Journal of Jilin University(Engineering and Technology Edition) ›› 2023, Vol. 53 ›› Issue (6): 1621-1637.doi: 10.13229/j.cnki.jdxbgxb.20221428

Finite element analysis method for mechanical properties of steel⁃concrete composite beam bridges with multiple damages

Jian-qing BU1( ),Zhi-bo GUO2,Ji-ren ZHANG3,Jing-chuan XUN4,Xiao-ming HUANG5

),Zhi-bo GUO2,Ji-ren ZHANG3,Jing-chuan XUN4,Xiao-ming HUANG5

- 1.School of Traffic and Transportation,Shijiazhuang Tiedao University,Shijiazhuang 050043,China

2.School of Civil Engineering,Shijiazhuang Tiedao University,Shijiazhuang 050043,China

3.School of Civil Engineering,Hunan University,Changsha 410082,China

4.CSCEC Road and Bridge Group Co. ,Ltd. ,Shijiazhuang 050043,China

5.School of Traffic and Transportation,Southeast University,Nanjing 210096,China

CLC Number:

- U447

| 1 | 卫星, 肖林, 温宗意, 等. 钢混组合结构桥梁2020年度研究进展[J]. 土木与环境工程学报, 2021, 43(): 107-119. |

| Wei Xing, Xiao Lin, Wen Zong-yi, et al. State-of-the art review of steel-concrete composite bridges in 2020[J]. Journal of Civil and Environmental Engineering, 2021, 43(Sup.1): 107-119. | |

| 2 | 张吉仁, 卜建清, 曹文龙, 等. 栓钉式钢-混凝土组合梁疲劳刚度退化研究[J]. 铁道标准设计, 2022, 66(5): 77-82. |

| Zhang Ji-ren, Bu Jian-qing, Cao Wen-long, et al. Study on the fatigue stiffness degradation of studded steel-concrete composite beams[J]. Railway Standard Design, 2022, 66(5): 77-82. | |

| 3 | 王勇, 王功臣, 王本淼, 等. 火灾后混凝土连续板剩余承载力试验研究及理论分析[J]. 工程力学, 2022, 39(2): 96-109. |

| Wang Yong, Wang Gong-chen, Wang Ben-miao, et al. Experimental study and theoretical analysis on the residual capacities of fire-damaged concrete continuous slabs[J]. Engineering Mechanics, 2022, 39(2): 96-109. | |

| 4 | 陈俊, 张白, 杨鸥, 等. 微锈蚀钢筋混凝土高温后粘结锚固性能试验研究[J]. 工程力学, 2018, 35(10): 92-100. |

| Chen Jun, Zhang Bai, Yang Ou, et al. Bond Performance between slightly corroded steel bars and concrete after exposed to high temperatures[J]. Engineering Mechanics, 2018, 35(10): 92-100. | |

| 5 | 王卫永, 李国强. 钢-混凝土组合梁抗火性能研究综述[J]. 建筑钢结构进展, 2014, 16(5): 1-8, 28. |

| Wang Wei-yong, Li Guo-qiang. A state-of the-art review on fire resistance of steel-concrete comp osite beams[J]. Progress in Steel Building Structures, 2014, 16(5): 1-8, 28. | |

| 6 | 张岗, 宋超杰, 李徐阳, 等. 碳氢火灾下钢-混组合梁破坏试验研究[J]. 中国公路学报, 2022, 35(6): 135-146. |

| Zhang Gang, Song Chao-jie, Li Xu-yang, et al. Experimental study on failure of steel-concrete composite bridge girders under hydrocarbon fire exposure conditions[J]. China Journal of Highway and Transport, 2022, 35(6): 135-146. | |

| 7 | 武芳文, 冯彦鹏, 王广倩, 等. 高温后钢-混组合梁抗剪性能试验研究[J]. 工程力学, 2022, 39: 1-14. |

| Wu Fang-wen, Feng Yan-peng, Wang Guang-qian, et al. Experimental study on shear performance of steel-concrete composite beams after experiencing high temperatures[J]. Engineering Mechanics, 2022, 39: 1-14. | |

| 8 | 鞠晓臣, 赵欣欣, 刘晓光, 等. 火灾作用下剪力钉抗拔性能研究[J]. 桥梁建设, 2018, 48(2): 55-60. |

| Ju Xiao-chen, Zhao Xin-xin, Liu Xiao-guang, et al. Study of pullout performance of shear stud under fire[J]. Bridge Construction, 2018, 48(2): 55-60. | |

| 9 | 姚伟发, 黄侨, 张娟秀. 钢-混组合梁的火灾试验及剩余承载力[J]. 东南大学学报:自然科学版, 2016, 46(2): 347-352. |

| Yao Wei-fa, Huang Qiao, Zhang Juan-xiu. Fire experiment and residual strength of steel-concrete composite girders[J]. Journal of Southeast University (Natural Science Edition), 2016, 46(2): 347-352. | |

