Journal of Jilin University(Engineering and Technology Edition) ›› 2023, Vol. 53 ›› Issue (4): 973-981.doi: 10.13229/j.cnki.jdxbgxb.20210779

Previous Articles Next Articles

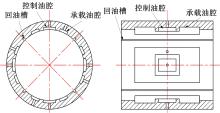

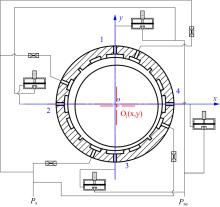

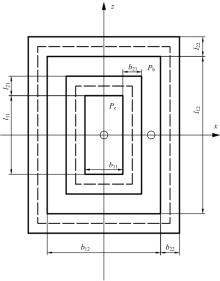

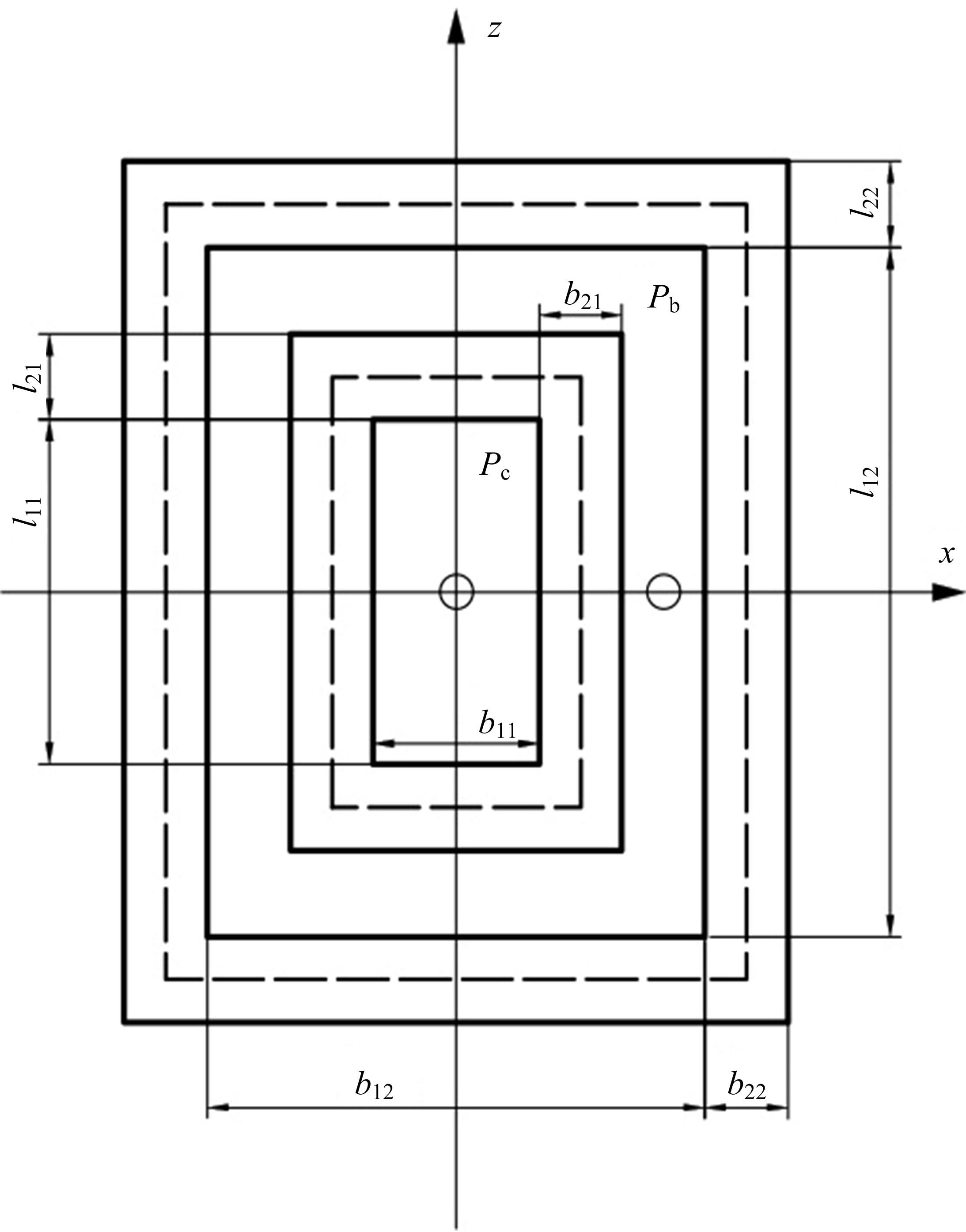

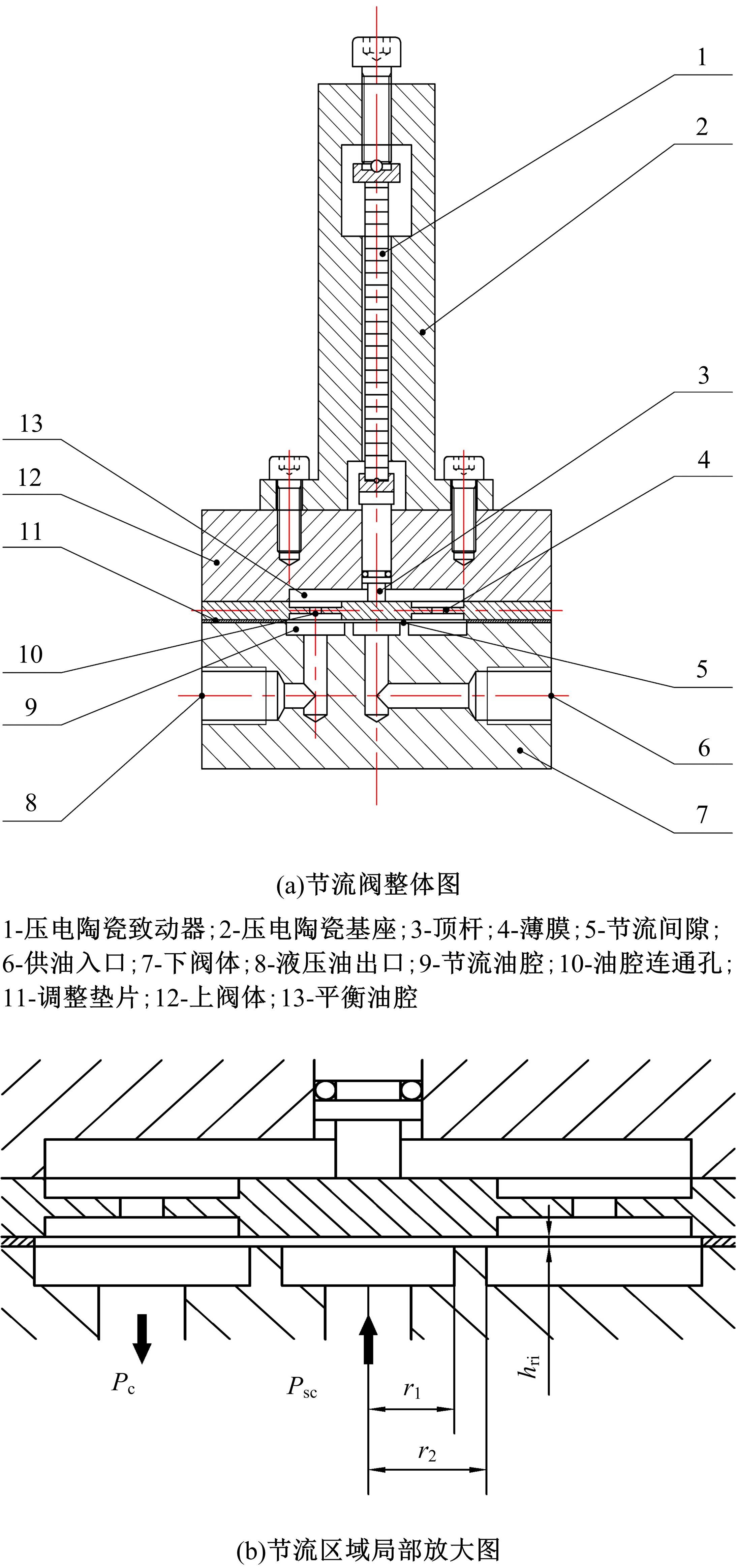

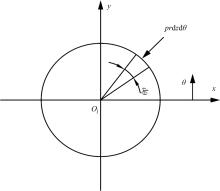

