Journal of Jilin University(Engineering and Technology Edition) ›› 2025, Vol. 55 ›› Issue (5): 1536-1543.doi: 10.13229/j.cnki.jdxbgxb.20240542

Previous Articles Next Articles

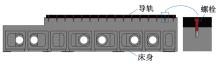

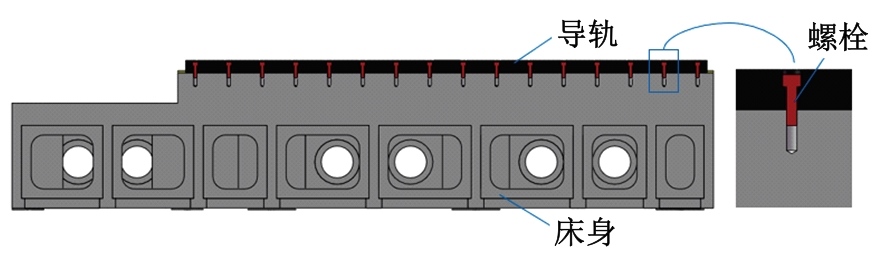

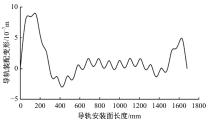

Modeling of CNC machine tool line rail assembly accuracy and its control method

Zhi-feng LIU1( ),Ji-min CHEN2,Ying LI2(

),Ji-min CHEN2,Ying LI2( ),Yong-sheng ZHAO2,Xing YAN2,Fu-quan SUN2

),Yong-sheng ZHAO2,Xing YAN2,Fu-quan SUN2

- 1.College of Mechanical and Aerospace Engineering,Jilin University,Changchun 130022,China

2.School of Mechanical and Energy Engineering,Beijing University of Technology,Beijing 100124,China

CLC Number:

- TG95

| [1] | 黄贤振, 李超, 孙超, 等. 基于失效模式和动态贝叶斯网络的数控机床可靠性分析[J].吉林大学学报:工学版,2024: 10.13229/j.cnki.jdxbgxb.2024005 |

| Huang Xian-zhen, Li Chao, Sun Chao, et al. Reliability analysis of CNC machine tools based on failure modes and dynamic Bayesian networks[J]. Journal of Jilin University(Engineering and Technology Edition), 2024: 10.13229/j.cnki.jdxbgxb.2024005 | |

| [2] | Ajani I, Lu C. Assembly variation analysis of the non-rigid assembly with a deformation gradient model[J]. Assembly Automation, 2022, 42(1): 40-53. |

| [3] | Mu X K, Wang Y L, Yuan B, et al. A new assembly precision prediction method of aeroengine high-pressure rotor system considering manufacturing error and deformation of parts[J]. Journal of Manufacturing Systems,2021, 61: 112-124. |

| [4] | Yang X, Ran Y, Wang Z C, et al. Early prediction method for assembly precision of mechanical system and assessment of precision reliability[J]. The International Journal of Advanced Manufacturing Technology, 2021, 112: 203-220. |

| [5] | 蔡尚文, 汪惠芬, 刘庭煜. 基于误差传递模型的机床进给系统装配精度预测与调整方法[J]. 机械制造与自动化, 2016, 45(6): 6-10. |

| Cai Shang-wen, Wang Hui-fen, Liu Ting-yu. Assembly precision prediction and adjustment method based on error propagation model[J]. Mach Build Autom, 2016, 45(6): 6-10. | |

| [6] | Liu T, Cao Y L, Wang J, et al. Assembly error calculation with consideration of part deformation[J]. Procedia Cirp, 2016, 43: 58-63. |

| [7] | Lu C, Wang S L. An approach to evaluating product assembly precision considering the effect of joint surface deformation[J]. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 2014, 228(14): 2604-2617. |