| 10 | 张岗, 宗如欢, 施颖, 等. 钢-混组合简支箱梁耐火性能研究[J]. 桥梁建设, 2017, 47(3): 41-46. |

| Zhang Gang, Zong Ru-huan, Shi Ying, et al. Study of fire resistance performance of simply-supported steel and concrete composite box girder[J]. Bridge Construction, 2017, 47(3): 41-46. | |

| 11 | 周焕廷, 郑志远, 郝聪龙, 等. 预应力连续钢-混组合梁抗火性能[J]. 长安大学学报:自然科学版, 2018, 38(6): 40-48. |

| Zhou Huan-ting, Zheng Zhi-yuan, Hao Cong-long, et al. Fire resistance of prestressed continuous steel-concrete composite beams[J]. Journal of Chang'an University (Natural Science Edition), 2018, 38(6): 40-48. | |

| 12 | 赵硕硕. 剪力钉锈蚀对钢-混凝土组合梁负弯矩区力学性能的影响研究[D]. 成都:西南交通大学土木工程学院, 2021. |

| Zhao Shuo-shuo. Effect of stud corrosion onmechanical properties of steel-concrete composite beams innegative bending moment region[D]. Chengdu: School of Civil Engineering, Southwest Jiaotong University, 2021. | |

| 13 | 许波, 刘永健, 朱伟庆, 等. 焊钉锈蚀后钢-混组合梁抗弯承载力简化计算方法[J]. 交通运输工程学报, 2019, 19(2): 25-35. |

| Xu Bo, Liu Yong-jian, Zhu Wei-qing, et al. Simplified method of calculating flexural capacity of steel-concrete composite beam after stud corrosion[J]. Journal of Traffic and Transportation Engineering, 2019, 19(2): 25-35. | |

| 14 | 王威, 刘杰. 锈蚀损伤对钢-混组合梁抗弯性能的影响研究[J]. 中外公路, 2020, 40(): 180-184. |

| Wang Wei, Liu Jie. Study on the effect of corrosion damage on the flexural behavior of steel-concrete composite beams[J]. Journal of China & Foreign Highway, 2020, 40(Sup.2): 180-184. | |

| 15 | 陈冠. 多部件非均匀锈蚀对钢混组合梁承载力退化的影响研究[J]. 公路工程, 2022, 47(3): 35-42, 130. |

| Chen Guan. Study on the effect of multi-component non-uniform corrosion onbearing capacity degradation of steel-concrete composite beams[J]. Highway Engineering, 2022, 47(3): 35-42, 130. | |

| 16 | Lin J P, Wang G, Xu R. Variational principles and explicit finite-element formulations for the dynamic analysis of partial-interaction composite beams[J]. Journal of Engineering Mechanics, 2020, 146(6): No.04020055. |

| 17 | Lin J P, Wang G, Bao G, et al. Stiffness matrix for the analysis and design of partial-interaction composite beams[J]. Construction and Building Materials, 2017, 156: 761-772. |

| 18 | 范晨, 王莹, 李兆霞. 以疲劳评估为目标的大跨钢箱梁桥车桥耦合动力分析方法[J]. 振动与冲击, 2020, 39(6): 236-242. |

| Fan Chen, Wang Ying, Li Zhao-xia. Vehicle-bridge coupling dynamic analysis method for the fatigue assessment of a long-span steel box-girder bridge[J]. Journal of Vibration and Shock, 2020, 39(6): 236-242. | |

| 19 | 樊学平, 杨光红, 尚志鹏, 等. 考虑适用性的大跨桥梁主梁动态可靠性融合预测[J]. 吉林大学学报:工学版, 2022, 52(1): 144-153. |

| Fan Xue-ping, Yang Guang-hong, Shang Zhi-peng, et al. Dynamic reliability fusion prediction of long-span bridge girder considering structural serviceability[J]. Journal of Jilin University (Engineering and Technology Edition), 2022, 52(1): 144-153. | |

| 20 | 王莹, 李兆霞, 缪海萍. 考虑环境变温作用的大跨桥梁疲劳损伤分析[J]. 湖南大学学报:自然科学版, 2018, 45(1): 26-36. |

| Wang Ying, Li Zhao-xia, Miao Hai-ping. Analysis on fatigue damage of long-span bridges considering effect of environment varying-temperature[J]. Journal of Hunan University(Natural Sciences), 2018, 45(1): 26-36. | |

| 21 | Sun B, Xu Y L, Zhu Q, et al. Auto-adaptive multiblock cycle jump algorithm for fatigue damage simulation of long-span steel bridges[J]. Fatigue & Fracture of Engineering Materials & Structures, 2019, 42(3): No. 12960. |

