吉林大学学报(工学版) ›› 2024, Vol. 54 ›› Issue (5): 1347-1354.doi: 10.13229/j.cnki.jdxbgxb.20230005

• 交通运输工程·土木工程 • 上一篇

进口集装箱堆场箱位分配与场桥调度协同优化

- 上海海事大学 物流科学与工程研究院,上海 201306

Integrated optimization of storage space allocation and yard crane scheduling in import container yards

- Institute of Logistics Science and Engineering,Shanghai Maritime University,Shanghai 201306,China

摘要:

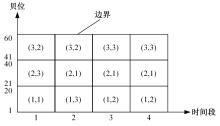

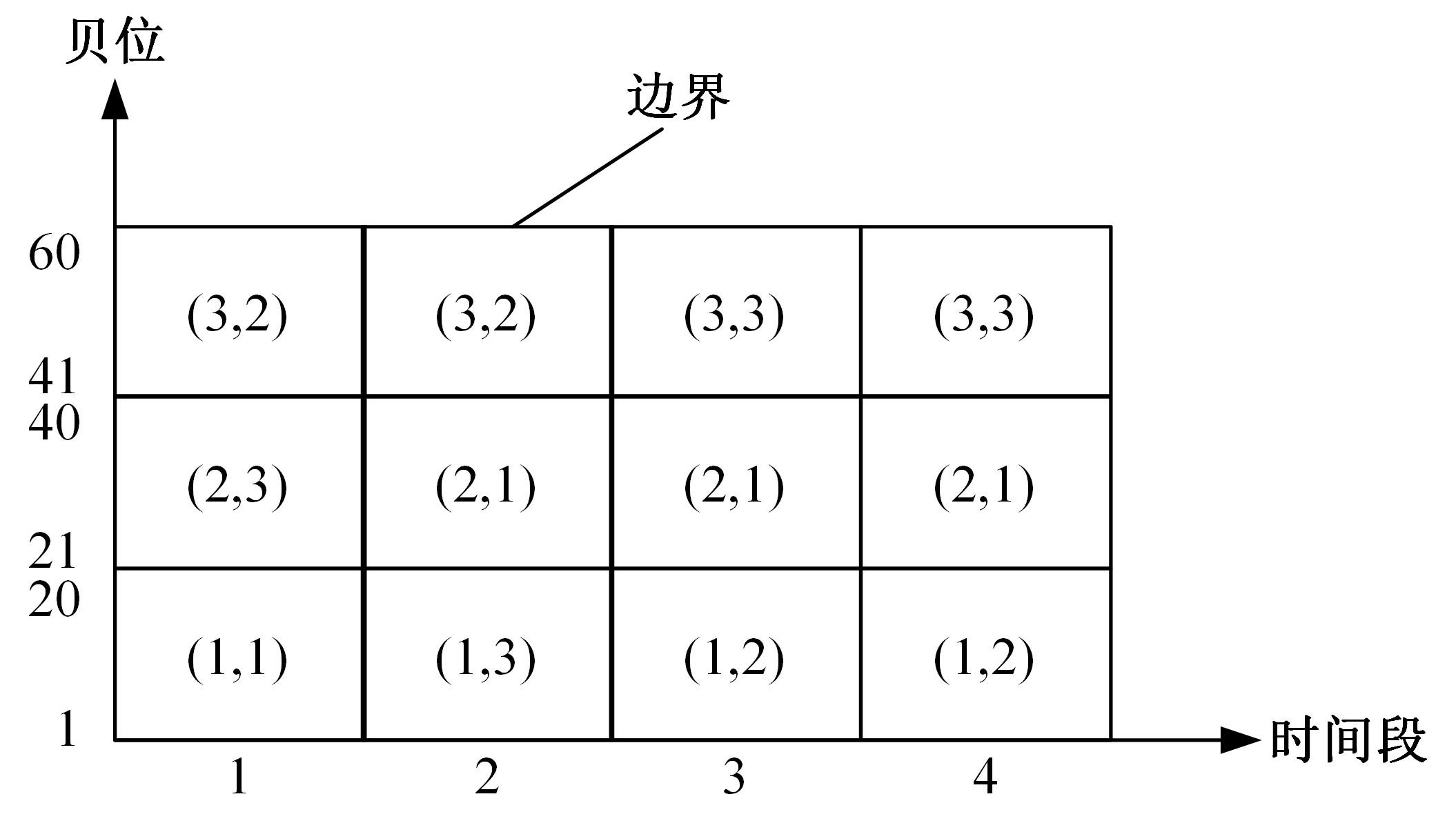

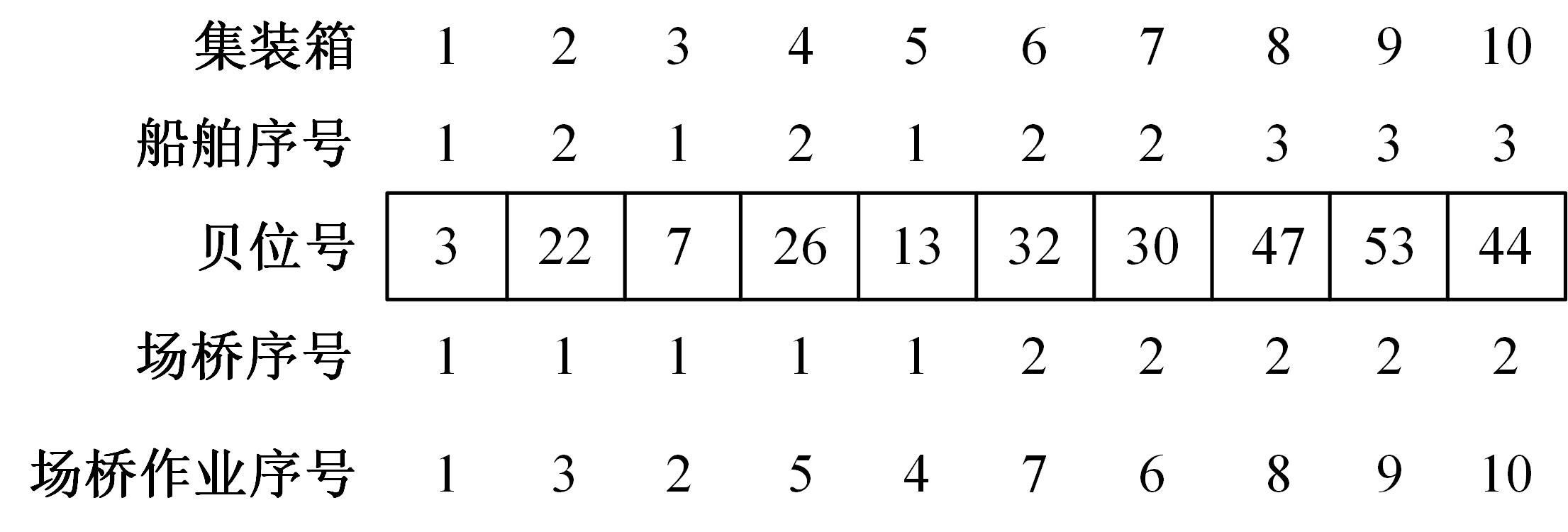

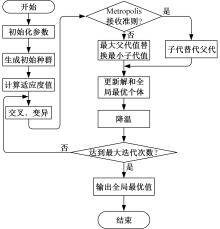

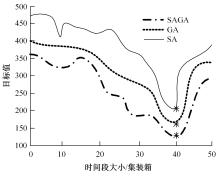

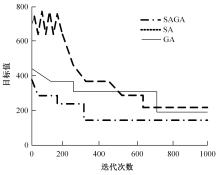