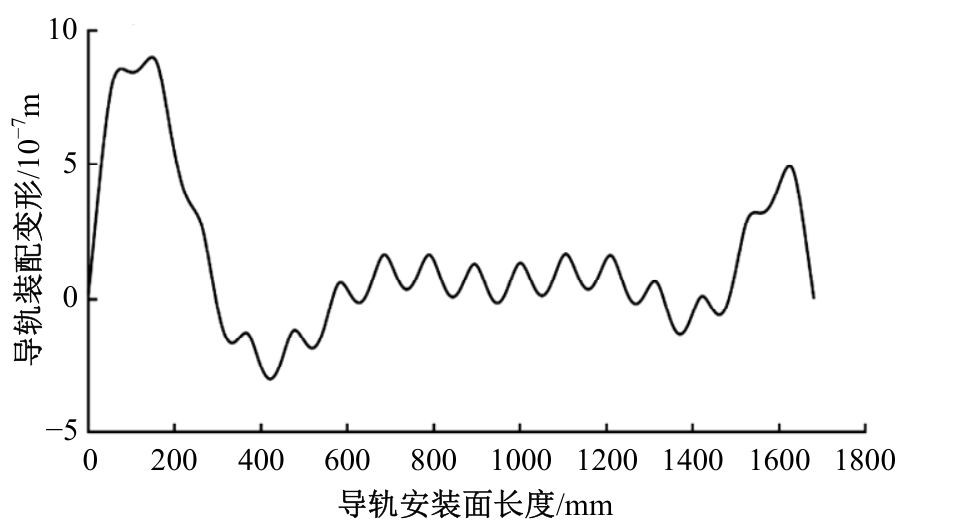

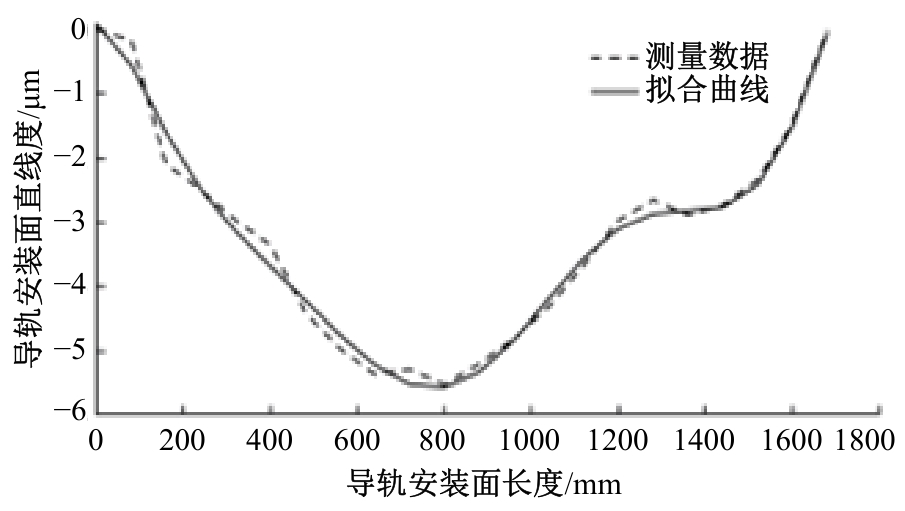

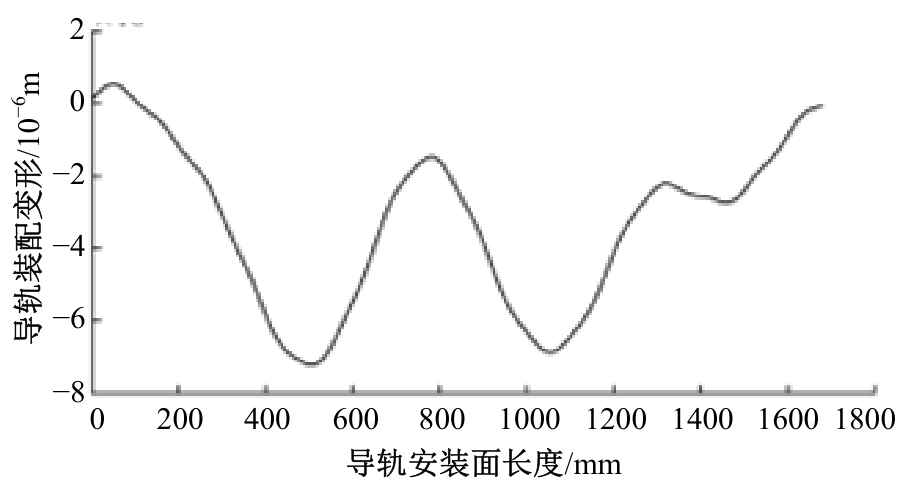

| [8] | Song L Q, Zhang Q, Zhao X S, et al. The influence of the mounting surface error on the deformation of the guideway[J]. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 2024, 238(9): 4071-4084. |

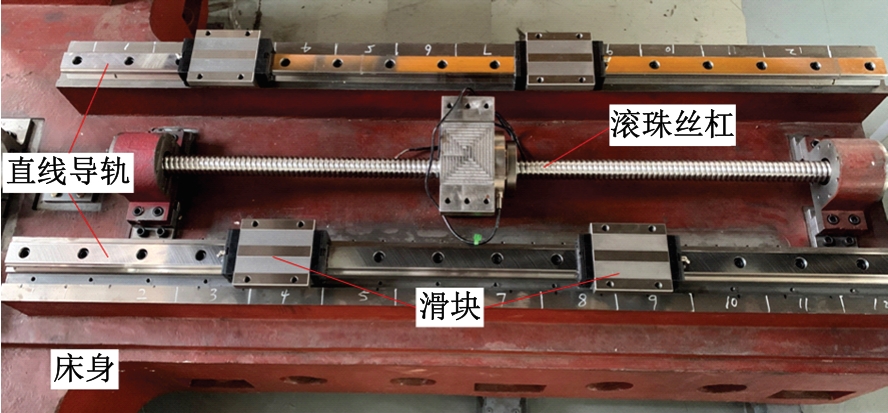

| [9] | Liu C, Zhao C Y, Wen B C. Dynamics analysis on the MDOF model of ball screw feed system considering the assembly error of guide rails[J]. Mechanical Systems and Signal Processing, 2022, 178: 109290. |

| [10] | Sun G M, He G Y, Weng L T, et al. Research on assembly deformation of machine tool guideway[C]∥ IEEE International Conference on Advanced Manufacturing, Chongqing, China, 2018: 231-234. |

