吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (6): 1512-1518.doi: 10.13229/j.cnki.jdxbgxb.20220960

• 车辆工程·机械工程 • 上一篇

自激振荡喷嘴流动特性对近嘴区射流雾化的影响

- 山东交通学院 汽车工程学院,济南 250357

Effect of fuel flow in self-excited oscillating nozzle on near-nozzle region jet atomization

Yong-qiang GAO( ),Shi-qian ZHOU,Long QI,Qian-qi YIN,Xue-tao HUANG,Jia-xing ZHANG

),Shi-qian ZHOU,Long QI,Qian-qi YIN,Xue-tao HUANG,Jia-xing ZHANG

- School of Automotive Engineering,Shandong Jiaotong University,Jinan 250357,China

摘要:

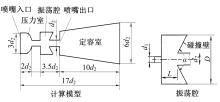

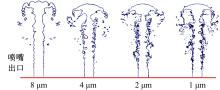

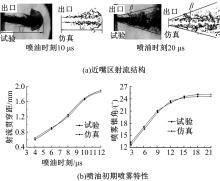

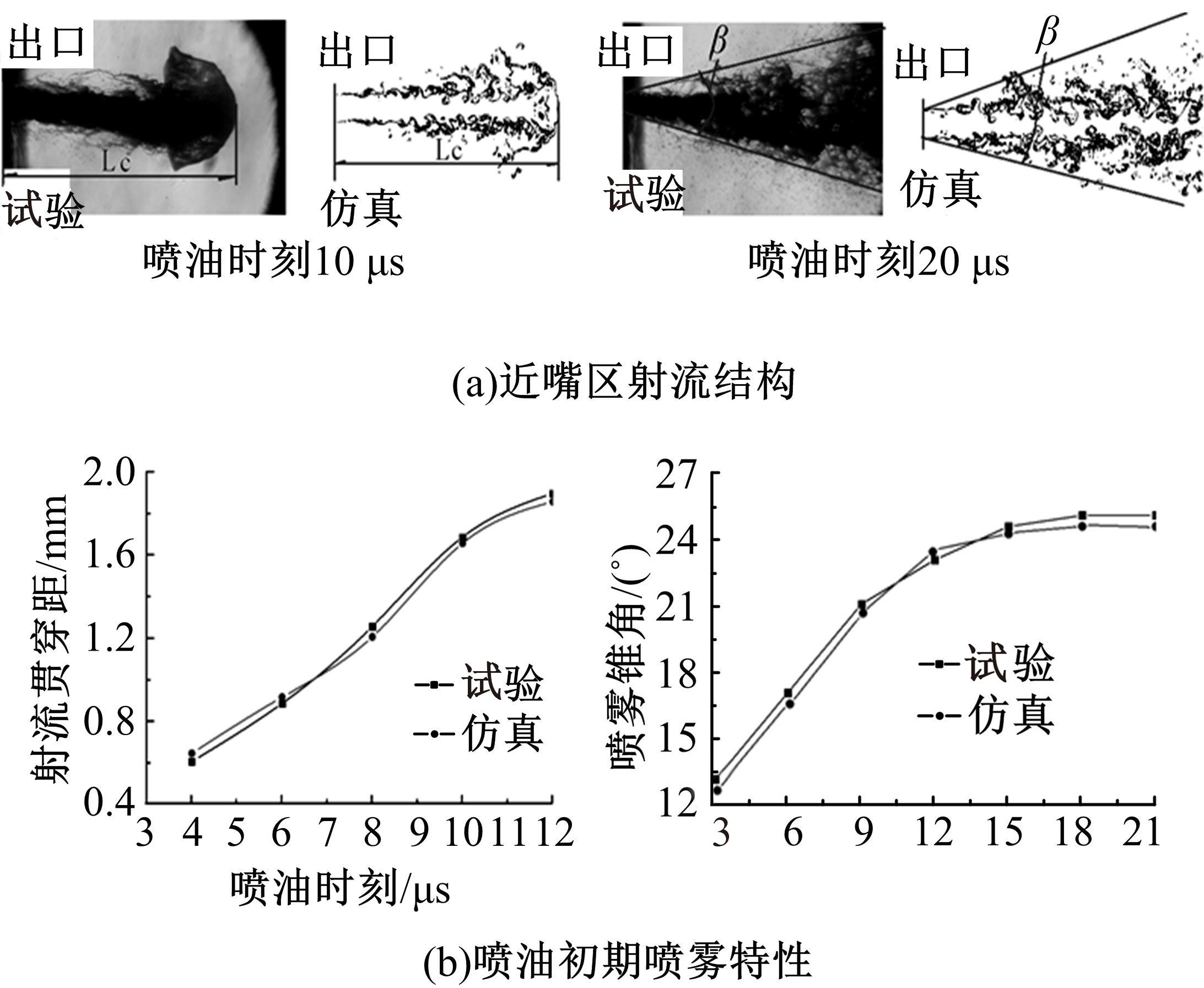

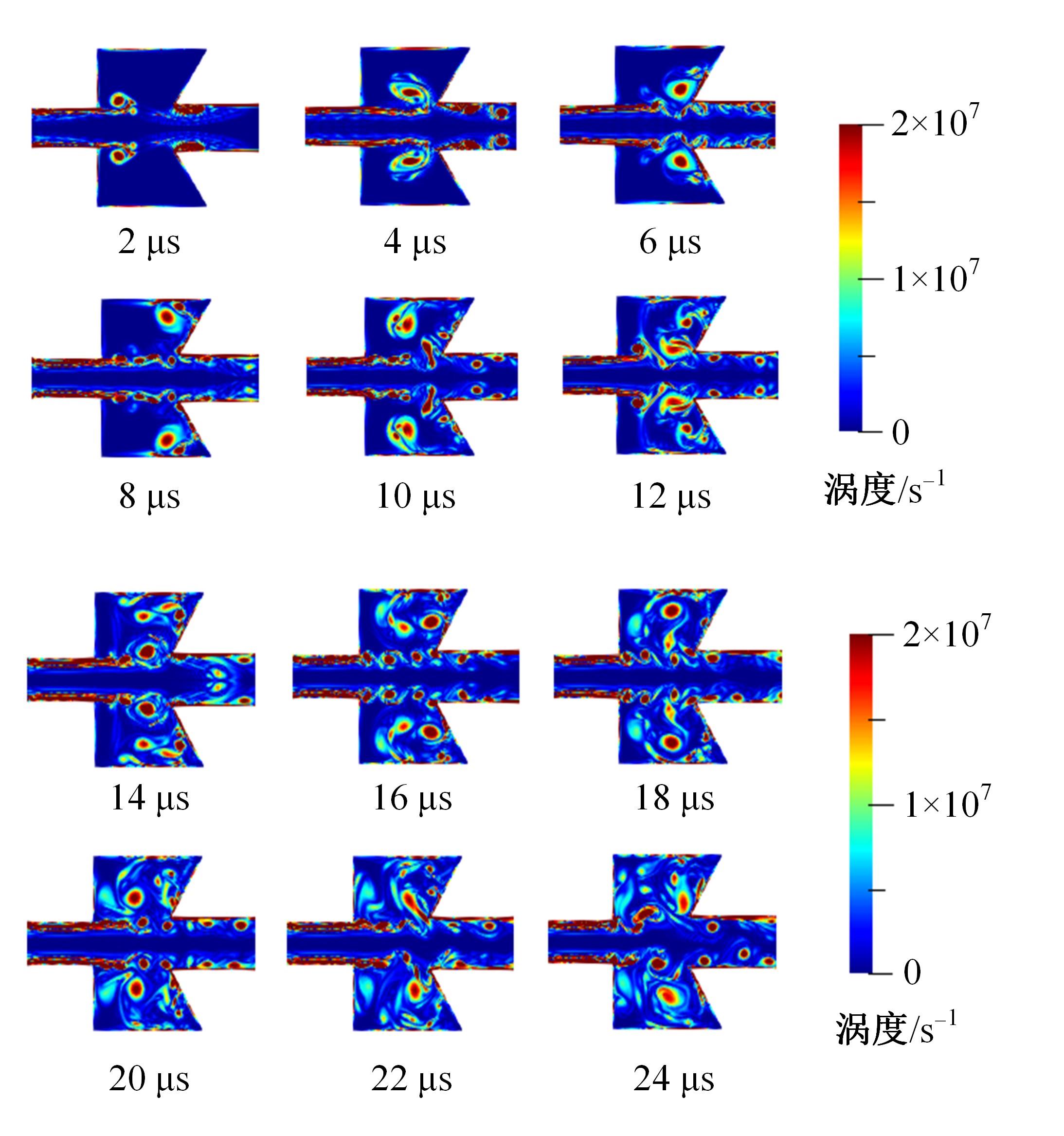

