Journal of Jilin University(Engineering and Technology Edition) ›› 2019, Vol. 49 ›› Issue (5): 1636-1643.doi: 10.13229/j.cnki.jdxbgxb20180343

Effect of creep and artificial aging on fatigue crack growth performance of 2524 aluminum alloy

Yi-lun LIU1,2( ),Qing WANG1,Chi LIU1,Song-bai LI1,Jun HE1,Xian-qiong ZHAO1

),Qing WANG1,Chi LIU1,Song-bai LI1,Jun HE1,Xian-qiong ZHAO1

- 1. College of Mechanical and Electrical Engineering, Central South University, Changsha 410083, China

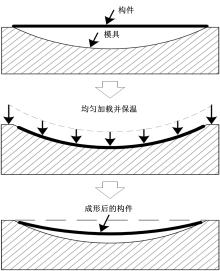

2. Light Alloy Research Institute, Central South University, Changsha 410083, China

CLC Number:

- TG146.2

| 1 | Nakai M , Eto T . New aspects of development of high strength aluminum alloys for aerospace applications[J]. Materials Science and Engineering A, 2000, 285(1-5): 62-68. |

| 2 | Starke E , Staley J T . Application of modern aluminum alloys to aircraft[J]. Progress in Aerospace Sciences, 1996, 32(2): 131-172. |

| 3 | Warner T . Recently-developed aluminium solutions for aerospace applications[J]. Materials Science Forum, 2006(519-521): 1271-1278. |

| 4 | Zeng Y , Huang X . Forming technologies of large integral panel[J]. Acta Aeronautica Et Astronautica Sinica, 2008, 29(3): 721-727. |

| 5 | Zhan L , Lin J , Dean T A . A review of the development of creep age forming: experimentation, modelling and applications[J]. International Journal of Machine Tools & Manufacture, 2011, 51(1): 1-17. |

| 6 | Jeunechamps P P , Ho K C , Lin J , et al . A closed form technique to predict springback in creep age-forming[J]. International Journal of Mechanical Sciences, 2006, 48(6): 621-629. |

| 7 | Zhan L , Lin J , Dean T A , et al . Experimental studies and constitutive modelling of the hardening of aluminium alloy 7055 under creep age forming conditions[J]. International Journal of Mechanical Sciences, 2011, 53(8): 595-605. |

| 8 | Zhang J , Zhang S N , Liang E W . Blazar Anti-Sequence of spectral variation within individual blazars: cases for Mrk 501 and 3C 279[J]. The Astrophysical Journal, 2013(767): 1-7. |

| 9 | Jeshvaghani R A , Zohdi H , Shahverdi H R , et al . Influence of multi-step heat treatments in creep age forming of 7075 aluminum alloy: optimization for springback, strength and exfoliation corrosion[J]. Materials Characterization, 2012, 73(11): 8-15. |

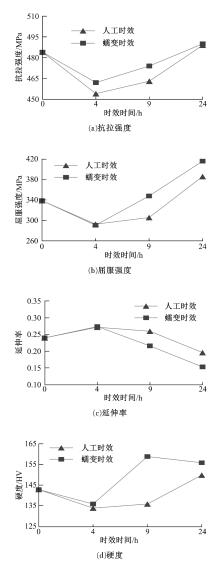

| 10 | Xu Y , Zhan L , Li W . Effect of pre-strain on creep aging behavior of 2524 aluminum alloy[J]. Journal of Alloys & Compounds, 2017, 691: 564-571. |

| 11 | Yin D , Liu H , Chen Y , et al . Effect of grain size on fatigue-crack growth in 2524 aluminium alloy[J]. International Journal of Fatigue, 2016, 84: 9-16. |

| 12 | Srivatsan T S , Kolar D , Magnusen P . The cyclic fatigue and final fracture behavior of aluminum alloy 2524[J]. Materials & Design, 2002, 23(2): 129-139. |

| 13 | Baptista C A R P , Adib A M L , Torres S , et al . Describing fatigue crack growth and load ratio effects in Al 2524 T3 alloy with an enhanced exponential model[J]. Mechanics of Materials, 2012, 51: 66-73. |

