Xiao-bo, HUANG Xi-chao, ZOU Yi. Simple Calculation & Computer Program of Two-dimensional Impact [J]. 吉林大学学报(工学版), 2001, (2): 91-95. |

|

||