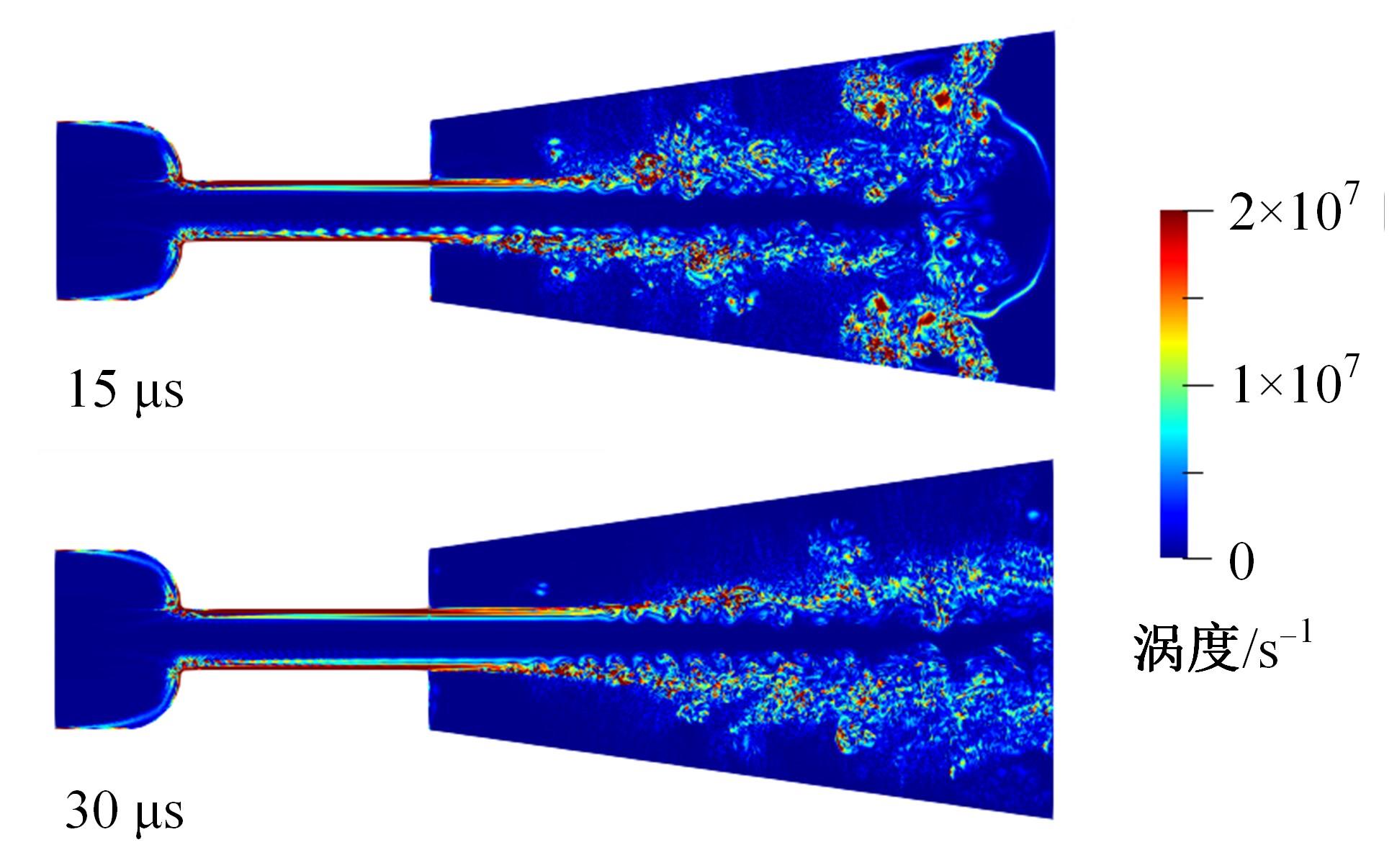

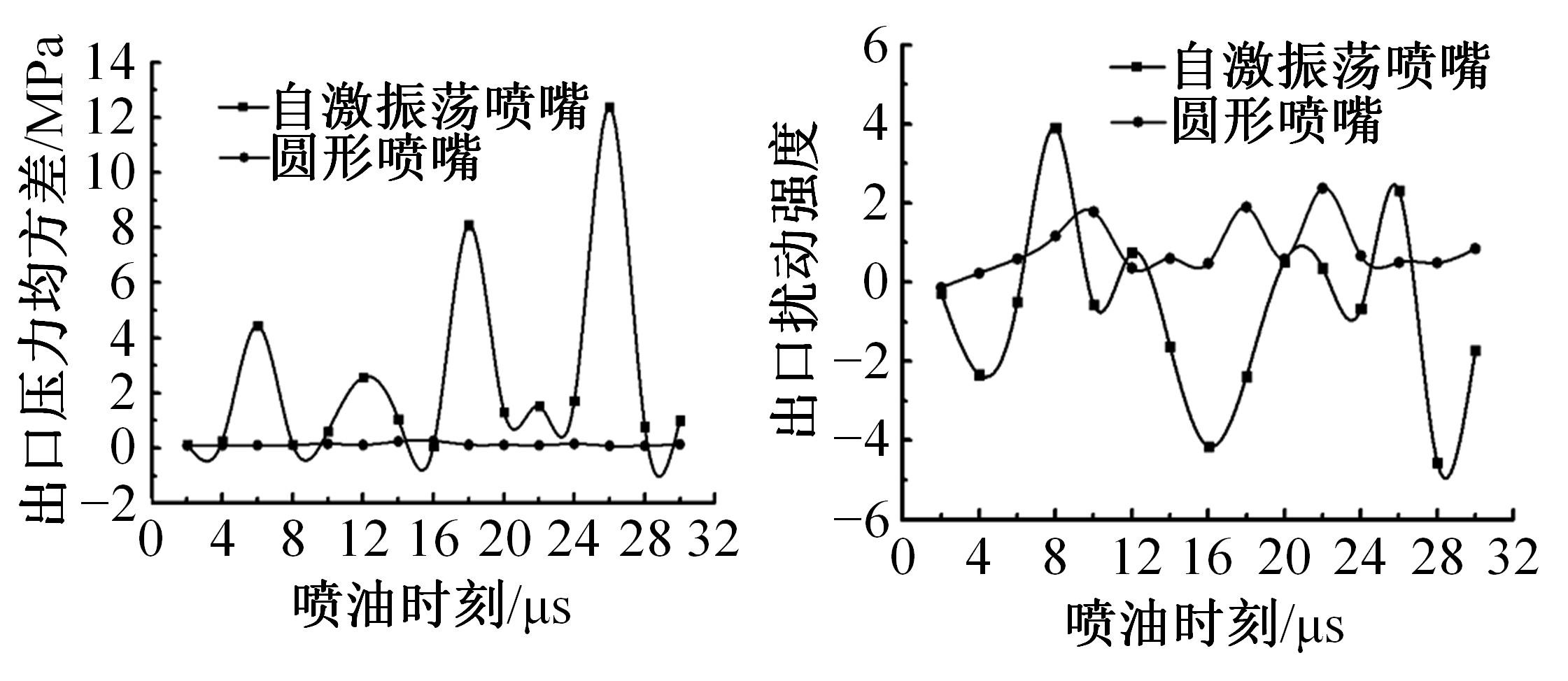

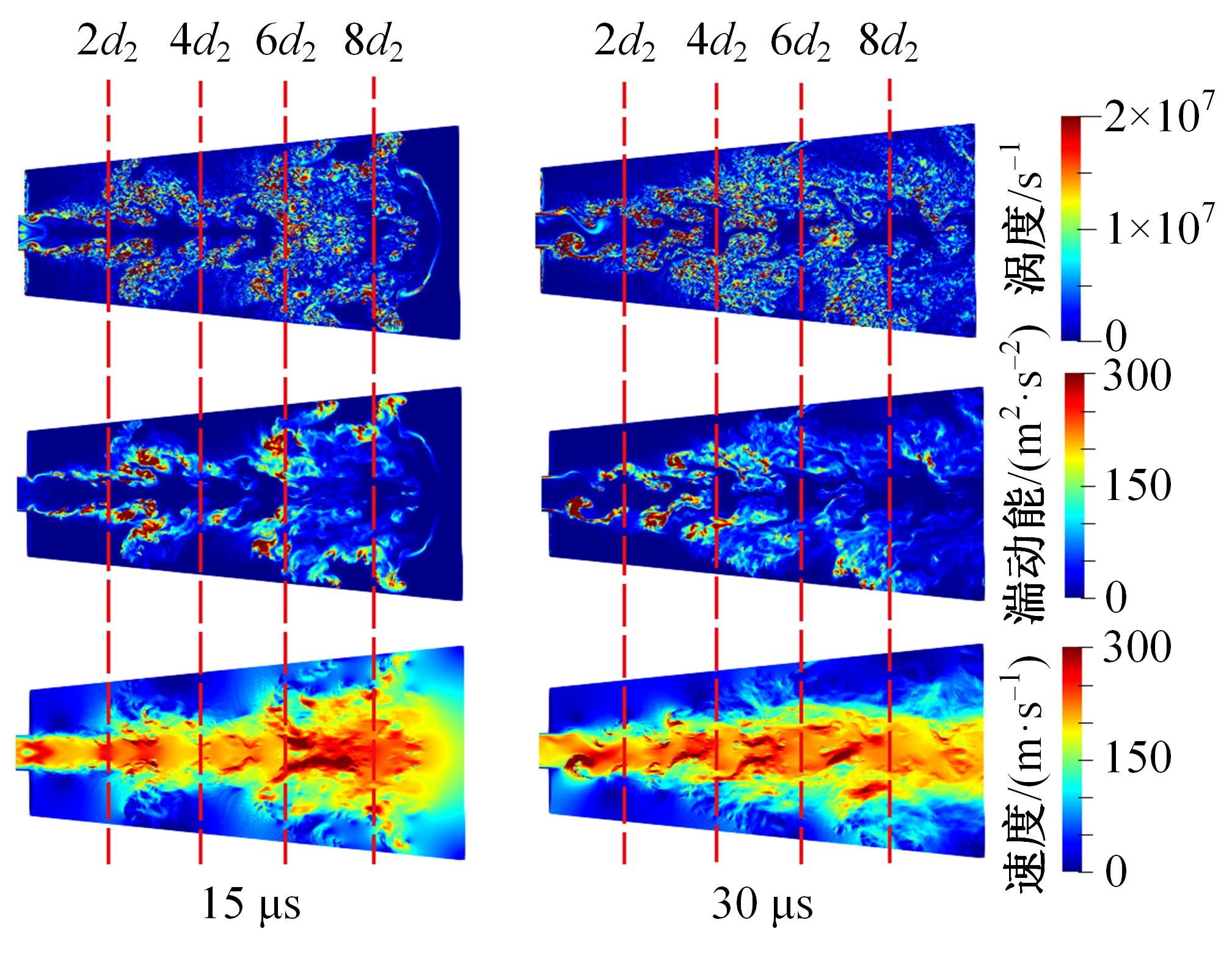

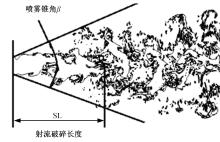

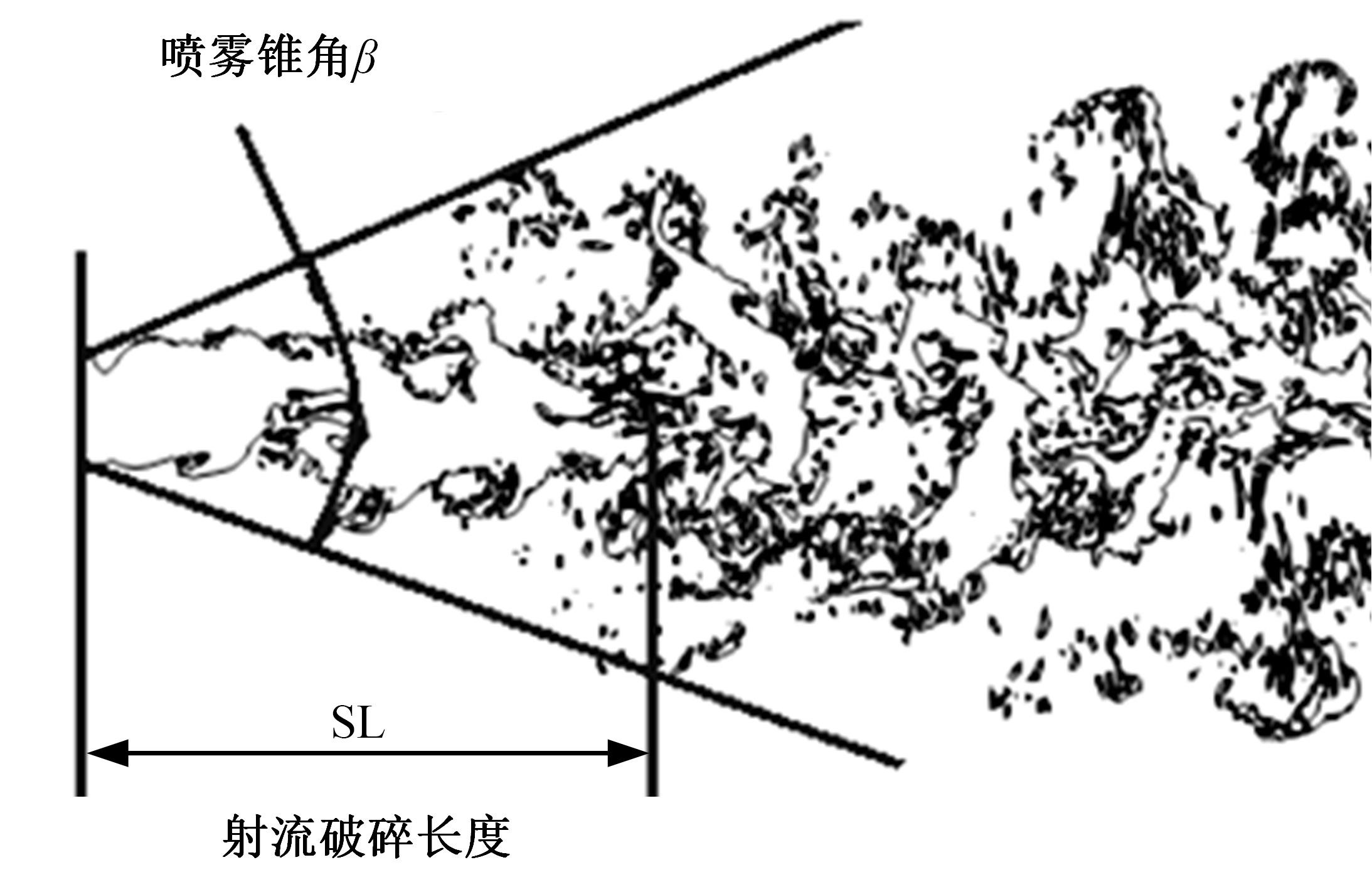

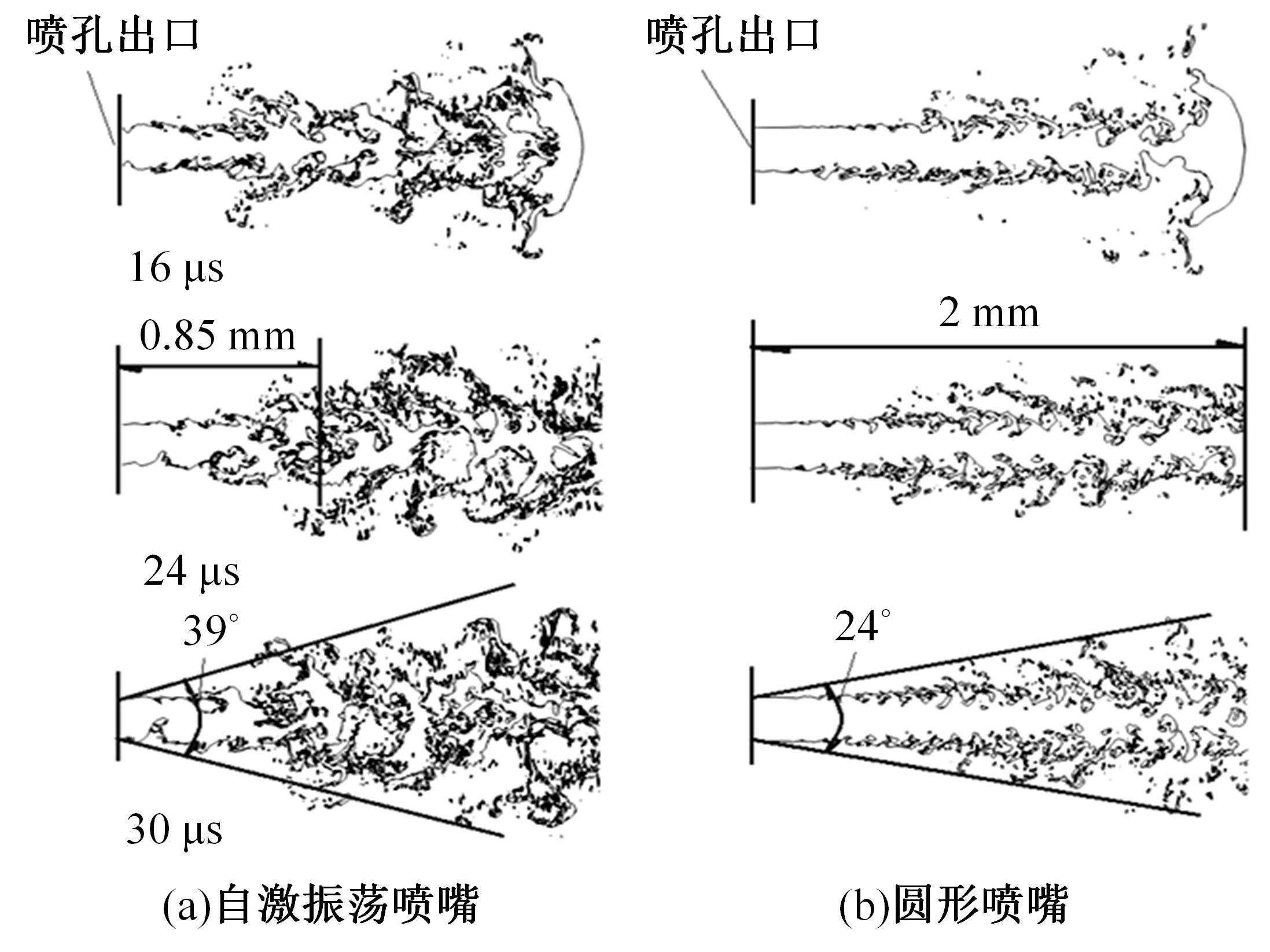

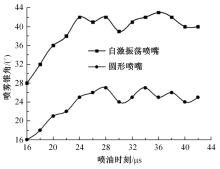

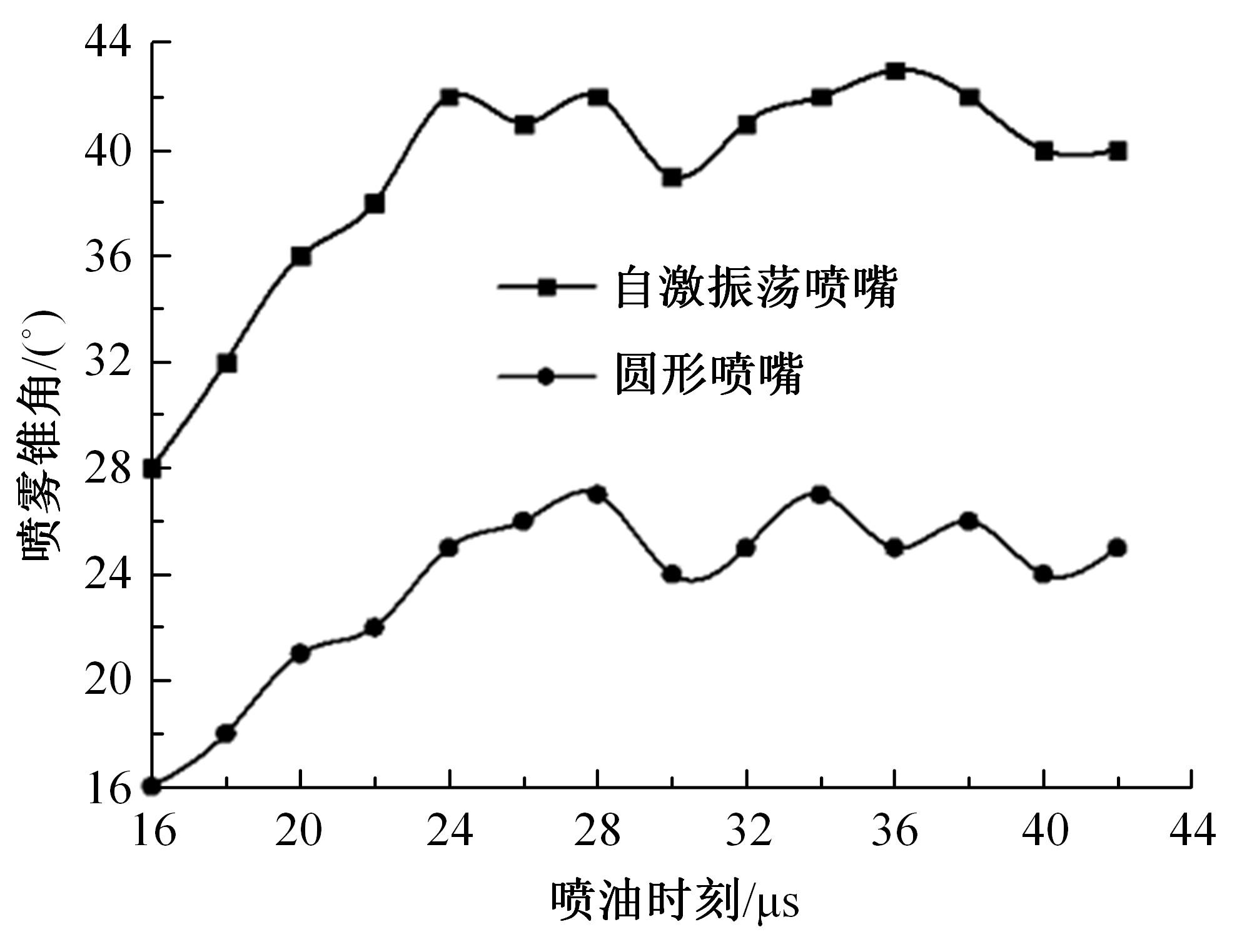

