吉林大学学报(工学版) ›› 2019, Vol. 49 ›› Issue (5): 1630-1635.doi: 10.13229/j.cnki.jdxbgxb20181222

• • 上一篇

软硬相间层状仿生材料摩擦因数影响因素

王蜜1,2( ),李致远1,樊文选1,李家亿1,刘镇宁1,卢国龙1(

),李致远1,樊文选1,李家亿1,刘镇宁1,卢国龙1( )

)

- 1. 吉林大学 工程仿生教育部重点实验室,长春 130022

2. 长春师范大学 工程学院,长春 130032

Influence factors upon friction coefficient of bioinspired materials with integrated soft and hard layers

Mi WANG1,2( ),Zhi-yuan LI1,Wen-xuan FAN1,Jia-yi LI1,Zhen-ning LIU1,Guo-long LU1(

),Zhi-yuan LI1,Wen-xuan FAN1,Jia-yi LI1,Zhen-ning LIU1,Guo-long LU1( )

)

- 1. Key Laboratory for Bionic Engineering Ministry of Education, Jilin University, Changchun 130022, China

2. College of Engineering, Changchun Normal University, Changchun 130032, China

摘要:

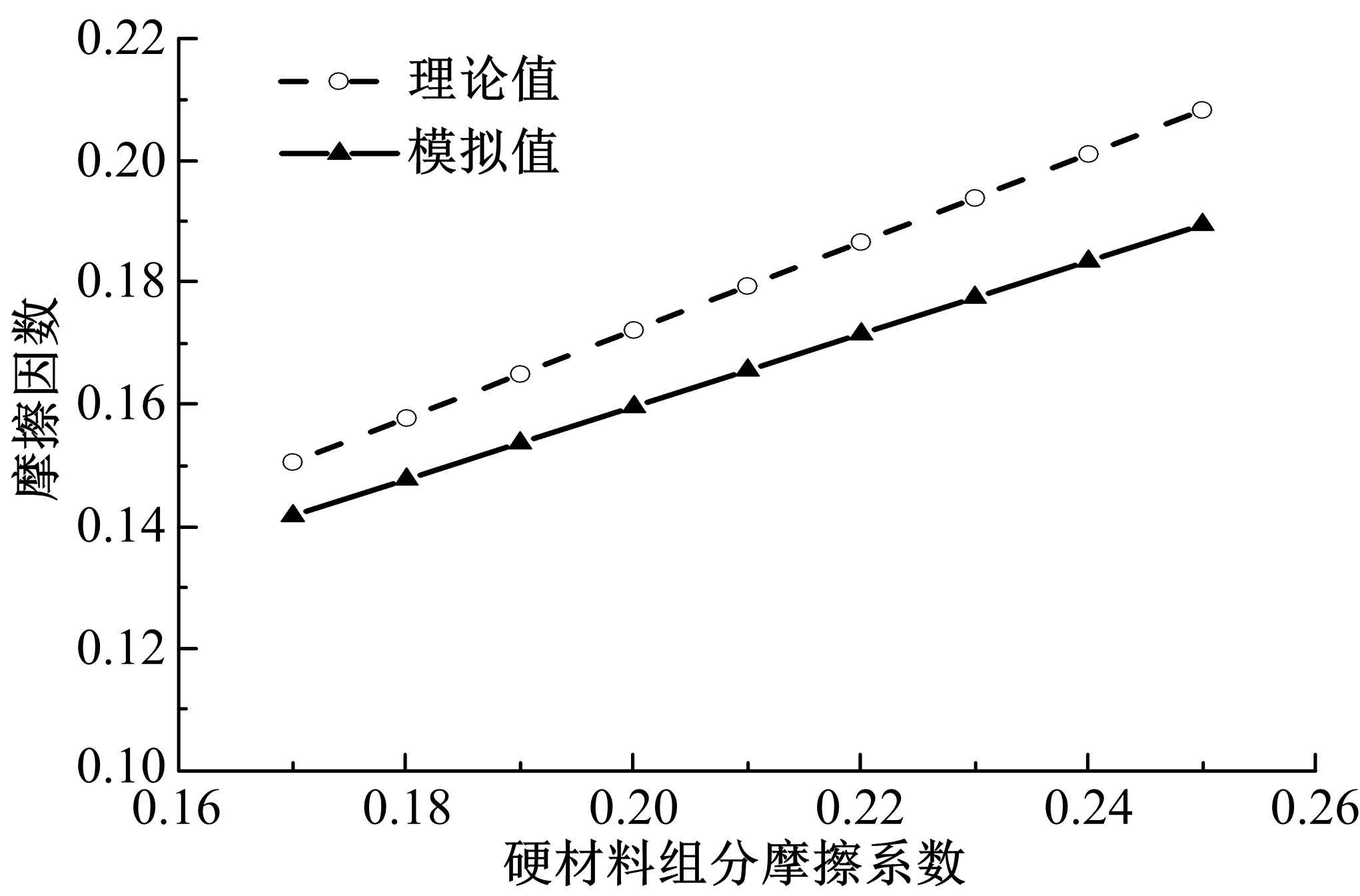

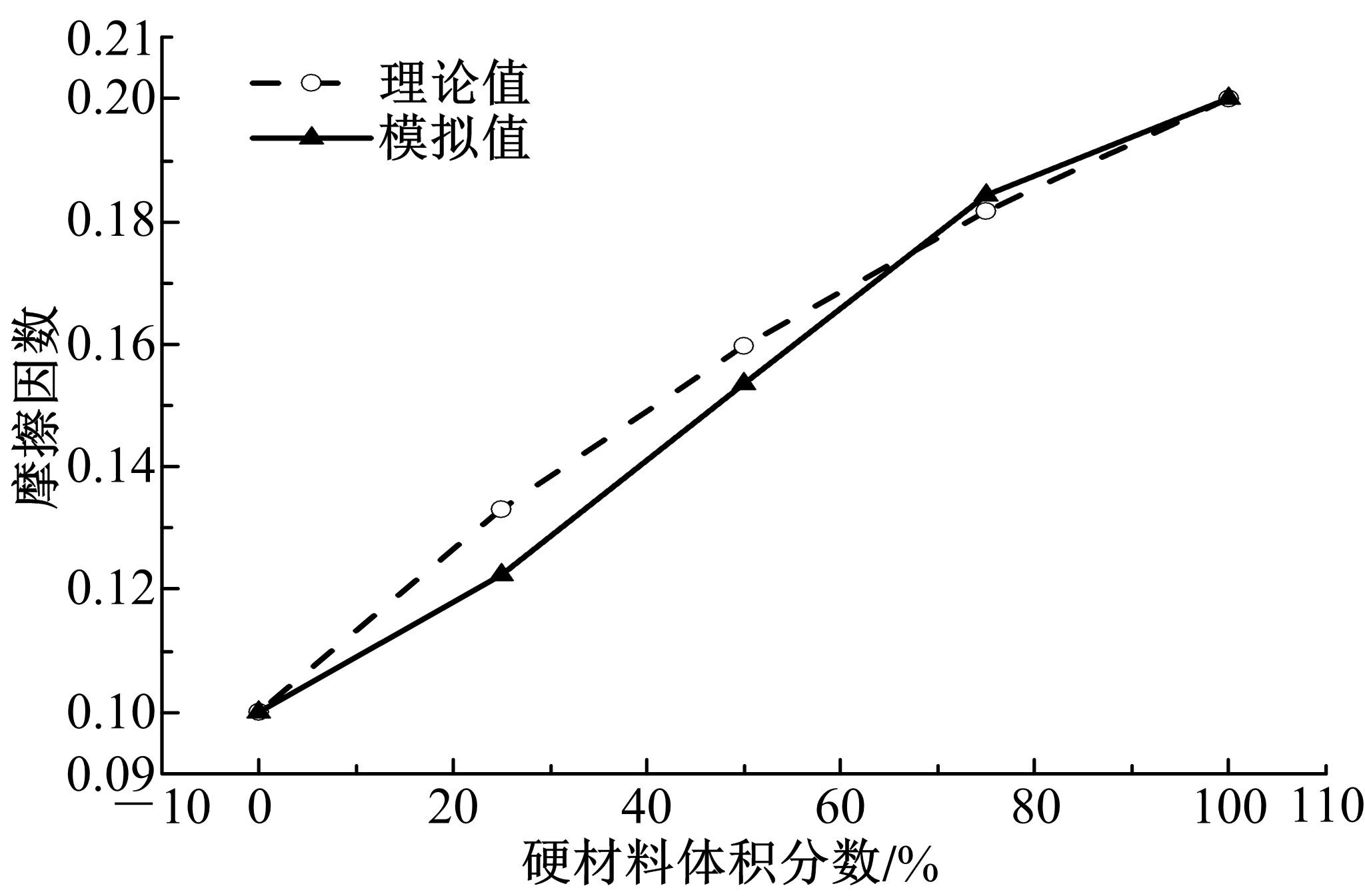