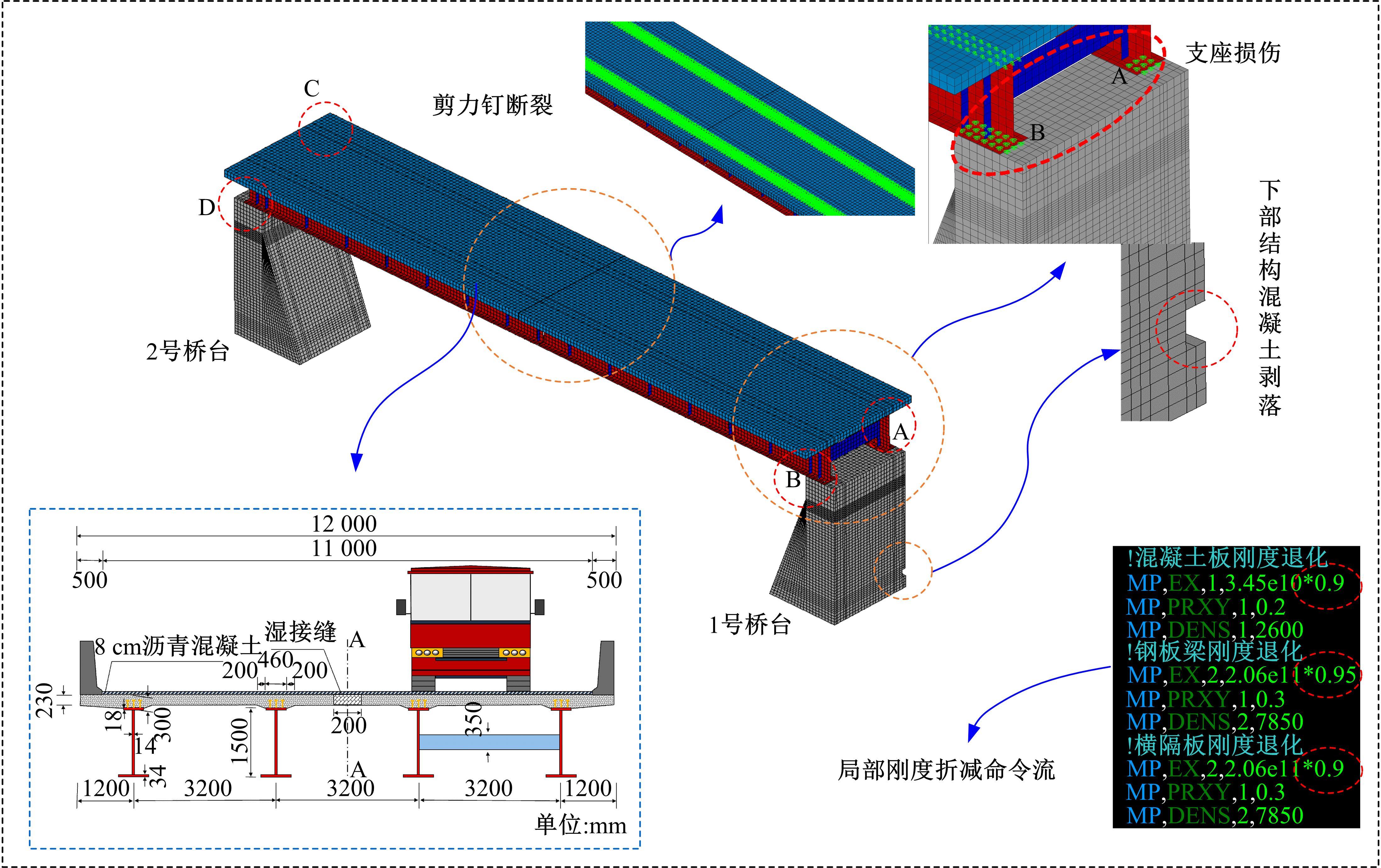

| 22 | 黄海新, 李振龙, 方乐焱. 既有桥梁损伤状态模拟方式和判断标准的探究[J]. 河北工业大学学报, 2018, 47(2): 60-66. |

| Huang Hai-xin, Li Zhen-long, Fang Le-yan. Research on the simulation methods and criteria of damage state of existing bridges[J]. Journal of Hebei University of Technology, 2018, 47(2): 60-66. | |

| 23 | 李敏峰, 吴娇媚, 陈长华. 某连续刚构桥主桥考虑损伤影响的有限元模拟[J]. 河北建筑工程学院学报, 2020, 38(4): 46-50. |

| Li Min-feng, Wu Jiao-mei, Chen Chang-hua. Finite element simulation of main bridge of a continuous rigid frame bridge considering damage effect[J]. Journal of Hebei Institute of Architecture and Civil Engineering, 2020, 38(4): 46-50. | |