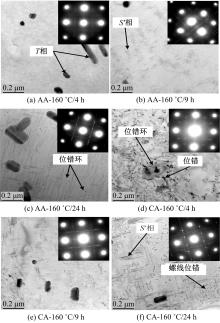

| 14 | Shih H C , Ho N J , Huang J C . Precipitation behaviors in Al-Cu-Mg and 2024 aluminum alloys[J]. Metallurgical & Materials Transactions A, 1996, 27(9): 2479-2494. |

| 15 | Bagaryatsky Y A . Structural changes on aging Al-Cu-Mg alloys[J]. Doklady Akademii nauk SSSR, 1952, 87(3): 397-559. |

| 16 | Chen Y Q , Yi D Q , Jiang Y , et al . Twinning and orientation relationships of T-phase precipitates in an Al matrix[J]. Journal of Materials Science, 2013, 48(8): 3225-3231. |

| 17 | Chen Z , Chen P , Li S . Effect of Ce addition on microstructure of Al20Cu2Mn3 twin phase in an Al-Cu-Mn casting alloy[J]. Materials Science & Engineering A, 2012, 532: 606-609. |

| 18 | 刘义伦, 羿九火, 杨大炼, 等 . 固溶温度对7075铝合金组织及高周疲劳性能的影响[J]. 金属热处理, 2016, 41(3): 1-7. |

| Liu Yi-lun , Yi Jiu-huo , Yang Da-lian , et al . Effects of solution treatment on microstructure and high cycle fatigue properties of 7075 aluminum alloy[J]. Heat Treatment of Metals, 2016, 41(3): 1-7. | |

