吉林大学学报(工学版) ›› 2019, Vol. 49 ›› Issue (5): 1615-1621.doi: 10.13229/j.cnki.jdxbgxb20190194

• • 上一篇

选区激光熔化304L不锈钢的组织结构及力学性能分析

佟鑫1,2,3( ),张雅娇3,黄玉山3,胡正正2,王庆1,2,张志辉1,2(

),张雅娇3,黄玉山3,胡正正2,王庆1,2,张志辉1,2( )

)

- 1. 吉林大学 工程仿生教育部重点实验室,长春 130022

2. 吉林大学 生物与农业工程学院, 长春 130022

3. 广州恒尚科技有限公司,广州 510705

Microstructure and mechanical properties of 304L stainless steel processed by selective laser melting

Xin TONG1,2,3( ),Ya-jiao ZHANG3,Yu-shan HUANG3,Zheng-zheng HU2,Qing WANG1,2,Zhi-hui ZHANG1,2(

),Ya-jiao ZHANG3,Yu-shan HUANG3,Zheng-zheng HU2,Qing WANG1,2,Zhi-hui ZHANG1,2( )

)

- 1. Key Laboratory of Bionic Engineering Ministry of Education, Jilin University, Changchun 130022, China

2. College of Biological and Agricultural Engineering, Jilin University, Changchun 130022

3. Guangzhou Husun Technologies Co. , Ltd. ,Guangzhou 510705, China

摘要:

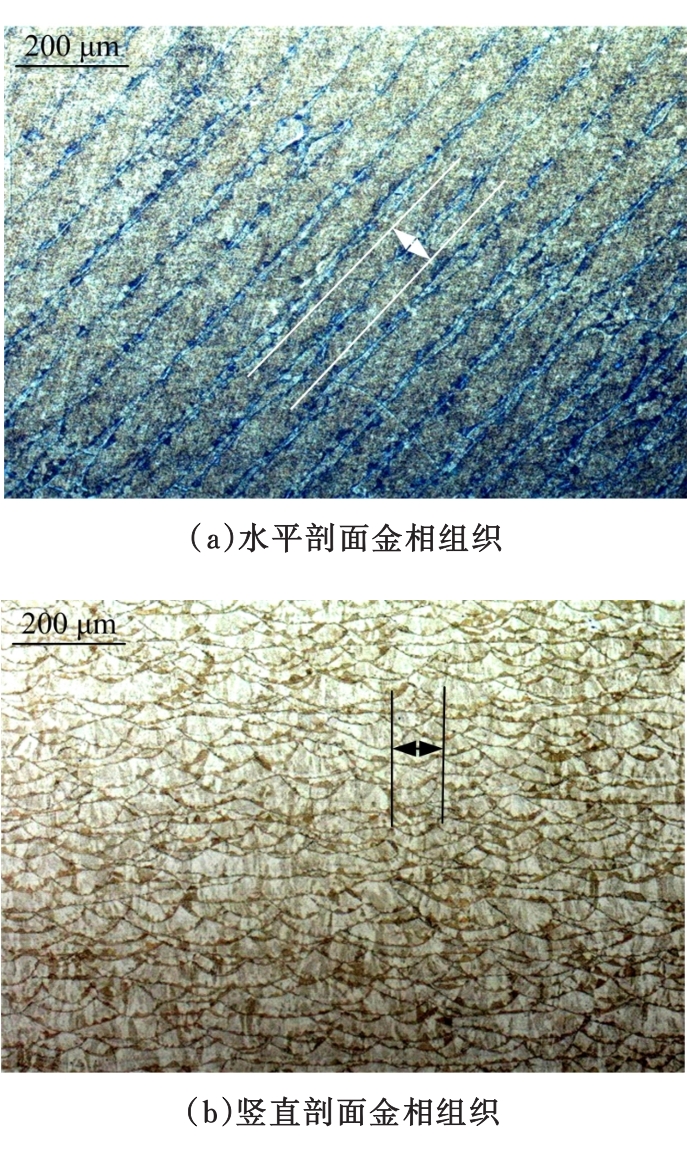

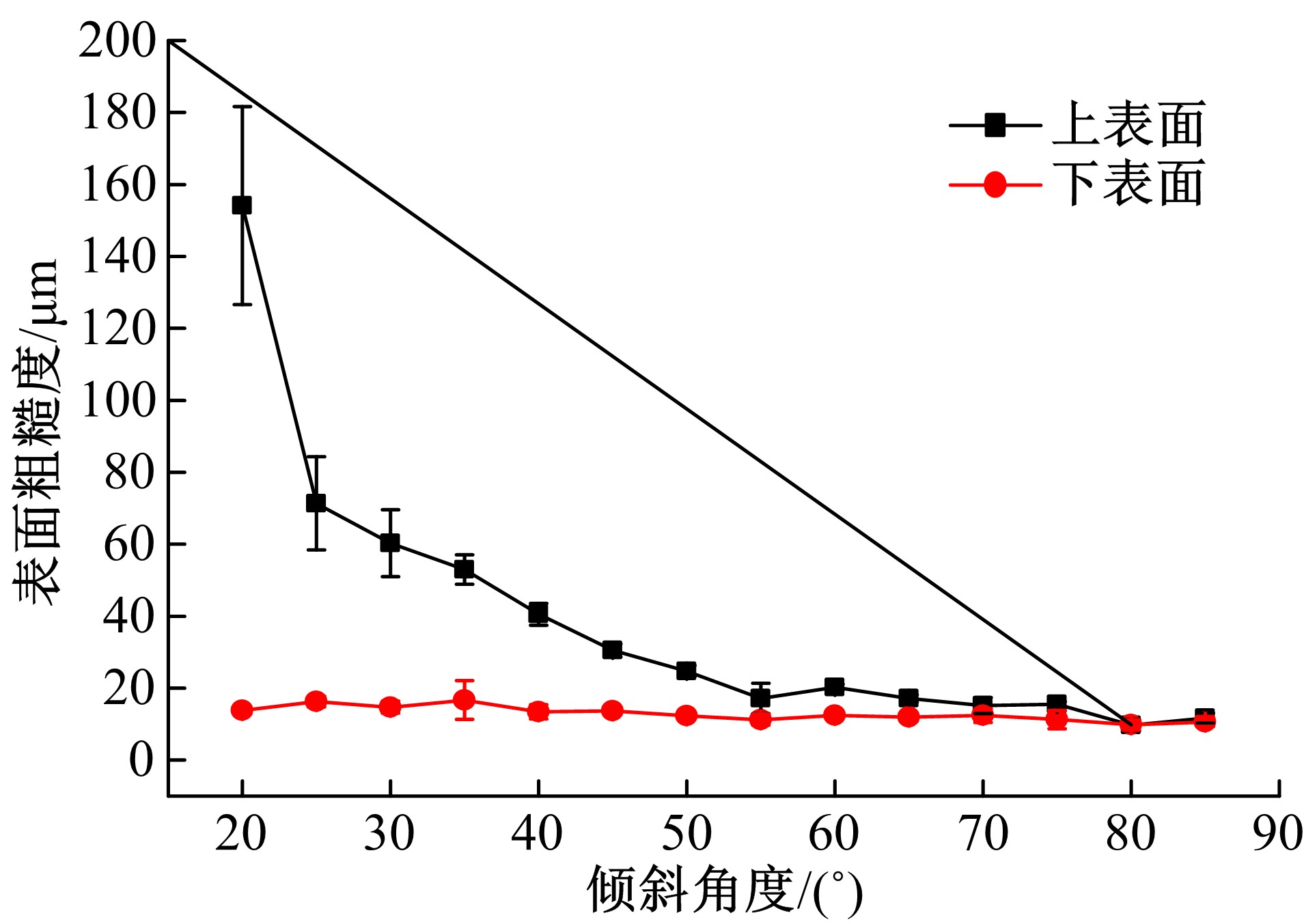

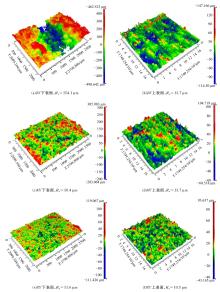

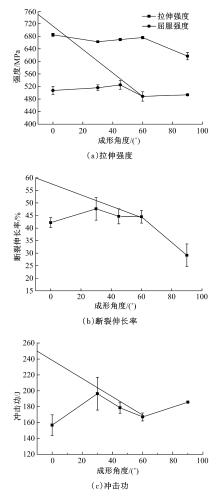

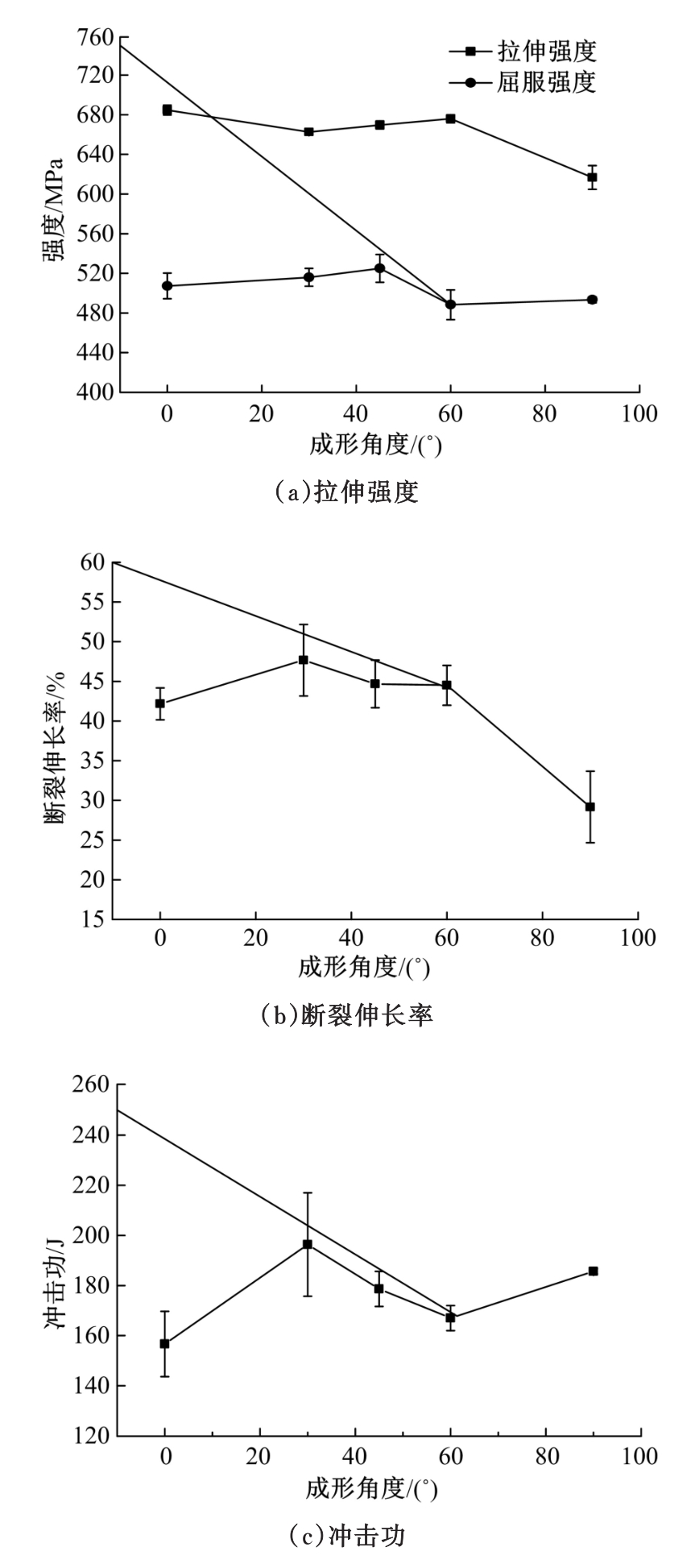