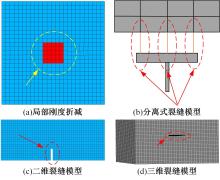

| 24 | 周林仁, 欧进萍. 钢筋混凝土结构裂缝损伤状态模型建模方法与分析[J]. 大连理工大学学报, 2012, 52(3): 399-405. |

| Zhou Lin-ren, Jin-ping Ou. Modeling method and analysis of crack damage state model of reinforced concrete structure[J]. Journal of Dalian University of Technology, 2012, 52(3): 399-405. | |

| 25 | 王文洁, 吕中荣, 刘济科. 含呼吸裂缝的桥梁振动响应与时频特性分析[J]. 振动与冲击, 2013, 32(11): 12-16. |

| Wang Wen-jie, Zhong-rong Lü, Liu Ji-ke. Dynamic response and time-frequency feature analysis for a bridge with breathing cracks[J]. Journal of Vibration and Shock, 2013, 32(11): 12-16. | |

| 26 | Law S S, Zhu X Q. Dynamic behavior of damaged concrete bridge structures under moving vehicular loads[J]. Engineering Structures, 2004, 26(9): 1279-1293. |

| 27 | Kim S H, Mha H S, Lee S W. Effects of bearing damage upon seismic behaviors of a multi-span girder bridge[J]. Engineering Structures, 2006, 28(7): 1071-1080. |

| 28 | 刘佳锋. 车载下既有损伤公路混凝土简支梁桥动力响应分析[D]. 哈尔滨:哈尔滨工业大学交通科学与工程学院, 2014. |

| Liu Jia-feng. Dynamic response analysis of highway concrete simply supported beambridges with damage under moving vehicles[D]. Harbin: School of Transportation Science and Transportation, Harbin Institute of Technology, 2014. | |

| 29 | 黄辉. 基于车桥耦合振动的既有损伤高速铁路混凝土简支梁桥动力响应研究[D]. 成都:西南交通大学土木工程学院, 2019. |

| Huang Hui. Dynamic response analysis of high-speed railway concrete simplysupported girder bridge withdamage under vehicle-bridge coupled vibrations[D]. Chengdu: School of Civil Engineering, Southwest Jiaotong University, 2019. | |

| 30 | Abdel Wahab M M, De Roeck G, Peeters B. Parameterization of damage in reinforced concrete structures using model updating[J]. Journal of Sound and Vibration, 1999, 228(4): 717-730. |

| 31 | Adams R D, Cawley P, Pye C J, et al. A vibration technique for non-destructively assessing the integrity of structures[J]. Journal of Mechanical Engineering Science, 1978, 20(2): 93-100. |

| 32 | Ostachowicz W M, Krawczuk M. Analysis of the effect of cracks on the natural frequencies of a cantilever beam[J]. Journal of Sound and Vibration, 1991, 150(2): 191-201. |

| 33 | 唐站站. 钢桥弹塑性地震反应计算方法及钢材地震损伤指标研究[D]. 杭州:浙江大学建筑工程学院, 2016. |

| Tang Zhan-zhan. Research on seismic response evaluation method of steel bridges and seismic damage index of steel material[D]. Hangzhou: College of Civil Engineering and Architecture, Zhejiang University, 2016. | |

| 34 | Miki C, Sasaki E. Fracture in steel bridge piers due to earthquakes[J]. International Journal of Steel Structures, 2005, 5(2): 133-140. |