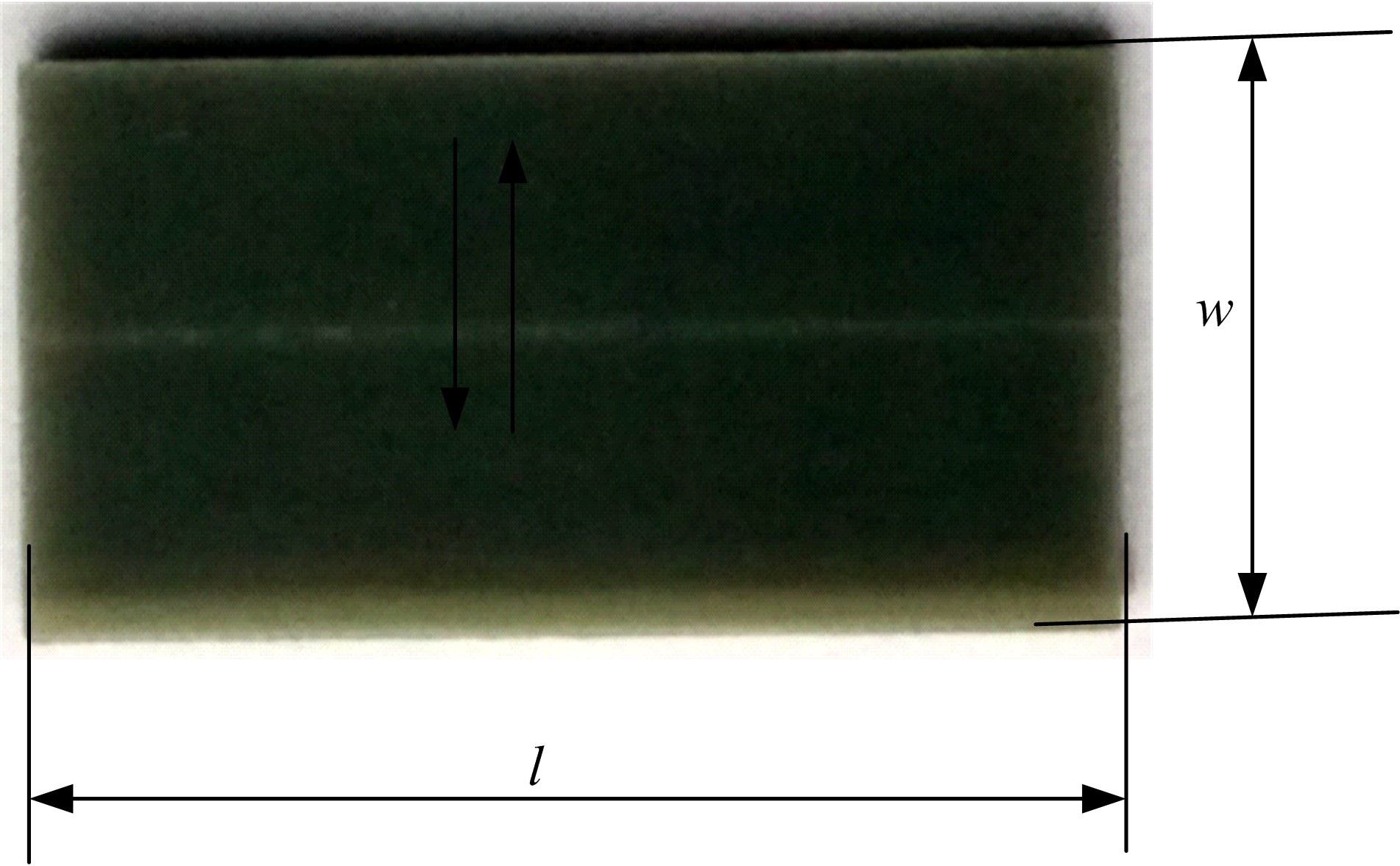

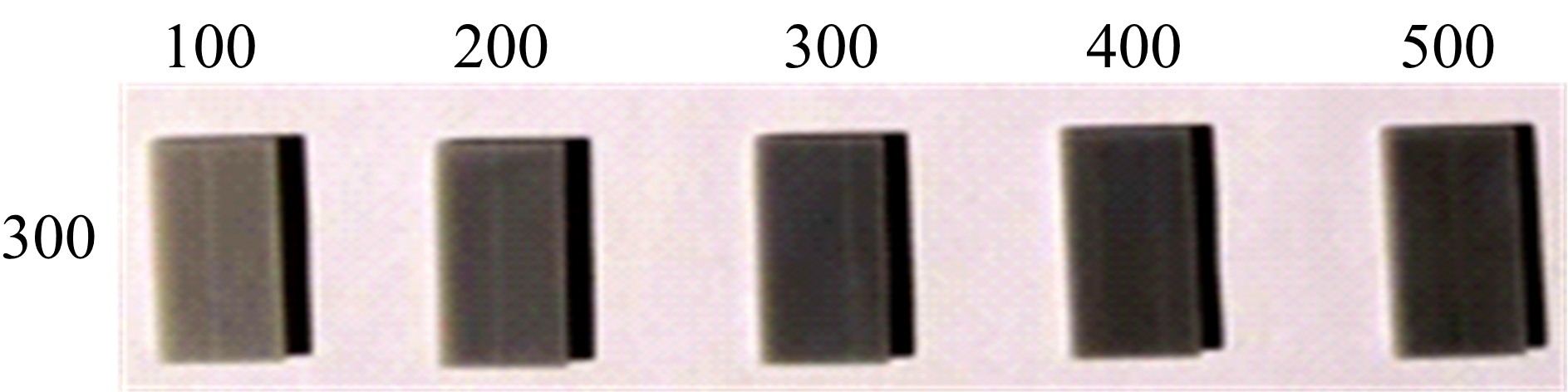

以粘着摩擦理论为基础,结合软硬相间层状结构特点,确立了软硬相间层状仿生材料摩擦过程数学模型。利用数值分析软件Abaqus建立了软硬相间层状仿生材料摩擦过程有限元模型,研究了软、硬材料组分的材料属性,软、硬材料组分的体积分数,软、硬材料组分各自摩擦因数对软硬相间层状仿生材料摩擦因数的影响规律。采用ProJet 5500X 3D打印机制备了软硬相间层状仿生材料并进行了摩擦试验,验证了理论及模拟结果。

中图分类号:

- TB33

| 1 | 史正良, 刘金龙, 宋明, 等. 人工髋关节摩擦学的研究现状[J]. 中国组织工程研究, 2008, 12(4): 731-734. |

| ShiZheng-liang, LiuJin-long, SongMing, et al. Research progress in tribology of artificial hip joint[J]. Journal of Clinical Rehabilitative Tissue Engineering Research, 2008, 12(4): 731-734. | |

| 2 | GeorgeM. Rigid biological systems as models for synthetic composites[J]. Science, 2005, 310(5751): 1144-1147. |