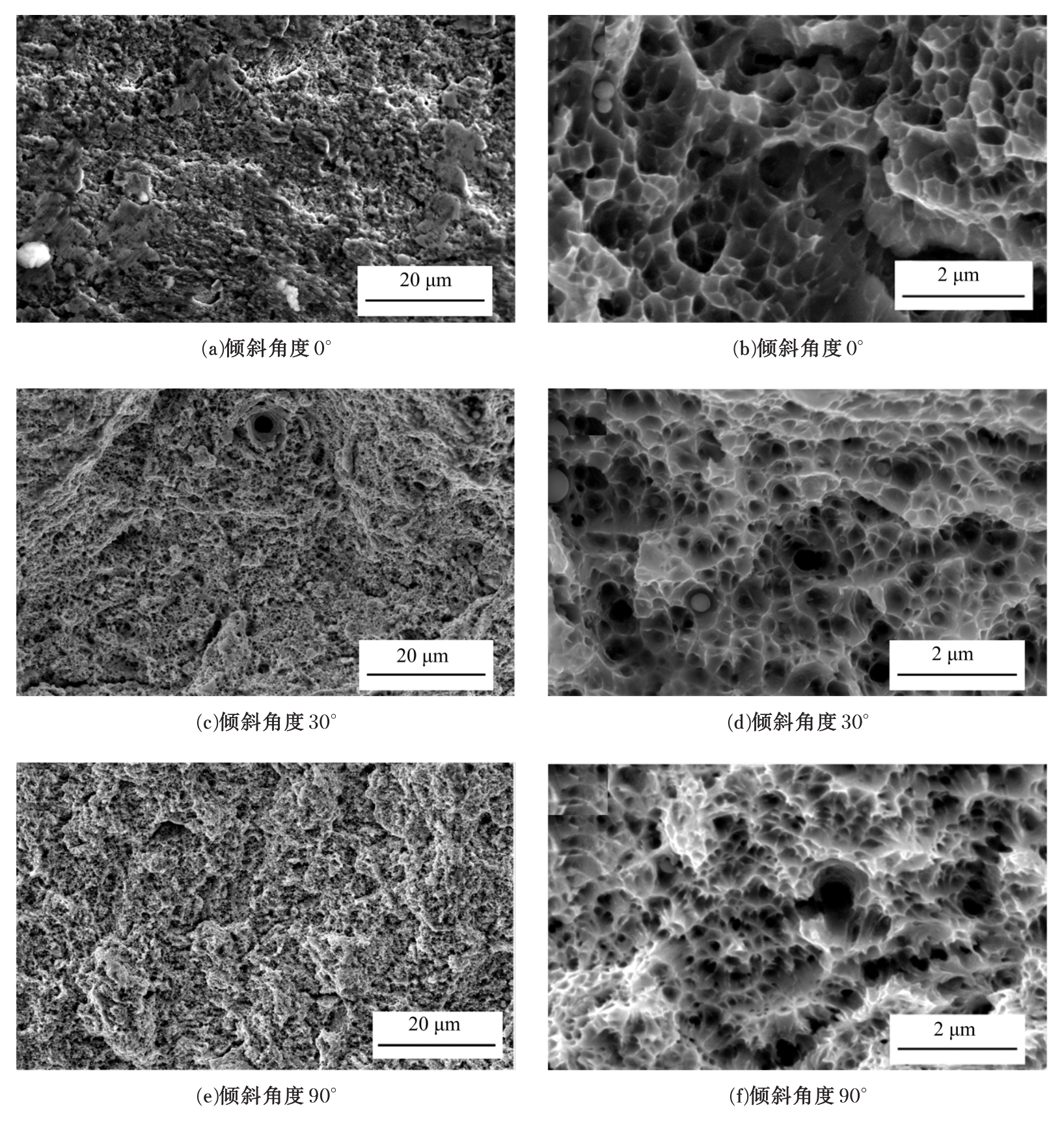

采用选区激光熔化技术成形304L不锈钢,研究了成形后的显微组织和形貌特征,以及不同构建方向对力学性能的影响。结果表明:304L不锈钢组织中无明显气孔和夹杂缺陷;试样的表面粗糙度随倾斜角度的增大而减小。获得准确完整成形几何特征的前提是,薄壁试样厚度的设计值大于0.3 mm,无支撑圆孔试样直径设计值在1~12.5 mm之间,试样外尖角角度设计值大于5°,试样的内尖角垂直摆放时设计值大于15°,水平摆放时设计值大于8°。不同构建方向对试样的抗拉强度和屈服强度影响不明显,当试样的构建方向与基板呈0°时,试样抗拉强度达到最大值684.7 MPa,当构建方向与基板呈30°时,试样的断后伸长率达到最大为47.7%,同时冲击功达到最大值196.3 J,断裂机制均为韧性断裂。

中图分类号:

- TG430.40

| 1 | 陈凯, 杜东海, 陆辉, 等 . 304L不锈钢在高温高压水中的腐蚀疲劳裂纹扩展行为[J]. 腐蚀与防护, 2018, 39(1): 17-23. |

| Chen Kai , Du Dong-hai , Lu Hui , et al . Corrosion fatigue crack growth behavior of 304L stainless steel in high temperature and high pressure water[J]. Corrosion & Protection, 2018, 39(1): 17-23. | |

| 2 | 唐望磊, 曹东, 王虎, 等 . 弹性应力下304L不锈钢在3.5% NaCl溶液中的点蚀行为[J]. 材料保护, 2018, 51(10): 16-21. |

| Tang Wang-lei , Cao Dong , Wang Hu , et al . Pitting corrosion behavior of 304L stainless steel in 3.5% NaCl solution under elastic stress[J]. Material Protection, 2018, 51(10): 16-21. | |

| 3 | 罗开玉, 柴卿锋, 王长雨, 等 . 激光冲击强化对2Cr13不锈钢腐蚀疲劳性能的影响[J/OL]. [2019-02-15]. http:∥www.cnki.com.cn/Article/CJFDTotal-JLGY2018052300U.htm |

| 4 | 杨永强, 陈杰, 宋长辉, 等 . 金属零件激光选区熔化技术现状及进展[J]. 激光与光电子学进展, 2018, 55(1): 3-15. |

| Yang Yong-qiang , Chen Jie , Song Chang-hui , et al . Current status and progress on technology of selective laser melting of metal parts[J]. Laser & Optoelectronics Progress, 2018, 55(1): 3-15. | |

| 5 | Frazier W E . Metal additive manufacturing: a review[J]. Journal of Materials Engineering and Performance, 2014, 23(6): 1917-1928. |

| 6 | Gao W , Zhang Y , Ramanujan D , et al . The status, challenges, and future of additive manufacturing in engineering[J]. Computer-Aided Design, 2015, 69: 65-89. |

| 7 | 杨强, 鲁中良, 黄福享, 等 . 激光增材制造技术的研究现状及发展趋势[J]. 航空制造技术, 2016, 59(12): 26-31. |

| Yang Qiang , Lu Zhong-liang , Huang Fu-xiang , et al . Research on status and development trend of laser additive manufacturing[J]. Aeronautical Manufacturing Technology, 2016, 59(12): 26-31. | |

| 8 | Gu D D , Meiners W , Wissenbach K , et al . Laser additive manufacturing of metallic components: materials, processes andmechanisms[J]. International Materials Reviews, 2012, 57(3): 133-164. |

| 9 | 谭丽斌, 余心宏 . 3D打印技术在金属成形领域的应用和展望[J]. 精密成形工程, 2015, 7(6): 58-64. |

| Tan Li-bin , Yu Xin-hong . Application and prospect of 3D printing in metal forming[J]. Precision Forming Engineering, 2015, 7(6): 58-64. | |

| 10 | Herzog D , Seyda V , Wycisk E , et al . Additive manufacturing of metals[J]. Acta Materialia, 2016, 117: 371-392. |

| 11 | Huang H S , Liu P , Mokasdar A , et al . Additive manufacturing and its societal impact: a literature review[J] International Journal of Advanced Manufacturing Technology, 2012, 67(5-8): 1191-1203. |

| 12 | Suryawanshi J , Prashanth K G , Scudino S , et al . Simultaneous enhancements of strength and toughness in an Al-12Si alloy synthesized using selective laser melting[J]. Acta Materialia, 2016, 115: 285-294. |

| 13 | 戴晓琴, 陈瀚宁, 雷剑波, 等 . 激光增材制造304不锈钢显微结构特征与性能研究[J]. 热加工工艺, 2017, 46(16): 83-86. |

| Dai Xiao-qin , Chen Han-ning , Lei Jian-bo , et al . Study on microstructure and properties of 304 stainless steel by laser additive augmentation[J]. Hot Working Technology, 2017, 46(16): 83-86. | |

| 14 | 杨丹, 宁玉恒, 赵宇光, 等 . 工艺参数对304不锈钢表面激光熔覆Ni基合金涂层的组织、耐磨性及耐腐蚀性的影响[J]. 材料导报, 2017, 31(24): 133-140. |