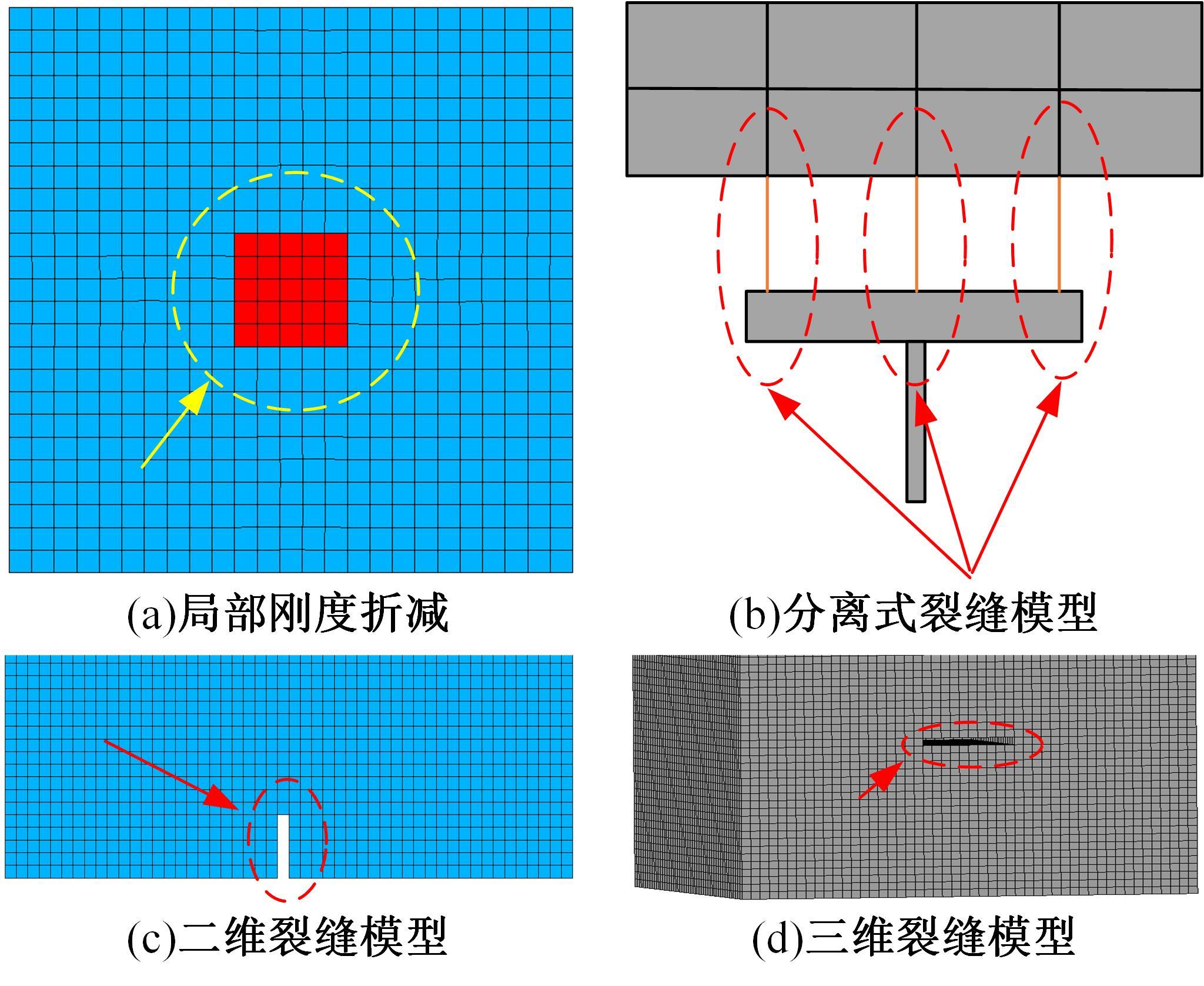

| 35 | 王新敏, 李义强, 许宏伟. ANSYS结构分析单元与应用[M]. 北京:人民交通出版社, 2011: 15-20. |

| 36 | 尹江南. 装配式钢筋混凝土空心板桥支座与铰缝损伤的数值仿真分析[D]. 天津:天津大学建筑工程学院, 2009. |

| Yin Jiang-nan. Numerical simulation analysis on damage of bearing and hinge joint of prefabricated reinforced concrete hollow slab bridge[D]. Tianjin: Tianjin University School of Civil Engineering, 2009. | |

| 37 | 陈少峰, 刘骁, 彭周. 局部铰缝开裂的装配式空心板梁有限元分析[J]. 公路, 2013(10): 128-131. |

| Chen Shao-feng, Liu Xiao, Peng Zhou. Finite element analysis of assembled hollow slab beam with local hinge crack[J]. Highway, 2013(10): 128-131. | |

| 38 | 杜修力, 韩强, 李忠献, 等. 5.12汶川地震中山区公路桥梁震害及启示[J]. 北京工业大学学报, 2008, 34(12): 1270-1279. |

| Du Xiu-li, Han Qiang, Li Zhong-xian, et al. 5.12 Wenchuan earthquake damage to highway and bridge in zhongshan district and its enlightenment[J]. Journal of Beijing University of Technology, 2008, 34(12): 1270-1279. | |

| 39 | . 公路桥梁板式橡胶支座 [S]. |

| 40 | 郑明军, 谢基龙. 压缩状态下橡胶件大变形有限元分析[J]. 北方交通大学学报, 2001, 25(1): 76-79. |

| Zheng Ming-jun, Xie Ji-long. Finite element analysis of large deformation of compressed rubber component[J]. Journal of Northern Jiaotong University, 2001, 25(1): 76-79. | |

| 41 | 王桂萱, 葛政青, 秦建敏. 基于ANSYS模拟桥梁支座的弹簧单元刚度系数率定与振动台试验验证[J]. 公路, 2020, 65(2): 74-78. |