| 3 | AbbaM T, HungerP M, KalidindiS R, et al. Nacre-like hybrid films: structure, properties, and the effect of relative humidity[J]. Journal of the Mechanical Behavior of Biomedical Materials, 2015, 55: 140-150. |

| 4 | KatharineS. Structure: artificial armour[J]. Nature, 2015, 519(7455): 14,15. |

| 5 | GongS, CuiW, ZhangQ, et al. Integrated ternary bioinspired nanocomposites via synergistic toughening of reduced graphene oxide and double-walled carbon nanotubes[J]. Acs Nano, 2015, 9(12): 11568-11573. |

| 6 | KeC, ShiB, YueY, et al. Binary synergy strengthening and toughening of bio-inspired nacre-like graphene oxide/sodium alginate composite paper[J]. Acs Nano, 2015, 9(8): 8165-8175. |

| 7 | 陈莉. 激光仿生非光滑表面热作模具的磨料磨损性能研究[D]. 长春: 吉林大学材料科学与工程学院, 2007. |

| ChenLi. Study on the grinding abrasion of hot die with bionic non-smooth surface[D]. Changchun: College of Materials Science and Engineering, Jilin University, 2007. | |

| 8 | ShanH, ZhouH, SunN, et al. Study on adhesion resistance behavior of sample with striated non-smooth surface by laser processing technique[J]. Journal of Materials Processing Technology, 2008, 199(1-3): 221-229. |

| 9 | 孙娜. 不同仿生耦合单元体对蠕墨铸铁摩擦磨损性能的影响[D]. 长春: 吉林大学材料科学与工程学院, 2010. |

| SunNa. Influences of various biomimetic coupling units on the friction and wear behaviors of compacted graphite cast iron[D].Changchun: College of Materials Science and Engineering, Jilin University, 2010. |

| [1] | 马彬, 许洪国, 刘宏飞. 路面分形和橡胶特性对轮胎滑动摩擦因数的影响[J]. 吉林大学学报(工学版), 2013, 43(02): 317-322. |

| [2] | 张阔, 谭庆昌, 王顺, 王聪慧, 边丽娟. 粗糙软接触润滑的摩擦因数[J]. 吉林大学学报(工学版), 2012, 42(增刊1): 86-90. |

|

||