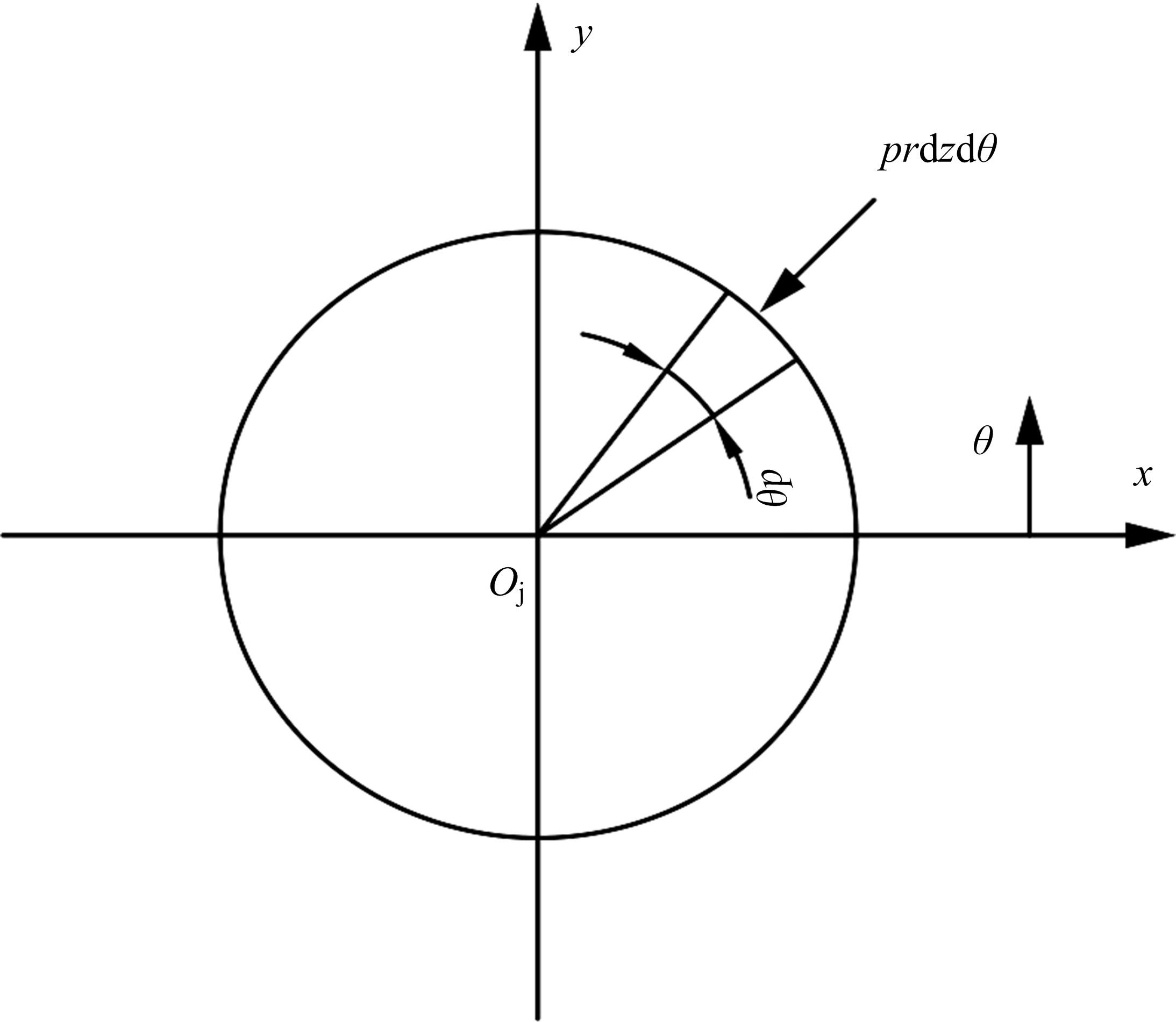

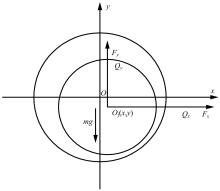

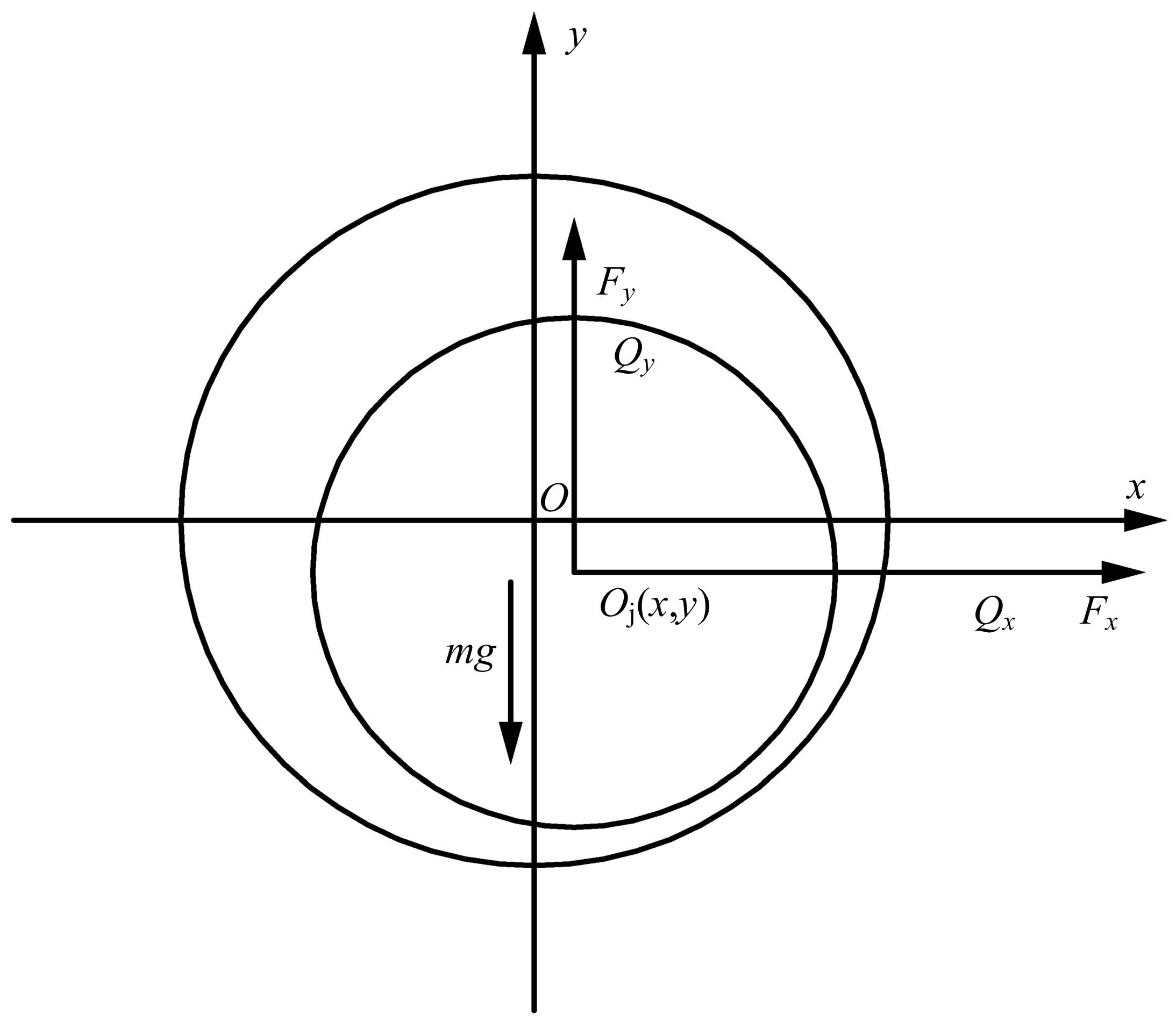

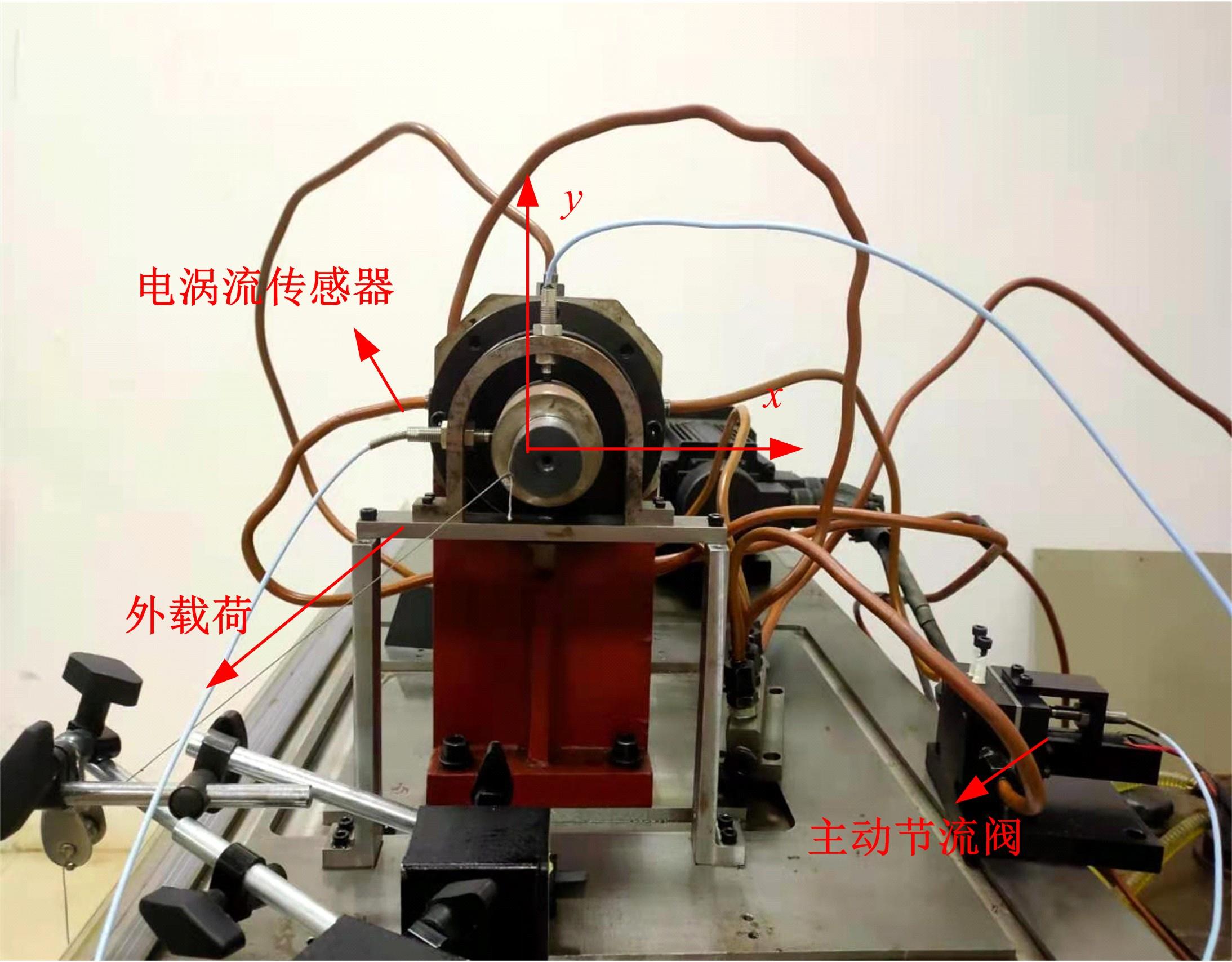

Analysis and experiment of active motion control of hydrostatic spindle embedded with control recess

Shu-jiang CHEN( ),Chun-wang XU,Chang-hou LU,Kang WANG

),Chun-wang XU,Chang-hou LU,Kang WANG

- School of Mechanical Engineering,Shandong University,Jinan 250061,China

CLC Number:

- TH133.3