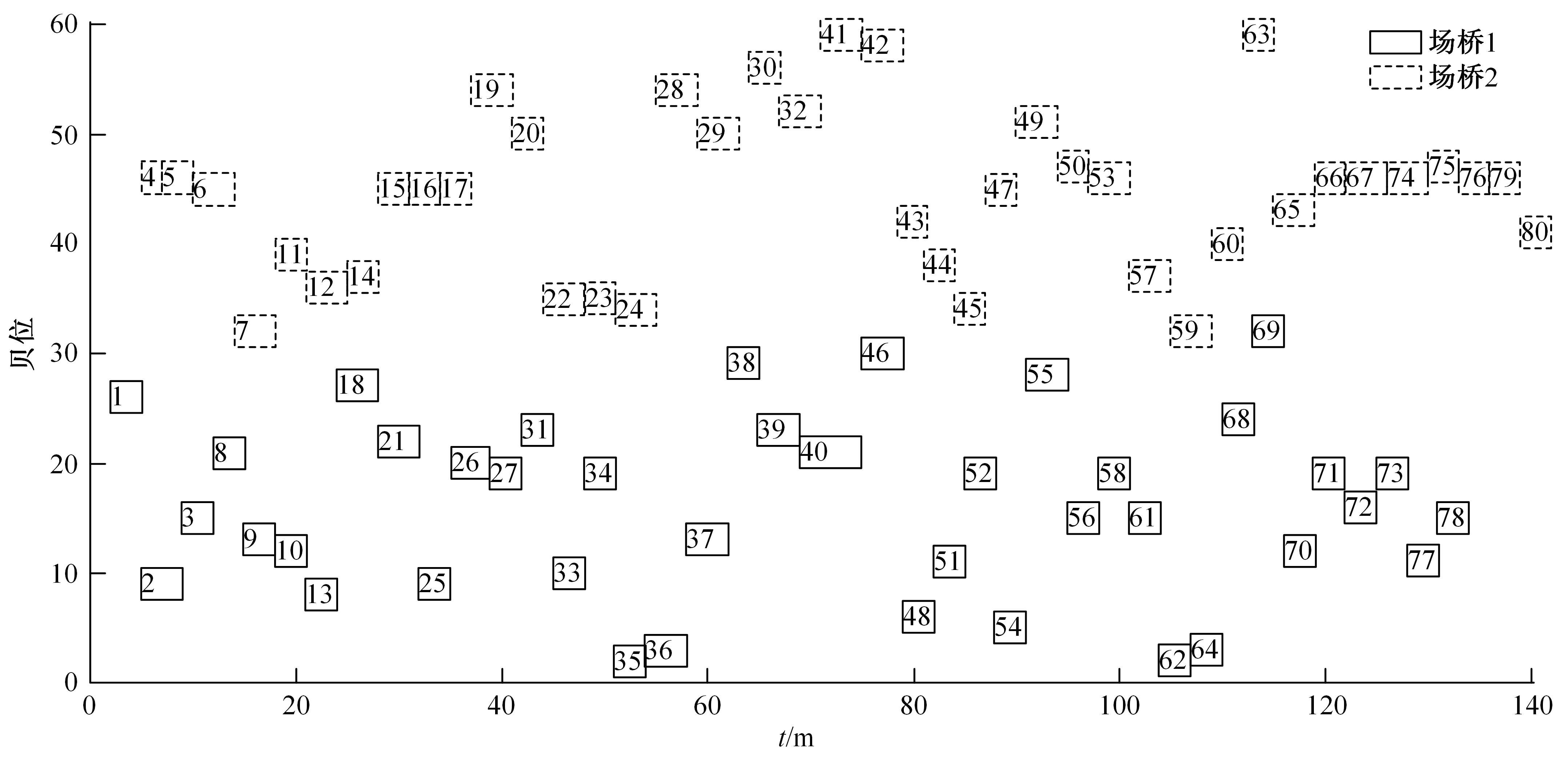

针对场桥作业均衡和效率问题,设计了分时段平衡策略(TPBS),考虑了场桥之间作业安全距离和堆场容量的约束,建立了一个混合整数规划模型,以最大限度地减少双场桥的作业量方差和作业总时间,为了求解建立的模型并分析算例,开发了模拟退火遗传算法(SAGA)。通过不同算法对比实验和3种平衡策略在集装箱数量为80~500个时的对比实验及分析,实验结果表明:SAGA对比于GA和SA的目标值分别平均降低7.32%、20.66%,分时段平衡策略可以均衡场桥作业任务量,缩短集装箱装卸任务的完成时间,有效地提高了堆场空间的利用率,并有助于提高场桥的整体作业效率。

中图分类号:

- U169.6

| 1 | 田宇, 周强, 朱本飞. 自动化集装箱码头双循环AGV与场桥的集成调度研究[J]. 交通运输系统工程与信息, 2020, 20(4): 216-223. |

| Tian Yu, Zhou Qiang, Zhu Ben-fei. Integrated scheduling of dual-cycle AGV and yard crane at automated container terminal[J]. Journal of Transportation Systems Engineering and Information Technology, 2020, 20(4): 216-223. | |

| 2 | Chang Y M, Zhu X N. A novel two-stage heuristic for solving storage space allocation problems in rail-water intermodal container terminals[J]. Symmetry-Basel, 2019, 11(10): 1-18. |

| 3 | Maldonado S, Gonzalez-ramirez R G, Quijada F, et al. Analytics meets port logistics: a decision support system for container stacking operations[J]. Decision Support Systems, 2019, 121(6): 84-93. |

| 4 | Lin D Y, Chiang C W. The storage space allocation problem at a container terminal[J]. Maritime Policy&Management, 2017, 44(6): 685-704. |

| 5 | 倪敏敏,苌道方. 基于动态平衡策略下的集装箱堆场箱位分配方案研究[J]. 计算机应用研究, 2019, 36(8): 2363-2367. |

| Ni Min-min, Chang Dao-fang. Storage space allocation based on dynamic strategy in container terminal yard[J]. Application Research of Computers, 2019, 36(8): 2363-2367. | |

| 6 | 武慧荣, 朱晓宁, 邓红星. 集装箱海铁联运港口混堆堆场箱区均衡分配模型[J]. 重庆交通大学学报: 自然科学版, 2018, 37(4): 109-115. |

| Wu Hui-rong, Zhu Xiao-ning, Deng Hong-xing. Container space equilibrium assignment model of the mixed storage yard in container sea-rail port[J]. Journal of Chongqing Jiaotong University (Natural Science), 2018, 37(4): 109-115. | |

| 7 | 倪全慧, 梁承姬. 基于作业量平衡的集装箱堆场堆存策略研究[J]. 武汉理工大学学报, 2012, 34(3):75-79. |

| Ni Quan-hui, Liang Cheng-ji. The stock strategy research of container port yard based on working balance[J]. Journal of Wuhan University of Technology, 2012, 34(3): 75-79. | |

| 8 | Jiang X J, Chew E P, Lee L H, et al. Flexible space-sharing strategy for storage yard management in a transshipment hub port[J]. OR Spectrum, 2013, 35(2): 417-439. |

| 9 | Han X L, Wang Q, Huang J. Scheduling cooperative twin automated stacking cranes in automated container terminals[J]. Computers & Industrial Engineering, 2019, 128(2): 553-558. |

| 10 | 王志超, 丁一. 考虑箱区作业均衡的自动化码头集装箱船舶配载计划[J]. 计算机应用, 2021, 41(): 299-303. |

| Wang Zhi-chao, Ding Yi. Stowage planning for container ships in automatic container terminal considering yard workload balance[J]. Journal of Computer Applications, 2021, 41(Sup.2): 299-303. | |

| 11 | Zhou C H, Wang W C, Li H B. Container reshuffling considered space allocation problem in container terminals[J]. Transportation Research Part E: Logistics and Transportation Review, 2020, 136(4): 1-23. |

| 12 | 王清永, 曲伟强. 基于线性规划的城市轨道交通运行调度优化算法[J]. 吉林大学学报: 工学版, 2023, 53(12): 3446-3451. |

| Wang Qing-yong, Qu Wei-qiang. Optimization algorithm of urban rail transit operation scheduling based on linear programming[J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(12): 3446-3451. | |

| 13 | 焦玉玲, 张鹏, 田广东,等. 基于多种群遗传算法的自动化立体库货位优化[J]. 吉林大学学报: 工学版, 2018, 48(5): 1398-1404. |

| Jiao Yu-ling, Zhang Peng, Tian Guang-dong, et al. Slotting optimization of automated warehouse based on multi-population GA[J]. Journal of Jilin University (Engineering and Technology Edition), 2018, 48(5): 1398-1404. | |

| 14 | 郑红星, 隋延清, 贺国燕. 集装箱码头海侧作业资源配置的仿真优化[J]. 计算机仿真, 2020, 37(6): 136-141. |

| Zheng Hong-xing, Sui Yan-qing, He Guo-yan. Simulation optimization of the allocation of terminal's seaside operating resources[J]. Computer Simulation, 2020, 37(6): 136-141. |

| [1] | 赵伟;李文辉;夏云飞 . 基于非线性规划的凸多面体间碰撞检测算法[J]. 吉林大学学报(工学版), 2008, 38(03): 676-0679. |

|

||