| Wang Gui-xuan, Ge Zheng-qing, Qin Jian-min. Calibration of spring element stiffness coefficient of bridge bearing based on ANSYS simulation and verification of shaking table test[J]. Highway, 2020, 65(2): 74-78. | |

| 42 | . 车辆振动输入路面平度表示方法 [S]. |

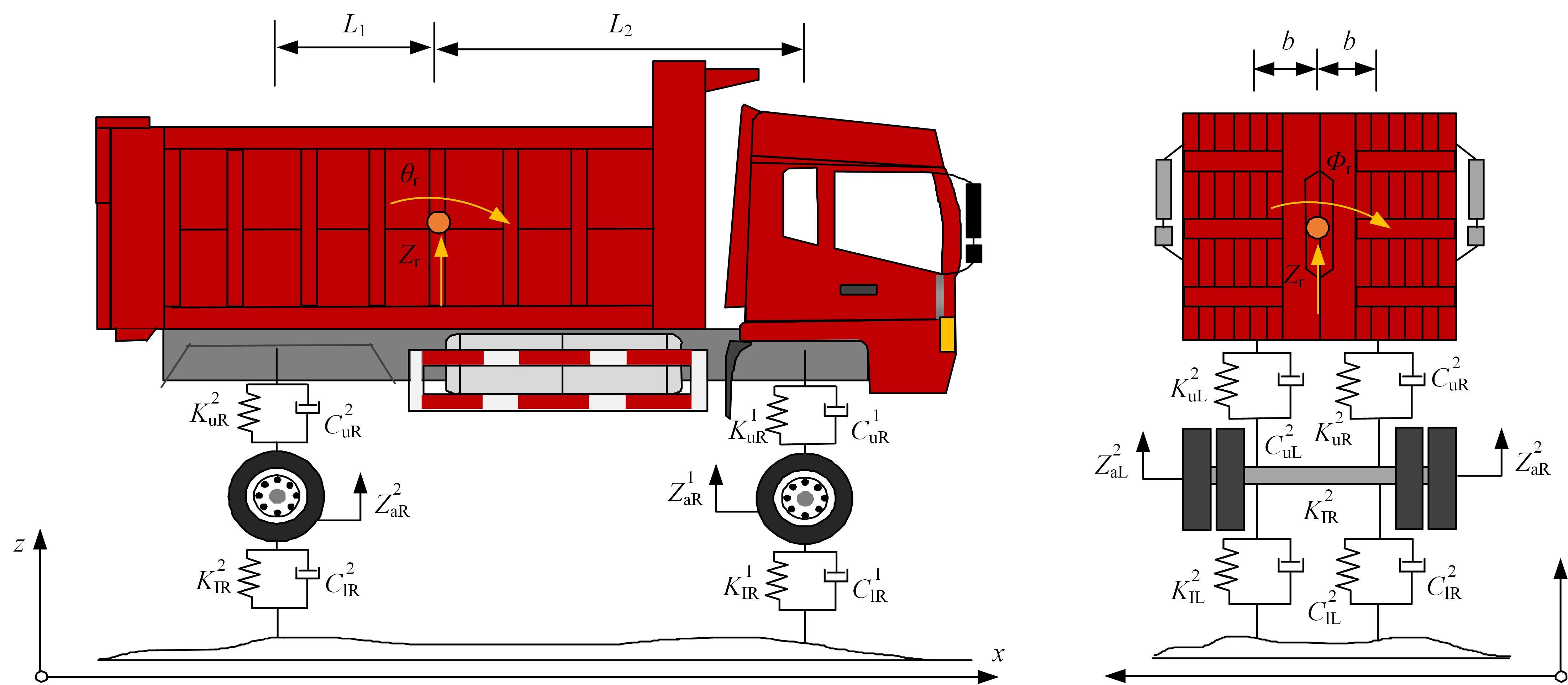

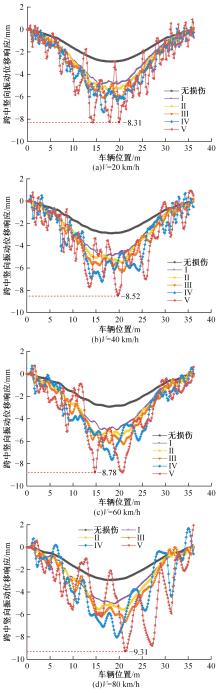

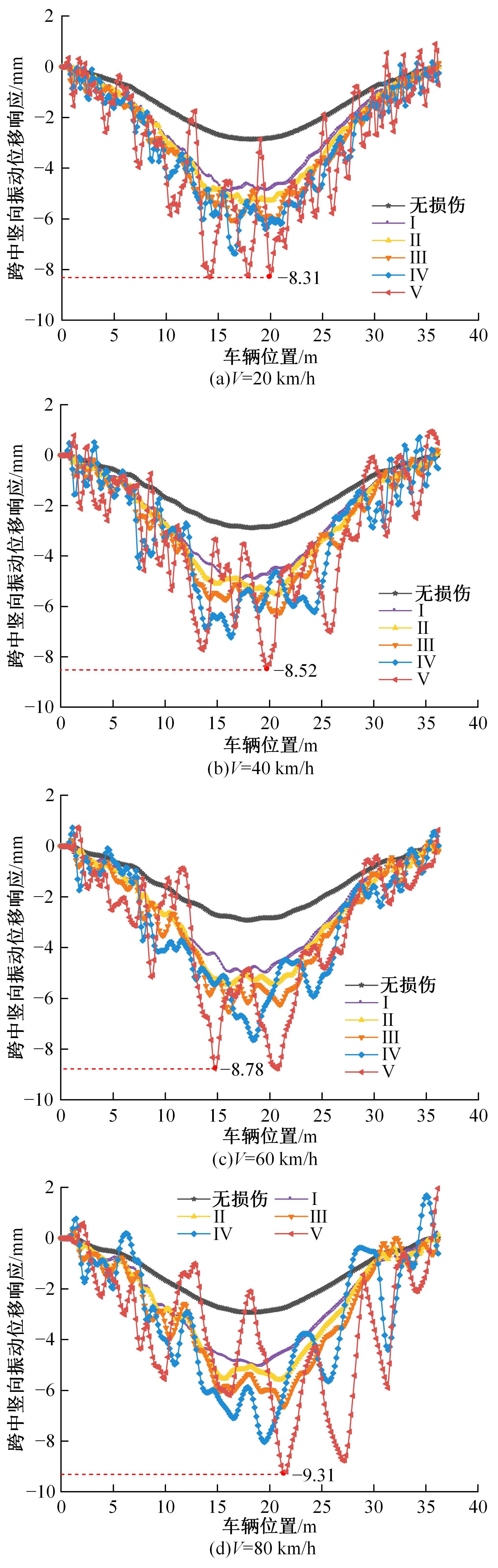

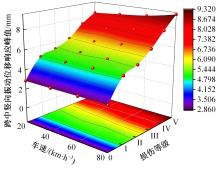

| 43 | 庞志强. 车载作用下分离式钢-混凝土组合曲线连续箱梁力学行为研究[D]. 石家庄:石家庄铁道大学土木工程学院, 2022. |

| Pang Zhi-qiang. Study on the mechanical behavior of separatedsteel-concrete composite curved continuous box girder under vehicle load[D].Shijiazhuang: School of Civil Engineering, Shijiazhuang Railway University, 2022. | |

| 44 | 张劲泉. 公路混凝土梁式桥结构损伤评定[M]. 北京:人民交通出版社, 2014: 18-26. |

| 45 | 周绪红, 刘永健. 钢桥[M]. 北京:人民交通出版社股份有限公司, 2020: 115-117. |

| 46 | Shen H, Chen X, Lu K, et al. A new vehicle-bridge coupling analysis method based on model polycondensation[J]. KSCE Journal of Civil Engineering, 2021, 25(1): 245-255. |

| 47 | Wang L, Jiang P, Hui Z, et al. Vehicle-bridge coupled vibrations in different types of cable stayed bridges[J]. Frontiers of Structural and Civil Engineering, 2016, 10(1): 81-92. |

| 48 | 邓露, 何维, 王芳. 不同截面类型简支梁桥动力冲击系数研究[J]. 振动与冲击, 2015, 34(14): 70-75. |

| Deng Lu, He Wei, Wang Fang. Dynamic impact factors for simply supported bridges with different cross-section types[J]. Journal of Vibration and Shock, 2015, 34(14): 70-75. | |

| 49 | 张洁. 公路车辆与桥梁耦合振动分析研究[D]. 成都:西南交通大学土木工程学院, 2007. |

| Zhang Jie. Studies on coupling vibrationof highway vehicle-bridge system[D]. Chengdu: School of Civil Engineering, Southwest Jiaotong University, 2007. | |