| 1 | Wu Q H, Sun Y Z, Chen W Q, et al. Effect of motor rotor eccentricity on aerostatic spindle vibration in machining processes[J]. Journal of Mechanical Engineering Science, 2018, 232(7): 1331-1342. |

| 2 | Zhang S J, To S. Spindle vibration influencing form error in ultra-precision diamond machining[J]. Journal of Mechanical Engineering Science, 2017, 231(17): 3144-3151. |

| 3 | Chen G D, Sun Y Z, Zhang F H, et al. Influence of ultra-precision flycutting spindle error on surface frequency domain error formation[J]. International Journal of Advanced Manufacturing Technology, 2017, 88(9-12): 3233-3241. |

| 4 | 李永祥,毕晓勤. 机床主轴回转误差对零件加工精度的影响[J]. 河南工业大学学报: 自然科学版, 2005, 26(3): 57-59, 62. |

| Li Yong-xiang, Bi Xiao-qin. The Influence of lathe spindle rotary errors on spares machining precision[J]. Journal of Henan University of Technology(Natural Science Edition), 2005, 26(3): 57-59, 62. | |

| 5 | Turek P, Jędrzejewski J, Modrzycki W. Methods of machine tool error compensation[J]. Journal of Machine Engineering, 2010, 10(4): 5-25. |

| 6 | 路琳, 刘晓玲. 主轴轴承的选配与主轴部件旋转精度关系初探[J]. 组合机床与自动化加工技术, 2001, 42(6): 54-55. |

| Lu Lin, Liu Xiao-ling. The Relationship between the selection of spindle bearing and the rotation accuracy of spindle[J]. Modular Machine Tool & Automatic Manufacturing Technique,2001, 42(6): 54-55. | |