| [11] | Zheng B, Yu H D, Lai X M. Assembly deformation prediction of riveted panels by using equivalent mechanical model of riveting process[J]. The International Journal of Advanced Manufacturing Technology, 2017, 92: 1955-1966. |

| [12] | Sun Y P, Wang D L, Dong H M, et al. Pre-deformation for assembly performance of machine centers[J]. Chinese Journal of Mechanical Engineering, 2014, 27(3): 528-536. |

| [13] | Motosh N. Development of design charts for bolts preloaded up to the plastic range[J]. Journal of Manufacturing Science and Engineering, 1976, 98(3): 849-851. |

| [14] | Ekinci T O, Mayer J R R. Relationships between straightness and angular kinematic errors in machines[J]. International Journal of Machine Tools and Manufacture, 2007, 47(12):1997-2004. |

| [15] | Tang H, Duan J A, Zhao Q C. A systematic approach on analyzing the relationship between straightness & angular errors and guideway surface in precise linear stage[J]. International Journal of Machine Tools and Manufacture, 2017, 120: 2-9. |

| [1] | An-jiang CAI,Pei-peng WANG,Chen-xi WANG,Ling LI. Construction method of virtual simulation machining platform for CNC machine tools with multi-spindle heads [J]. Journal of Jilin University(Engineering and Technology Edition), 2024, 54(6): 1528-1536. |

| [2] | Li-juan YU,Ang LIU,Zhao-jun YANG,Hai-long TIAN,Chuan-hai CHEN,Jing-wen GAO. Reliability analysis of numerical control machine tools based on analytic network process and date enevalopment analys [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(2): 400-408. |

| [3] | Chuan-hai CHEN,Cheng-gong WANG,Zhao-jun YANG,Zhi-feng LIU,Hai-long TIAN. Research status and development trend analysis of reliability modeling of CNC machine tools [J]. Journal of Jilin University(Engineering and Technology Edition), 2022, 52(2): 253-266. |

| [4] | Yong-ping LIU,Chang-bin DONG,Yong-qiao WEI. Analysis of tooth surface contact and dynamic wear of elliptic gear transmission system [J]. Journal of Jilin University(Engineering and Technology Edition), 2021, 51(5): 1620-1627. |

| [5] | REN Qing-lei, WEI Xin, XIE Xiao-zhu, HU Wei. Micro contact mechanism based on force in self rotation grinding of silicon wafer [J]. 吉林大学学报(工学版), 2018, 48(3): 796-802. |

| [6] | TONG Jin, WANG Ya-hui, LU Ji-sheng, ZHANG Shu-jun, CHEN Dong-hui. Coaxiality measurement of large-size forged components based on CCD [J]. 吉林大学学报(工学版), 2013, 43(04): 945-950. |

| [7] | ZHANG Hua-jun, HUANG Qing-xue, QUAN Long. Servo control of the composite controller based on combined given curve [J]. 吉林大学学报(工学版), 2013, 43(02): 346-351. |

| [8] | SHI Yong-jie, ZHENG Di, HU Li-yong, WANG Long-shan. Force-position-posture decoupling technique for NC polishing of aspherical part [J]. 吉林大学学报(工学版), 2012, 42(01): 116-121. |

| [9] | XU Bin-bin, YANG Zhao-jun, CHEN Fei, HAO Qing-bo, ZHAO Hong-wei, LI Guo-fa. Reliability model of CNC machine tools based on non-homogenous poisson process [J]. 吉林大学学报(工学版), 2011, 41(增刊2): 210-214. |

| [10] | ZHANG Ying-zhi, ZHENG Rui, SHEN Gui-xiang, WANG Zhi-qiong, LI Huai-yang, et al. Failure dependency of CNC equipment based on copula theory [J]. 吉林大学学报(工学版), 2011, 41(6): 1636-1640. |

| [11] | REN Di, WANG Zu-Wen, BAO Gang, YANG Qing-Jun. Static characteristic for |newstyle high stiffness externally pressurized spherical gas bearings [J]. 吉林大学学报(工学版), 2010, 40(06): 1599-1603. |

| [12] | KONG Fan-Sen, LIU Peng, CAO Yang-Hua, DAN Jin-Dan. Fuzzy comprehensive evaluation on work environment in a gearbox plant [J]. 吉林大学学报(工学版), 2010, 40(02): 475-0479. |

| [13] | CHEN Jun, HU Ping, MA Li-Li. Time buffer control mechanism based on drumbufferrope for remanufacturing system [J]. 吉林大学学报(工学版), 2009, 39(05): 1197-1201. |

| [14] | ZHAO Yang, ZHAO Ji, ZHANG Lei, JI Li-Zhe. Robotic blade grinding based on reverse engineering [J]. 吉林大学学报(工学版), 2009, 39(05): 1176-1180. |

| [15] | MENG Ling-qi,DU Yong,MA Sheng-biao,GUO Bin . Nonlinearity of vertical vibration of medium plate mill [J]. 吉林大学学报(工学版), 2009, 39(03): 712-0715. |

|