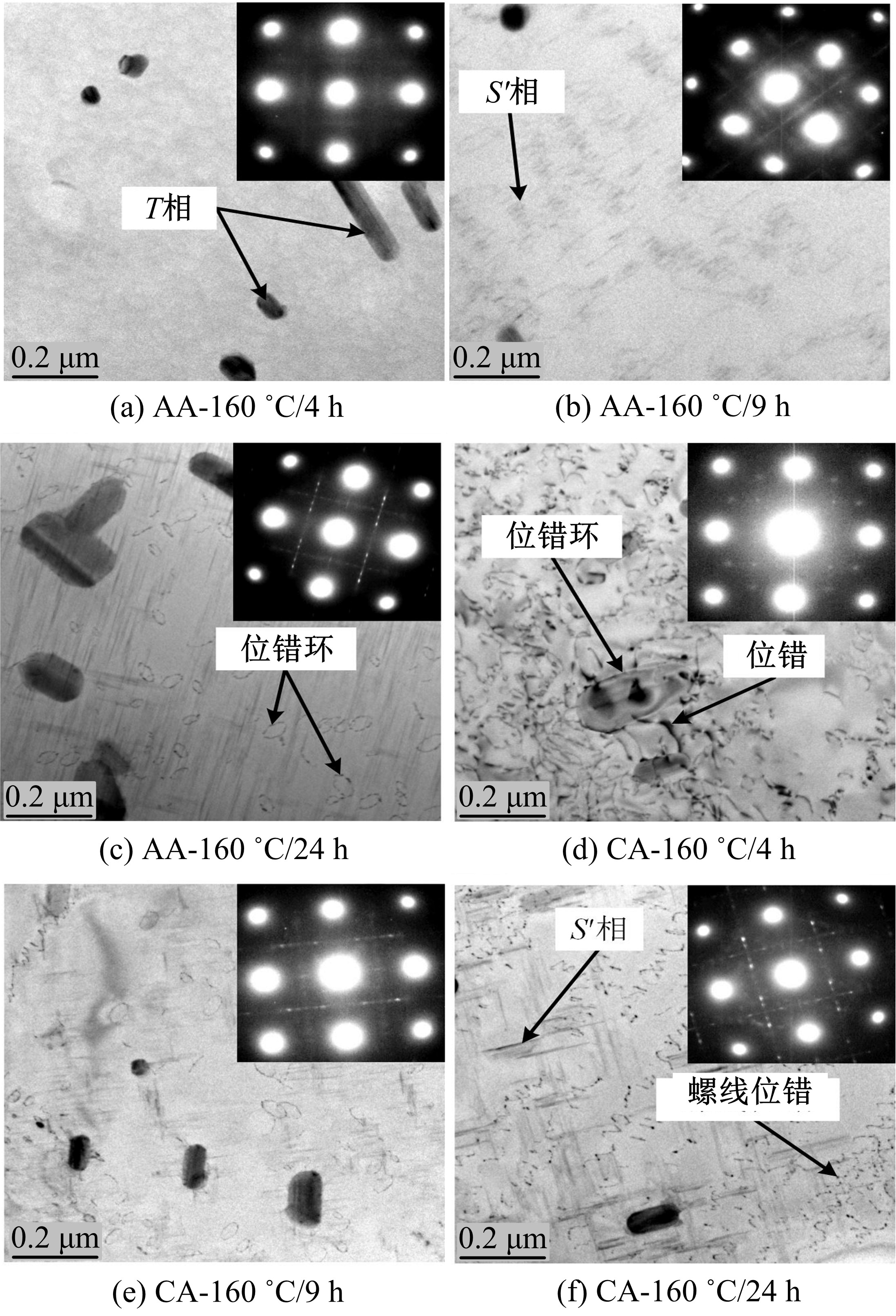

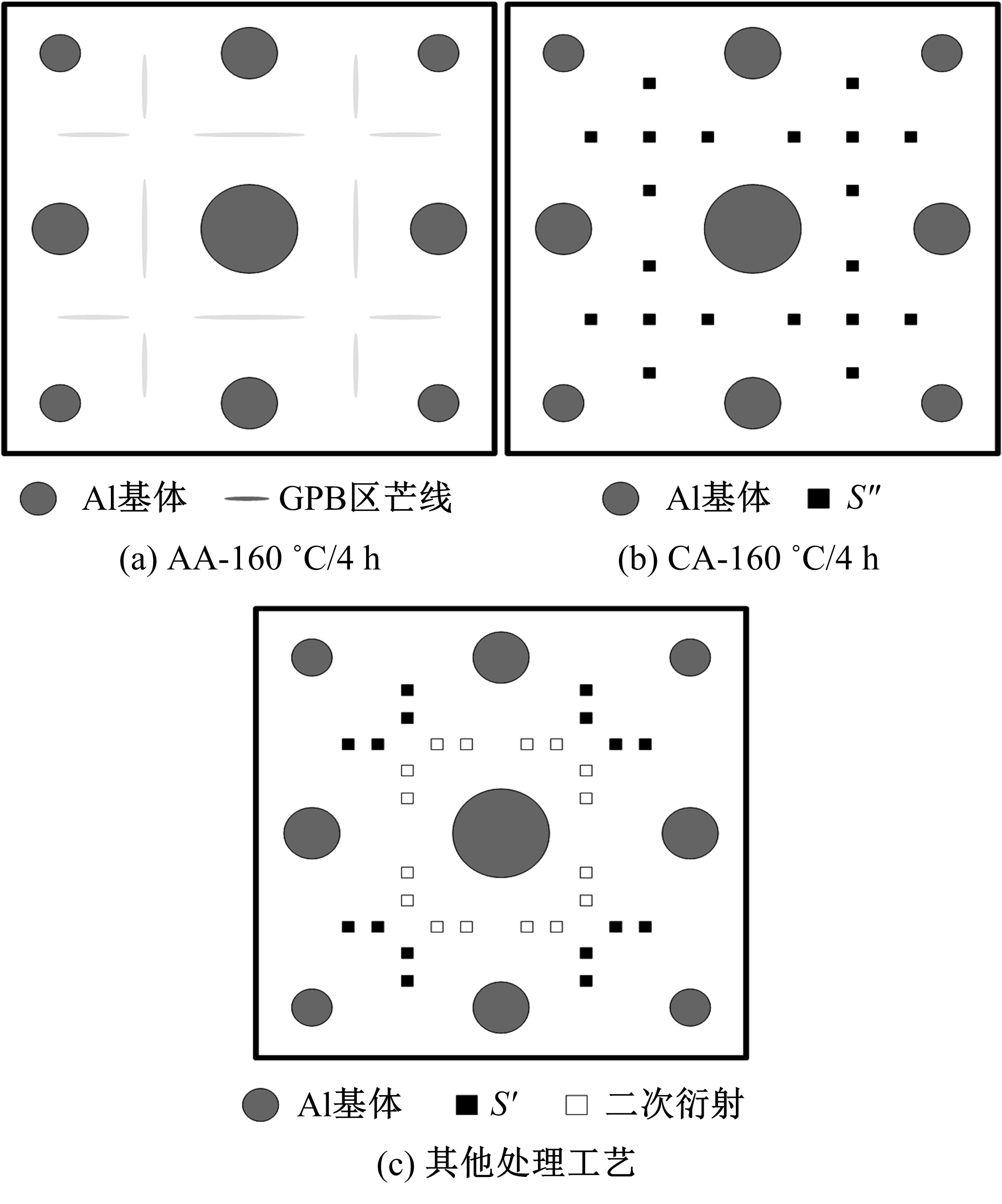

| 19 | 陈宇强, 潘素平, 刘文辉, 等 . 析出相对Al-Cu-Mg合金蠕变行为的影响[J]. 中国有色金属学报, 2015, 25(4): 900-909. |

| Chen Yu-qiang , Pan Su-ping , Liu Wen-hui , et al . Effect of precipitates on creep behaviors of Al-Cu-Mg alloy [J]. The Chinese Journal of Nonferrous Metals, 2015, 25(4): 900-909. | |

| 20 | Ringer S P , Sakurai T , Polmear I J . Origins of hardening in aged Al-Cu-Mg-(Ag) alloys[J]. Acta Materialia, 1997, 45(9): 3731-3744. |

| 21 | 湛利华, 李炎光, 黄明辉 . 应力作用下2124合金蠕变时效的组织与性能[J]. 中南大学学报:自然科学版, 2012, 43(3): 926-931. |

| Zhan Li-hua , Li Yan-guang , Huang Ming-hui . Microstructures and properties of 2124 alloy creep ageing under stress[J]. Journal of Central South University (Science and Technology), 2012, 43(3): 926-931. | |

| 22 | 汤华国, 马贤锋, 赵伟, 等 . 高性能金属铝的制备、微观结构及其热稳定性[J]. 吉林大学学报: 工学版, 2017, 47(5): 1542-1547. |

| Tang Hua-guo , Ma Xian-feng , Zhao Wei , et al . Synthesis microstructure and thermal properties of high performance bulk Al[J]. Journal of Jilin University (Engineering and Technology Edition), 2017, 47(5): 1542-1547. | |

| 23 | 杨悦, 陈彬 . SiC纳米颗粒对6060型铝合金微弧氧化膜组织结构及耐蚀性能的影响[J]. 吉林大学学报: 工学版, 2011, 41(增刊1): 106-110. |

| Yang Yue , Chen Bin . Effects of SiC nano-particles on microstructure and the corrosion resistance of micro-arc oxidation films produced on aluminium alloy[J]. Journal of Jilin University (Engineering and Technology Edition), 2011, 41(Sup.1): 106-110. | |