| 7 | 熊万里, 孙文彪, 刘侃, 等. 高速电主轴主动磁悬浮技术研究进展[J]. 机械工程学报, 2021, 57(13): 1-17. |

| Xiong Wan-li, Sun Wen-biao, Liu Kan, et al. Active magnetic bearing technology development in high-speed motorized spindles[J]. Journal of Mechanical Engineering, 2021, 57(13): 1-17. | |

| 8 | Santos I F. Controllable sliding bearings and controllable lubrication principles—an overview[J]. Lubricants, 2018, 6(1): 1-12. |

| 9 | Santos I F. On the future of controllable fluid film bearings[J]. Mechanics and Industry, 2011, 12(4): 275-281. |

| 10 | Salazar J G, Santos I F. Feedback-controlled lubrication for reducing the lateral vibration of flexible rotors supported by tilting-pad journal bearings[J]. Journal of Engineering Tribology, 2015, 229(10): 1264-1275. |

| 11 | 谢磊, 计江, 师浩浩. 一种轧辊静压轴承主动控制方法 [J]. 冶金设备, 2021, 42(3): 1-6. |

| Xie Lei, Ji Jiang, Shi Hao-hao. An active control method of roll hydrostatic bearing[J]. Metallurgical Equipment, 2021, 42(3): 1-6. | |

| 12 | Rehman W U R, Luo Y X, Wang Y Q, et al. Fuzzy logic-based intelligent control for hydrostatic journal bearing[J]. Measurement and Control, 2019, 52(3/4): 229-243. |

| 13 | Rehman W U, Jiang G Y, Luo Y X, et al. Control of active lubrication for hydrostatic journal bearing by monitoring bearing clearance[J]. Advances in Mechanical Engineering, 2018, 10(4): 1-17. |

| 14 | Rehman W U, Jiang G Y, Iqbal N, et al. Intelligent servo feedback control for hydrostatic journal bearing [C]∥Proceedings of 1st International Conference on Intelligent Manufacturing and Internet of Things /The 5th International Conference on Computing for Sustainable Energy and Environment, Chongqing, China, 2018: 352-364. |

| 15 | Yang X G, Wang Y Q, Jiang G Y, et al. Dynamic characteristics of hydrostatic active journal bearing of four oil recesses[J]. Tribology Transactions, 2015, 58(1): 7-17. |

| 16 | 丁振乾. 流体静压支承设计[M]. 上海: 上海科学技术出版社, 1989. |

| 17 | 宋佳星. 压电陶瓷驱动伺服阀的设计及特性研究[D]. 哈尔滨: 哈尔滨工业大学机电工程学院, 2019. |

| Song Jia-xing. Research on design and characteristics of servovalve actuated by piezoelectric ceramics[D]. Harbin: School of Mechatronics Engineering, Harbin Institute of Technology, 2019. |

| [1] | Ji-hai JIANG,Cun-ran ZHAO,Guan-long ZHANG,Ming-yang CHE. Tribological properties of coating materials of tribopairs for aviation kerosene piston pump [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(1): 147-153. |

| [2] | ZHANG Niao-na, ZHOU Sui, ZHANG De-jiang. Synchronization control of finite time convergence between two different structure chaos systems [J]. 吉林大学学报(工学版), 2011, 41(4): 1131-1134. |

| [3] | DENG Zong-quan, WANG Xin-jie, YUE Hong-hao, . Active control of photostrictive laminated thin paraboloidal shell [J]. 吉林大学学报(工学版), 2011, 41(05): 1433-1438. |

| [4] |

Li Peng, Cheng Guang-ming, Dong Jing-shi, Yang Zhi-gang, Zeng Ping .

Piezoelectric pump with active electromagnetic driven valve [J]. 吉林大学学报(工学版), 2008, 38(增刊): 111-0114. |

| [5] | Wang Shipeng, Chen Suhuan. Upper and lower bounds of eigenvalues of uncertain closedloop systems with secondorder perturbation [J]. 吉林大学学报(工学版), 2006, 36(增刊1): 56-0061. |

| [6] | Tan Ping. Traveling wave control for structure [J]. 吉林大学学报(工学版), 2006, 36(03): 417-0421. |

| [7] | Liu Zhiru,Wang Qingnian, Wang Guangping. Active control during shifting in hybrid electric vehicle [J]. 吉林大学学报(工学版), 2006, 36(02): 153-0156. |

|

||