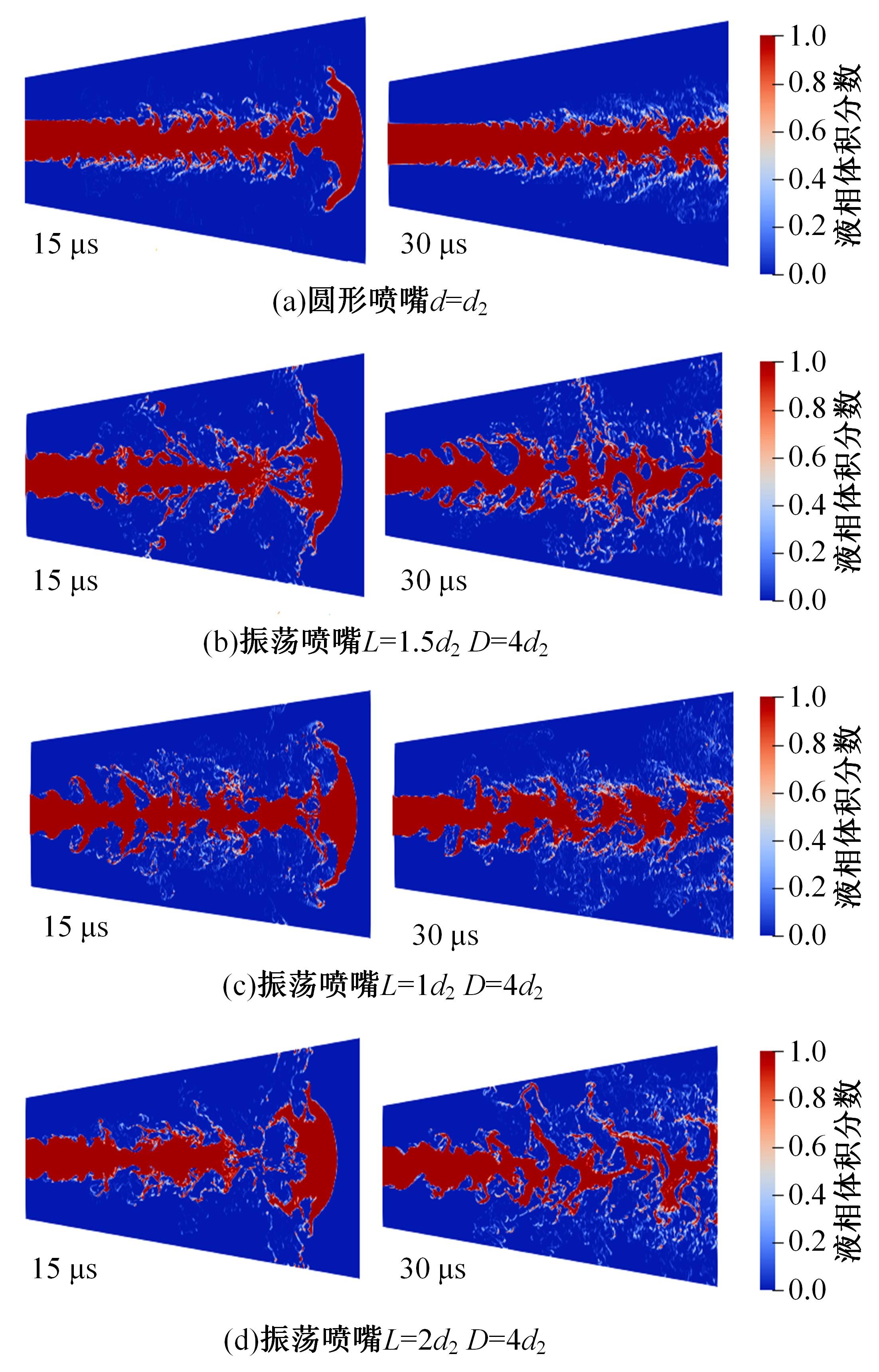

基于大涡模拟(LES)和流体体积分数法(VOF)模型,建立了自激振荡喷嘴流场的数学模型,仿真研究了自激振荡喷嘴内流动及射流破碎过程。结果表明:燃油流过自激振荡喷嘴能显著提高流体涡度和扰动强度,射流扰动强度的振荡幅值增大3倍多。射流扰动对近嘴区射流破碎的影响更加敏感,显著提高了射流破碎质量;近嘴区射流破碎距离(SL)明显减小,SL在距喷嘴出口(2~5)倍直径处变化;近嘴区喷雾锥角也随之增大,最大增幅超过60%,燃油雾化效果得到显著提高。本文计算结果可为自激振荡脉冲雾化喷嘴提供有力的理论依据。

中图分类号:

- TK427

| 1 | Yuan L, Shen C. Computational investigation on combustion instabilities in a rocket combustor[J]. Acta Astronautica, 2016, 127: 634-643. |

| 2 | Ju D, Sun X, Jia X, et al. Experimental investigation of the atomization behavior of ethanol and kerosene in acoustic fields[J]. Fuel, 2017, 202: 613-619. |

| 3 | Lešnik L, Kegl B, Bombek G,et al. The influence of in-nozzle cavitation on flow characteristics and spray break-up[J]. Fuel, 2018, 222:550-560. |

| 4 | Salvador F, Ruiz S, Crialesi E M, et al. Analysis on the effects of turbulent inflow conditions on spray primary atomization in the near-field by direct numerical simulation[J]. International Journal of Multiphase Flow,2018,102:49-63. |

| 5 | Dong P, Keiya N, Ogata Y, et al. Characterization of multi-hole nozzle sprays and internal flow for different nozzle hole lengths in direct-injection diesel engines[J]. Automobile Engineering,2017,231(4):500-515. |

| 6 | Gao Y, Wei M, Yan F, et al. Effects of cavitation flow and stagnant bubbles on the initial temporal evolution of diesel spray[J]. Experimental Thermal and Fluid Science, 2017, 87: 69-79. |