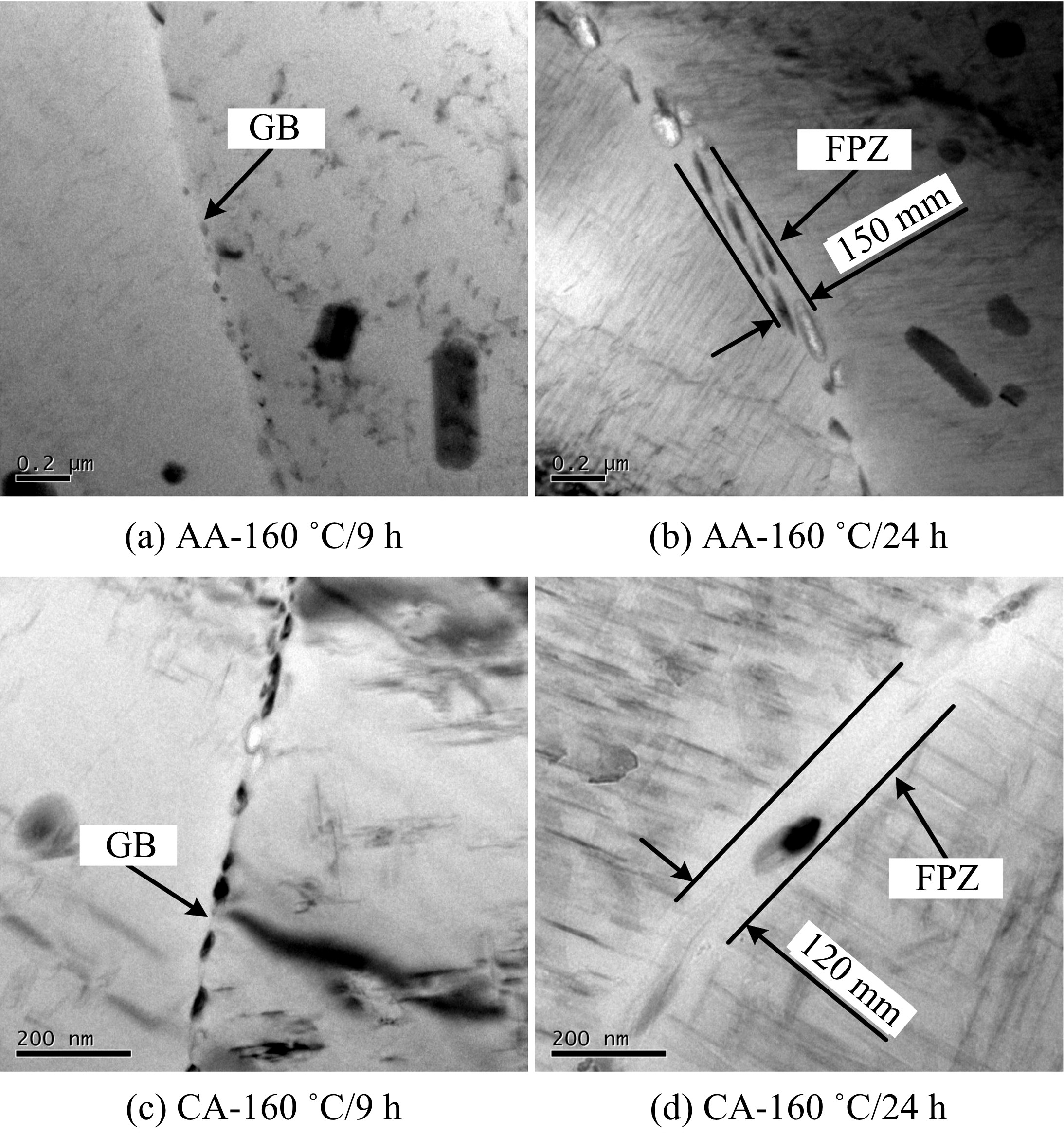

| 24 | Krol T , Baither D , Nembach E . The formation of precipitate free zones along grain boundaries in a superalloy and the ensuing effects on its plastic deformation[J]. Acta Materialia, 2004, 52(7): 2095-2108. |

| [1] | WANG Teng, ZHOU Ming-ru, MA Lian-sheng, QIAO Hong-xia. Fracture grouting crack growth of collapsible loess based on fracture theory [J]. 吉林大学学报(工学版), 2017, 47(5): 1472-1481. |

|

||