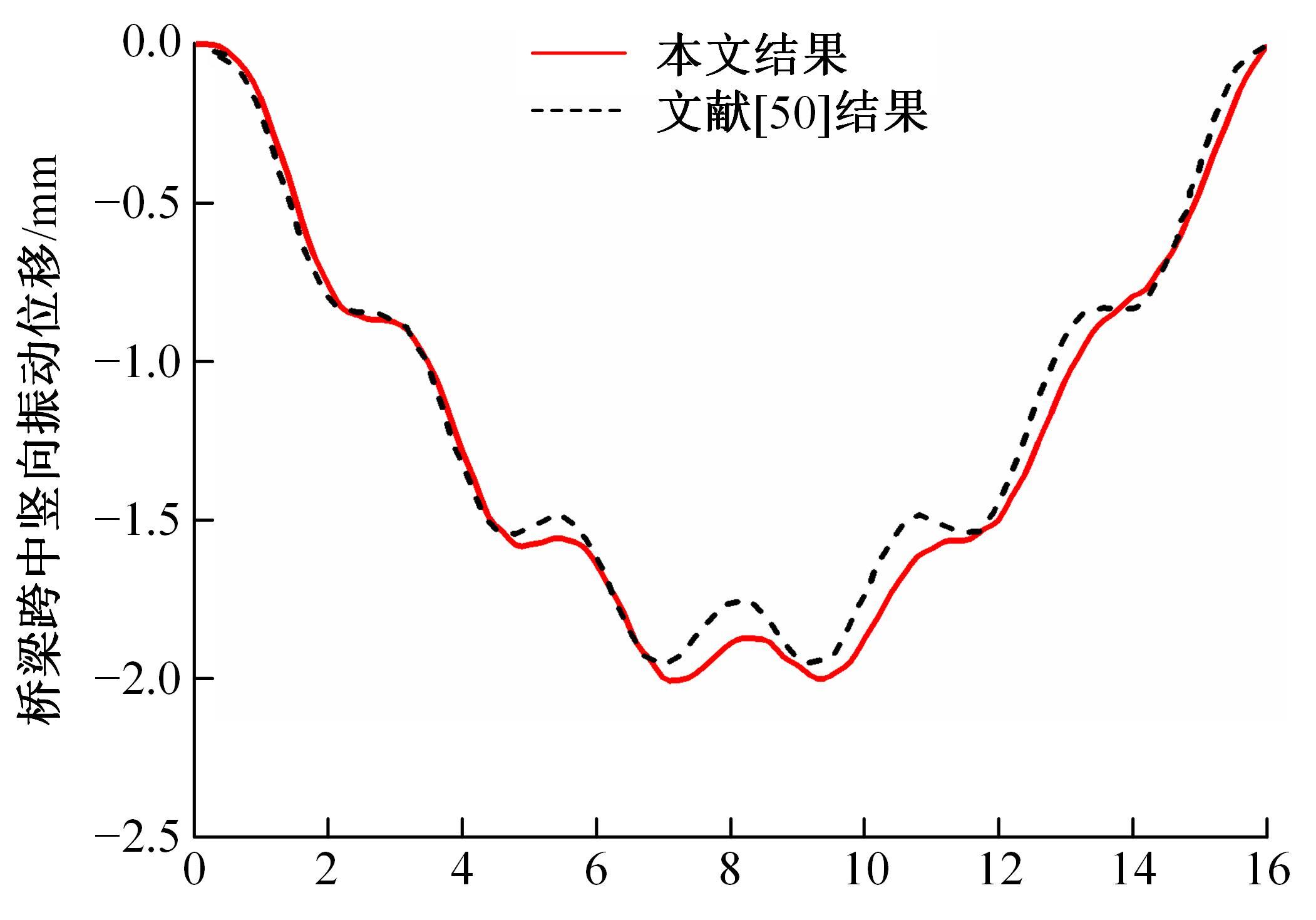

| 50 | 李喜梅, 王新, 母渤海, 等. 车辆荷载作用下双工字钢-混组合连续梁桥振动控制研究[J]. 中国公路学报, 2022, 35(7): 173-183. |

| Li Xi-mei, Wang Xin, Mu Bo-hai, et al. Research on vibration control of twin-i steel-concretecomposite continuous girder bridge under vehicle load[J]. China Journal of Highway and Transport, 2022, 35(7): 173-183. | |

| 51 | . 公路桥涵设计通用规范 [S]. |

| [1] | Zhi-qiang HAN,Gang XIE,Yong-jun ZHOU,Shi-zhong LIU,Min-jie JIN. Numerical analysis method of vehicle⁃bridge coupling vibration of curved bridge [J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(2): 515-522. |

| [2] | Guo-jun YANG,Qi-wei TIAN,Ming-hang LYU,Yong-feng DU,Guang-wu TANG,Zong-jian HAN,Yi-duo FU. Review of mechanic characteristics of tunnel⁃type anchorage of long⁃span suspension bridge [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(6): 1245-1263. |

| [3] | Zhi-yuan YUANZHOU,Bo-hai JI,Jun-yuan XIA,Tong SUN. Pneumatic impact test on rib⁃to⁃diaphragm fatigue crack of steel box girder [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(12): 2883-2891. |

| [4] | Chun-liang LI,Zhi-hao LIN,Luo-luo ZHAO. Effect of damaged hinge joint and damaged slab on transverse force of hollow slab bridge [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(2): 611-619. |

|

||