| 7 | Guo G M, He Z X, Wang Q, et al. Effects of the residual/sucked air bubbles on diesel near-nozzlespray structure[C]∥ SAE Paper, 2017-01-2314. |

| 8 | Wang Z M, Li Y F, Wang C M,et al. Experimental study on primary breakup of diesel spray under cold start conditions[J]. Fuel, 2016, 183:617-626. |

| 9 | Junkyu P, Donghwan K, Sungwook P. Effects of nozzle L/D on near-field development and macroscopic spray characteristics of common-rail[J]. International Journal of Automotive Technology,2020,21(3):657-666. |

| 10 | Wei Y J, Li T, Zhou X Y, et al. Time-resolved measurement of the near-nozzle air entrainment of high pressure diesel spray by high speed micro-PTV technique[J]. Fuel, 2020, 268:1-12. |

| 11 | Yu S, Yin B, Jia H, et al. Numerical research on micro diesel spray characteristics under ultrahigh injection pressure by Large Eddy Simulation (LES) [J]. International Journal of Heat and Fluid Flow, 2017, 64:129-136. |

| 12 | Yin B, Yu S, Jia H, et al. Numerical research of diesel spray and atomization coupled cavitation by Large Eddy Simulation (LES) under high injection pressure[J]. International Journal of Heat and Fluid Flow, 2016, 59(6):1-9. |

| 13 | He Z, Guo G, Tao X, et al. Study of the effect of nozzle hole shape on internal flow and spray characteristics[J]. International Communication in Heat and Mass Transfer, 2016, 71: 1-8. |

| 14 | 解方喜,姚卓彤,胡雪松,等. 针阀运动和油压波动对燃油喷雾特性的影响[J].吉林大学学报:工学版,2013,43(4):898-902. |

| Xie Fang-xi, Yao Zhuo-tong, Hu Xue-song, et al. Influence of dynamic change of needle and hydraulic pressurein diesel injection nozzle on fuel spray characteristic[J]. Journal of Jilin University (Engineering and Technology Edition ), 2013,43(4):898-902. | |

| 15 | 解方喜,于泽洋, 刘思楠,等. 喷射压力对燃油喷雾和油气混合特性的影响[J].吉林大学学报:工学版,2013,43(6):1504-1509. |

| Xie Fang-xi, Yu Ze-yang, Liu Si-nan, et al. Effects of injection pressure on fuel spray and air-fuel mixing process of diesel engine[J]. Journal of Jilin University (Engineering and Technology Edition), 2013, 43(6):1504-1509. | |

| 16 | 廖振方,唐川林.自激振荡脉冲射流喷嘴的理论分析[J]. 重庆大学学报:自然科学版,2002,25(2):24-27. |

| Liao Zhen-fang, Tang Chuan-lin. Theory of the self-excited oscillation pulsed jet nozzle[J]. Journal of Chongqing University(Natural Science Edition),2002, 25(2):24-27. | |

| 17 | 汪朝晖, 胡亚男, 廖振方,等. 基于自激振荡脉冲效应的雾化喷嘴出口流道空化特性研究[J].机械工程学报,2016,52(14):204-211. |

| Wang Zhao-hui, Hu Ya-nan, Liao Zhen-fang, et al. Cavitation characteristics study on the outlet channel of atomization nozzle based on the self-excited oscillating pulse effects[J]. Journal of Mechanical Engineering,2016, 52(14):204-211. | |

| 18 | 蔚晓嘉,刘邱祖. 自激振荡射流喷嘴内部流场及雾化效果的数值模拟[J].中国粉体技术,2016,22(2):7-10. |

| Wei Xiao-jia, Liu Qiu-zu. Numerical simulation on internal flow field and atomization effect of self-excited oscillation jet nozzle[J].China Power Science and Technology, 2016,22(2):7-10. | |

| 19 | Sone K, Patel N, Menon S. Large-eddy simulation of fuel-air mixing in an internal combustion engine[C]. ∥Aiaa Paper, 2001-0635, 2001. |

| 20 | 高永强. 空化燃油射流破碎机理的理论和试验研究[D].武汉:武汉理工大学汽车工程学院,2018. |

| Gao Yong-qiang. Experimental and simulation investigation of the mechanism breaking of cavitation fuel jet[D]. Wuhan: School of Automotive Engineering, Wuhan University of Technology, 2018. | |

| 21 | Ghiji M, Goldsworthy L, Brandner P A, et al. Numerical and experimental investigation of early stage diesel sprays[J]. Fuel, 2016,175: 274-286. |

| [1] | 解方喜,赵士杰,王梓森,刘爽,李小平,张程. 多孔喷油器闪急沸腾喷雾坍塌影响因素的仿真分析[J]. 吉林大学学报(工学版), 2023, 53(12): 3314-3325. |

| [2] | 虞浏, 刘忠长, 刘金山, 刘江唯, 杜宏飞, 程鹏. 汽油喷雾前锋粒径特性[J]. 吉林大学学报(工学版), 2018, 48(3): 720-726. |

| [3] | 江涛, 林学东, 李德刚. 超高压喷射对直喷柴油机混合气形成、燃烧及排放特性的影响[J]. 吉林大学学报(工学版), 2016, 46(5): 1484-1493. |

| [4] | 李君, 朱昌吉, 马光兴. 二甲基醚喷雾特性试验[J]. 吉林大学学报(工学版), 2003, (1): 13-16. |

|

||