Journal of Jilin University(Engineering and Technology Edition) ›› 2025, Vol. 55 ›› Issue (5): 1525-1535.doi: 10.13229/j.cnki.jdxbgxb.20230840

Previous Articles Next Articles

Analysis of relaxation characteristics of multi-bolted connections under the transverse cyclic load

Ling LI( ),Hui-tao TIAN,Dong-hao MIAO,Miao-xia XIE,Fu-an CHENG(

),Hui-tao TIAN,Dong-hao MIAO,Miao-xia XIE,Fu-an CHENG( )

)

- School of Mechanical and Electrical Engineering,Xi'an University of Architecture and Technology,Xi'an 710055,China

CLC Number:

- TH131

| [1] | 徐阳, 阳光武, 杨龙,等. 螺栓连接松动与疲劳失效研究[J]. 铁道车辆, 2022, 60(4): 9-14. |

| Xu Yang, Yang Guang-wu, Yang Long, et al. Reaseech on bolted joints looseness and fatigue failure[J]. Rolling Stock, 2022, 60(4): 9-14. | |

| [2] | Ibrahim R A, Pettit C L. Uncertainties and dynamic problems of bolted joints and other fasteners[J]. Journal of Sound and Vibration, 2005, 279(3): 857-936. |

| [3] | Junker G H. Criteria for self-loosening of fasteners under vibration[J]. Aircraft Engineering and Aerospace Technology, 1969, 44(10): 14-16. |

| [4] | Zhang M, Lu L, Wang W, et al. The roles of thread wear on self-loosening behavior of bolted joints under transverse cyclic loading[J]. Wear, 2018, 394: 30-39. |

| [5] | Liu J, Ouyang H, Peng J, et al. Experimental and numerical studies of bolted joints subjected to axial excitation[J]. Wear, 2016, 346: 66-77. |

| [6] | Liu J, Ouyang H, Feng Z, et al. Study on self-loosening of bolted joints excited by dynamic axial load[J]. Tribology International, 2017, 115: 432-451. |

| [7] | 杜永强, 刘建华, 刘学通,等. 偏心载荷作用下螺栓连接结构的松动行为研究[J]. 机械工程学报, 2018,54(14):74-81. |

| Du Yong-qiang, Liu Jian-hua, Liu Xue-tong, et al. Research on self-loosening behavior of bolted joints under eccentric excitation[J]. Journal of Mechanical Engineering, 2018, 54(14): 74-81. | |

| [8] | Nassar S A, Housari B A. Self-loosening of threaded fasteners due to cyclic transverse loads[C]∥ ASME Pressure Vessels and Piping Conference, Denvor, USA, 2005: 169-187. |

| [9] | 李海江, 田煜, 孟永钢,等. 横向振动作用下螺纹联接松动过程的实验研究[J]. 清华大学学报: 自然科学版, 2016, 56(2): 171-175. |

| Li Hai-jiang, Tian Yu, Meng Yong-gang, et al. Experimental study of the loosening of threaded fasteners with transverse vibration[J]. Journal of Tsinghua University(Science and Technology), 2016, 56(2): 171- 175. | |

| [10] | 胡阳, 姜东, 王旻睿,等. 横向载荷作用下螺栓连接松动过程研究[J]. 振动.测试与诊断, 2020, 40(6): 1091-1098. |

| Hu Yang, Jiang Dong, Wang Min-rui, et al. Study on loosening process of bolted joints under transverse load[J]. Journal of Vibration, Measurement & Diagnosis, 2020, 40(6): 1091-1098. | |

| [11] | 刘光辉, 伍川, 吕中宾, 等. 输电铁塔螺栓紧固特性影响因素试验研究[J]. 现代制造工程, 2022, 498(3): 84-91. |

| Liu Guang-hui, Wu Chuan, Zhong-bin Lyu, et al. Experimental study on factors of bolt fastening characteristics for transmission line tower[J]. Modern Manufacturing Engineering, 2022, 498(3): 84-91. | |

| [12] | Yang L, Yang B, Yang G, et al. Research on factors affecting competitive failure between loosening and fatigue of bolt under combined excitation[J]. Journal of Constructional Steel Research, 2022, 189:No.107110. |

| [13] | 王开平, 张明远, 闫明, 等. 冲击载荷下材料松动期内螺栓松动影响因素研究[J]. 振动与冲击, 2020, 39(22): 35-40. |

| Wang Kai-ping, Zhang Ming-yuan, Yan Ming, et al. Factors affecting bolt loosening during material loosening period under impact loading[J]. Journal of Vibration and Shock, 2020, 39(22): 35-40. | |

| [14] | Okugawa M, Tanaka T. Effect on detection sensitivity for smart washer configuration and ambient temperature characteristics on bolted joint[J]. Proc SPIE, 2007, 6532:No. 12715684. |

| [15] | 莫易敏, 梁绍哲, 晏熙,等. 汽车高强度螺栓的防松性能的影响因素研究[J]. 机械设计与制造, 2015, 2015(9):89-92. |

| Mo Yi-min, Liang Shao-zhe, Yan Xi, et al. A study of effects on anti-loosening performance of automobile high-strength threaded fasteners[J]. Machinery Design & Manufacture, 2015(9): 89-92. | |

| [16] | 王旻睿, 谭志勇, 何顶顶, 等. 高温环境复合材料螺栓连接振动的防松试验[J]. 振动、测试与诊断, 2018, 38(6): 1004-1175. |

| Wang Min-rui, Tan Zhi-yong, He Ding-ding, et al. Anti-loosening experiment of composite bolted structures under high temperature and vibration circumstance[J]. Journal of Vibration, Measurement & Diagnosis, 2018, 38(6): 1004-1175. | |

| [17] | 李志彬, 陈岩, 孙伟程, 等. 横向振动下螺栓连接失效及影响因素研究[J]. 宇航总体技术, 2018, 2(4): 24-30. |

| Li Zhi-bin, Chen Yan, Sun Wei-cheng, et al. Study on failure of bolt connection and influence factors under transverse vibration[J]. Astronautical Systems Engineering Technology, 2018, 2(4): 24-30. | |

| [18] | Wang Z, Jiang Y. Study of a major mechanism for self-loosening of bolted joints[C]∥ASME Pressure Vessels and Piping Conference, Vancouver, Canada, 2006: 221-227. |

| [19] | Chen J, Hsieh S, Lee A. The failure of threaded fasteners due to vibration[J]. Journal of Mechanical Engineering Science, 2005, 219(3): 299-314. |

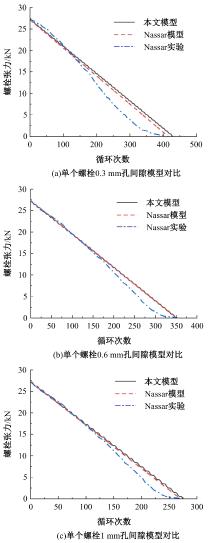

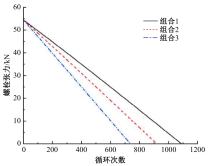

| [20] | Nassar S A, Housari B A. Study of the effect of hole clearance and thread fit on the self-loosening of threaded fasteners[J]. Journal of Mechanical Design, 2007, 129(6): 1053-1062. |

| [1] | CHEN Dong-hui, LYU Jian-hua, LONG Gang, ZHANG Yu-chen, CHANG Zhi-yong. Static rollover stability of semi-mounted agricultural machinery based on ADAMS [J]. 吉林大学学报(工学版), 2018, 48(4): 1176-1183. |

|