| Yang Dan , Ning Yu-heng , Zhao Yu-guang , et al . The effect of process parameters on the structure, wear resistance and corrosion resistance of laser cladding Ni-based alloy coating on 304 stainless steel surface[J]. Materials Review, 2017, 31(24): 133-140. | |

| 15 | 白玉超 . 马氏体时效钢激光选区熔化成型机理及其控性研究[D]. 广州: 华南理工大学机械与汽车工程学院, 2018. |

| Bai Yu-chao . Research on the mechanism and properties controllability of selective laser melting of maraging steel[D]. Guangzhou: College of Mechanical and Automotive Engineering, South China University of Technology, 2018. | |

| 16 | Debroy T , Wei H L , Zuback J S , et al . Additive manufacturing of metallic components-process, structure and properties[J]. Progress in Materials Science, 2018(92): 112-224. |

| [1] | 李明,王浩然,赵唯坚. 带抗剪键叠合板的力学性能[J]. 吉林大学学报(工学版), 2019, 49(5): 1509-1520. |

| [2] | 姜秋月,杨海峰,檀财旺. 22MnB5超高强钢焊接接头强化性能[J]. 吉林大学学报(工学版), 2018, 48(6): 1806-1810. |

| [3] | 庄蔚敏, 赵文增, 解东旋, 李兵. 超高强钢/铝合金热铆连接接头性能[J]. 吉林大学学报(工学版), 2018, 48(4): 1016-1022. |

| [4] | 刘晓波, 周德坤, 赵宇光. 不同等温热处理条件下半固态挤压Mg2Si/Al复合材料的组织和性能[J]. 吉林大学学报(工学版), 2016, 46(5): 1577-1582. |

| [5] | 李春玲, 樊丁, 王斌, 余淑荣. 5A06铝合金/镀锌钢预置涂粉对接激光熔钎焊组织与性能[J]. 吉林大学学报(工学版), 2016, 46(2): 516-521. |

| [6] | 邓成江,何晓聪,邢保英,王玉奇,曾凯,丁燕芳. 铝与铜异质板材自冲铆搭接接头的力学性能[J]. 吉林大学学报(工学版), 2015, 45(2): 473-480. |

| [7] | 李欣,王刚,陆冠含,谷诤巍,徐虹. 22MnB5热成形钢板钨极氩弧焊接性能[J]. 吉林大学学报(工学版), 2014, 44(3): 708-711. |

| [8] | 张霖, 赵宏伟, 杨倚寒, 马智超, 黄虎, 马志超. 单层石墨烯薄膜材料纳米压痕过程的分子动力学解析[J]. 吉林大学学报(工学版), 2013, 43(06): 1558-1565. |

| [9] | 白志范, 李桂中, 王超, 王良, 张志敏. 高速客车转向架构架焊接接头组织与力学性能[J]. 吉林大学学报(工学版), 2012, 42(增刊1): 207-211. |

| [10] | 谷诤巍, 于思彬, 韩立军, 孟佳, 徐虹. 超高强度钢与低合金钢的激光搭接焊性能[J]. 吉林大学学报(工学版), 2012, 42(02): 349-353. |

| [11] | 白志范, 李桂中, 王超. S355J2W+N钢焊接接头显微组织与力学性能[J]. 吉林大学学报(工学版), 2011, 41(增刊2): 202-204. |

| [12] | 姜日花1,白爽1,戴跃2 ,赵梅生3. 瘢痕疙瘩的生物力学特性[J]. 吉林大学学报(工学版), 2011, 41(6): 1675-1677. |

| [13] | 汪洪峰,左敦稳,王珉,缪宏. 5554铝合金异种焊料焊接的显微组织及力学性能[J]. 吉林大学学报(工学版), 2011, 41(4): 974-977. |

| [14] | 关庆丰,邱冬华,李艳,陈康敏,安春香,龙荷荪. 17-4PH不锈钢时效析出相的形成过程[J]. 吉林大学学报(工学版), 2011, 41(03): 654-658. |

| [15] | 贾超, 纪圣振, 张峰. 青岛海湾大桥混凝土墩的时变可靠度[J]. 吉林大学学报(工学版), 2010, 40(06): 1543-1549. |

|

||